Cutter belt processing device and processing method thereof

A technology for processing devices and knife belts, which is applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult and precise control of the process, limit the process level of knife belts, and poor dynamic stability of knife blanks, etc., to ensure the process and control stability, extremely high dynamic positioning stability, and the effect of improving sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

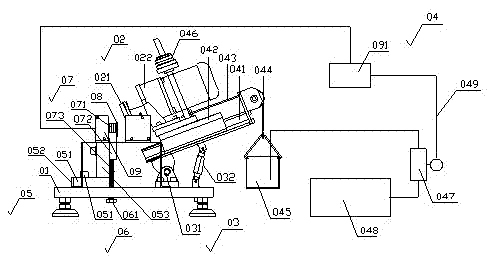

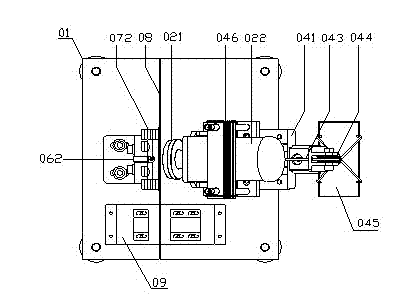

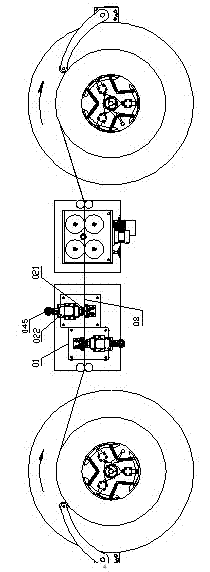

[0079] The knife belt processing device of the present invention places the knife belt 08 on the knife belt blank unwinding machine, and is driven by the knife belt clamping machine to move along the direction shown by the arrow in the accompanying drawing. The knife belt processing device of the present invention is arranged on the knife belt Between the billet unwinding machine and the knife belt clamping machine, it is located on one side of the knife belt 08 to be ground, and is used for fine grinding and positioning of the dynamic knife belt 08, and at the same time adjusts the feed rate of the grinding wheel 021, through the knife belt of the present invention The belt processing device grinds the cutting edge of the knife belt 08; the knife belt winding machine is used for winding the knife belt 08 whose cutting edge has been ground.

[0080] Due to the synergistic effect of the precise dynamic positioning function of the dynamic positioning device of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com