Quick valve

A shutter and valve port technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of severe wear, large frictional resistance, increased pressure loss, etc., and achieve high sealing reliability, zero pressure loss, and no operation. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

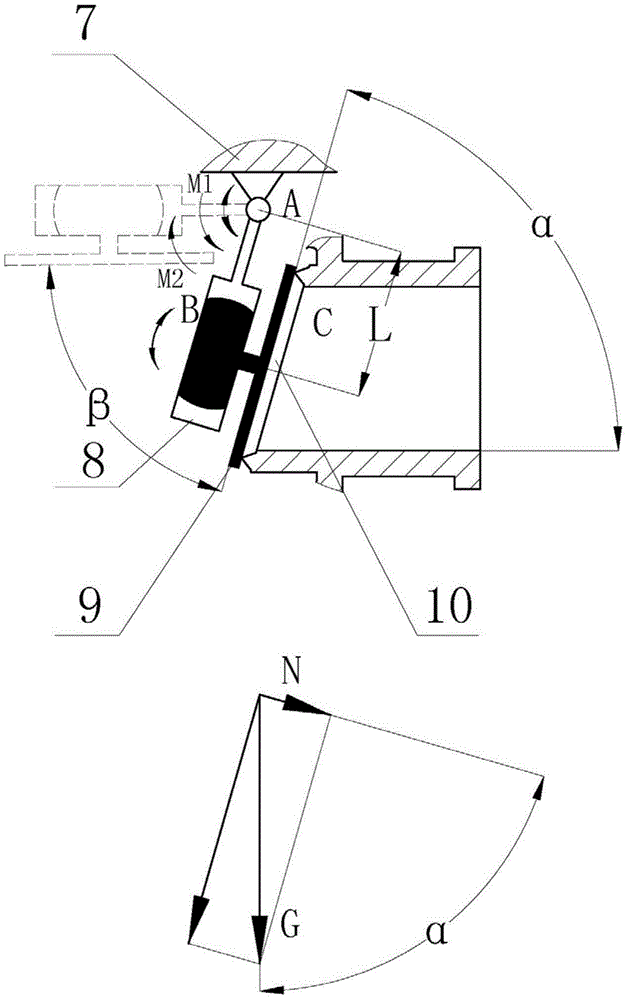

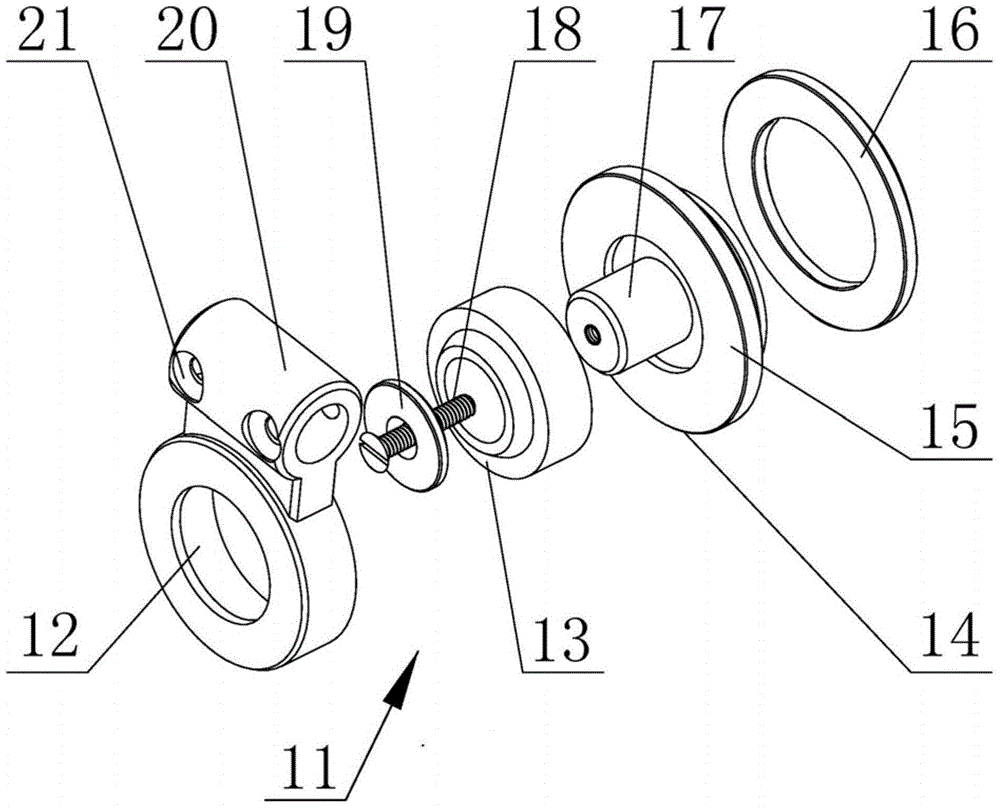

[0023] The invention is described below with reference to the drawings, in which like parts are identified with like reference numerals.

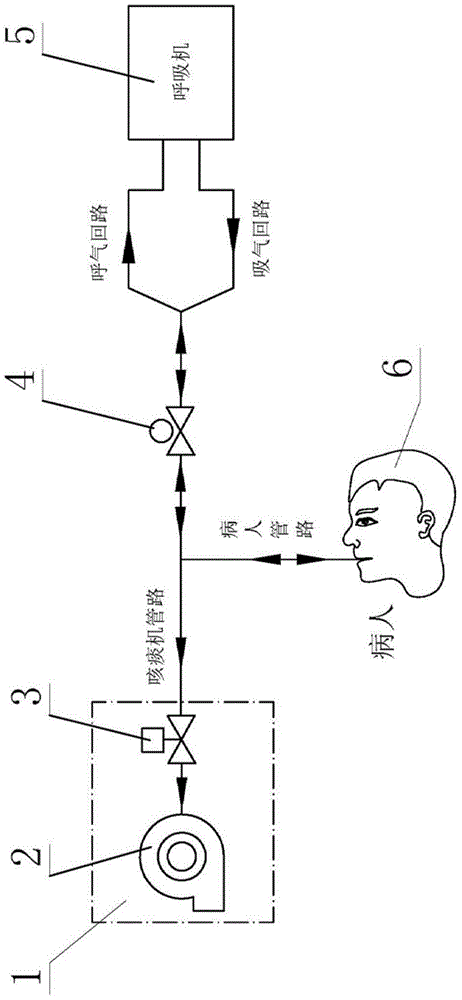

[0024] The innovation motivation of the present invention comes from the needs of a fully automatic synchronous expectoration machine. The fully automatic synchronous expectoration machine is used in ICU wards or respiratory departments. It is used in conjunction with a ventilator to automatically and instantly clear the respiratory sputum of mechanically ventilated patients by simulating human coughing. The so-called simulated patient cough means that after the ventilator gives the patient a positive pressure ventilation with a tidal volume large enough, the expectorant machine gives the patient a rapid and sudden reverse expiratory airflow. Combine below figure 1 Briefly introduce the innovative motivation of the present invention.

[0025] The expectorant machine 1, the ventilator 5 and the patient 6 are ventilated through the balloon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com