Thin molded article

A thin-thickness, molded product technology, applied in the field of thin-thickness molded products, can solve problems such as insufficient injection pressure, thin-thickness plate thickness deviation, molten resin cannot be rotated to the end of the thin-thickness plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

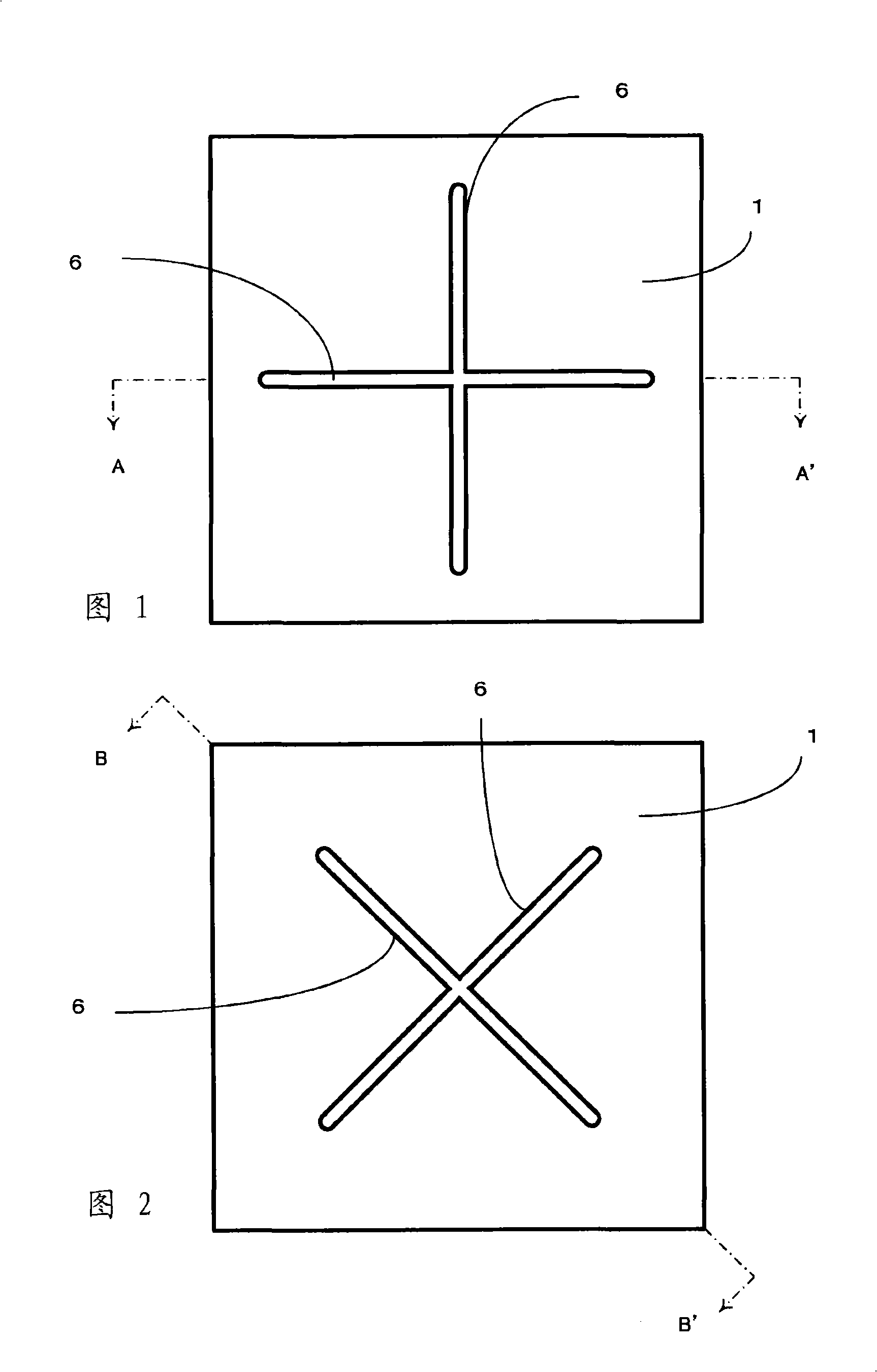

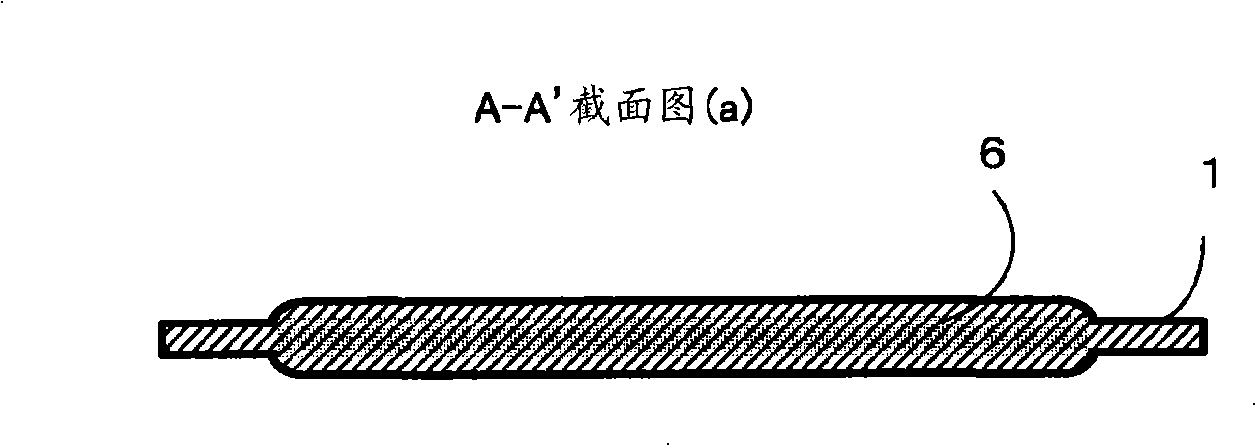

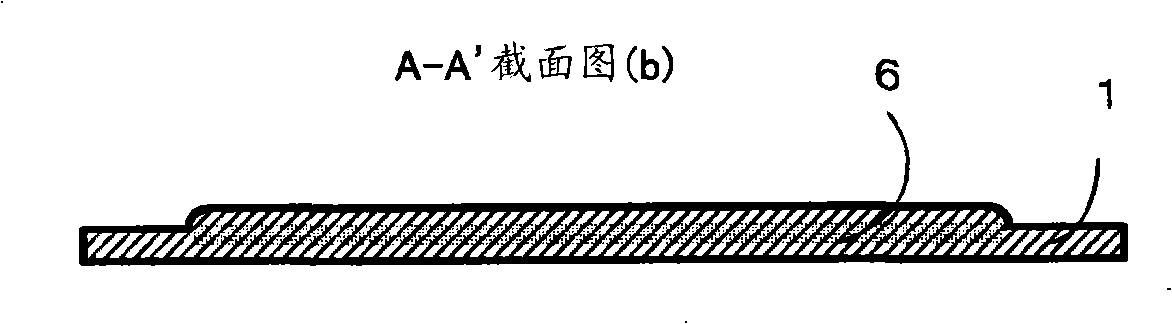

[0085] Fig. 1 shows an example of a plastic molded article having a thin flat plate structure of the present invention, in a manner extending from the central portion of the thin flat plate 1 to the direction of its outer edge, by providing a plurality of induction belts 6, a cross-shaped An induction zone 6 is formed. The induction zone 6 is a thick or wide rib for promoting the flow of the molten resin in the mold. Although not shown in the figure, the molten resin is poured into the mold on the cross-shaped rib or in the center. The gate is set. The molten resin flowing from the gate into the induction zone 6 flows toward the outer edge, and also flows from the periphery of the rib to the thin plate 1 .

[0086] Since the thick-diameter induction band 6 is provided radially from the center of the thin plate toward its outer edge, and the leading end of the induction band 6 does not reach the outer edge of the thin plate 1, the molten resin injected into the mold is After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com