Labeler of lighter

A technology for labeling machines and lighters, applied in labeling machines, labeling, labels, etc., can solve the problems of low labeling efficiency, risk-prone, and increased production costs of enterprises, so as to improve efficiency and accuracy, and ensure labeling The effect of unifying the location and reducing the cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

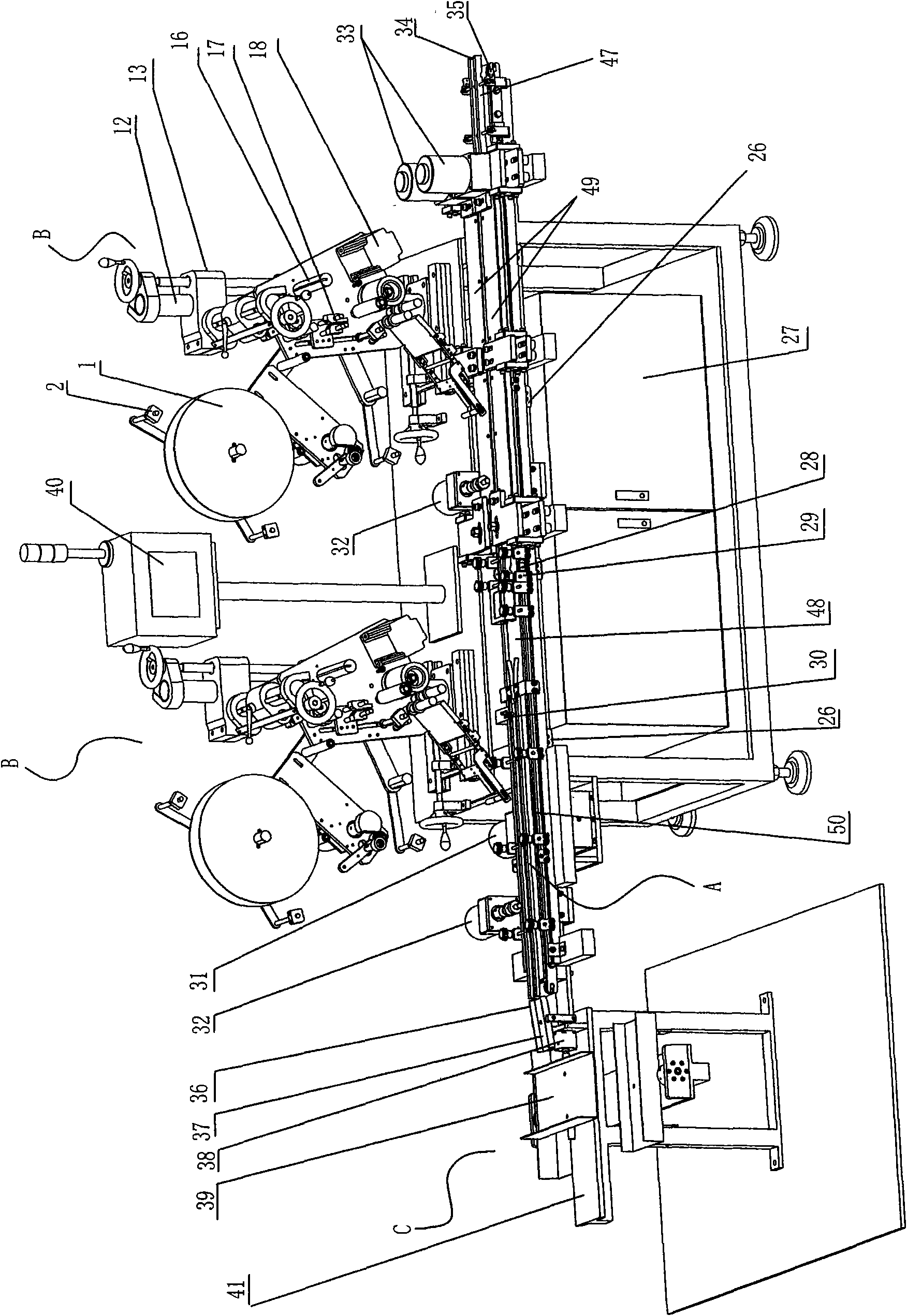

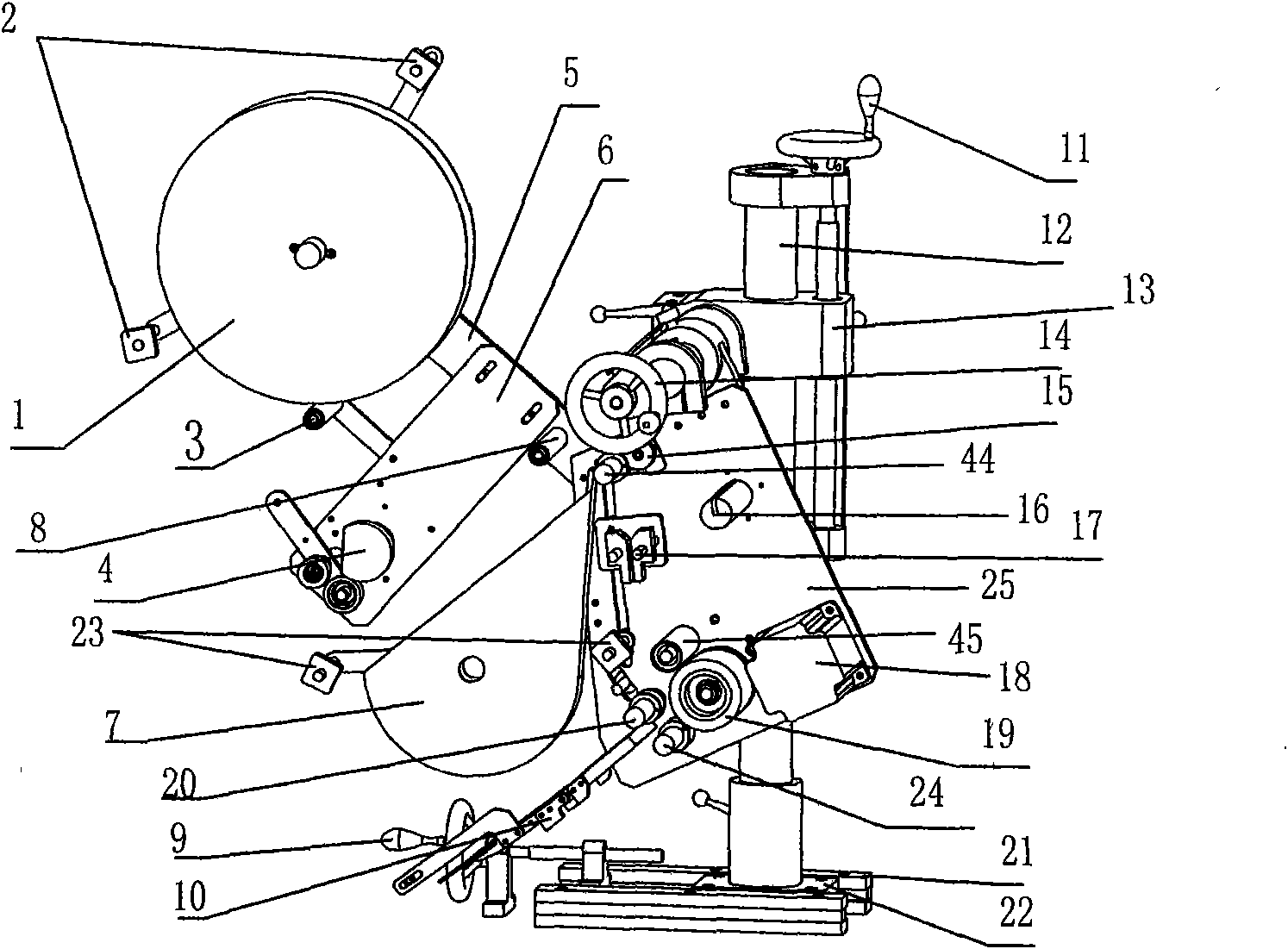

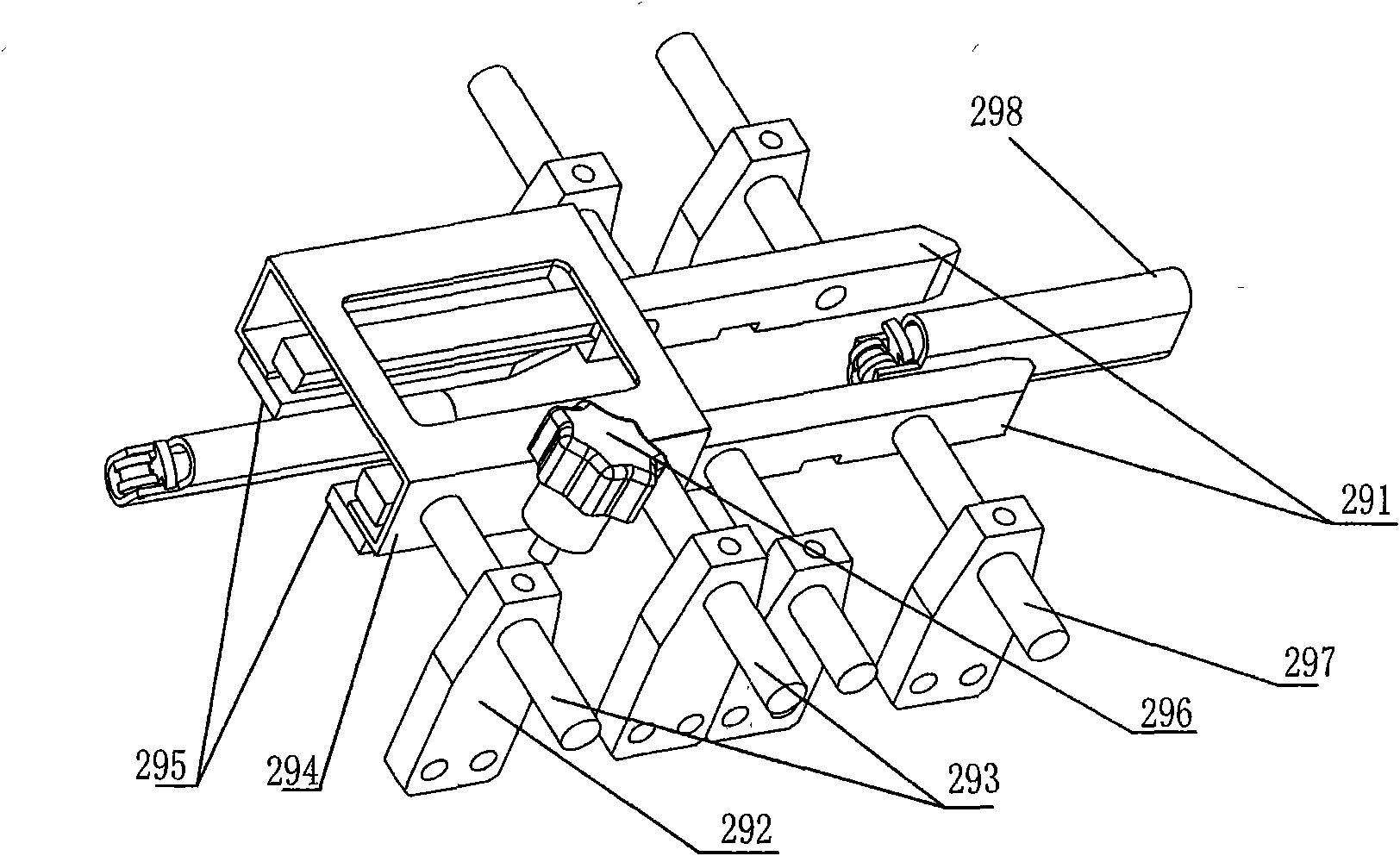

[0023] Embodiment one: by figure 1 The shown lighter labeling machine includes a frame 27, and the conveying mechanism installed on the frame 27 is composed of a bottom surface conveying assembly and a side conveying assembly. Wherein the bottom conveying assembly is made up of a longitudinally rotating bottom conveying belt 48 driven by a bottom conveying motor 31 and connecting pieces; the side conveying assembly is composed of two horizontally rotating side conveying belts and connecting pieces driven by two side conveying motors 33 . Bottom surface conveyer belt 48 is placed flatly on the whole frame 27, and the both sides of the front half section top of bottom surface conveyer belt 48 are vertically provided with side conveyer belt, form clamping channel, and the periphery of side conveyer belt is sheathed protective cover 49. A material inlet 34 is installed above the input end of the bottom conveyor belt 48, and the material inlet 34 includes two parallel side bars 47...

Embodiment 2

[0035] Embodiment 2: Another solution of the present invention is to only label one side of the lighter, and its structure mainly includes a bottom conveyor belt placed flat on the entire frame, and two parallel side conveyor belts are vertically placed on the entire bottom surface On both sides above the conveyor belt, the entire conveying process of the lighter is clamped by these three conveyor belts throughout the process to ensure its smooth conveying. At the same time, the frame of the lighter labeling machine of this scheme does not need to install displacement components and detection The displacement proximity switch also only needs to install a labeling mechanism on the frame, and the rest of the structure is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com