Tank containers and their end frames

A tank container and end frame technology, which is applied in packaging, transportation and packaging, large containers, etc., can solve the problems that the tank body and the end frame cannot be welded and connected, so as to avoid deformation, improve the performance of anti-longitudinal impact load, and manufacture simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

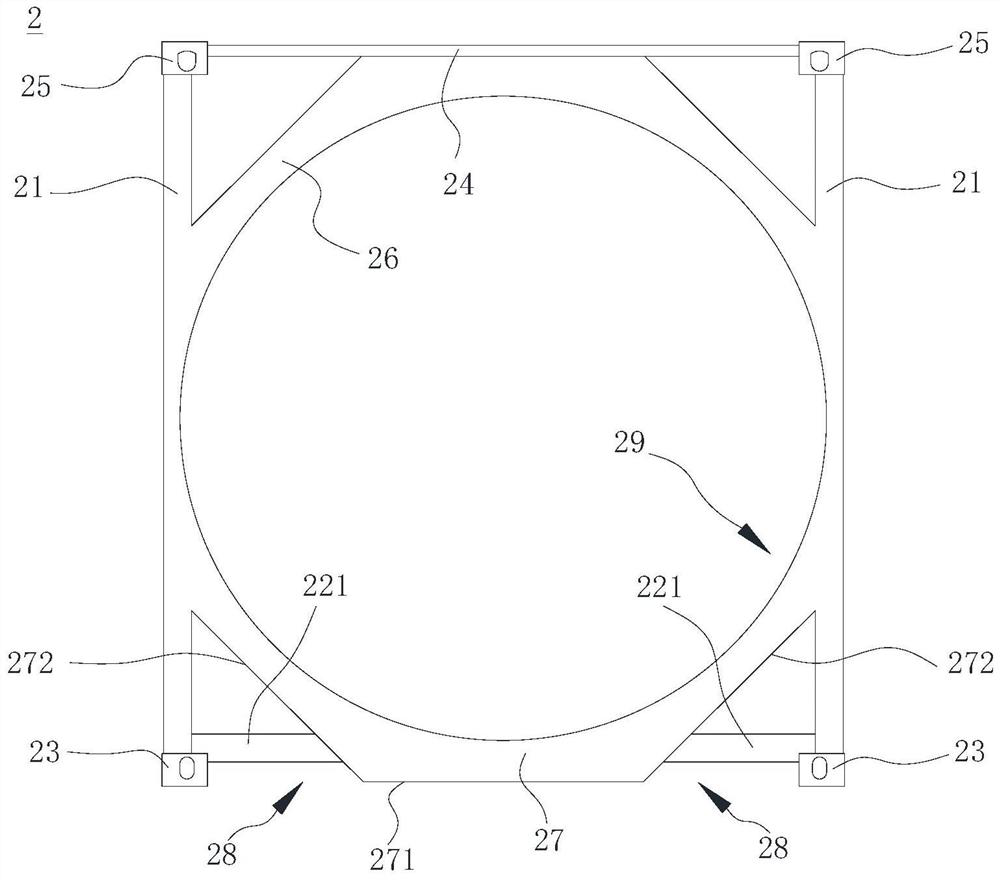

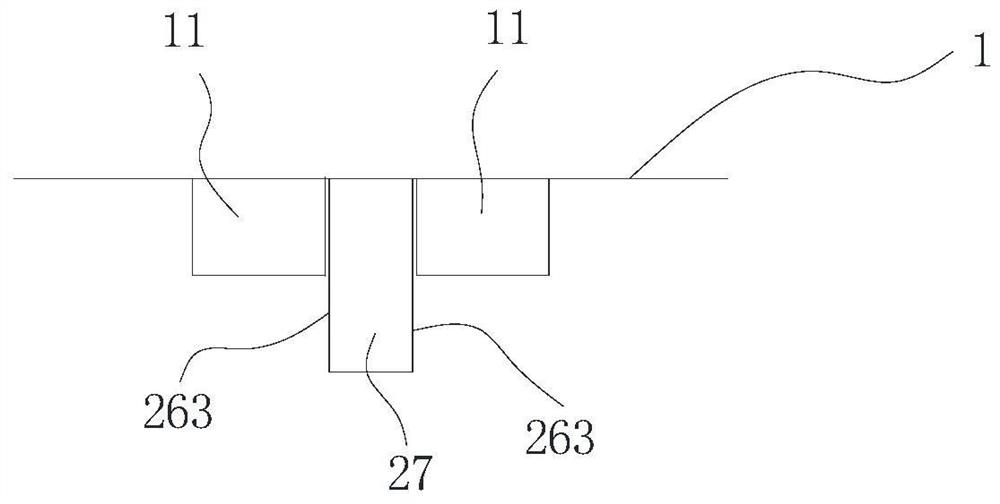

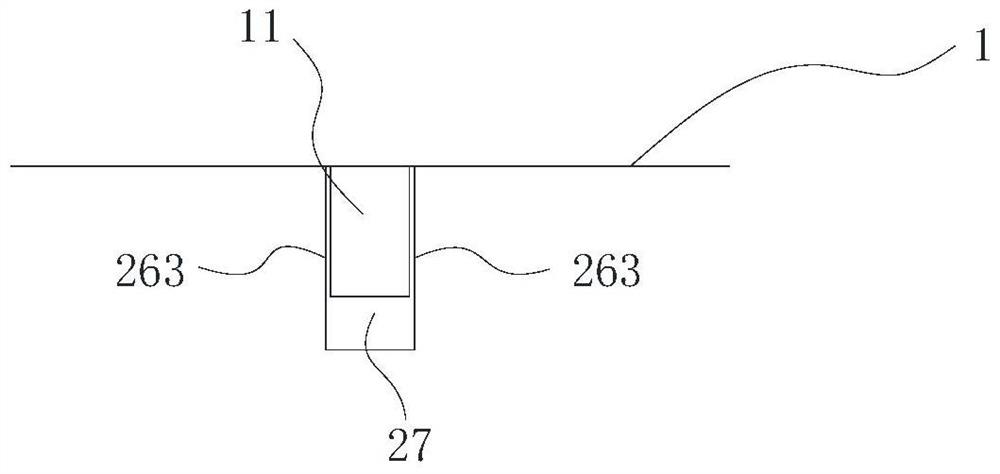

[0038] refer to Figure 1 to Figure 2B , the tank container in this embodiment includes a tank body 1 and end frames 2 arranged near both ends of the tank body, and the end frames 2 are used to support both ends of the tank body 1 . The positions of the bottoms at both ends of the tank body 1 are fixed or integrally formed with a plurality of protrusions 11 .

[0039] It should be noted that the materials of the tank body 1 and the end frame 2 in the present invention are different, and cannot be connected by welding according to conventional methods.

[0040] The end frame 2 includes: two uprights 21, an upper end beam 24 connected between the upper ends of the two uprights 21, an upper saddle 26 and a lower saddle 27, and the bottom and top ends of the uprights 21 are respectively fixed with top corner fittings 25 and bottom corner fittings 23. The top surface of the top corner piece 25 is provided with a hoisting hole (not shown in the figure), and the bottom surface of th...

Embodiment 2

[0058] refer to Figure 5 The difference between the end frame 2 in this embodiment and the end frame 2 in Embodiment 1 lies in the structure of the two support rods 221 . The two support rods 221 are connected between the upright post 21 and the lower saddle 27 and are inclined upward relative to the horizontal plane. The lower part of the end frame 2, that is, each support rod 221 and the outer side wall 272 of the lower saddle 27 adjacent to it form an avoidance groove 28a, and the avoidance groove 28a is larger in size than the avoidance groove 28 of the above-mentioned embodiment, further This reduces the chance of the support rod 221 being damaged by impact during the operation of the tank container, and reduces the use and maintenance cost of the tank container.

[0059] In actual use, the two support rods 221 can also be inclined downward relative to the horizontal plane and connected between the upright post 21 and the lower saddle 27. 27 height at one end of the co...

Embodiment 3

[0061] refer to Figure 6 The difference between the end frame 2 in this embodiment and the end frame 2 in Embodiment 1 lies in the structures of the columns 21 , the top corner pieces 25 and the bottom corner pieces 23 .

[0062] The positions near the top and the bottom of the two columns 21 of this embodiment are all deflected inwardly along the opposite direction, so that the distance between the tops of the two columns 21 and the distance between the bottoms are smaller than the distance between the middle parts of the two columns 21; 25 and bottom corner piece 23 are ISO standard parts. The structure of the column 21 makes the distance between the hoisting holes of the top corner fittings 25 installed at the tops of the two columns 21 and the distance between the fastening holes of the bottom corner fittings 23 installed at the bottoms of the two columns 21 conform to the distance of the ISO standard sling, omitting The refitting of the top corner piece 25 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com