Temperature sensor cutting device

A technology of temperature sensor and cutting device, which is applied in the field of temperature sensor cutting device, can solve the problems of different lengths, uneven cutting plane of CP wire, etc., and achieve the effect of neat cutting plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

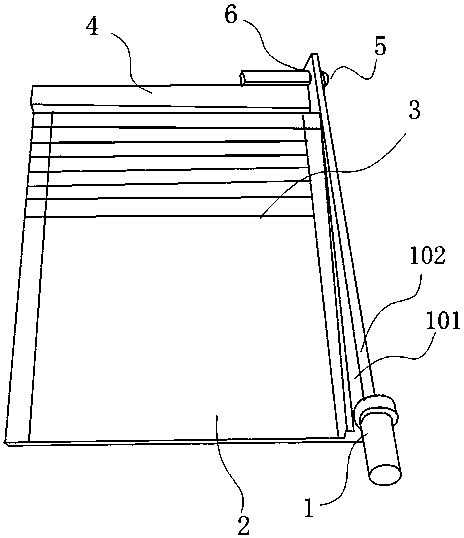

[0011] Such as figure 1 Shown, a kind of temperature sensor cutting device, it comprises cutting knife body 1 and cutting platform 2, and described cutting knife body 1 is fixedly arranged on cutting platform 2, and described cutting platform 2 is provided with scale scale layer 3, and described One end of the cutting platform 2 is provided with a boss 4 , and one end of the boss 4 is provided with a hinge device 5 , and the cutting knife body 1 is provided with a hinge hole 6 , and the hinge device 5 cooperates with the hinge hole 6 .

[0012] The width of the cutting platform 2 is 10-15cm.

[0013] The cutter body 1 is composed of a cutting blade 101 and a support frame 102, and the cutting blade 101 is made of stainless steel.

[0014] The width of the cutter body 1 is 5-8cm.

[0015] Before operation and during operation, take 5 pieces of semi-finished products to be trimmed at the end every hour, cut a few pieces, confirm whether the total length is 44-48mm, and the exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com