Method for judging bending of carcass cord of wide base radial tire

A technology of radial tires and carcass cords, applied in the field of simulation, to achieve high precision, solve bending problems, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

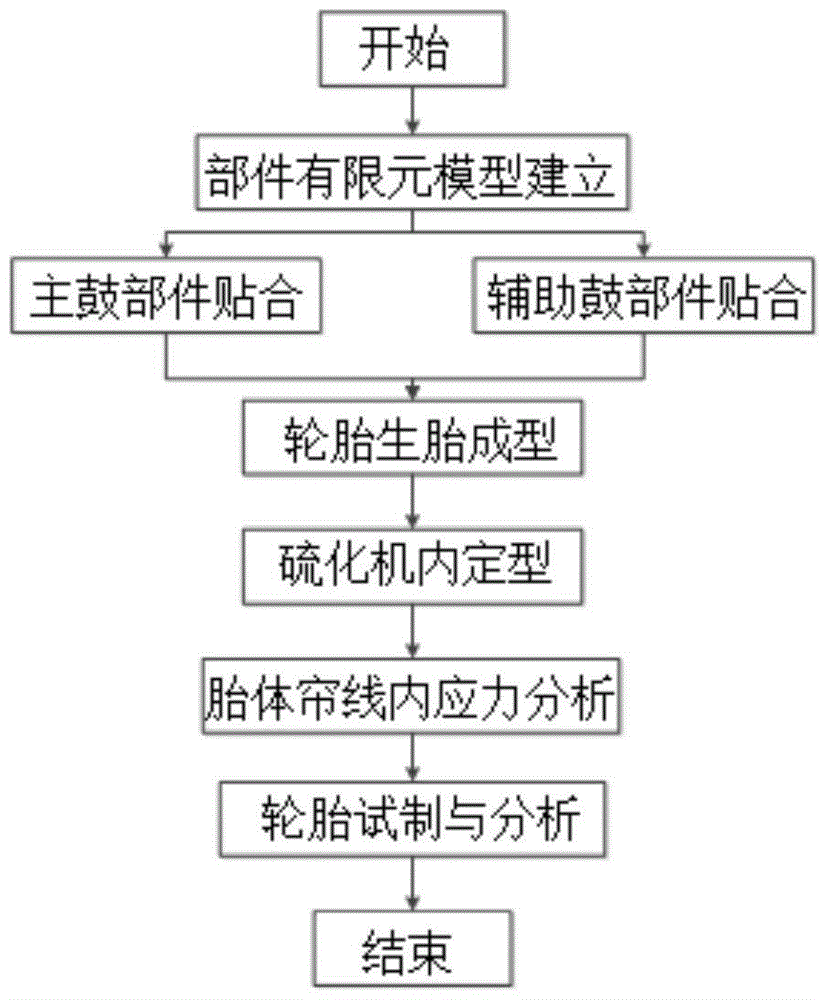

[0037] Taking the molding process of 435 / 50R19.5 all-steel heavy-duty wide-base radial tire as an example to illustrate the specific implementation steps, as follows figure 1 shown. The rated air pressure and rated load of this type of tire are 0.83MPa and 45kN respectively.

[0038] S1: Establishment of finite element model of tire components.

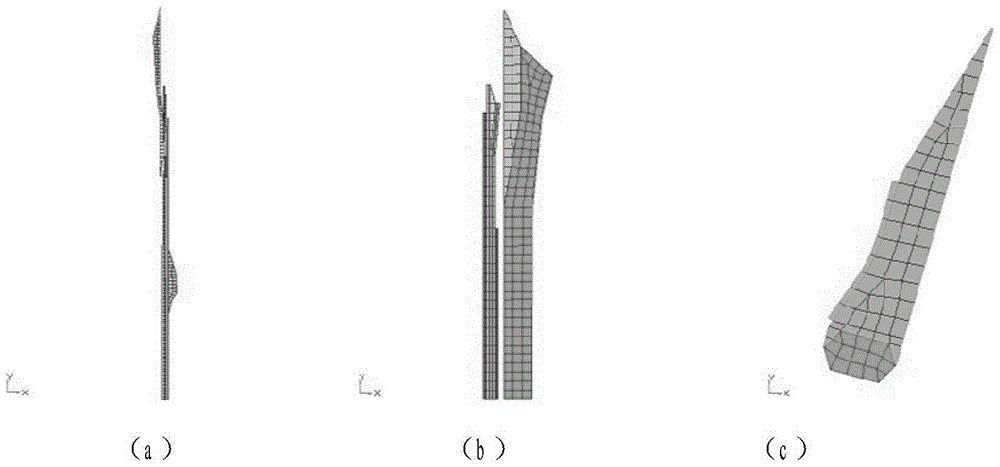

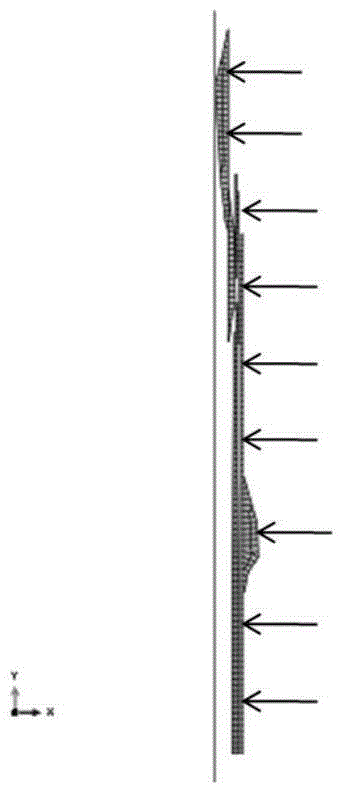

[0039] Wide-base radial tires mainly include main drum parts, auxiliary drum parts and apex parts. The main drum parts include sidewall rubber, wear-resistant rubber, film, inner liner, lower inner liner, reinforcing layer, carcass layer, and shoulder Pad rubber; auxiliary drum parts include No. 1 belt layer, No. 2 belt layer, No. 3 belt layer, No. 4 belt layer, and crown rubber; apex rubber parts include steel traveler, apex r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com