Shell and manufacturing method thereof

A manufacturing method and casing technology, which can be applied to casings/cabinets/drawer parts, electrical equipment casings/cabinets/drawers, decorative arts, etc., which can solve the problems of easy wear or even peeling, affecting product appearance, and halo And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

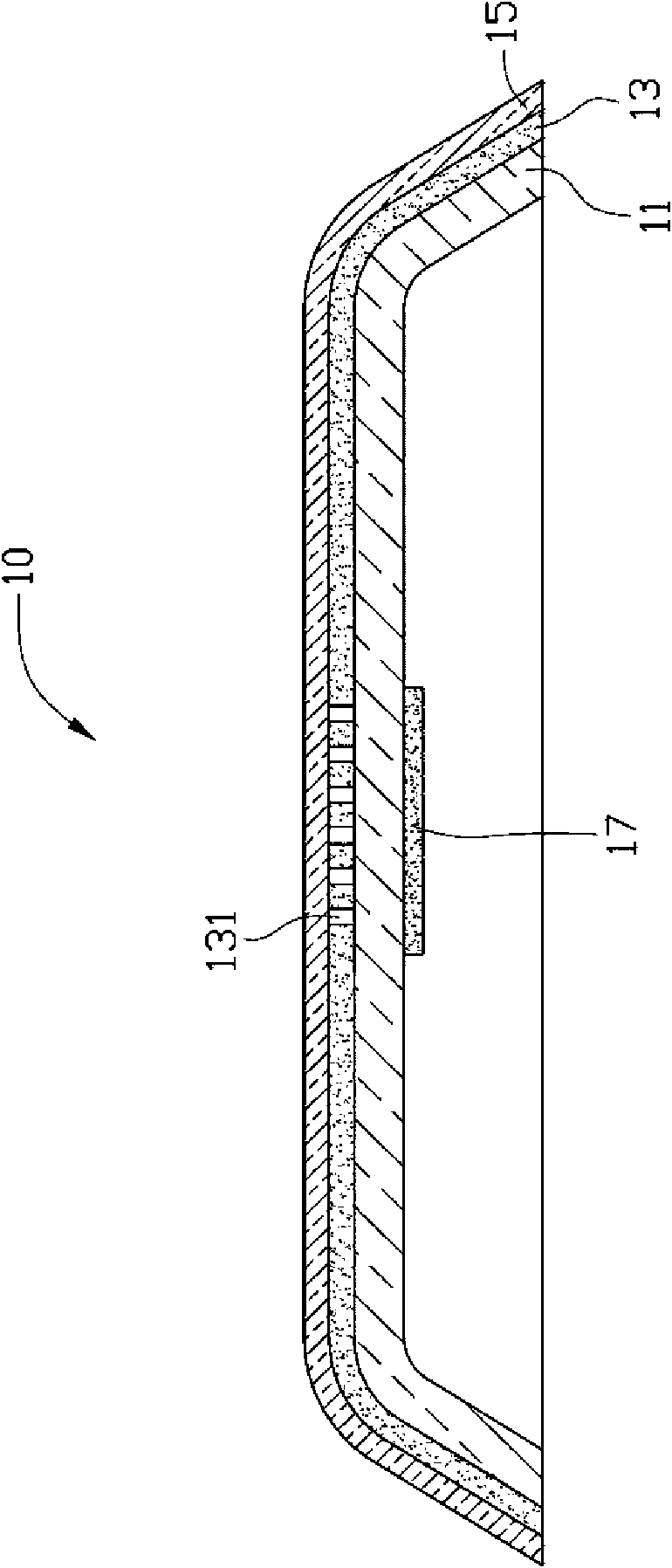

[0015] see figure 1 As shown, the casing 10 of the preferred embodiment of the present invention includes a transparent base 11 , a decoration layer 13 formed on the transparent base 11 and a transparent protective layer 15 formed on the decoration layer 13 .

[0016] The transparent base 11 is a plastic layer, which can be made by injection molding. The material forming the transparent substrate 11 can be selected from polyethylene (PE), polyamide (PA), polycarbonate (PC), acrylonitrile-styrene-butadiene copolymer (ABS), polymethacrylate Either polyester (PMMA) or polyethylene terephthalate (PET) plastics. The surface of the transparent substrate 11 that is not combined with the decoration layer 13 is provided with a colored ink 17 , and the colored ink 17 can be printed on a part of the surface of the transparent substrate 11 . The color of the colored ink 17 can be selected according to the needs of the product.

[0017] The decoration layer 13 is a colored paint layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com