Knitting device and knitting method for carbon-carbon throat liner preform

A technology of prefabricated body and throat lining, which is applied in the direction of braided fabrics, textiles and papermaking, etc., to achieve the effects of large voids, reduced flow resistance, and less glue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

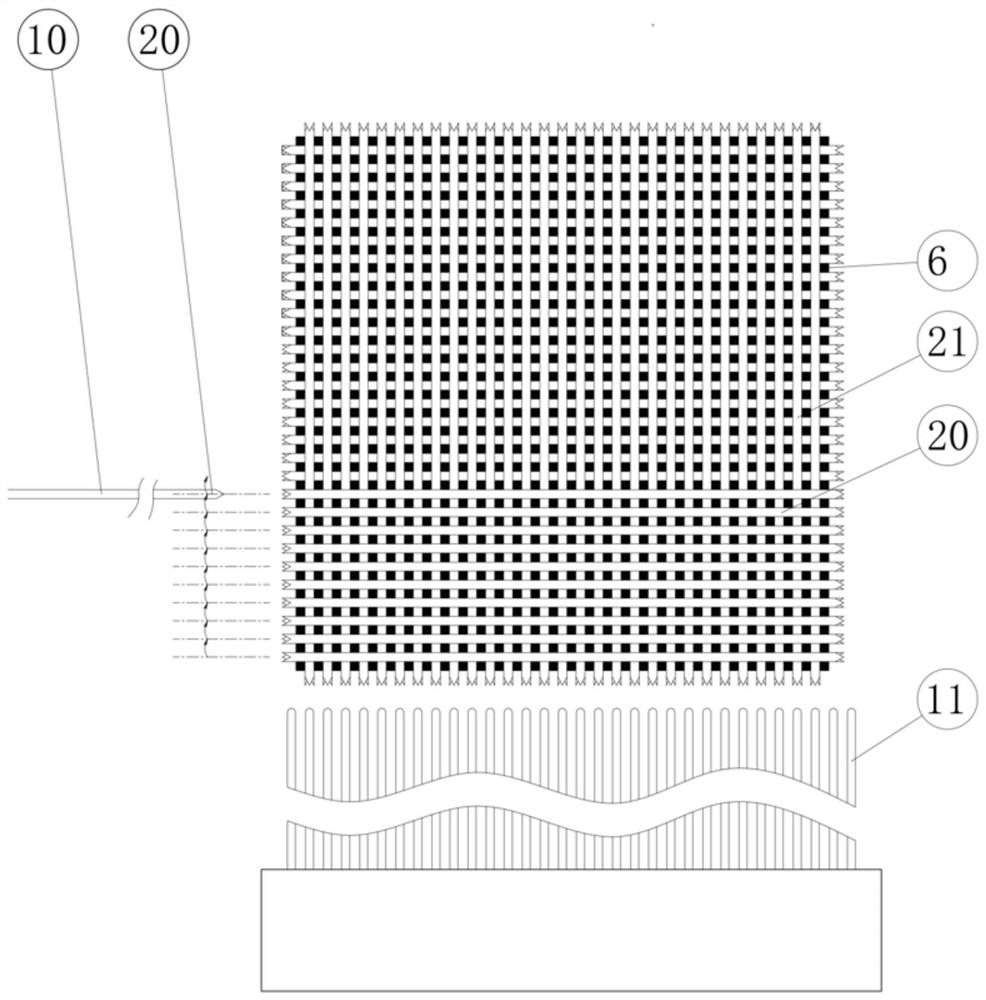

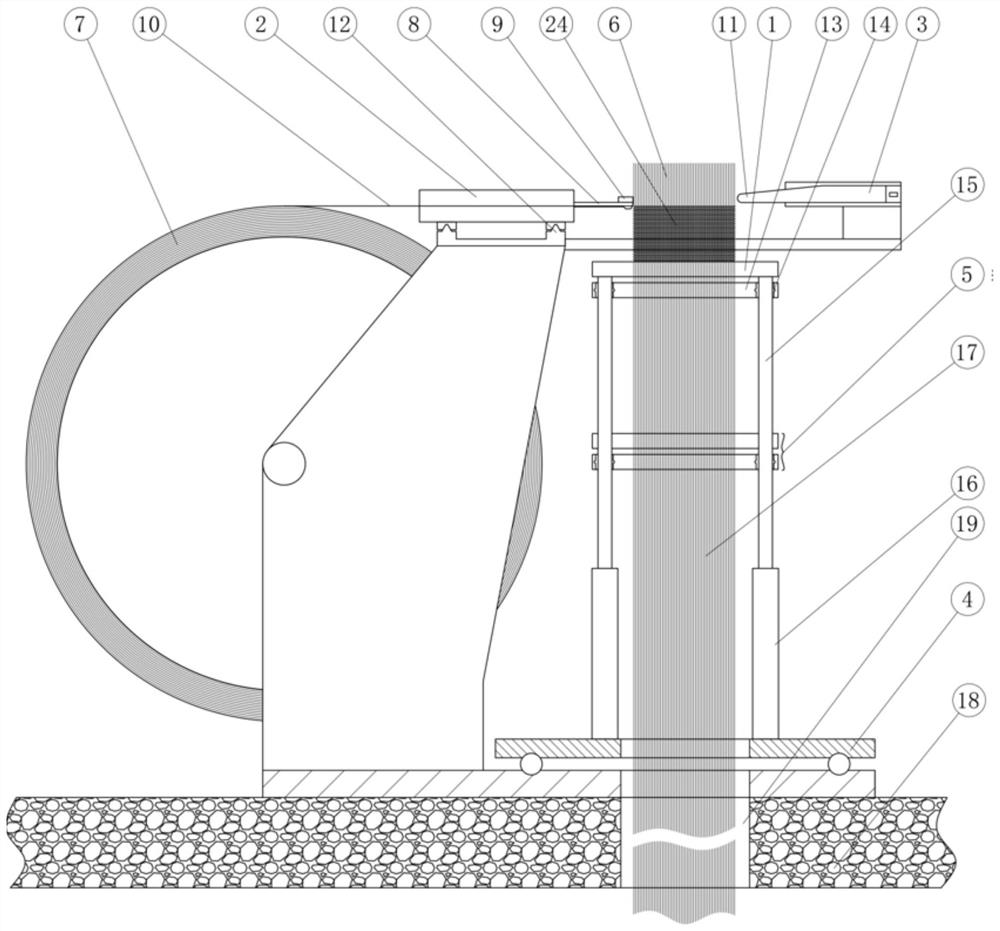

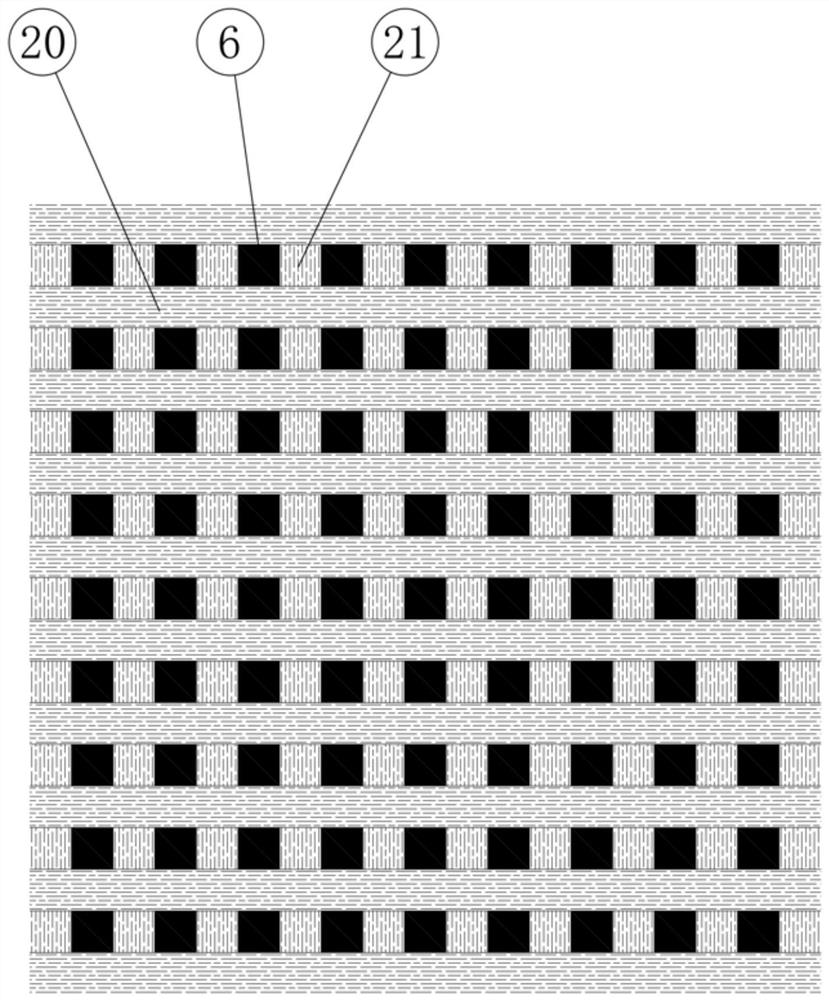

[0048] see figure 1 , this is a rigid rod-rod weaving method of 3D orthogonal carbon-carbon throat liner prefabricated body, all of which are braided with carbon rods, first fix one end of the Z-direction carbon rods on the weaving template, and then use carbon The rods are filled with a layer of flat rods that are orthogonal to the Z-direction carbon rods, and then filled with flat rods that are perpendicular to the Z-direction and the direction of the carbon rods on the upper layer is 90° flat rods, and the cycle is repeated, and finally a 3D three-dimensional prefabrication body. A carbon rod with a square cross-section is used in the Z direction, and a carbon rod with a rectangular cross-section is used in the two mutually orthogonal plane directions. Orthogonal 3D rigid rod-rod knitting machine, including the machine body, vertical rod tray, flat rod insertion head, steel comb buckle and flat rod reel, and the flat rod insertion head includes a lateral movement servo mec...

Embodiment 2

[0052] see figure 1 , this is a rigid rod-rod weaving method of 4D carbon-carbon throat lining prefabricated body. A layer of flat rods orthogonal to the carbon rods in the Z direction is filled, and then the flat rod insertion head is rotated 60°, and then a layer of carbon rods perpendicular to the Z direction is inserted, and the cycle is repeated, and finally a 4D three-dimensional prefabricated body is weaved. The carbon rods with regular triangular cross-sections are used in the Z direction, and the carbon rods with rectangular cross-sections are used in the three plane directions of 120° to each other. The length and width of the rectangular cross-section are determined according to the mechanical requirements of the product. The 4D rigid rod-rod knitting machine includes a machine body, a vertical rod tray, a flat rod insertion head, a steel comb buckle and a flat rod reel, and the flat rod insertion head includes a lateral movement servo mechanism and a longitudinal m...

Embodiment 3

[0059] see figure 1 , 5 6. This is a hard rod-rod weaving method using a 3D or 4D carbon-carbon throat lining prefabricated body with improved vertical rods. All carbon rods are used for weaving. First, one end of the Z-direction carbon rod is fixed on the weaving template Then, the flat rods perpendicular to the Z-direction carbon rods are inserted layer by layer with carbon rods in the horizontal order, and finally a three-dimensional prefabricated body completely woven with hard rods is woven.

[0060] First calculate the theoretical gap according to the 3D or 4D hard rod-rod weaving structure described in Embodiment 1 and Embodiment 2, then cut the filling blocks 20', 21', 22' of corresponding size with a transverse carbon rod, and according to a certain The position is bonded to the vertical rod to make an improved new vertical rod. The 3D orthogonal hard rod-rod woven packing blocks 20', 21' are cubes, and the 4D hard rod-rod woven packing blocks 20', 21', 22' are poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com