Cigarette/ filter candle sampling system

A sampling system and filter rod technology, applied in the direction of sampling devices, etc., can solve the problems of waste, limited sampling distance, rising production costs, etc., and achieve the effects of reducing production costs, improving utilization, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

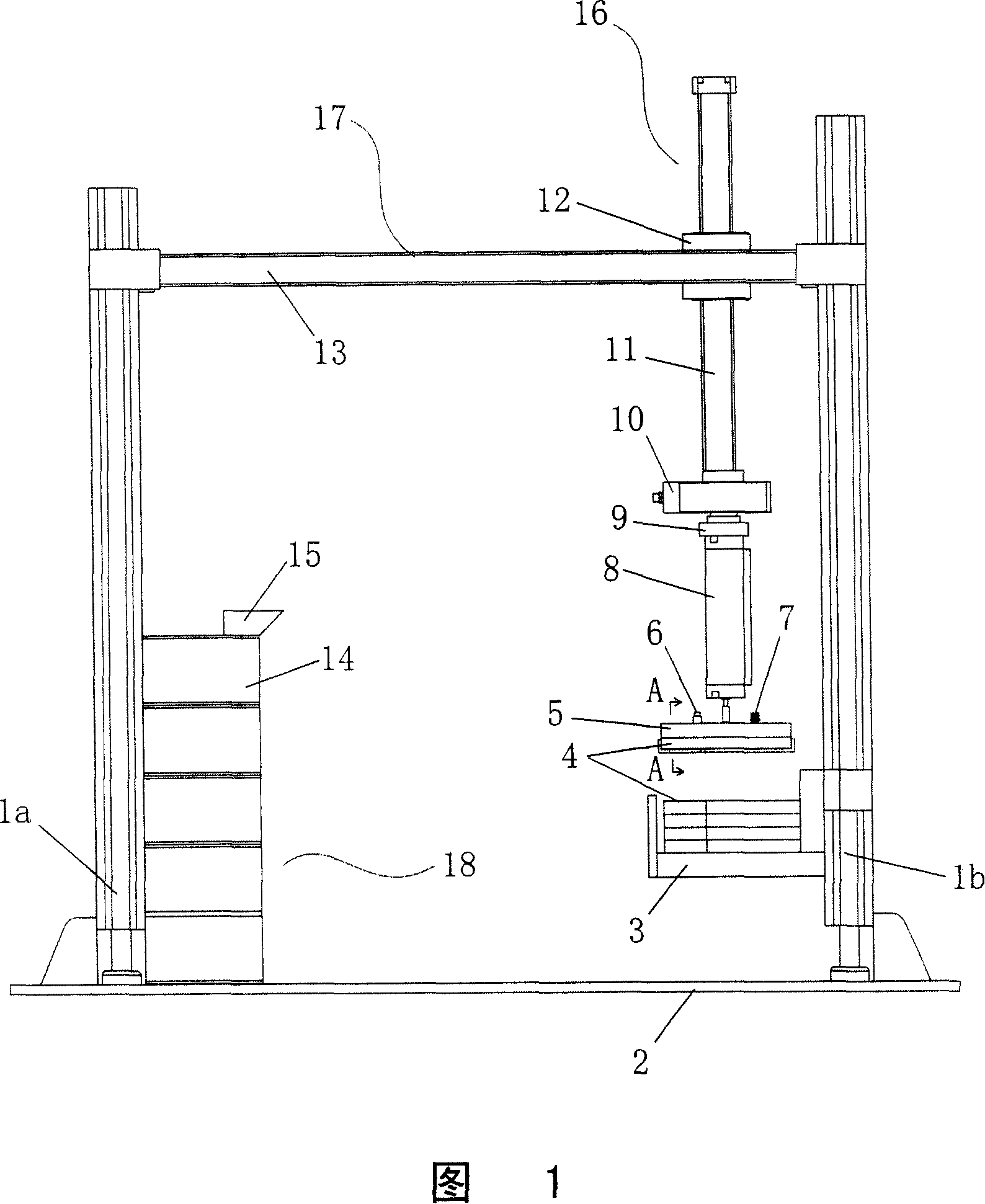

[0028] As shown in Figure 1, it is a structural schematic diagram of the cigarette / filter stick sampling system of the present invention, which is arranged at the large-flow outlet passage 3 where the cigarette / filter stick is produced, and the outlet passage 3 is connected to the lower part of the support column 1b by threads , a large amount of cigarettes / filter sticks 4 are supported on the outlet passage 3. The cigarette / filter stick sampling system of the present invention takes samples from the outlet channel 3, and its structure mainly includes: a sampling mechanism 16, a transmission mechanism 17, a receiving mechanism 18 and a control mechanism (not shown).

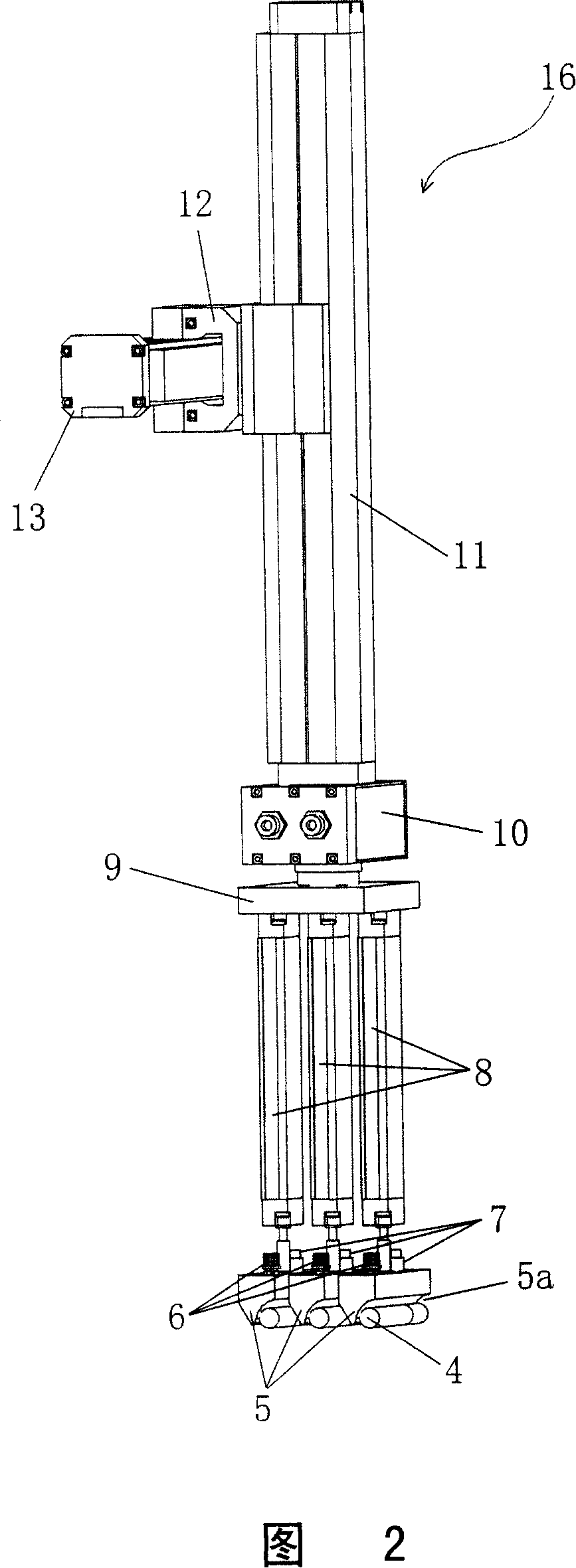

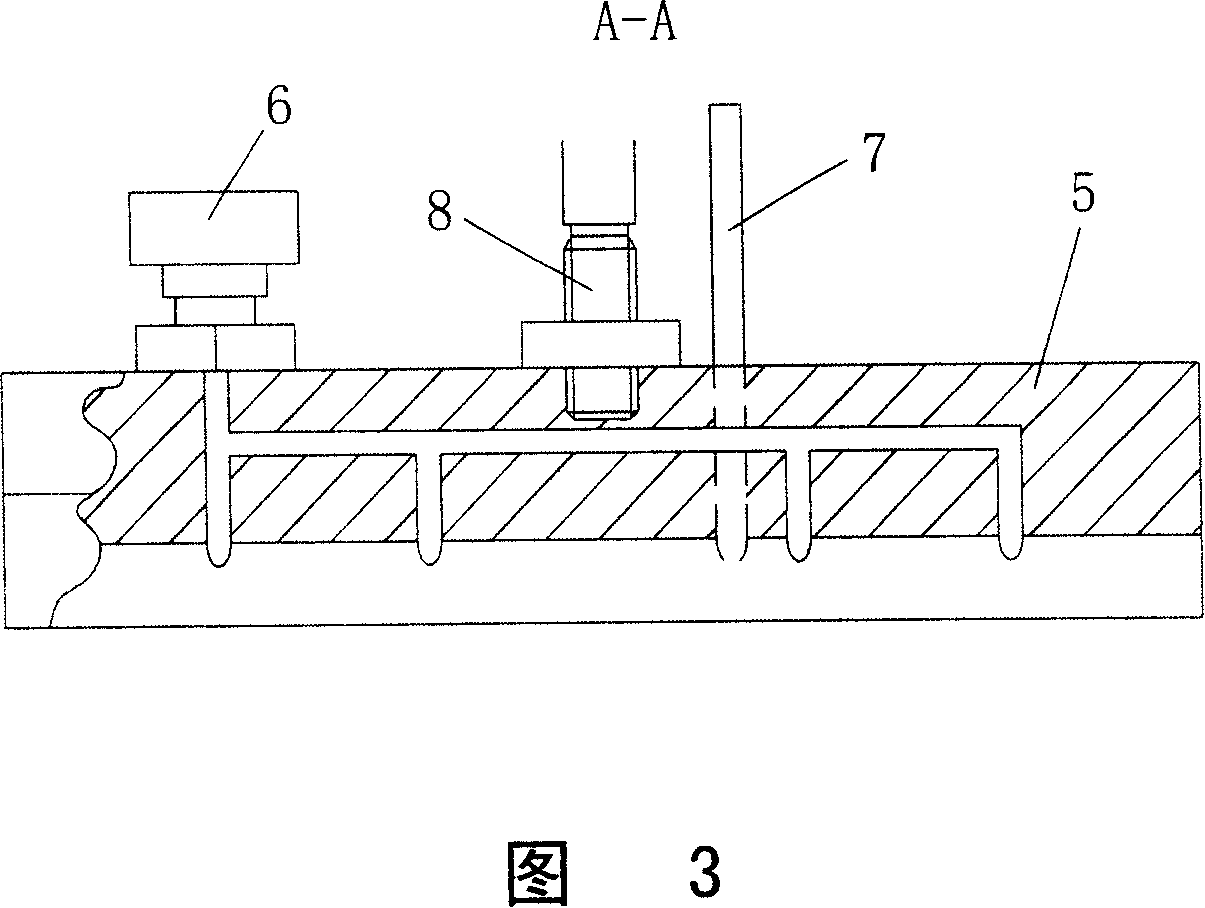

[0029] The sampling mechanism 16 is mainly used to separate the cigarettes / filter sticks 4 from the large-flow outlet channel 3, and grab several cigarettes / filter sticks 4 from the outlet channel 3 through negative pressure suction and cylinder action as samples. The structure is shown in Figures 2 and 3, with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com