Deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass

An aluminosilicate glass, yield point technology, applied in glass forming, glass forming, glass manufacturing equipment and other directions, can solve the problems of easy to be scratched, low elastic modulus, large deformation, etc., to achieve easy portability , low density, the effect of keeping the size unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

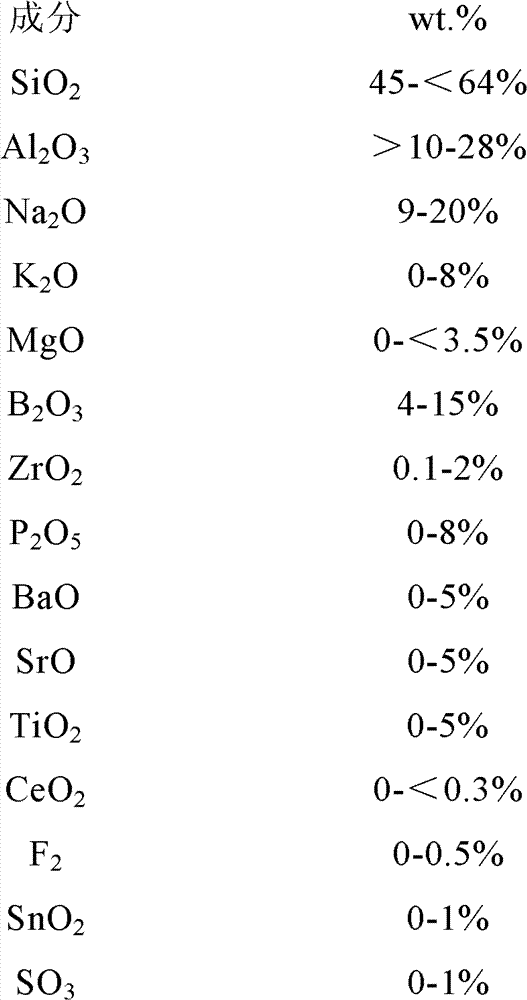

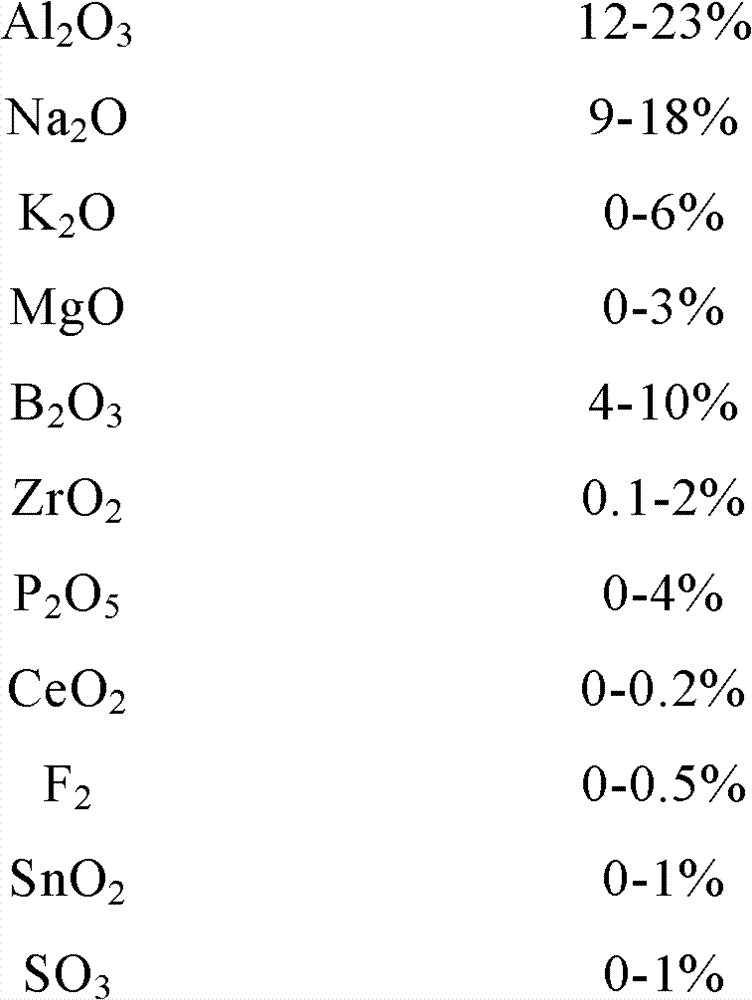

Method used

Image

Examples

Embodiment Construction

[0167] The raw materials used in the tests of the embodiments of the present invention are oxides, hydroxides, carbonates and nitrates (all purchased from Sinopharm Chemical Reagent Co., Ltd., Suzhou, chemical grade).

[0168] The test of the embodiment of the present invention measures the transition temperature T of glass on the relaxation-resistant dilatometer (relaxation-resistant DIL402PC) g and coefficient of thermal expansion CTE. After the glass sample is made into a strip sample of about 50mm, the temperature is raised from room temperature at a rate of 5°C / min until the test is completed.

[0169] The density of glass is determined by Archimedes' principle. The volume of the sample is obtained by placing a glass sample in a container of water and precisely measuring the change in volume of the water in the container. Density data is obtained by dividing the accurately measured sample weight by the volume.

[0170] Samples are chemically tempered. Tempering is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com