Static pouring column type membrane component and machining method thereof

A technology of static casting and processing methods, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., which can solve the problems of easy blockage of water inlet holes, detachment of resin from membrane filaments and membrane shells, and low bonding strength of membrane filaments and other problems to achieve the effect of solving the uneven and straight distribution of membrane filaments, avoiding easy bending and leaking points, and high utilization of membrane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

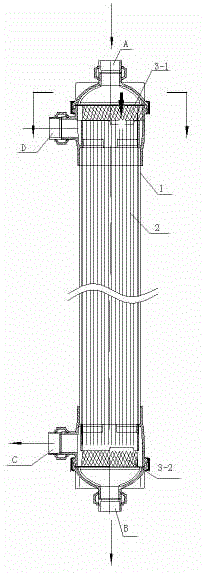

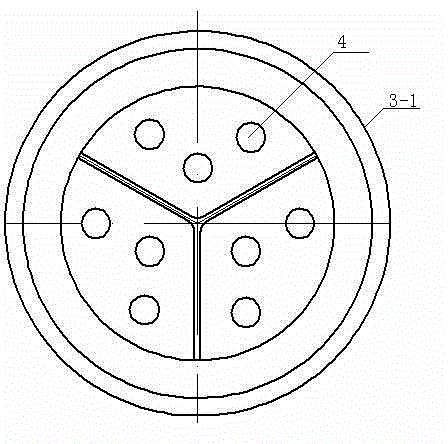

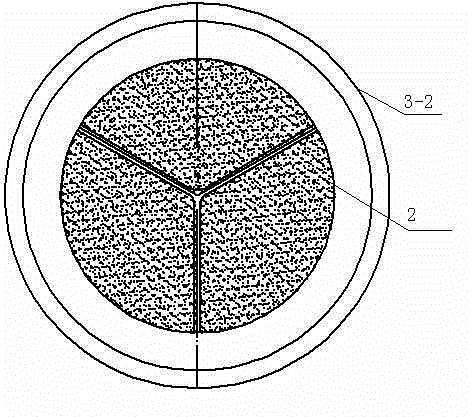

[0032] Embodiment 1: The specific structure of the static casting column membrane module in this embodiment is: the static casting column membrane module includes a casing 1, a membrane filament 2, a water inlet A, a water outlet B, a spare port C, and a concentrate outlet D. The water inlet and water outlet are respectively provided with resin ends. The water inlet resin end 3-1 is composed of flexible resin, membrane wire, and water inlet hole 4, and the water outlet resin end 3-2 is composed of flexible resin and membrane wire, and the two ends of the membrane wire are respectively sealed by flexible resin. It is fixed at the resin end. In this embodiment, the diameter of the water inlet hole is 6 mm, and the number is 6. The flexible resin filled is epoxy resin, and the number of membrane threads is 12,000.

[0033] Its production and processing methods are as follows: (1) drying the membrane wire; (2) vertically fixing the dried membrane wire with a pouring frame, and ins...

Embodiment 2

[0035] Embodiment 2: The structure of the membrane module in this embodiment is basically the same as that in Embodiment 1, except that the number of membrane filaments in this embodiment is 10,000, the diameter of the water inlet hole is 9 mm, and the number is 10. The filling The flexible resin is polyurethane.

[0036] Similarly, in the pouring method of this embodiment, 10 casting rods for water inlet holes are selected, and the diameter of the casting rods is 9 mm. inlet holes of the same diameter.

[0037] The membrane module and its processing method provided in this embodiment reduce the number of membrane filaments and increase the size and number of water inlet holes. The membrane module formed by casting the method of this embodiment is not easy to block the water inlet holes, and the overall filtration effect is inferior to that of the implementation. example 1.

Embodiment 3

[0038] Embodiment 3: The membrane module structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the number of membrane filaments in this embodiment is 8000, the diameter of the water inlet hole is 12 mm, and the number is 12. The filled The flexible resin is silicone resin.

[0039] Similarly, in the pouring method of this embodiment, 12 casting rods for water inlet holes are selected, and the diameter of the casting rods is 12 mm. For water inlet holes with the same diameter, the overall filtering effect is inferior to that of Example 1.

[0040] The membrane module and its processing method provided in this embodiment can further reduce the number of membrane filaments and increase the size and number of water inlet holes. The membrane module formed by casting the method of this embodiment can increase the amount of raw water inflow, ensure the inflow and outflow of raw water, and effectively reduce the Membrane contamination.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com