Method for preparing nano carbon fiber/inorganic powder antistatic material additive

A technology of nano-carbon fiber and inorganic powder, which is applied in the field of nano-materials, can solve problems such as environmental pollution, increase process complexity and product cost, and achieve the effects of high purity, moderate length-to-diameter ratio, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

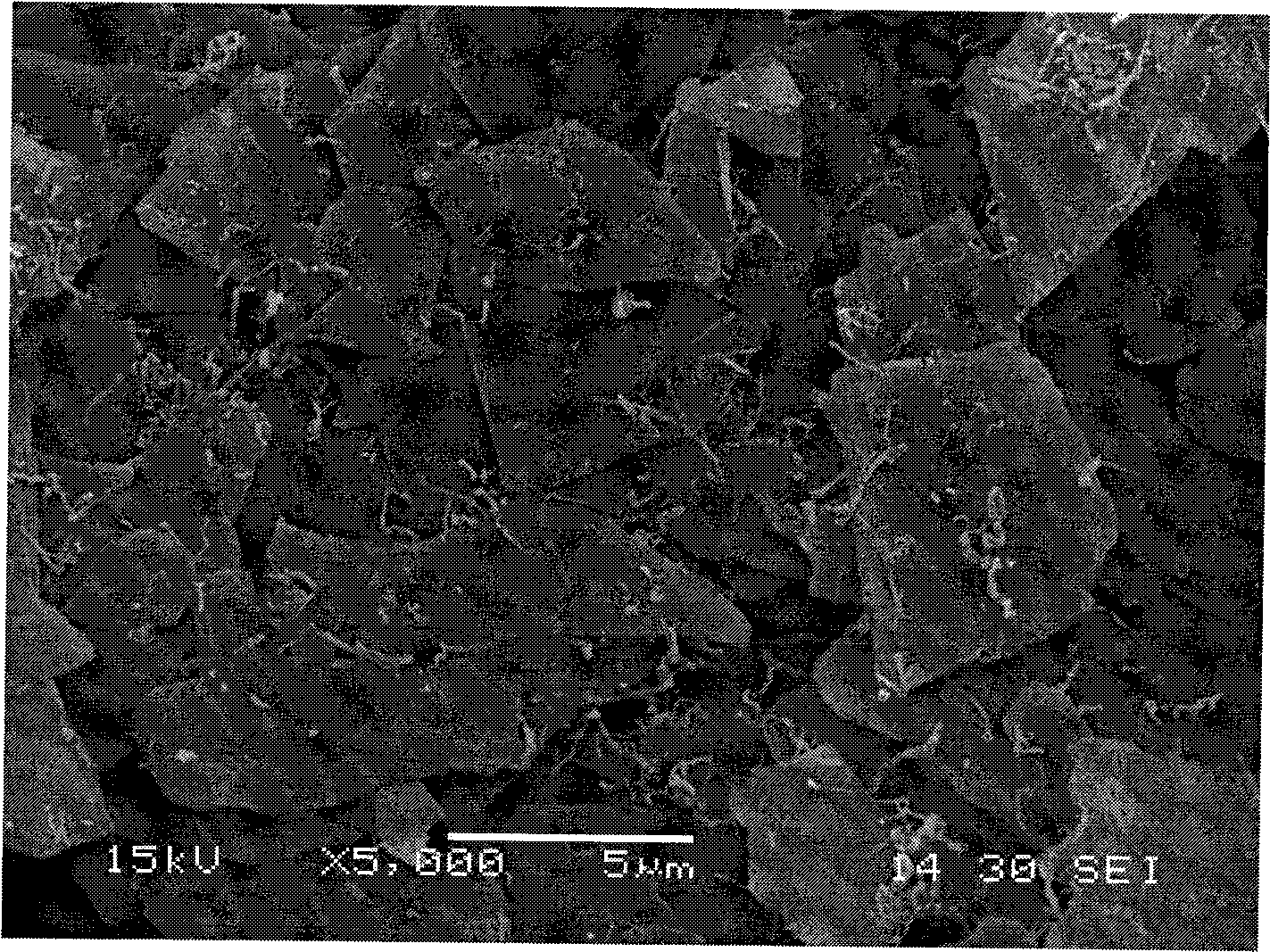

[0037] Example 1 , Preparation of carbon nanofiber / mica antistatic material additive

[0038] 1.1. Supporting iron catalyst on mica surface

[0039] First measure the water absorption rate of mica (with a particle diameter of 10-100 μm), and the value is about 0.445ml water / g mica. Weigh 10.8505g of Fe(NO 3 ) 3 9H 2 O and it was dissolved in 4.205ml of water, and after it was completely dissolved, ferric nitrate solution was dripped dropwise into 18.5g of mica for equal volume impregnation, and then it was placed in a 120°C oven and dried for 12 hours to obtain a catalyst precursor. The catalyst precursor was ground and calcined at 600° C. for 3 hours to prepare 20 grams of 7.5 wt % iron / mica catalyst precursor.

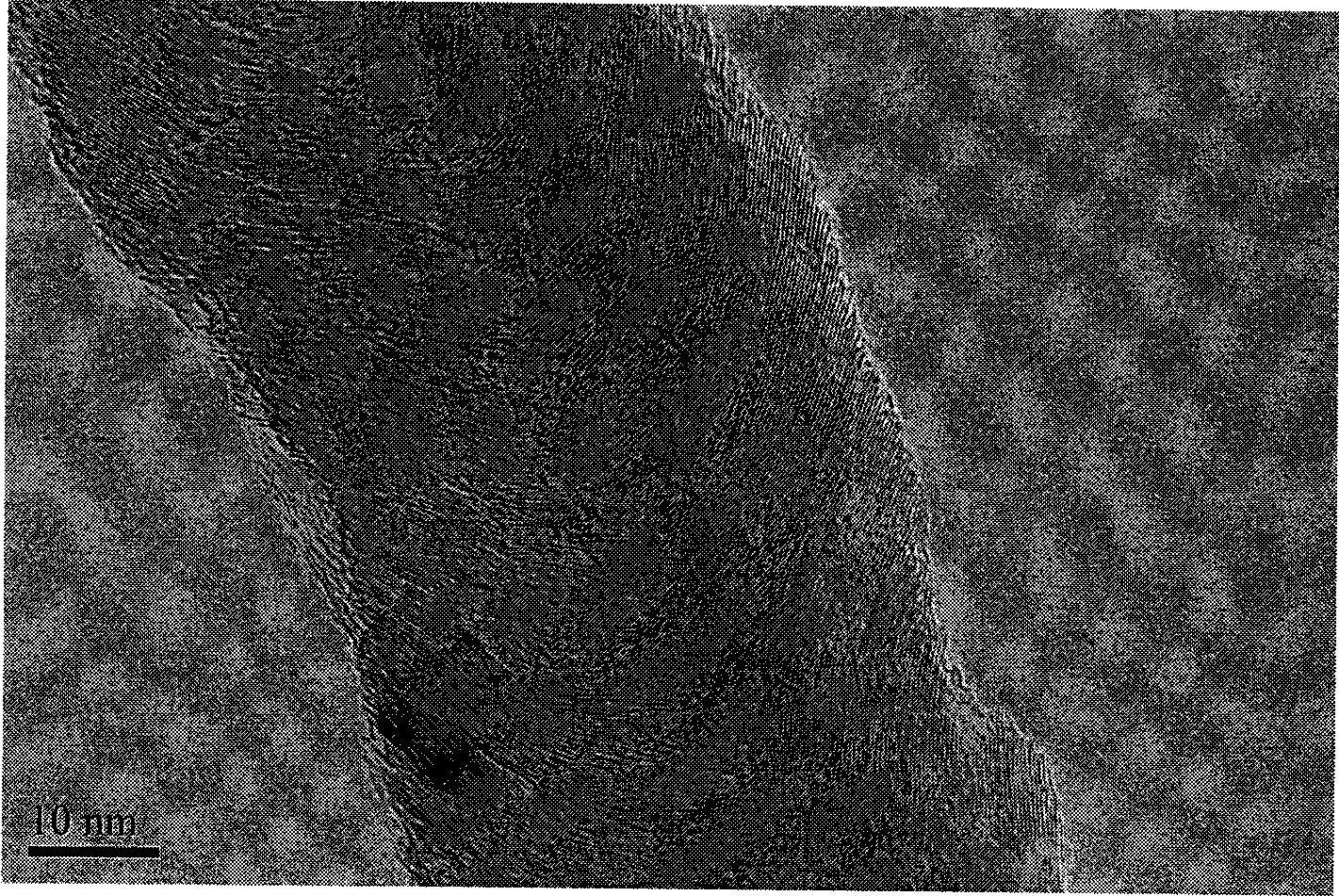

[0040] 1.2. Growth of carbon nanofibers on mica surface

[0041] Take by weighing 6.0g iron / mica catalyst precursor and spread it evenly in the quartz boat, then the quartz boat is placed in the middle part of the fixed bed quartz reactor equipped with heating...

Embodiment 2

[0042] Example 2 , Preparation of carbon nanofiber / mica antistatic material additive

[0043] 2.1. Supporting iron catalyst on mica surface

[0044] Weigh 14.4673 Fe(NO 3 ) 3 9H 2 O and dissolve it in 4.25ml of water. After it is completely dissolved, drop the ferric nitrate solution dropwise into 19g of mica for equal volume impregnation, and then place it in an oven at 120°C to dry for 12 hours to obtain a catalyst precursor. Catalyst The precursor was ground and calcined at 600° C. for 3 hours to prepare 20 grams of 10.0 wt % iron / mica catalyst precursor.

[0045] 2.2. Growth of carbon nanofibers on mica surface

[0046] Take by weighing 6.0g iron / mica catalyst precursor and spread it evenly in the quartz boat, then the quartz boat is placed in the middle part of the fixed-bed quartz reactor equipped with heating furnace; In hydrogen (200ml / min) and argon ( 600ml / min) in a mixed atmosphere from room temperature to 600°C within 3 hours, and stay for 4 hours to reduce th...

Embodiment 3

[0047] Example 3 , Preparation of carbon nanofiber / mica antistatic material additive

[0048] 3.1. Nickel catalyst supported on mica surface

[0049] Weigh 4.9542g of Ni (NO 3 ) 2 ·6H 2 O and dissolve it in 4.25ml of water. After it is completely dissolved, drop the ferric nitrate solution dropwise into 19g of mica for equal volume impregnation, and then place it in an oven at 120°C to dry for 12 hours to obtain a catalyst precursor. Catalyst The precursor was ground and calcined at 600° C. for 3 hours to prepare 20 grams of a 5.0 wt % nickel / mica catalyst precursor.

[0050] 3.2. Growth of carbon nanofibers on mica surface

[0051] Take by weighing 6.0g nickel-mica catalyst precursor and spread it evenly in the quartz boat, then place the quartz boat in the middle of the fixed-bed quartz reactor equipped with heating furnace; / min) in a mixed atmosphere from room temperature to 600°C within 3 hours, and stay for 3 hours to reduce the catalyst, the particle size of nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com