Vertical machining center

A vertical machining center, worktable technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of guide rail damage, falling on the guide rail, etc., and achieve reliable, economical, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

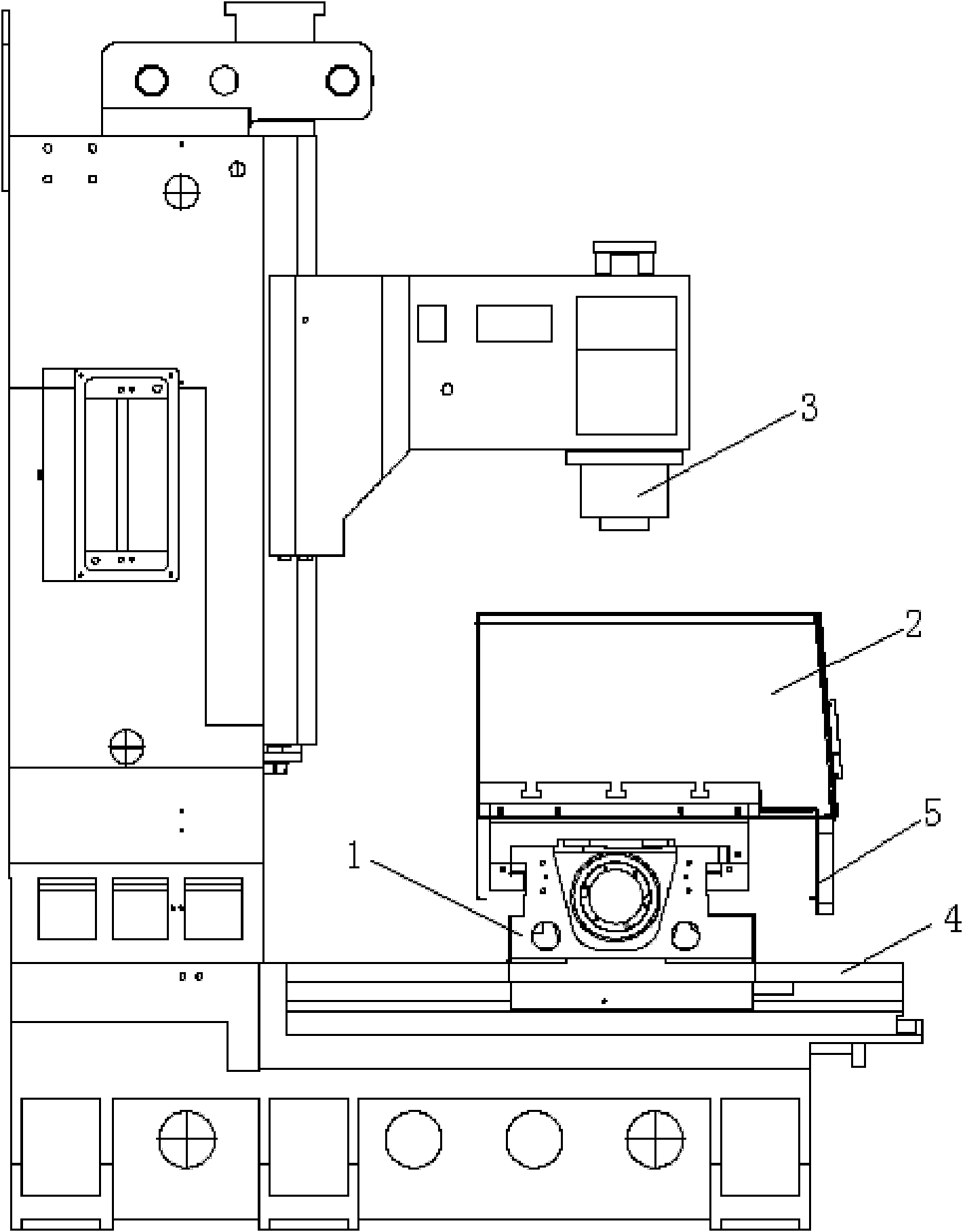

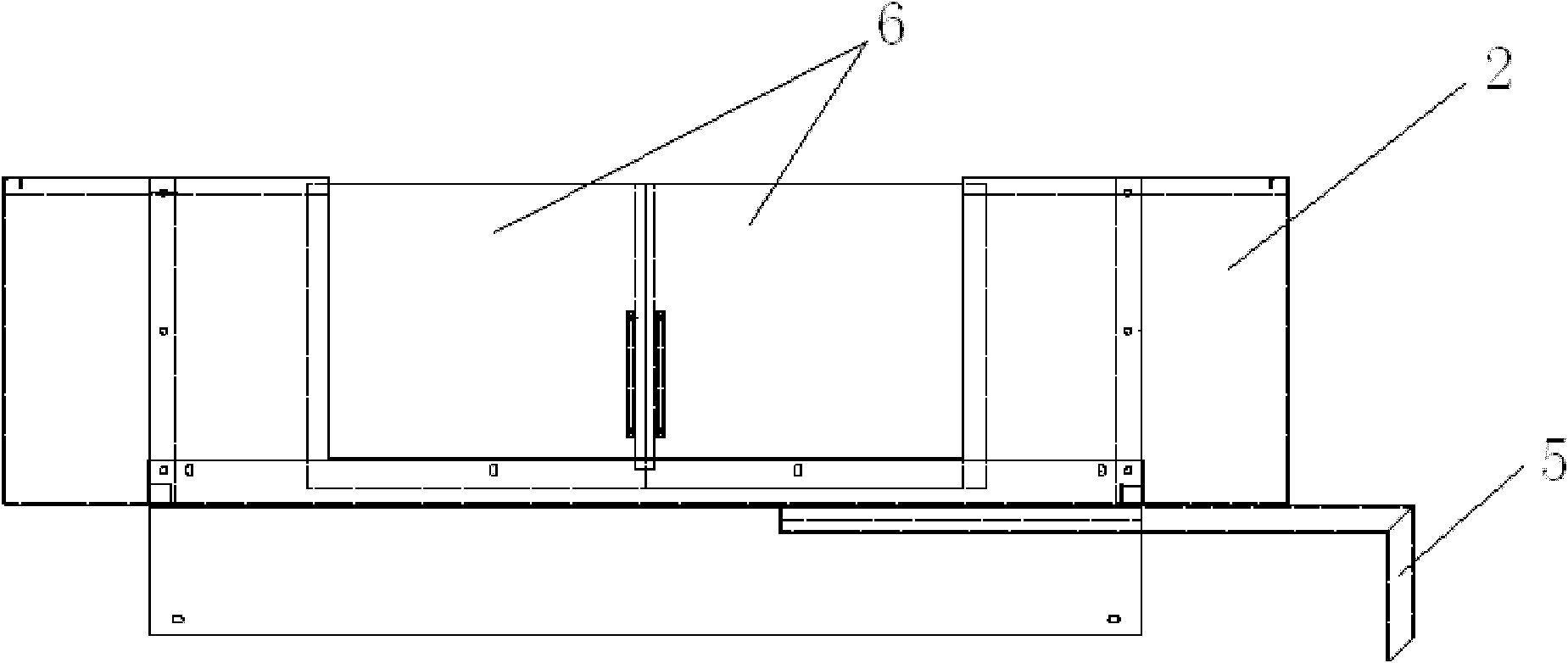

[0017] see figure 1 with figure 2 , The vertical machining center of this embodiment includes a table cover 2 detachably fixedly installed with the work table 1. The table cover 2 has no roof. The bottom of the table cover is a sealed structure. It is arranged under the main shaft 3 and above the guide rail extension shield 4. A cutting liquid discharge pipe 5 is welded to the lower part of the table cover 2, and a transparent movable door 6 is provided on the side.

[0018] When using as a grinder, install the table cover 2 and install the corresponding tool on the spindle 3. The chipping liquid will be collected by the table cover 2, thereby isolating it from the bottom guide rail.

[0019] For other purposes, just remove the table cover 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com