Multi-drill-bit graphite machining equipment

A processing equipment and multi-drill technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of tool cooling, processing dust, and high processing cost of large processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

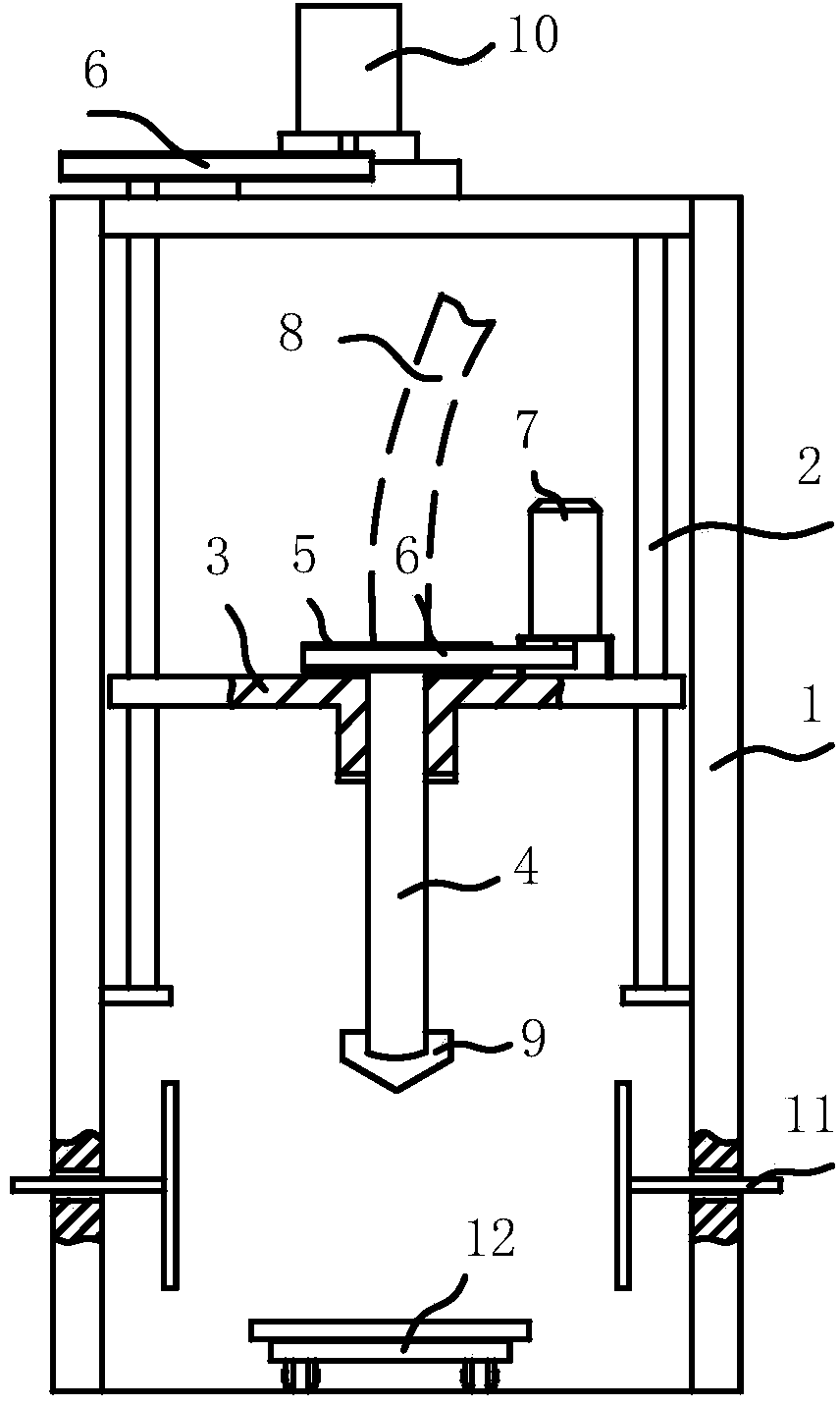

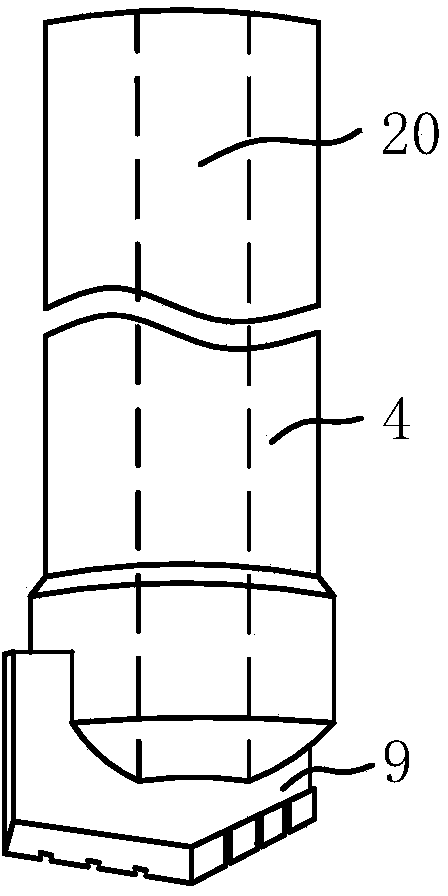

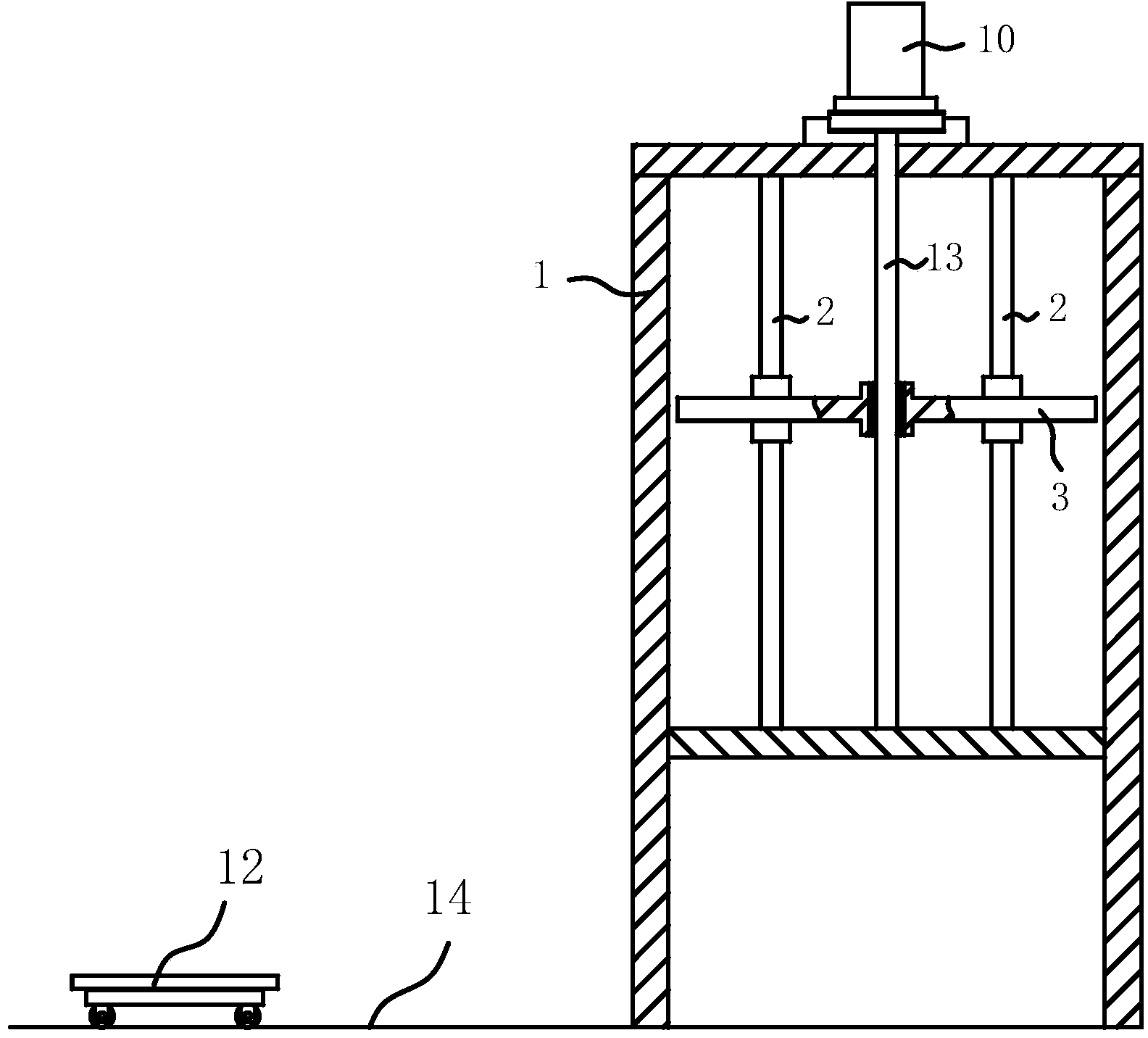

[0028] The invention discloses a multi-drill graphite processing equipment, comprising a vertical frame 1 and a lifting platform 3 installed on the frame 1, the lifting platform 3 is arranged on the light rod 2 on the upper part of the frame 1 and passes through the screw 13 rotates to drive lifting, the screw 2 is connected to the lifting motor 10; the lifting platform 3 is vertically installed with a main shaft 4 and several auxiliary shafts 21, the main shaft 4 is arranged at the center of the lifting platform 3, and several auxiliary shafts 21 are evenly surrounded Around the main shaft 4, the main shaft 4 and the auxiliary shaft 21 are connected by a gear 22; the main shaft 4 and the auxiliary shaft 21 are respectively provided with through holes 20 along the axial direction; the upper end of the main shaft 4 is provided with a pulley 5 and passed through a belt 6 is connected to the driving motor 7 installed on the upper end surface of the lifting platform 3, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com