Machining method of semi-rigid cable part

A processing method and semi-rigid technology, applied in metal processing equipment, manufacturing tools, pipe shearing devices, etc., can solve the problems of low production efficiency, poor straightness, high scrap rate, etc., and achieve improved production efficiency, convenient use, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

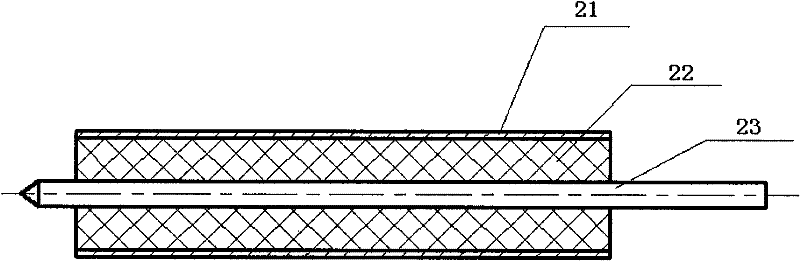

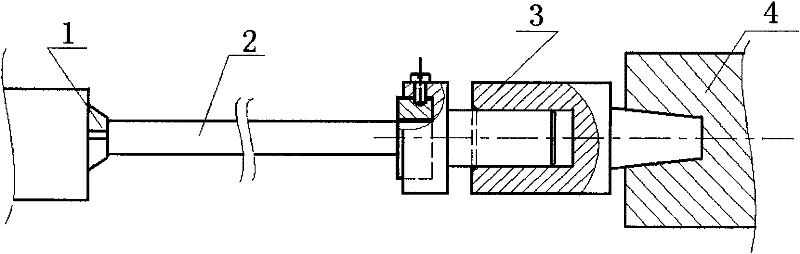

[0018] The feeder structure of the parts in this embodiment is as follows: figure 1 As shown, the semi-rigid cable material is used, and the part material is composed of three parts: metal copper tube 21, non-metal interlayer 22, and metal copper core 23. It is a composite flexible material with a maximum length-to-diameter ratio of up to 60. Drawing processing requires that after removing the metal copper tube 21, it becomes the required part feeder.

[0019] Present embodiment adopts processing method of the present invention to be:

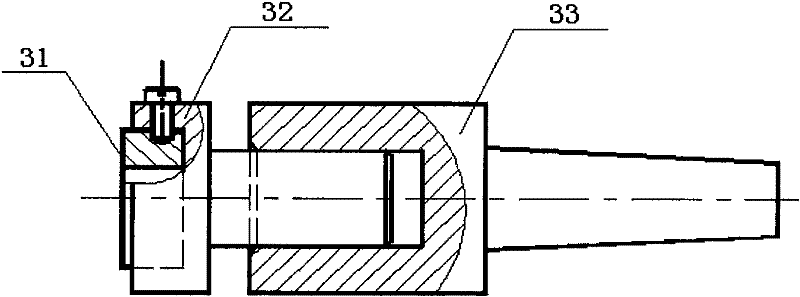

[0020] The first step is to design a special threaded sleeve such as figure 2 As shown, the special-purpose threaded sleeve 3 includes a die 31, a die locking sleeve 32 and a taper sleeve 33. The die 31 is a tool for processing external threads, among which the circular die is the most widely used, and the specification range is M0.25 ~M68mm. There are national standards for round dies and hexagonal dies, and their sizes are used in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com