A single piezoelectric ceramic drive hot melt glue dispensing valve

A piezoelectric ceramic-driven, hot-melt adhesive technology, which is used in devices and coatings that apply liquid to the surface, which can solve the problems of too many components, insufficient connection accuracy, and low dispensing accuracy of the glue valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

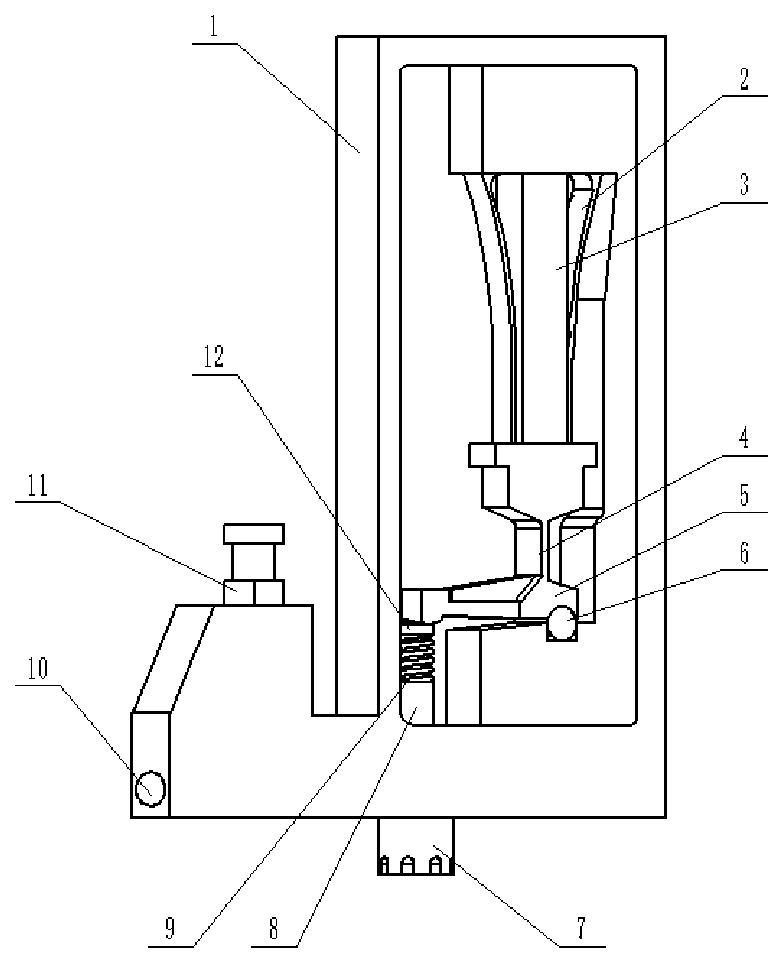

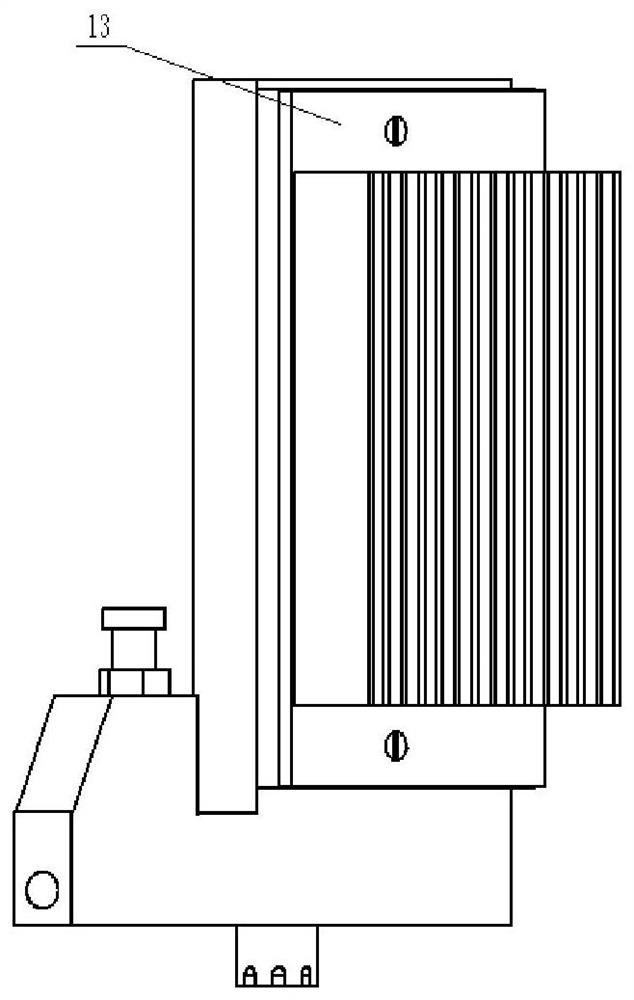

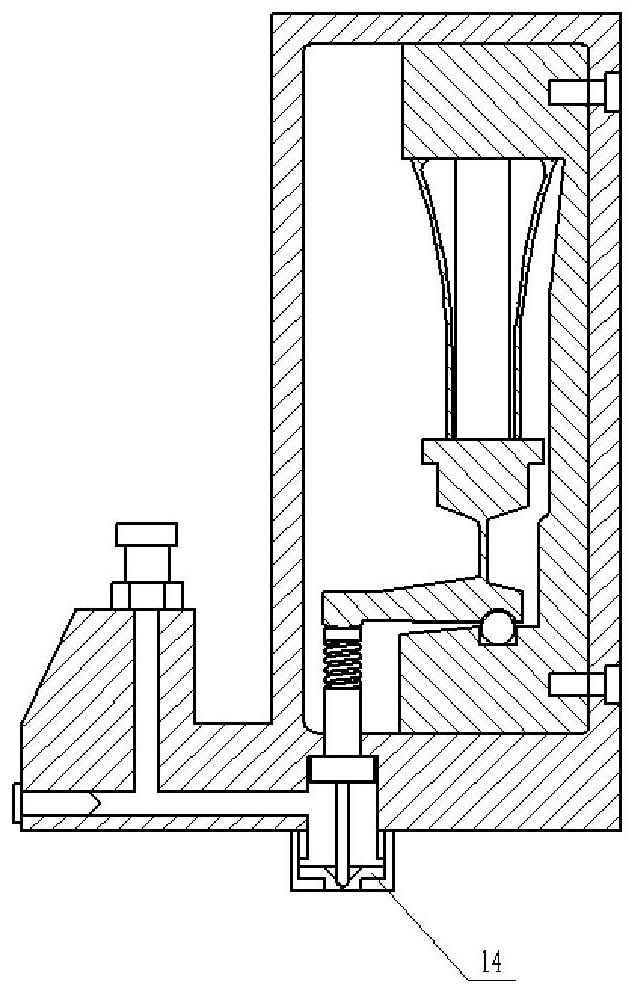

[0032] see Figure 1 to Figure 4 , the lower part of the valve body 1 is provided with two threaded holes, and the internal threaded holes are used to install the striker guide sleeve 8. When installing, first install the striker 12 and the striker spring 9 into the striker guide sleeve 8 from top to bottom, and then install the striker. 12. The striker guide sleeve 8 of the striker spring 9 is installed from bottom to top and locked on the valve body 1. The top of the striker is a flat surface in contact with the lever, and the bottom (at the tip) of the striker is a spherical surface, which can be connected with the integrated nozzle. The inner cavity forms a precise surface fit. The lowermost external threaded hole is used to install the cylindrical nut 7, and the outer surface of the integrated nozzle 14 is also threaded, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com