Layered fracturing technology for variable-length graded sliding sleeve

A layered fracturing and variable length technology, applied in the direction of wellbore/well components, production fluid, sealing/isolation, etc., can solve the problems that cannot meet the requirements of multi-stage fracturing construction technology in horizontal wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

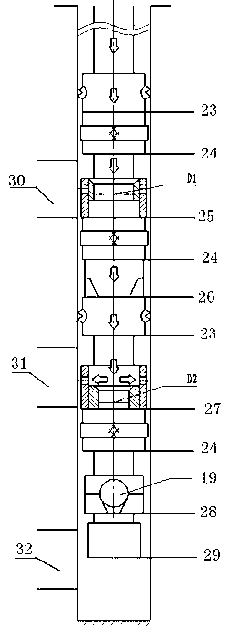

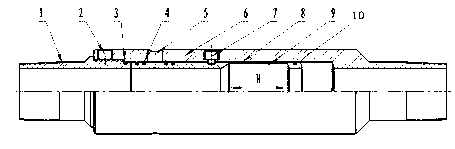

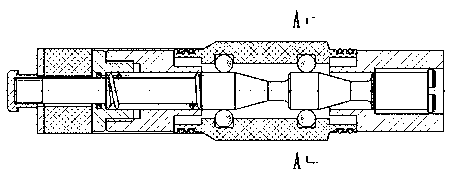

[0034] In the variable-length graded sliding sleeve layered fracturing technology, under the condition that the diameter of the sliding sleeve plug valve of each variable-length graded sliding sleeve remains unchanged, by changing the length of the sliding sleeve groove 9 and the sliding sleeve plug valve block 17 at each stage , Realize the graded slip sleeve technology of more than 10 grades, and perform layered fracturing. The variable-length graded sliding sleeve is composed of a sliding sleeve plug valve and a sliding sleeve valve seat assembly, and the sliding sleeve plug valve includes: a fishing head 11, a sealing rubber 12, an upper pressure cap 13, and an O-ring 14 , spring 15, body 16, tooth block 17, steel ball 19, hoop spring 20, mandrel 21, rubber cover plate 22, movable tooth block 17 is arranged on the body 16, and the two ends of tooth block 17 pass through hoop spring respectively 20 to tighten it in the body 16; the seal rubber 12 is integrated on the upper ...

Embodiment 2

[0036] Embodiment 2 is basically the same as Embodiment 1, the difference is: the described variable-length graded sliding sleeve layered fracturing technology, the specific method is as follows:

[0037] 1) Determine the number of variable-length graded sliding sleeves according to the number of construction layers, which is 1 less than the number of construction layers. The lower packer connected to the pipe string is a hydraulic pressure differential compression packer of Y344 structure; Carry out layer-by-layer fracturing from bottom to top, and the length of the pumped sliding sleeve plug valve must be shortened step by step from long to short, and the length of the tooth block 17L≤H sliding sleeve groove 9 length; each lower The sliding sleeve groove length H1 of the first-stage sliding sleeve valve seat assembly is greater than the sliding sleeve groove length H2 of the upper level, and the length L of the tooth block 17 on the sliding sleeve plug valve is also longer th...

Embodiment 3

[0041] It is basically the same as Example 2, except that: the number of the tooth blocks 17 is 6, (2-6 pieces are acceptable), and the mandrel 21 is used as the axis; or the width of the groove 18 The same diameter as the steel ball 19; or the sliding sleeve groove 9 and the tooth block 17 are a series of specifications with different lengths; or the material of the sliding sleeve valve seat assembly and the sliding sleeve plug valve is chrome-molybdenum alloy steel ; or the fishing head 11 is made of ductile iron; the technology of the present invention can be one or a combination of several of the above-mentioned features.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com