Overhead line cross wiring device

A technology for overhead lines and suspension wires, applied in the direction of overhead lines/cable equipment, etc., which can solve the problems of being unsuitable for long-distance construction and erecting wires, and having large use limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

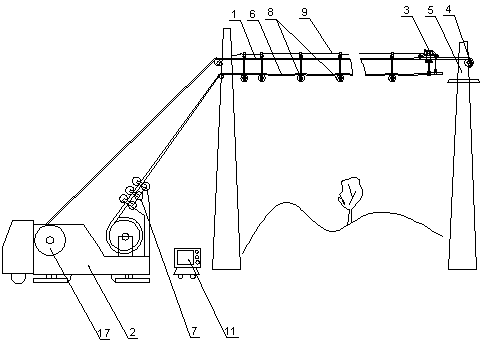

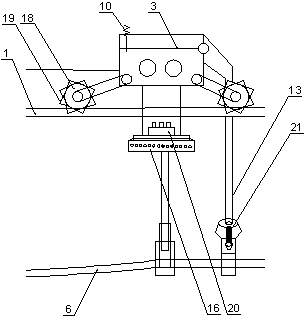

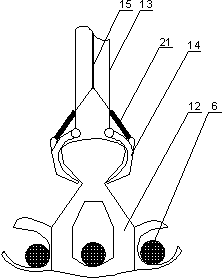

[0020] like figure 1 , 2 and image 3 As shown, an overhead line spanning wire laying device includes an overhead suspension wire 1, a pay-off vehicle 2, a traction block 3 with a driving mechanism, and a suspension wire pulley. On the fixed object 5 in front of the object, the traction block 3 pulls the wire 6 to be laid to move on the elevated suspension wire 1, and the suspended wire supporting wheel supports the wire 6 and hangs it on the elevated suspension wire 1. 2 wire anti-twisting devices 7 are arranged at the outlet end.

[0021] The suspended wire support wheel includes several groups of pulleys 8, and stay wires 9 are arranged between the pulleys 8, wherein the frontmost pulley 8 is connected to the traction block 3.

[0022] The driving mechanism includes a driving motor and a signal transceiver 10 , the driving motor is electrically connected to a power supply unit 20 through a storage device, and the signal transceiver 10 is wirelessly connected to a ground ...

specific Embodiment 2

[0029] A cross-laying device for overhead lines, which differs from the first embodiment in that: one overhead suspension wire 1 is provided.

specific Embodiment 3

[0030] A device for laying wires across an overhead line, the difference from the specific embodiment 1 or 2 is that: the fixed object 5 is provided with a traction mechanism connected to the traction block 3, and the traction mechanism is driven by a remote-controlled stepping motor .

[0031]In the above-mentioned embodiment, the present invention first erects the overhead suspension wire that crosses the obstacle, installs the traction block, clamps the wire to be laid, and sets the hull or three wire lifting rods under the traction block, so that multiple wires can be connected at the same time. Forward, the traction trolley realizes that the traction trolley pulls the laid wires to move on the elevated suspension wire through its own driving mechanism. root, the lower part of the traction block is equipped with a counterweight balancer to ensure the smooth movement of the traction block and prevent the rollover from being out of control. The movement gradually pulls away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com