Self-operated emergency cutting method of fluid pipe and self-operated flat-plate emergency cut-off valve

A fluid pipeline, self-supporting technology, applied in pipeline systems, sliding valves, valve devices, etc., can solve the problems of valves that cannot be opened and the production cost of cut-off valves increase, and achieve the effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it should not be used as any basis for limiting the present invention.

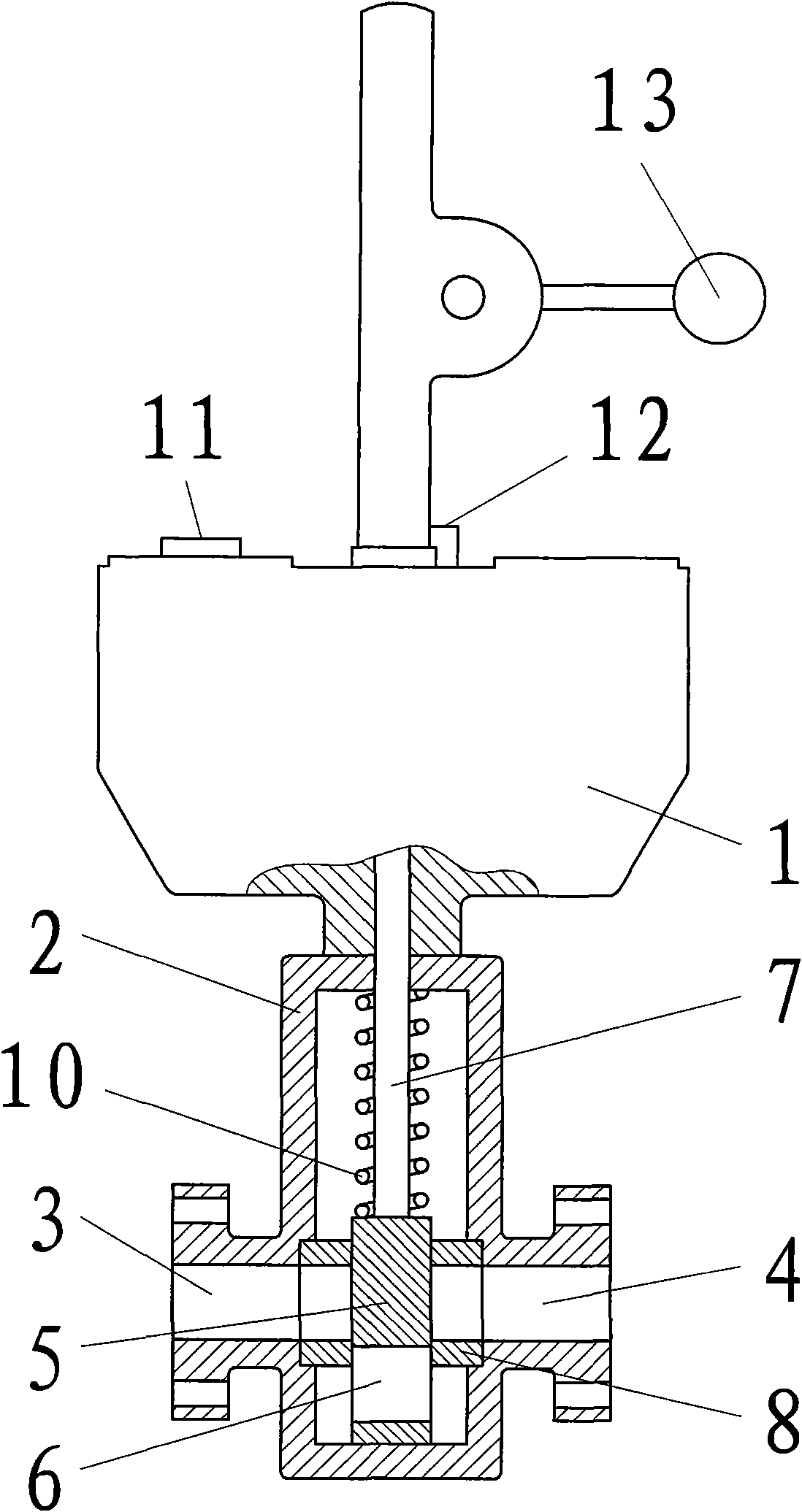

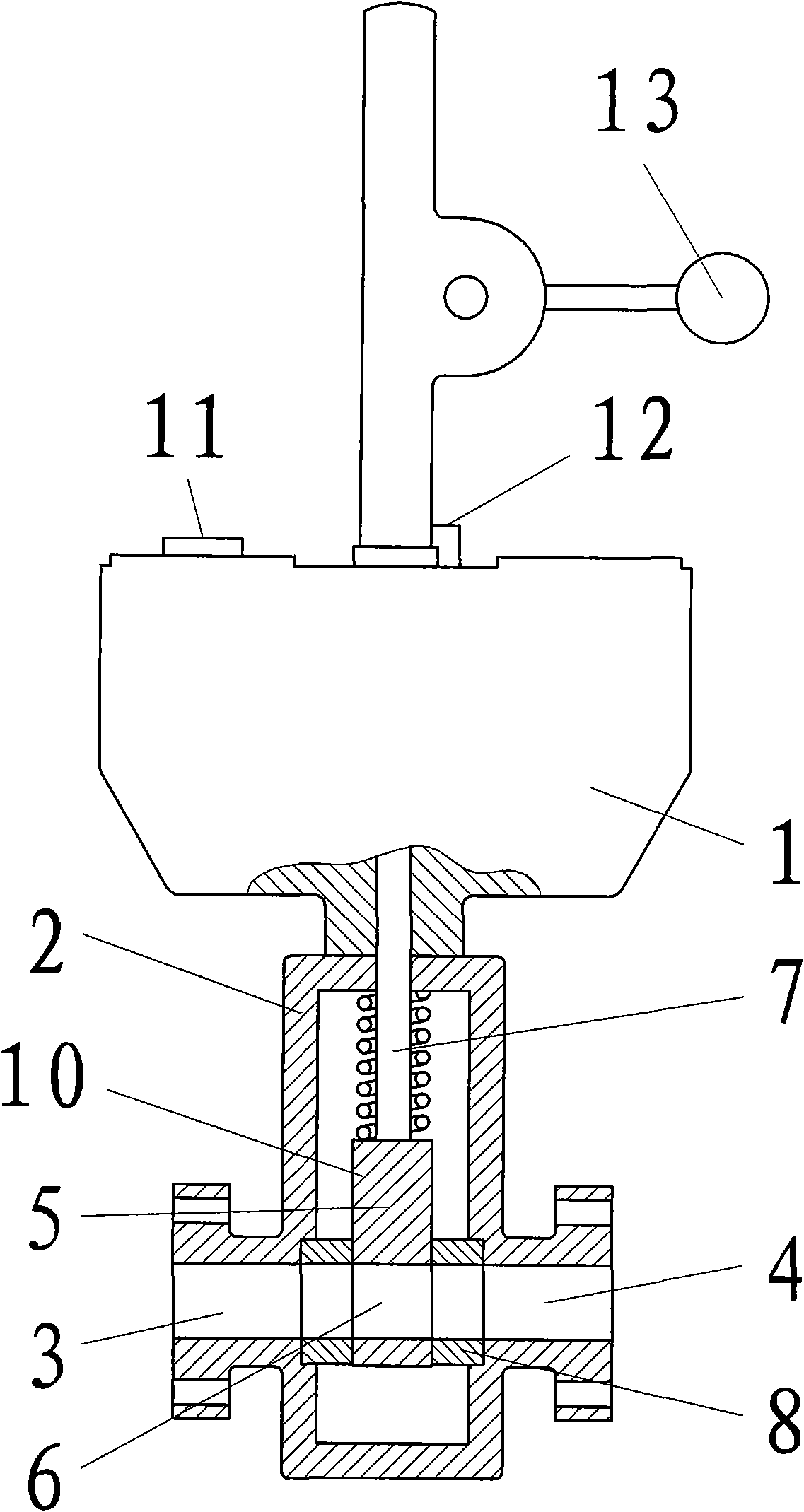

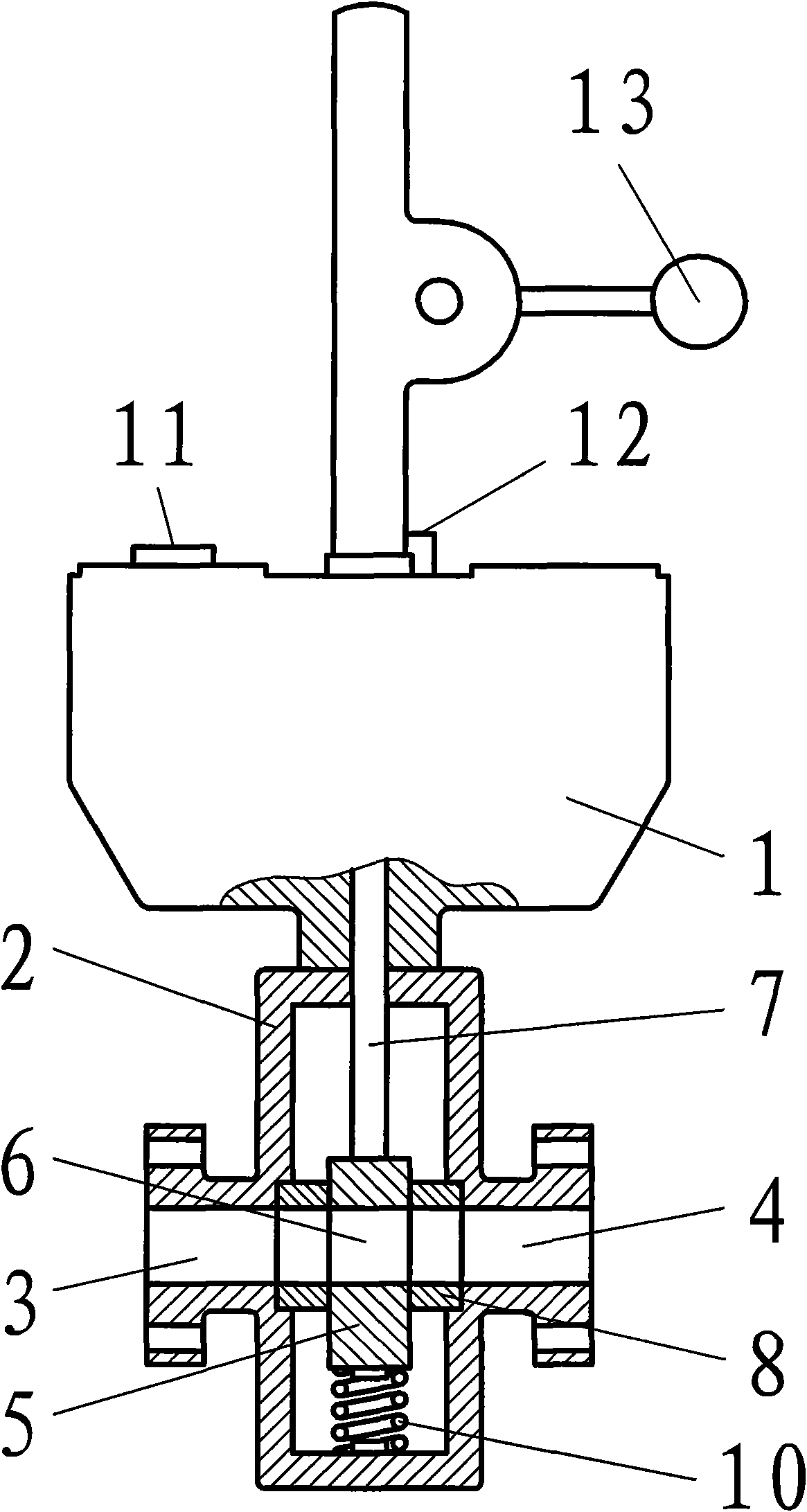

[0024] Example. The self-operated emergency shutoff method for fluid pipelines includes using a trigger mechanism (also known as a trigger), and also includes using a straight-through gate valve controlled to open and close by the trigger mechanism, so as to realize emergency shutoff of the pipeline. The trigger mechanism controls the opening and closing of the straight-through gate valve, preferably by controlling the lifting of the gate plate with the flow hole in the straight-through gate valve to realize the opening and closing of the straight-through gate valve. Sealing rings are preferably provided on both sides of the ram in the direction of movement, so as to improve the flexibility, wear resistance and reliability of the ram's lifting and lowering, and improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com