Device and method for producing and filling fine sausage meat, in particular an emulsion

一种乳状液、细粒的技术,应用在乳状液领域,能够解决不允许连续的过程等问题,达到高灵活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

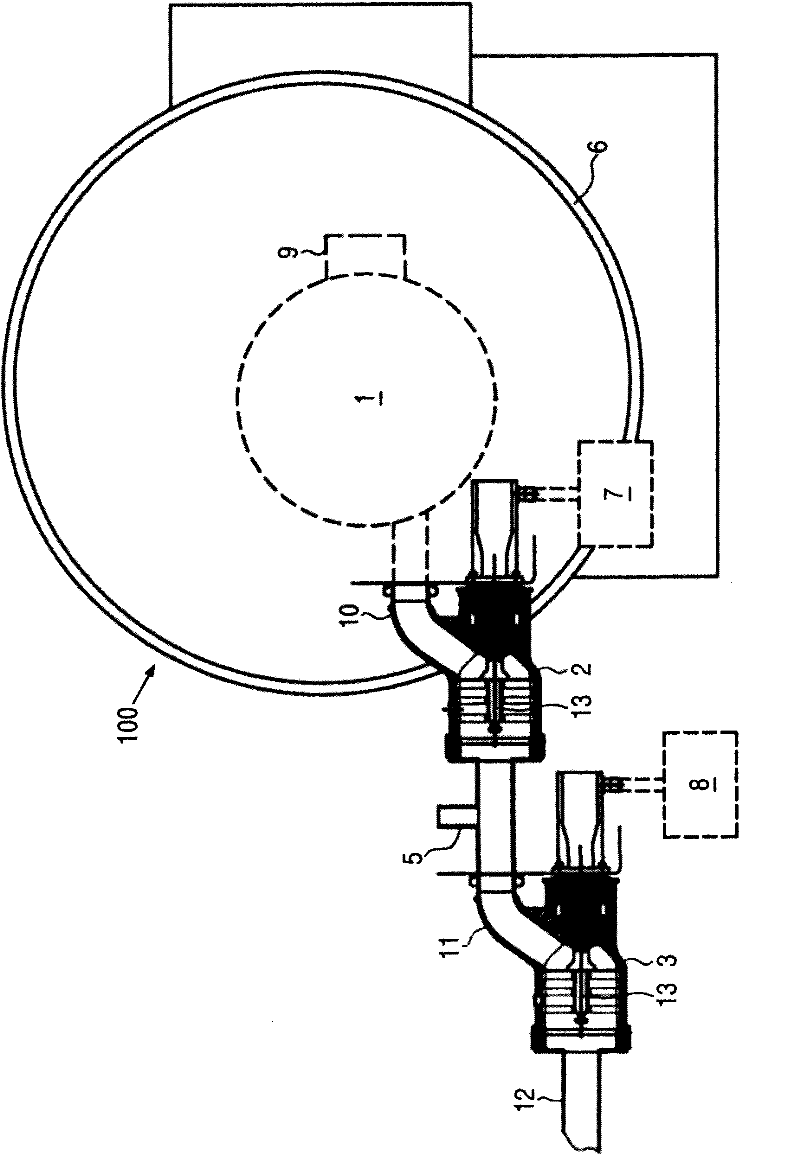

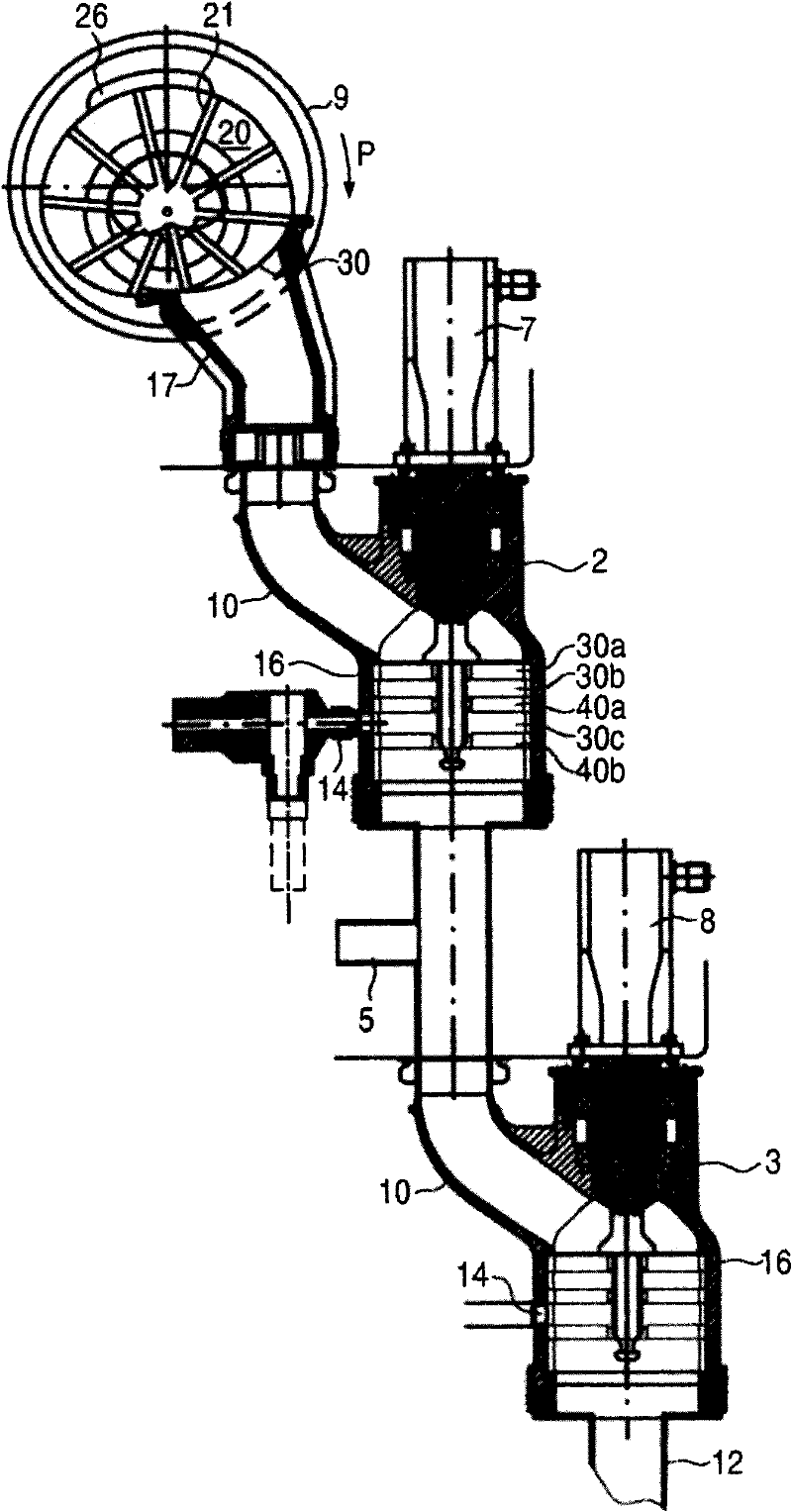

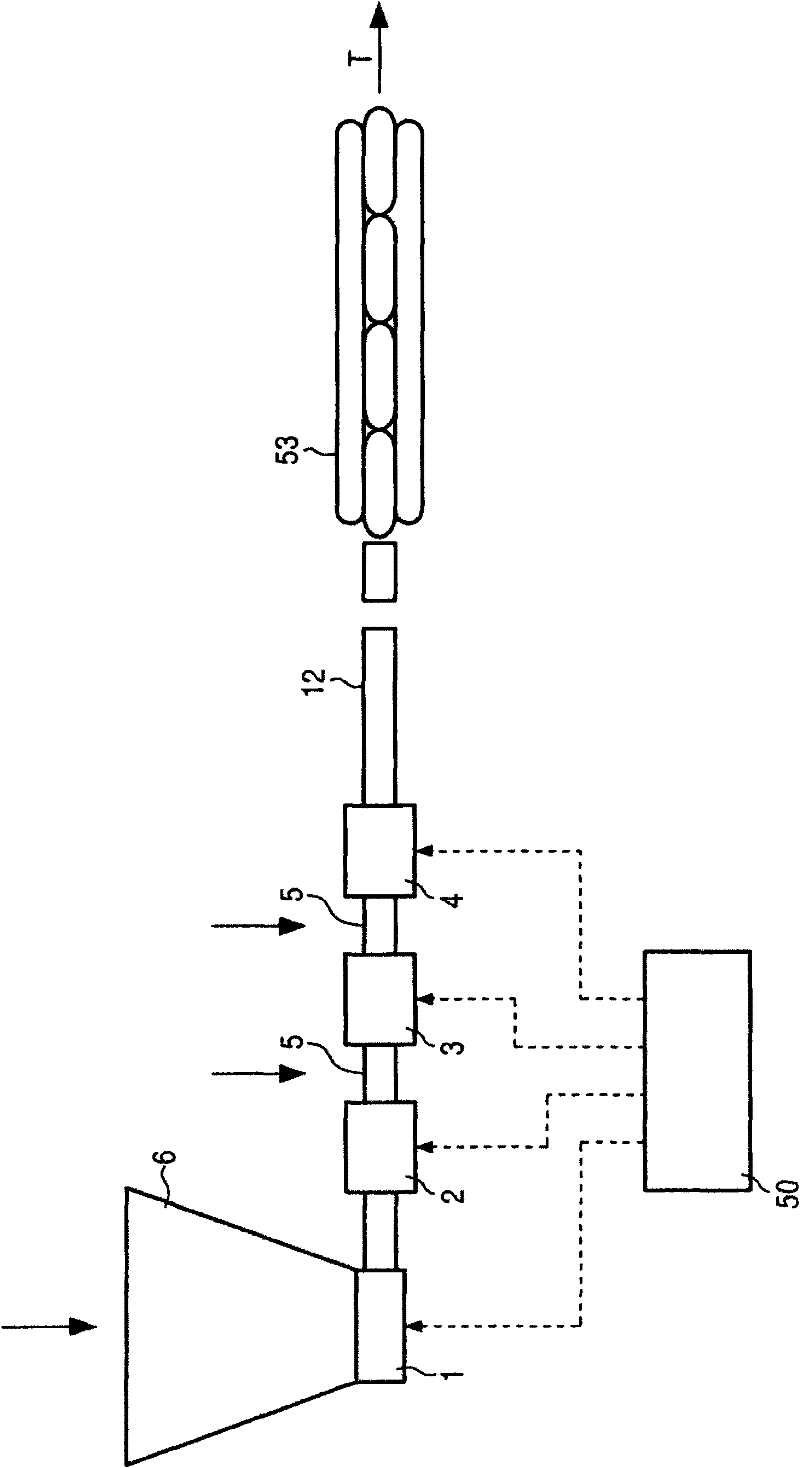

[0036] figure 1 An embodiment according to the invention is schematically illustrated. figure 2 Basically the same embodiment is shown, with some components described in more detail.

[0037] The device 100 comprises feed means 6 for the product, here in the form of a feed hopper. As products, there may be in particular food products such as meat, bacon, salt and additives. The size and composition of products are usually standardized. When the product is poured into the feed hopper 6, the product can be pre-mixed. figure 2 with image 3 The shown embodiment is also suitable for larger product pieces with a diameter > 20 mm. The feed pump 1 is arranged in the lower region of the feed hopper 6 . especially from figure 2 As can be seen in the figure, such a pump can be an impeller pump 1, which conveys the product via a feed line 10 with a discharge to a first grinding station, here a coarse-grain grinder 2 . Here, the feed pump 1 has a separate drive motor 9 (see f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com