Plate display producing apparatus

A technology for flat panel displays and manufacturing devices, applied in semiconductor/solid-state device manufacturing, manufacturing tools, transportation and packaging, etc., capable of solving problems such as substrate 40 fracture, impossible substrate, substrate 40 bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

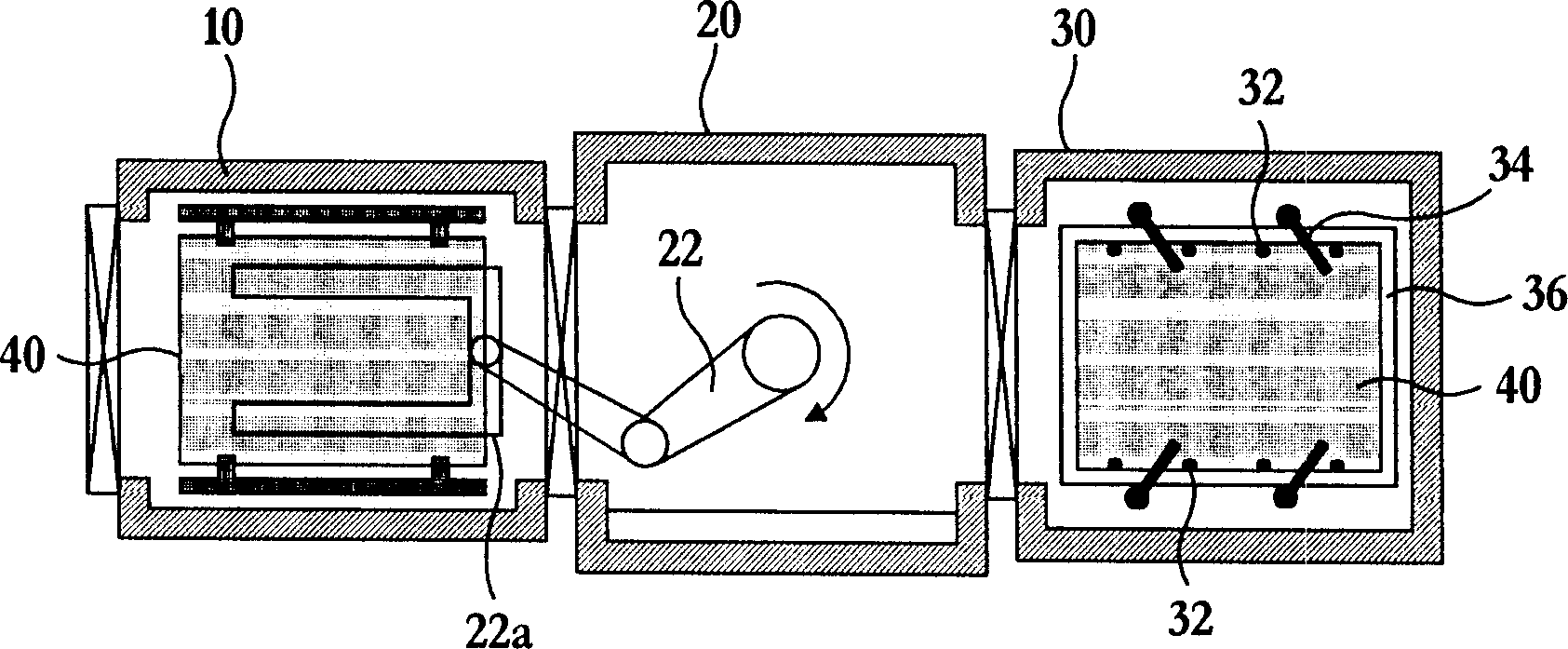

[0048] Figure 4 is a plan view for explaining a flat panel display manufacturing apparatus according to the first embodiment of the present invention.

[0049] refer to Figure 4 , the flat panel display manufacturing apparatus includes two chambers, ie, the transfer chamber 120 and the process chamber 130, unlike a conventional flat panel display manufacturing apparatus including three chambers. In the transfer chamber 120, a single robot 122 for transferring a substrate and a vacuum pump (not shown) are provided.

[0050] A substrate to be processed enters the process chamber 130 through the transfer chamber 120 from the outside by the operation of the robot 122 and the gate valves 125a and 125b. The process-completed substrate is discharged from the process chamber 130 to the outside through the transfer chamber 120 by the operation of the robot 122 and the gate valves 125a and 125b.

[0051] In the process chamber 130, a substrate support plate 136 mounting a substrate...

no. 2 example

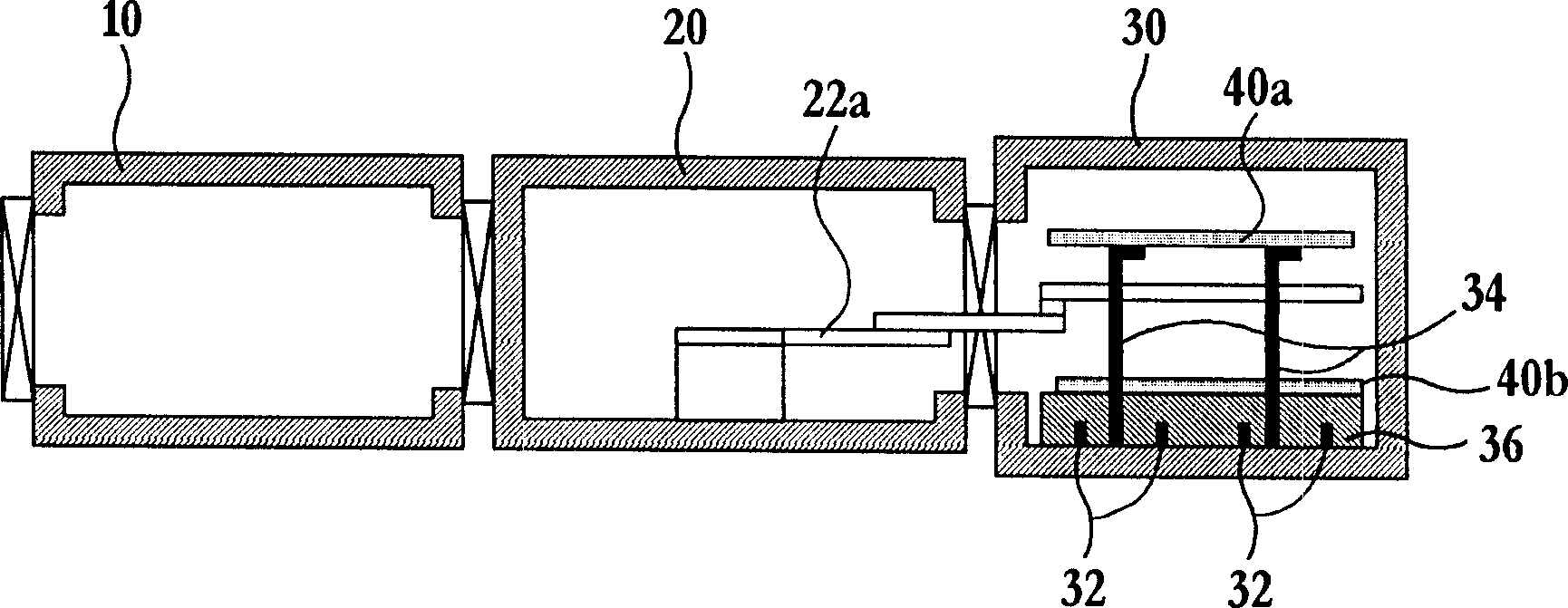

[0066] Image 6 is a plan view for explaining a flat panel display manufacturing apparatus according to a second embodiment of the present invention.

[0067] refer to Image 6 , the flat panel display manufacturing apparatus includes two chambers, ie, the transfer chamber 220 and the process chamber 230, unlike a conventional flat panel display manufacturing apparatus including three chambers. In the transfer chamber 220, a single robot 272 for transferring a substrate and a vacuum pump (not shown) are provided.

[0068] The substrate to be processed enters the process chamber 230 through the transfer chamber 220 from the outside by the operation of the robot 272 and the gate valves 225a, 225b. The process-completed substrate is discharged from the process chamber 230 to the outside through the transfer chamber 220 through the operation of the robot 272 and the gate valves 225a, 225b. In the process chamber 230, a substrate support plate 236 on which a substrate to be proc...

no. 3 example

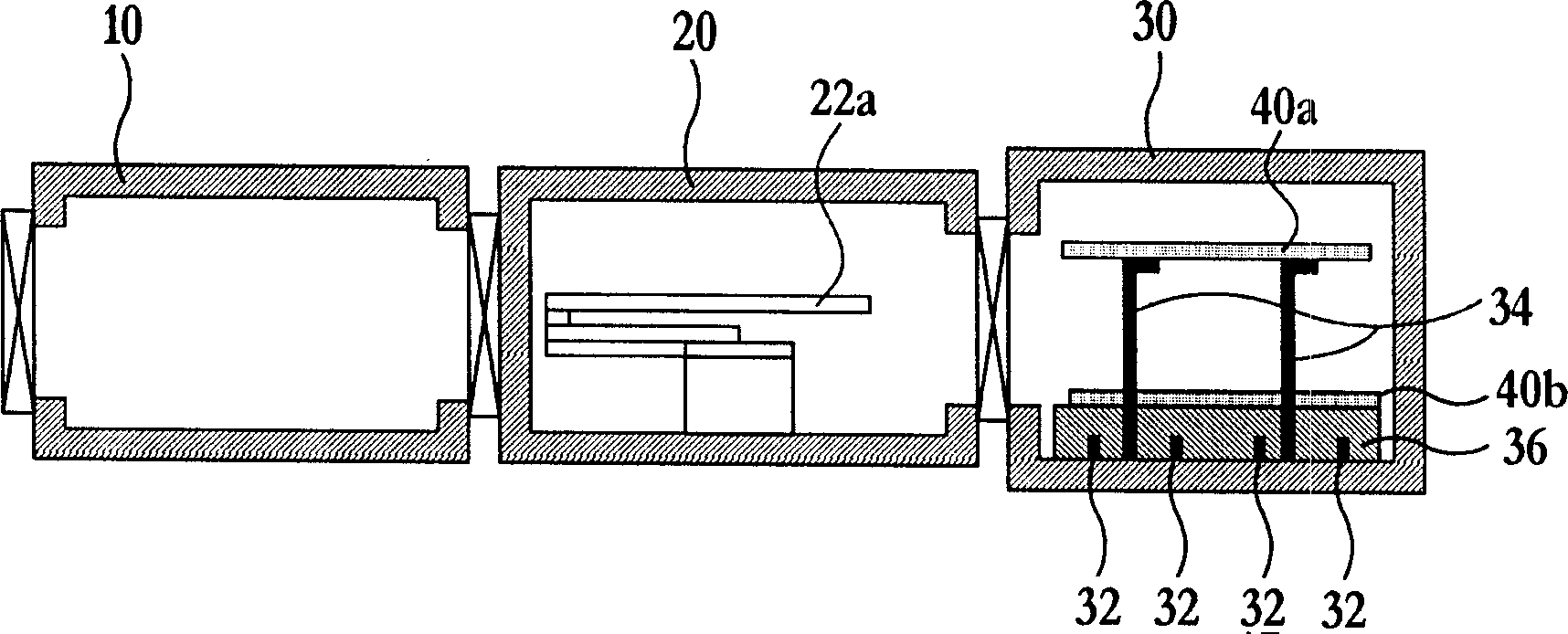

[0082] Figure 8 is a plan view for explaining a flat panel display manufacturing apparatus according to a third embodiment of the present invention.

[0083] refer to Figure 8 , a flat panel display manufacturing apparatus includes two chambers, ie, a transfer chamber 320 and a process chamber 330, unlike a conventional flat panel display manufacturing apparatus including three chambers. In the transfer chamber 320, a single robot 322 for transferring a substrate and a vacuum pump (not shown) are provided.

[0084] The substrate to be processed enters the process chamber 330 through the transfer chamber 320 from the outside by the operation of the robot 322 and the gate valves 325a, 325b. The process-completed substrate is discharged from the process chamber 330 to the outside through the transfer chamber 320 by the operation of the robot 322 and the gate valves 325a, 325b.

[0085] In the process chamber 330, a substrate support plate 336 on which a substrate to be proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com