Fixture

A fixed fixture and fixed clamping technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as affecting production quality and efficiency, pipe joints, nuts falling off, delaying time, etc., achieving simple structure and convenient twisting operation. , the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

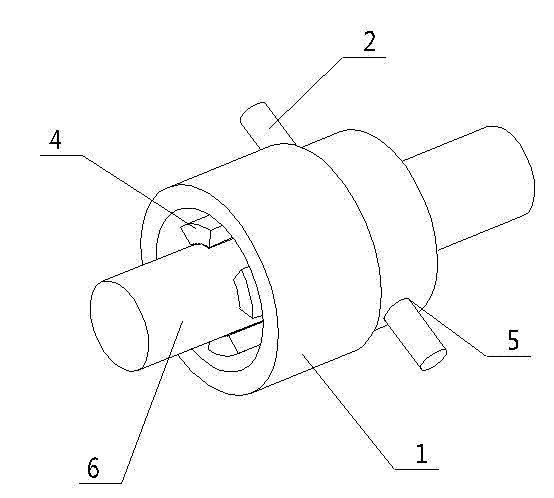

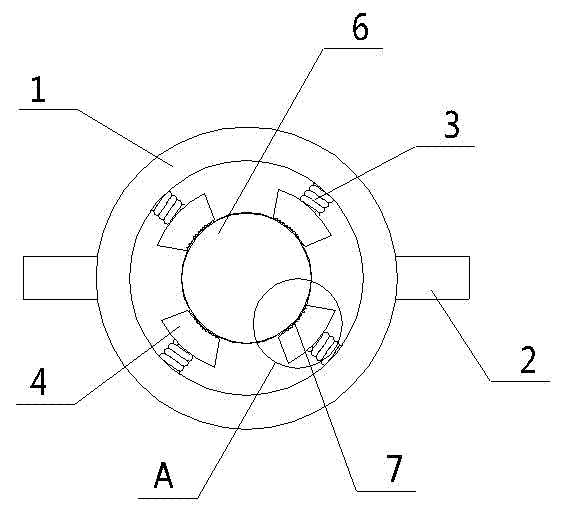

[0013] The present invention will be described below with reference to the drawings.

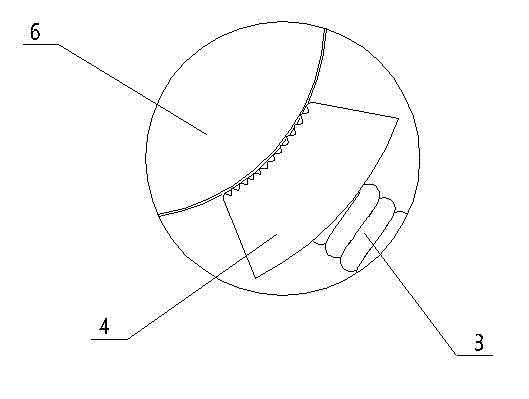

[0014] As attached figure 1 , 2 , 3 shows a fixing fixture according to the present invention, including a sleeve 1 and a fixing pin 2; four springs 3 are fixed around the inner wall of the sleeve 1; the springs 3 are evenly arranged in the sleeve On the inner wall of 1, and the other end of each spring 3 is fixed with a clamping block 4; the cross section of the clamping block 4 is arc-shaped, and its clamping surface 7 in contact with the workpiece is wavy; the sleeve A fixing hole 5 is opened at the end of the fixing hole 5; a fixing pin 2 matched with the fixing hole 5 is provided in the fixing hole 5.

[0015] The above-mentioned springs can also be three, and there are also three corresponding clamping blocks.

[0016] When in use, the fixed pin 2 is removed, the workpiece 6 to be operated is screwed into the sleeve 2, and then the fixed pin 2 is inserted into the fixed hole 5 and penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com