Cradle with shaft

A cradle and shaft technology, which is used in shakers, children's furniture, auxiliary devices for rope making, etc., can solve the problems of difficulty, uneven surface of strands, long time, etc., and achieves simple manufacturing structure, short maintenance time, and improved The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The accompanying drawings disclose a specific embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

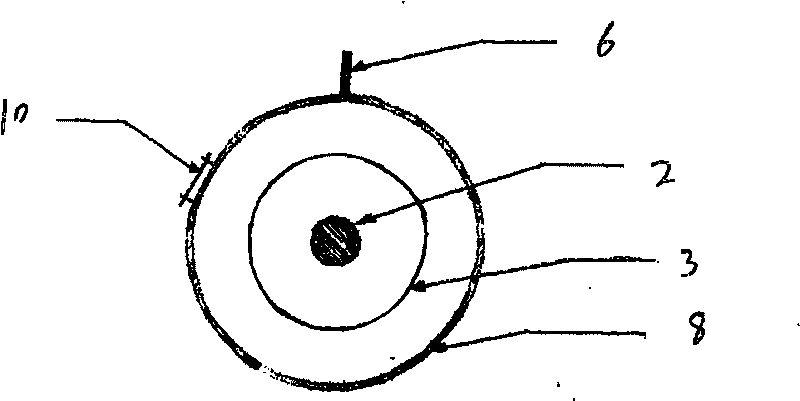

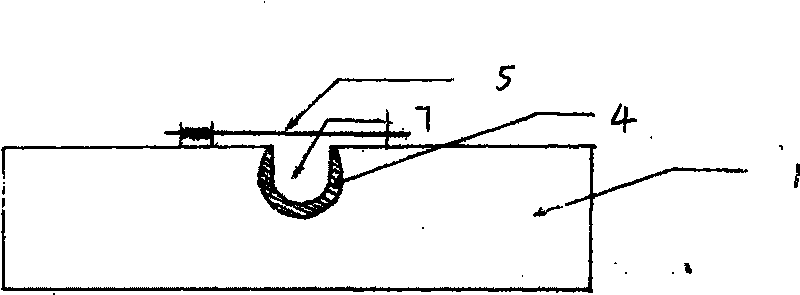

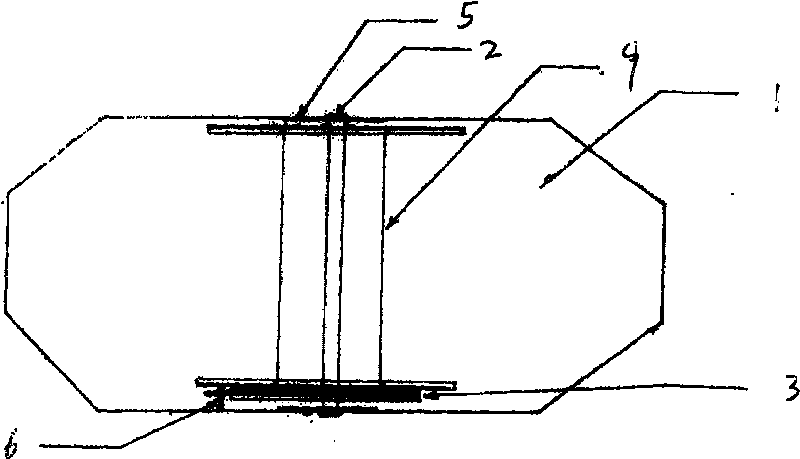

[0013] Such as figure 1 , 2 As shown in and 3, a cradle with a shaft, the device includes a cradle 1, which is characterized in that it also includes a shaft 2, a fence plate 3, a bearing bush 4, a spring pin rod 5 and a screw rod 6, and the openings on both sides of the cradle 1 are respectively opened. A U-shaped groove 7, the U-shaped groove 7 is provided with a bearing bush 4, the spring pin 5 is fixed on the top of the U-shaped groove 7, the shaft 2 is placed in the U-shaped groove 7 through the hole of the winding disk 9, and the spring pin 5 Fix the shaft 2, one end of the shaft 2 is fixed with a fence 3, and the fence 3 is equipped with a fence 8 composed of a steel belt and a brake pad, fixed with a bolt 10, and a screw rod 6 is fixed longitudinally on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com