High-efficiency energy-saving pretreatment process used for generating gas

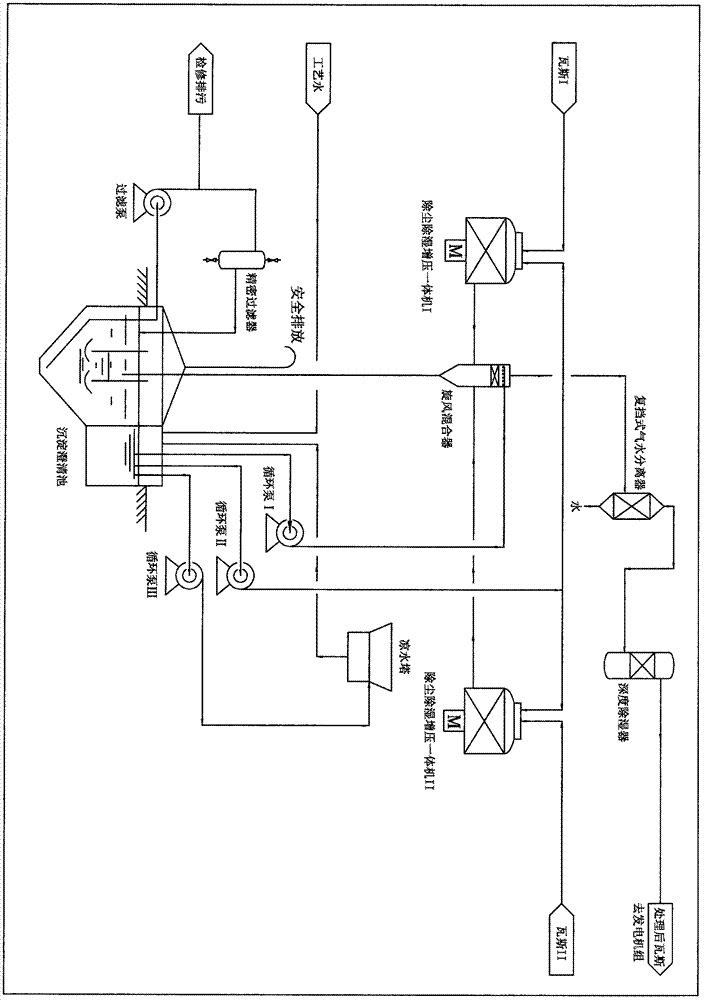

A process method, high-efficiency and energy-saving technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of pressure loss, large floor space, and pressure loss in the transportation system, achieve intermittent flow improvement, reduce floor space, The effect of the improved mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

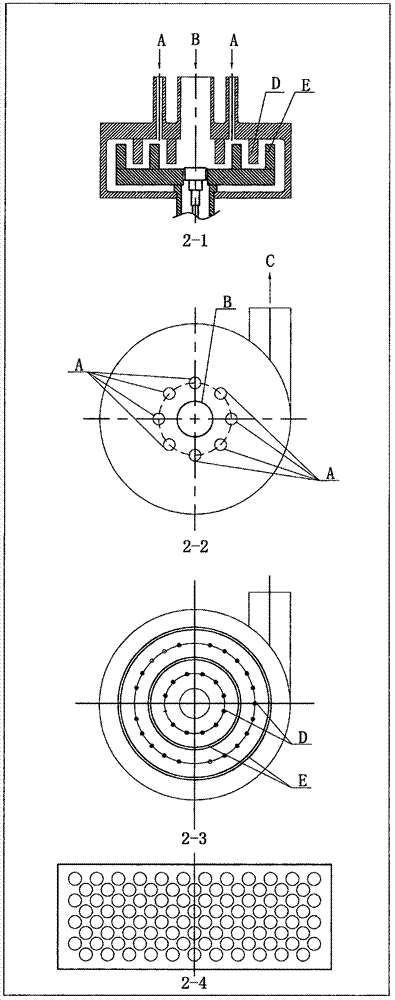

Embodiment 1

[0034] Gas source situation of coal mine drainage pumping station

[0035] Gas source I, gas content 20% to 25%, standard gas volume 12000 3 / h, the dust content is about 1050mg / m 3 , gas temperature 57°C, water content 113g / m 3 , the detection delivery pressure before the power station is 6kpa~9kpa;

[0036] Gas source II, gas content 16% to 18%, standard gas volume 15000m 3 / h, the dust content is about 800mg / m 3 , gas temperature 56°C, water content 109g / m 3 , the delivery pressure detected before the power station is 5.8kpa ~ 8.7kpa;

[0037]Before the transformation, the pressure fluctuation range before the generator set was 2kpa~3kpa; after the dust removal, dehumidification and pressurization pretreatment, the cylindrical pin type dust removal, dehumidification and pressurization integrated machine was adopted, and the deep dehumidifier adopted condensation dehydration, and the dust content was about 9mg / m 3 , the maximum particle size is less than 1.5um, the gas...

Embodiment 2

[0039] Gas source situation of coal mine drainage pumping station

[0040] Gas source I, gas content 21% to 24%, standard gas volume 14000 3 / h, the dust content is about 850mg / m 3 , gas temperature 46°C, water content 72g / m 3 , the detection delivery pressure before the power station is 5.9kpa~8kpa;

[0041] Gas source II, gas content 16% to 18%, standard gas volume 15750m 3 / h, the dust content is about 700mg / m 3 , gas temperature 47°C, water content 74g / m 3 , the delivery pressure detected before the power station is 5.8kpa ~ 8.7kpa;

[0042] Before the transformation, the pressure fluctuation range in front of the generator set was 2kpa~3kpa; after the pretreatment of dust removal, dehumidification and pressurization, a concentric circular hole type dust removal, dehumidification and pressurization integrated machine was adopted, and the deep dehumidification adopted adsorption dehydration, and the dust content was about 9mg / m 3 , the maximum particle size is less th...

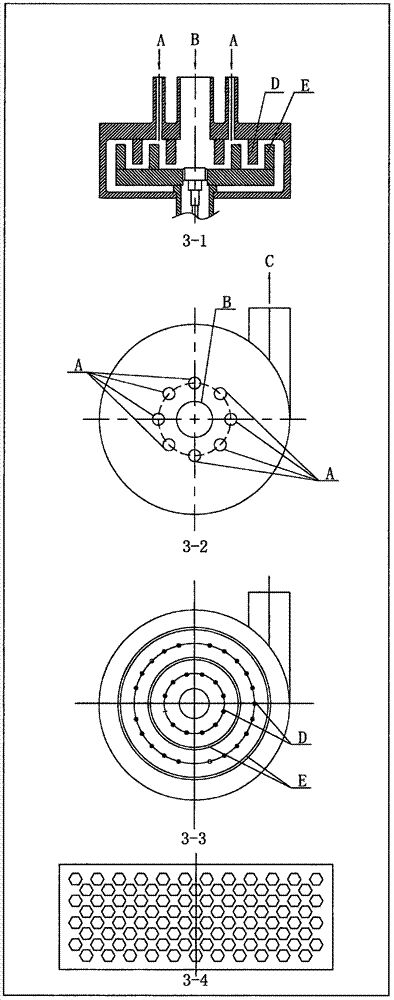

Embodiment 3

[0044] Gas source situation of coal mine drainage pumping station

[0045] Gas source I, gas content 29% to 34%, standard gas volume 18000 3 / h, the dust content is about 650mg / m 3 , gas temperature 50°C, water content 82g / m 3 , the detection delivery pressure before the power station is 6.1kpa~9kpa;

[0046] Gas source II, gas content 16% to 18%, standard gas volume 12700m 3 / h, the dust content is about 730mg / m 3 , gas temperature 49°C, water content 80g / m 3 , the delivery pressure detected before the power station is 5.7kpa ~ 8.5kpa;

[0047] Before the transformation, the pressure fluctuation range before the generator set was 2kpa~3kpa; after the pretreatment of dust removal, dehumidification and pressurization, a concentric ring hexagonal hole type dust removal, dehumidification and pressurization integrated machine was adopted, and the deep dehumidification adopted adsorption dehydration, and the dust content was about 7mg / m 3 , the maximum particle size is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com