Switching device for a gearbox

A technology of shifting device and gearbox, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve problems such as increasing the difficulty of piston rod and hindering embedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

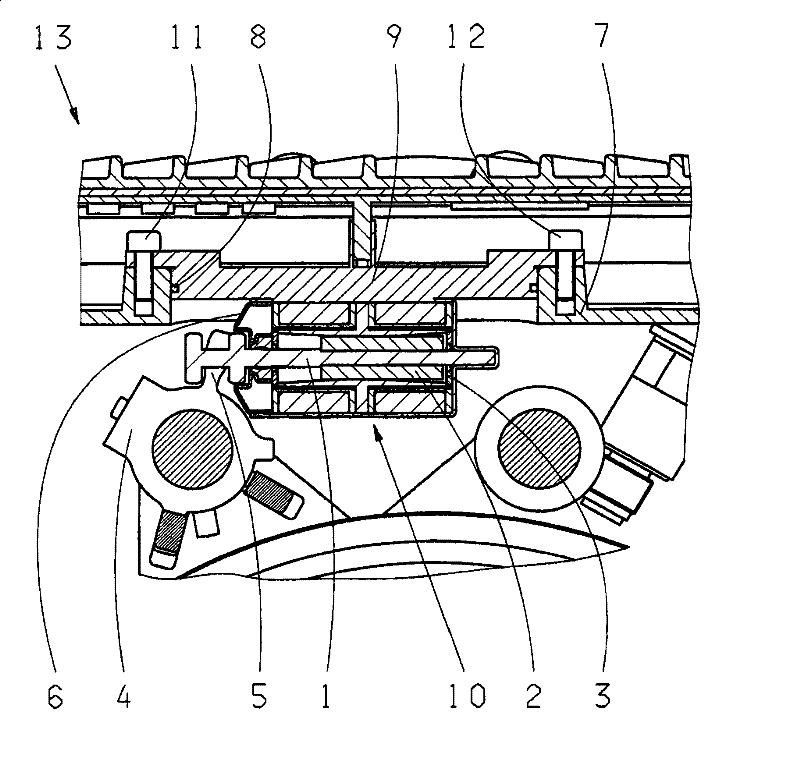

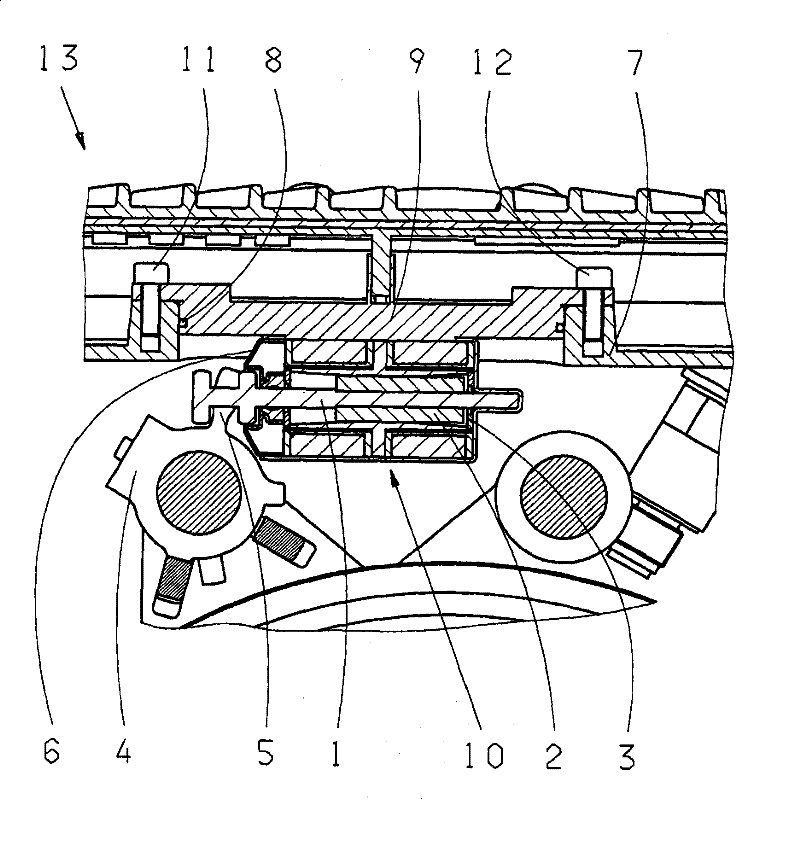

[0013] The single figure shows a partial view of the shifting device 13 for shifting the transmission. The armature 1 of the selection actuator 10 consists of a permanent magnet 2 . When installing the selection actuator, the armature 1 of the selection actuator 10 is connected to the drive cam 5 of the selection plate 4 . Fixing of the armature 1 in a position suitable for mounting the selector actuator 10 is achieved in such a way that the end stop 3 of the selector actuator 10 is made of a ferromagnetic material on which the permanent magnet 2 is attracted (forced end position fixed). For mounting the optional actuator 10 , therefore, no further means are required for securing the end position of the armature 1 . The gearbox is shifted to a specified gear before installing the selection actuator 10, so that the driving boss 5 of the selection plate 4 that must be embedded in the armature 1 of the selection actuator 10 can be seen from the outside. The conical element 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com