High pressure common rail electronic control fuel injector

A technology of electronically controlled fuel injection and high-pressure common rail, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as motion sticking, improve reliability, reduce processing costs, and reduce injection pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

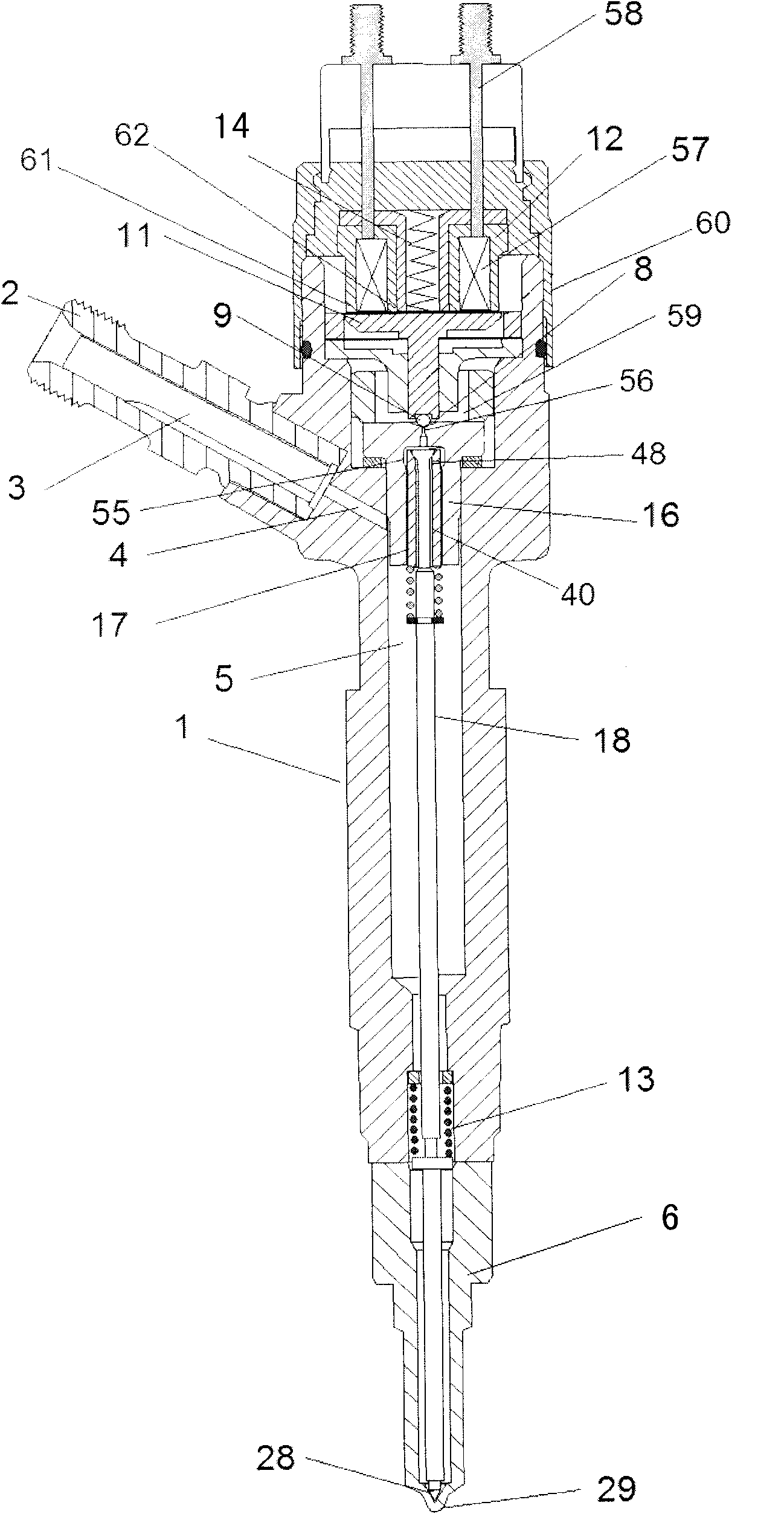

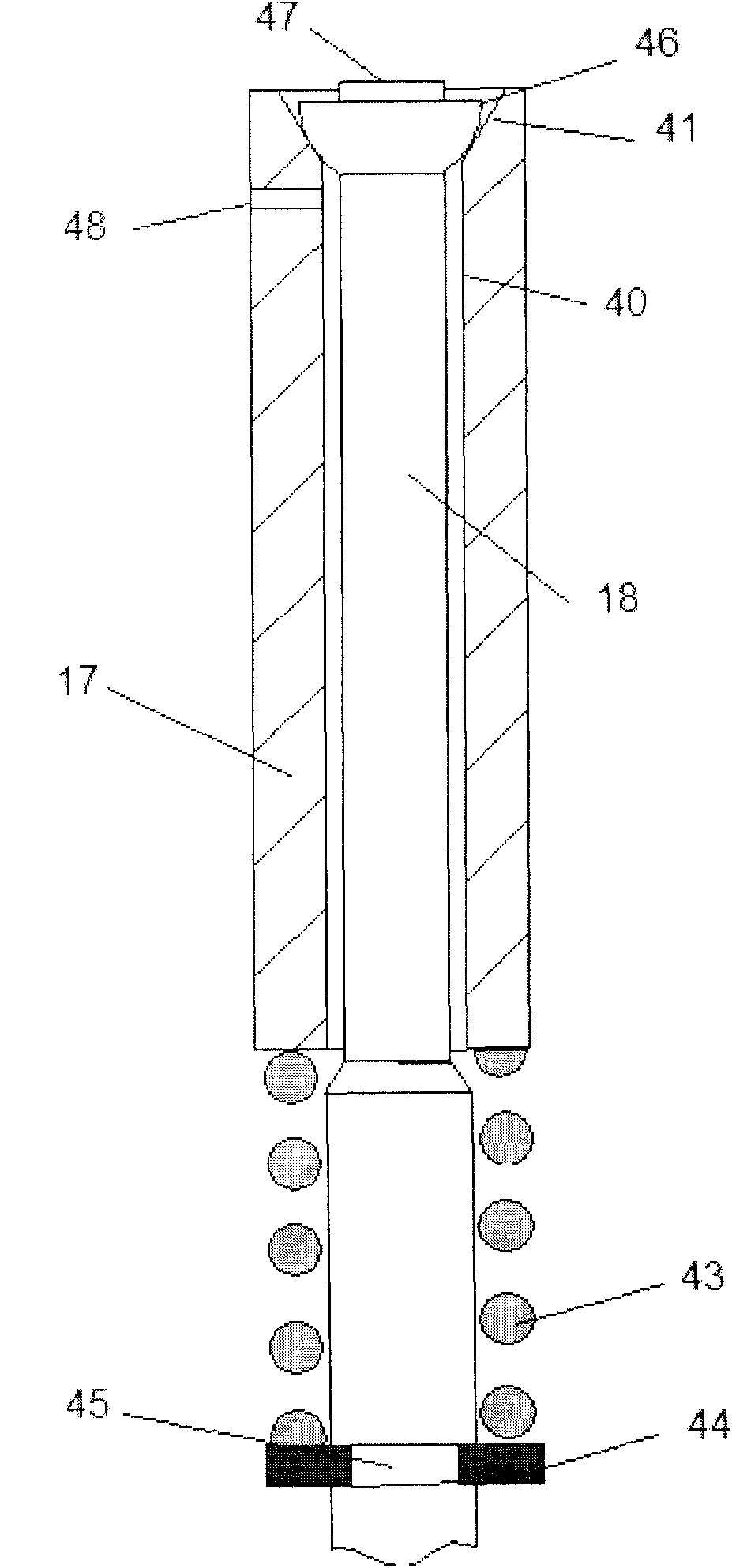

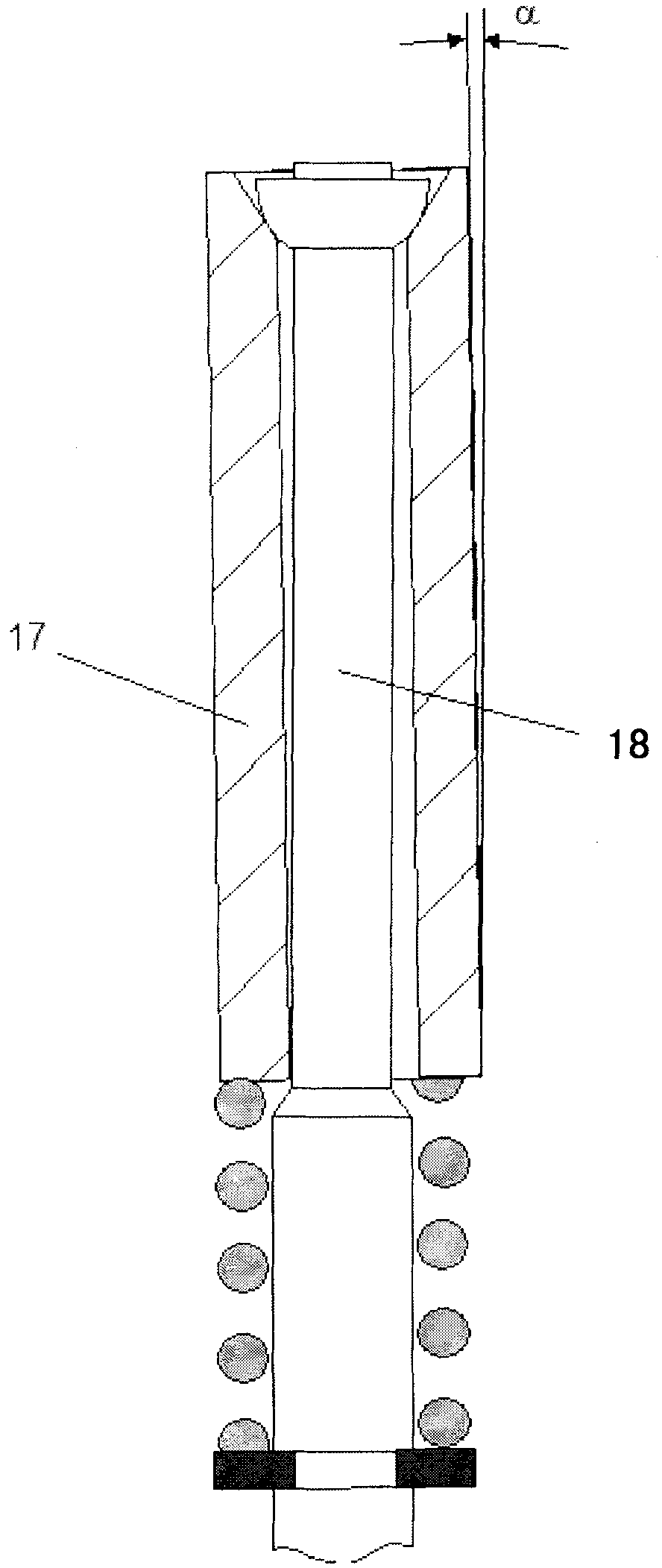

[0018] Figure 1-4 Disclosed is a high-pressure common rail electronically controlled fuel injector, including a control plunger 17, an oil needle 18, an oil needle sealing seat surface 28, and an injection hole 29. A volume cavity 5 is formed between it and the oil needle seal seat surface 28. The control plunger 17 is provided with a hollow fuel channel 40 in the vertical axis, and the lower part of the oil needle 18 is sandwiched between the oil needle spring 13 and the oil needle seal seat. Between the surfaces 28, the volume chamber 5 communicates with the control chamber 55 through the fuel passage 40 and the oil inlet hole 48, and the control chamber 55 communicates with the transition chamber 59 of the control valve 60 through the oil outlet hole 56, and the transition chamber 59 communicates with the injection nozzle T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com