Die and tool assembly and manufacturing method of intelligent composite material actuator

A technology for composite materials and actuators, applied in the field of mold tooling components and preparation of intelligent composite material actuators, can solve the problems of confidentiality and less introduction of actuator molds, tooling, and preparation methods, and achieve easy preparation and strong controllability , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

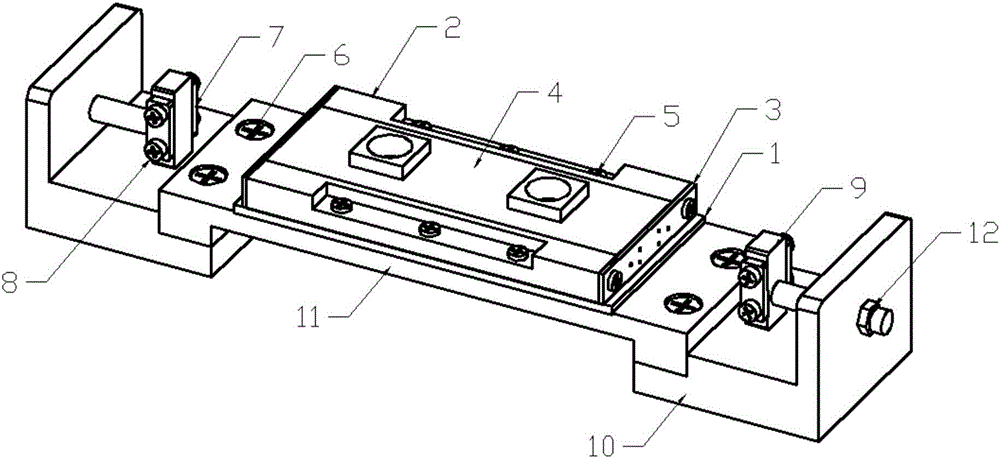

[0029] Such as figure 1 Shown is the overall view of the mold tooling assembly of the intelligent composite material active device of the preferred embodiment of the present invention, including a long convex bottom plate 1, a long baffle 2, a short baffle 3, a rectangular cover 4, a first Bolt 5, countersunk head bolt 6, SMA clip 7, second bolt 8, T-shaped tension screw 9, L-shaped end bearing plate 10, active device bearing plate 11 and nut 12.

[0030] Wherein, the left and right sides of the elongated convex bottom plate 1 are each provided with several internally threaded holes, preferably three in this embodiment, connected to the longitudinal baffle 2 by the first bolt 5, and the two ends of the long baffle 2 are also Internally threaded holes are provided to connect the short baffle 3 through the first bolt 5, and the rectangular cover 4 can be directly placed on the long baffle 2 and fit through the groove; Two countersunk screw holes are used to connect the L-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com