Resin material for cutting diamond wire and resin plate for cutting diamond wire

A technology for diamond wire cutting and resin materials, which is applied in the fields of resin materials for diamond wire cutting and resin plates for diamond wire cutting, and can solve the problems of complex recycling and utilization of solid waste in cutting slurry treatment, high pressure caused by environmental protection, and low hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

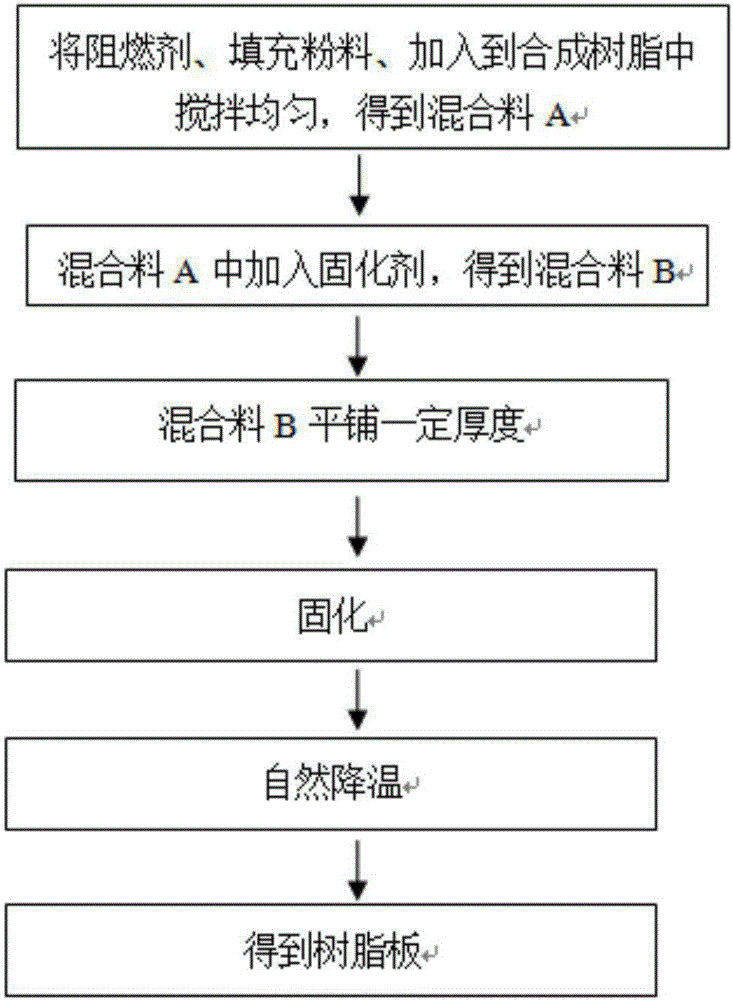

Method used

Image

Examples

Embodiment 1

[0041] Add 50 parts of flame retardant silicon dioxide, 3 parts of coupling agent Wolan, and 20 parts of silicon powder with a particle size of 0.5 to 100 μm into 40 parts of epoxy resin, stir well, and then add curing agent three 10 parts of methylhexamethylene diamine, after being fully stirred evenly, spread evenly in the mold by a distributing machine, put it into a constant temperature box at 100°C to cure for 30 minutes, and then cool down naturally to obtain a resin board for diamond wire cutting.

[0042] The resin plate has a Shore hardness of 88, no bending, no deformation, and is suitable for diamond wire cutting of silicon rods; the resin plate for diamond wire cutting prepared in Example 1 is used for slicing silicon rods, and the chipping rate of the slices is 1.3%. .

Embodiment 2

[0044] Add 10 parts of flame retardant tetrabromobisphenol A, two parts of silane coupling agent A-172, 60 parts of silicon powder with a particle size of 0.5 to 100 μm, and 0.1 part of initiator cobalt naphthenate into 40 parts of unsaturated resin , and then add 2 parts of curing agent methyl ethyl ketone peroxide to it, and after fully stirring evenly, spread it evenly in the mold through a distribution machine, enter the constant temperature box at 80°C and cure for 60 minutes, and then cool down naturally to obtain a resin plate for diamond wire cutting.

[0045] The resin plate has a Shore hardness of 90, no bending, no deformation, and is suitable for diamond wire cutting of silicon rods; the resin plate for diamond wire cutting prepared in Example 2 is used for silicon rod slices, and the chipping rate of slices is 0.93%. .

Embodiment 3

[0047] Add 25 parts of flame retardant melamine, 40 parts of silicon powder with a particle size of 0.5 to 100 μm, and 0.1 part of initiator cobalt naphthenate into 40 parts of epoxy resin, and then add 2 parts of curing agent methyl ethyl ketone peroxide , after fully stirring evenly, spread it evenly in the mold through a distribution machine, enter the constant temperature box at 80°C and cure for 60 minutes, and then cool down naturally to obtain a resin plate for diamond wire cutting.

[0048] The resin plate has a Shore hardness of 90, no bending, no deformation, and is suitable for diamond wire cutting of silicon rods; the resin plate for diamond wire cutting prepared in Example 3 is used for slicing silicon rods, and the chipping rate of the slices is 1.2%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com