Dual-clutch assembly for a dual-clutch transmission

A dual-clutch and transmission technology, applied in the direction of clutches, mechanically driven clutches, fluid-driven clutches, etc., can solve problems such as wear and tear, and achieve the effects of small installation space, low cost of materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

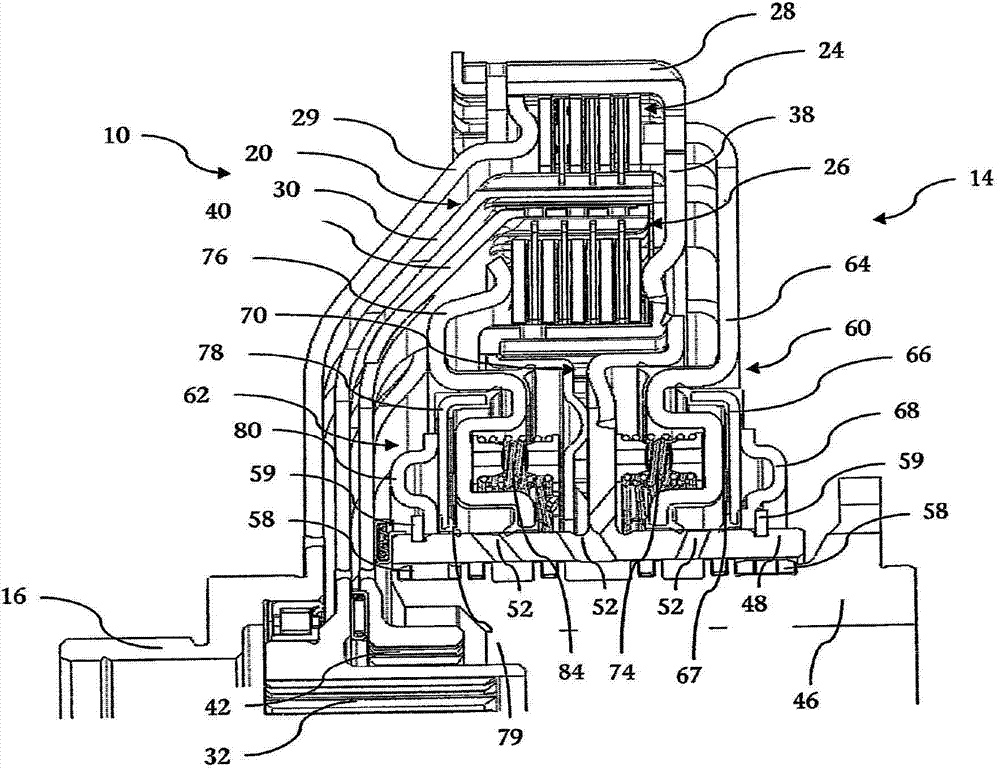

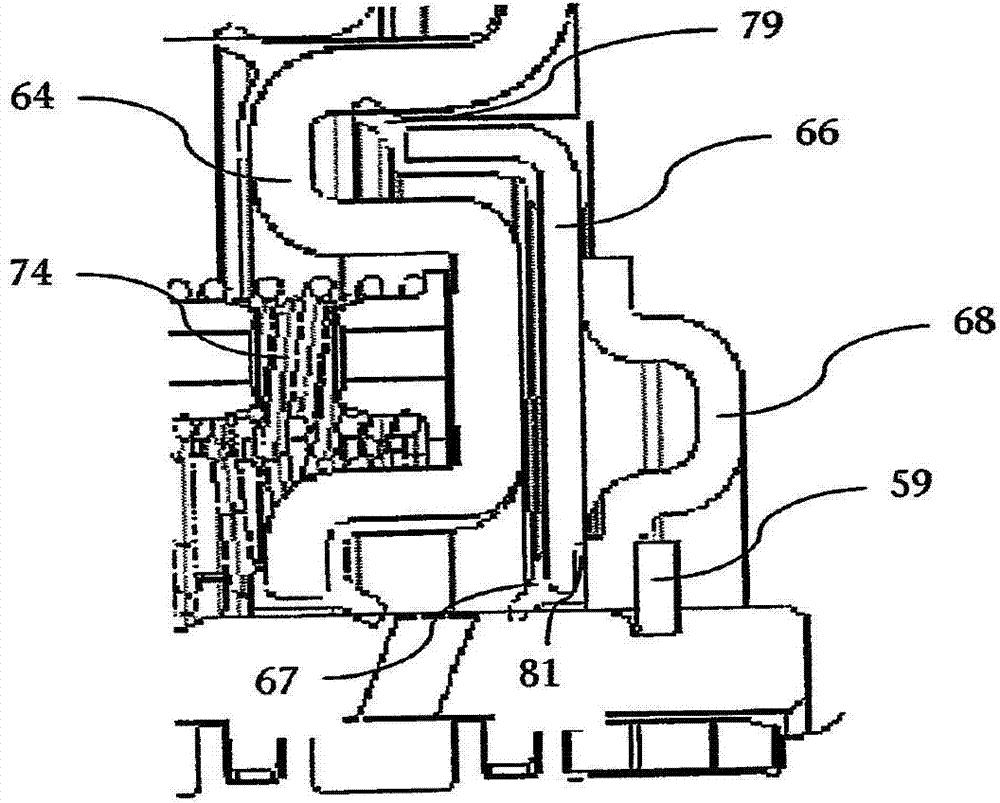

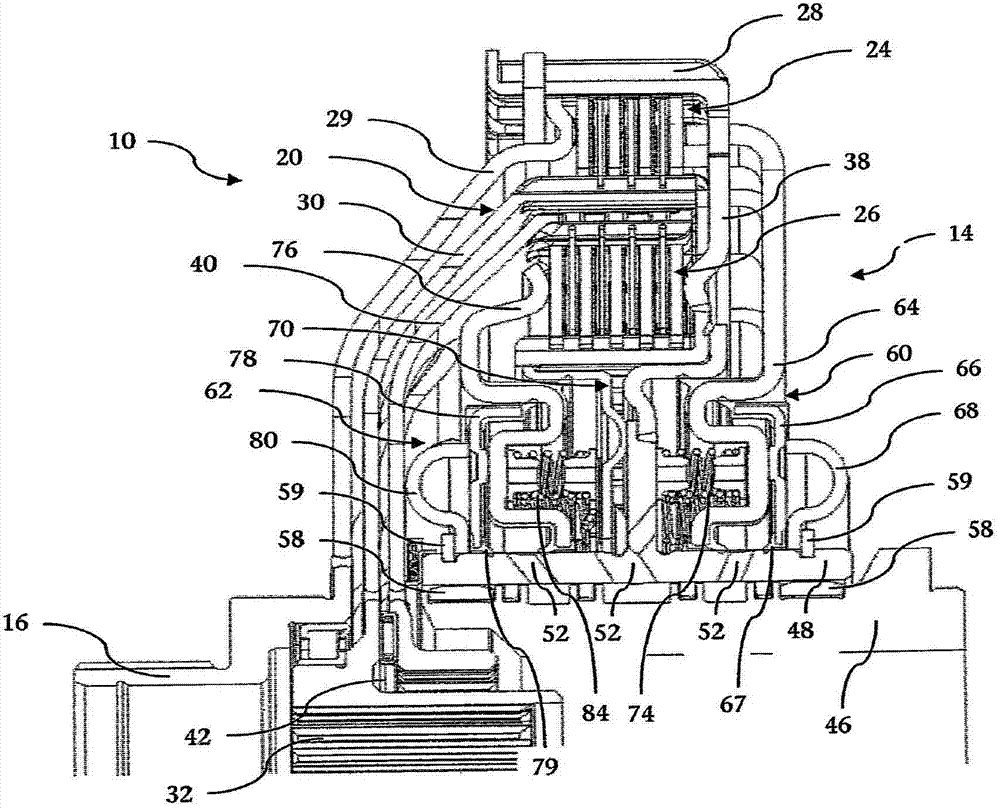

[0028] In the following description of the drawings, the same features are provided with the same reference numerals. If there are significant differences between individual features, this will be clearly indicated.

[0029] Figure 1 to Figure 6 The drive train 10 is shown with a drive motor (not shown), such as an internal combustion engine. The drive train 10 also has a dual clutch transmission 14 whose input shaft 16 is connected to the crankshaft of the drive motor. The dual clutch transmission 14 has a driven shaft (likewise not shown) which can be connected to driven wheels of a motor vehicle in a manner known to date.

[0030] The dual clutch transmission 14 has a dual clutch assembly 20 housed in a housing (not shown).

[0031] The dual clutch assembly 20 includes a first friction clutch 24 and a second friction clutch 26 . The two friction clutches 24 , 26 are arranged radially one inside the other, wherein the first friction clutch 24 is positioned radially on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com