Powder metal forging and method and apparatus of manufacture

一种粉末金属、锻件的技术,应用在金属加工设备、机械设备、车辆部件等方向,能够解决昂贵加工设置、模具寿命短、复杂等问题,达到小化材料浪费、减少模具成本、接触的时间最小化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

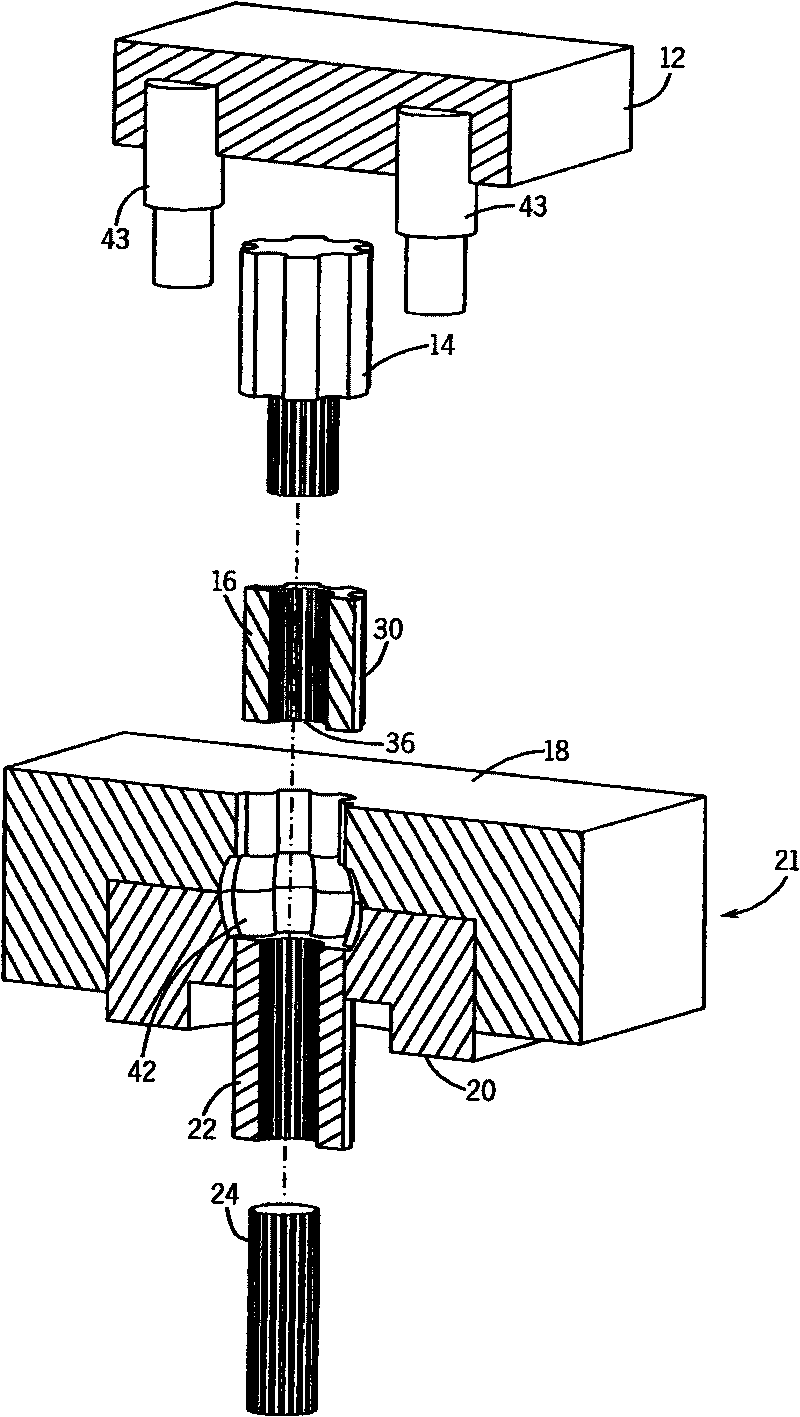

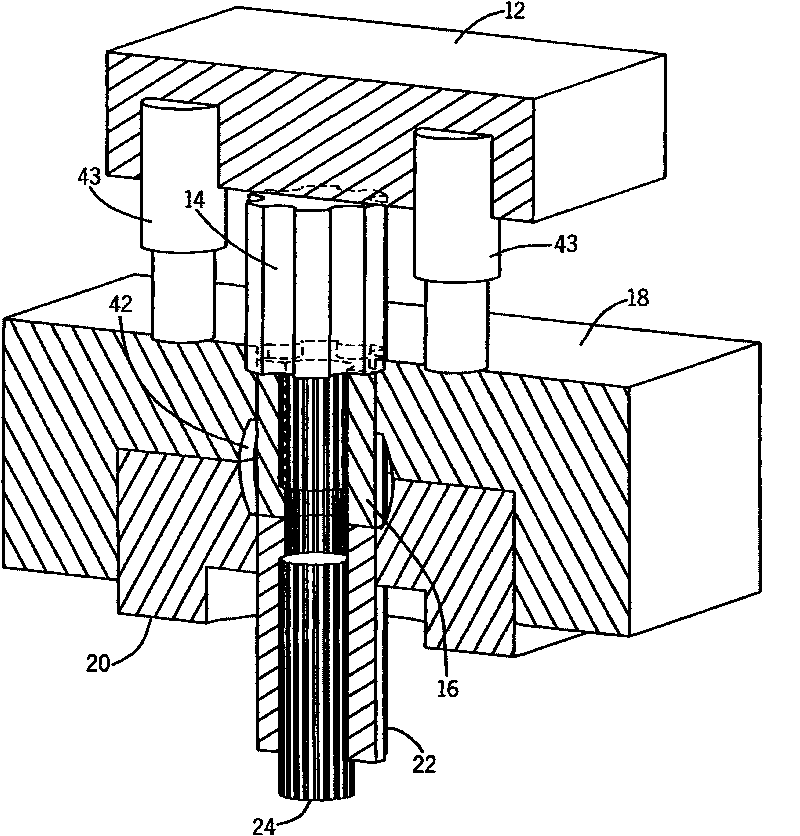

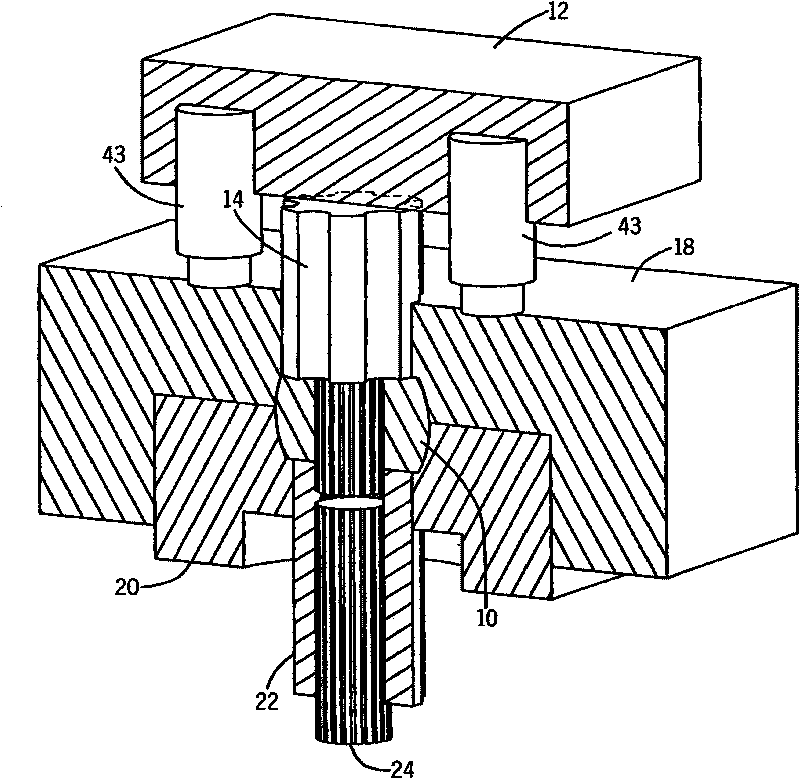

[0030] See now the accompanying drawings, especially figure 1 , Image 6 and Figure 7 , which illustrate a method and apparatus for forming a powder metal forging 10, which may include a ram or hammer 12, an upper punch 14, a preform 16, an upper die 18 and a lower die 20 forming a die set 21, a lower die Punch 22 and snag pin 24 .

[0031] See especially Image 6 , the preform 16 comprises a powdered metal composition that has been compacted and subsequently sintered. The composition of the powder metal includes nickel between about 0.40% and 2.00%, molybdenum between about 0.50% and 0.65%, manganese between about 0.10% and 0.35%, manganese between about 0.12% and 0.80% Between carbon, and the balance iron. The preform 16 is a non-cylindrical preform that includes a first end 26 , a second end 28 opposite the first end, and an outer profile 30 connecting the first end 26 and the second end 28 . The outer profile 30 comprises a plurality of longitudinal protrusions 32 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com