Jet preparation device of amorphous alloy strip and preparation method thereof

A technology of amorphous alloys and preparation devices, which is applied in metal processing equipment, manufacturing tools, casting equipment, etc., can solve problems such as uneven surface of amorphous alloy strips, complex equipment structures, and incomplete structures, and achieve smooth surfaces, The effect of simple equipment structure and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

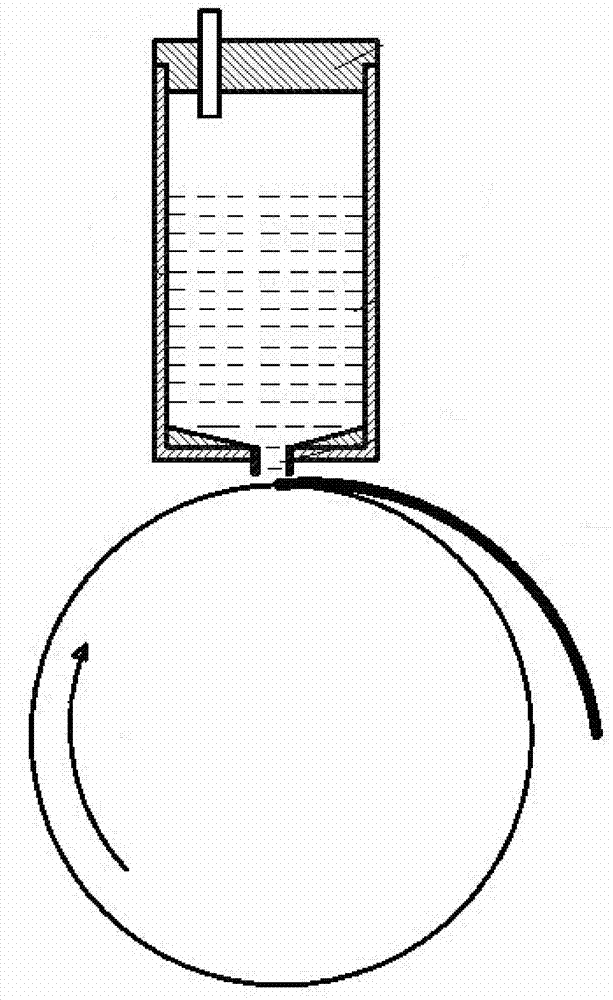

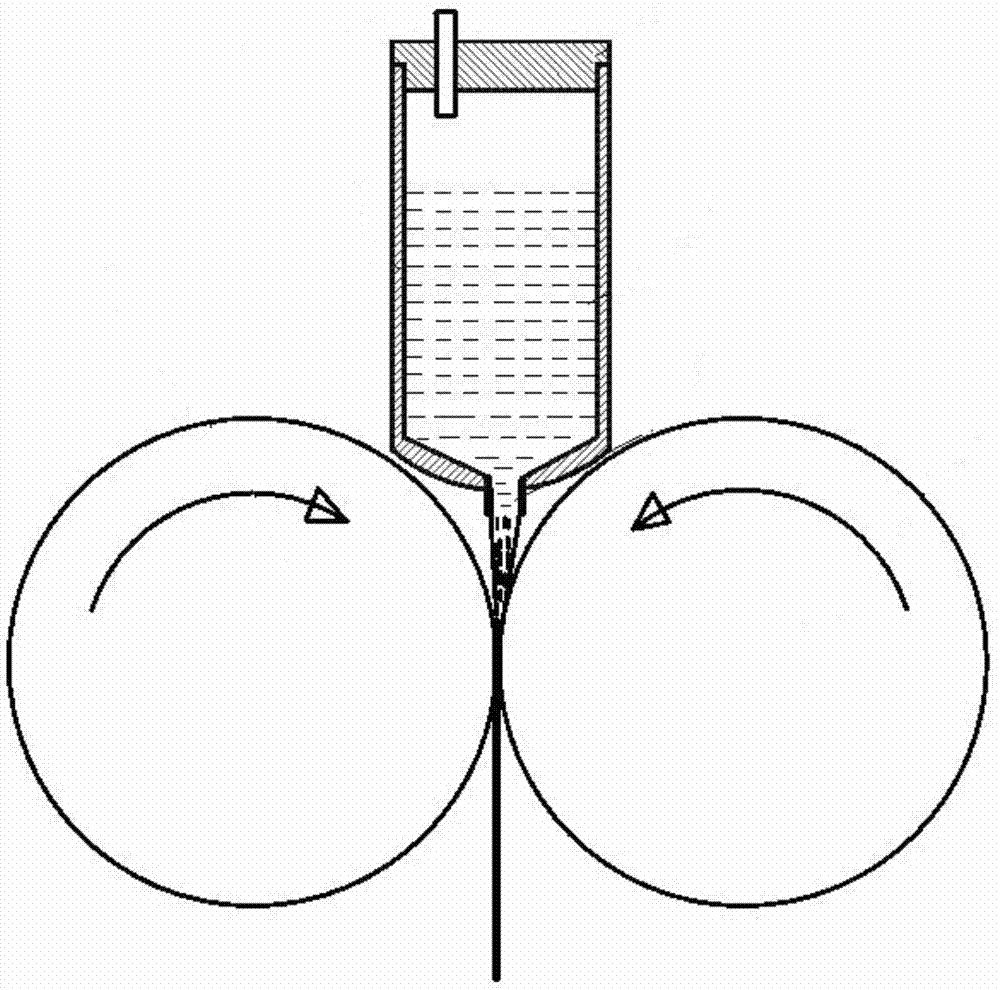

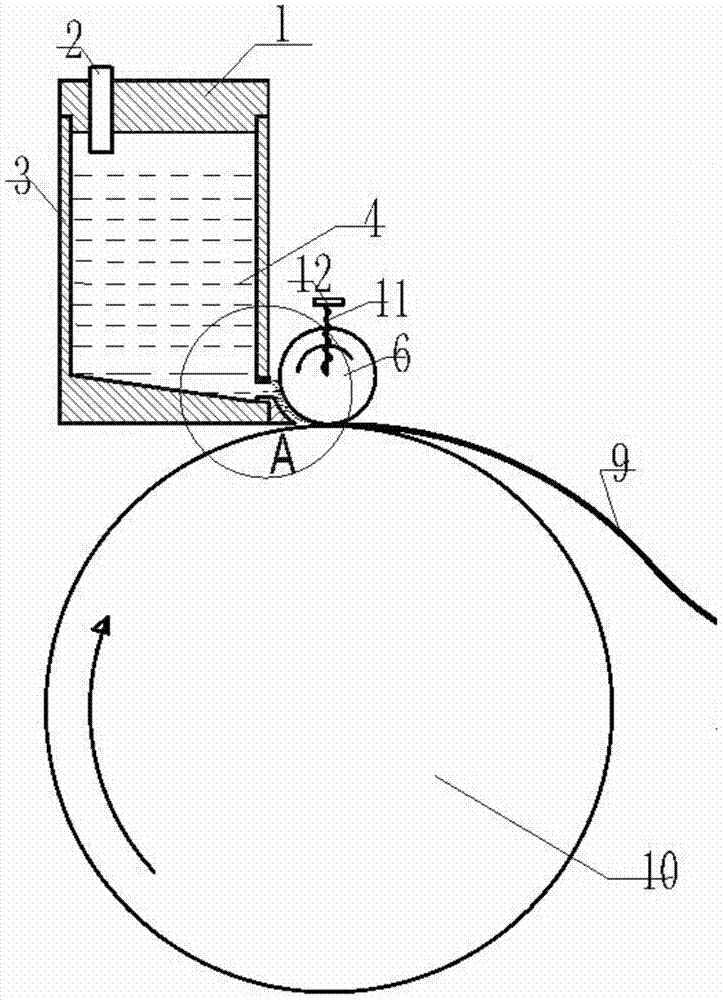

[0034] The technical scheme of the device for preparing amorphous alloy strips of the present invention is as follows, as Figure 3-4 Shown:

[0035] A spray preparation device for amorphous alloy strips, comprising: a sealing cover 1, an air pressure tube 2, a ladle 3, a nozzle opening 5, a pressure wheel 6, a molten steel guide groove 7, a cooling copper roller 10, a pressure regulating spring 11 and a limiter position device 12; the pressure roller 6 is close to the vertical top of the cooling copper roller 10; the nozzle mouth 5 is integrated with the molten steel guide groove 7 and is opened at the upper end of the molten steel guide groove 7, and the width is the same as that of the amorphous material to be sprayed. The width of the alloy strip 9 is consistent; the molten steel guide groove 7 is installed at the junction of the ladle wall and the ladle bottom with the nozzle mouth 5 facing upward, and the nozzle mouth 5 penetrates the ladle wall and is transparent to the i...

Embodiment 2

[0037] The device and method for preparing amorphous alloy strips of the present invention:

[0038] 1) Pressure wheel and device. ①The pressure wheel 6 is a small zirconia wheel with high temperature resistance and high hardness. The pressure roller 6 is assembled on the vertical top close to the cooling copper roller 10, and driven by the cooling copper roller 10, it rotates at a high speed at the same line speed; The height of the limit is equal to the required thickness of the amorphous alloy strip 9 to be sprayed, and the precision of the limit device is ±3 μm. Before spraying amorphous alloy strips, it is necessary to pre-set and adjust to a good limit height. In the no-load state before spraying, the pressure roller 6 and the cooling copper roller 10 are seamlessly attached, and the cooling copper roller drives the pressure roller to rotate at a high speed and at a linear speed of 20-40m / s. When spraying, the amorphous alloy steel At the moment of rapid quenching, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Vertical length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com