Pipeline apparatus for hyacinth salvage boat

A salvage ship, assembly line technology, used in transportation and packaging, special purpose ships, ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

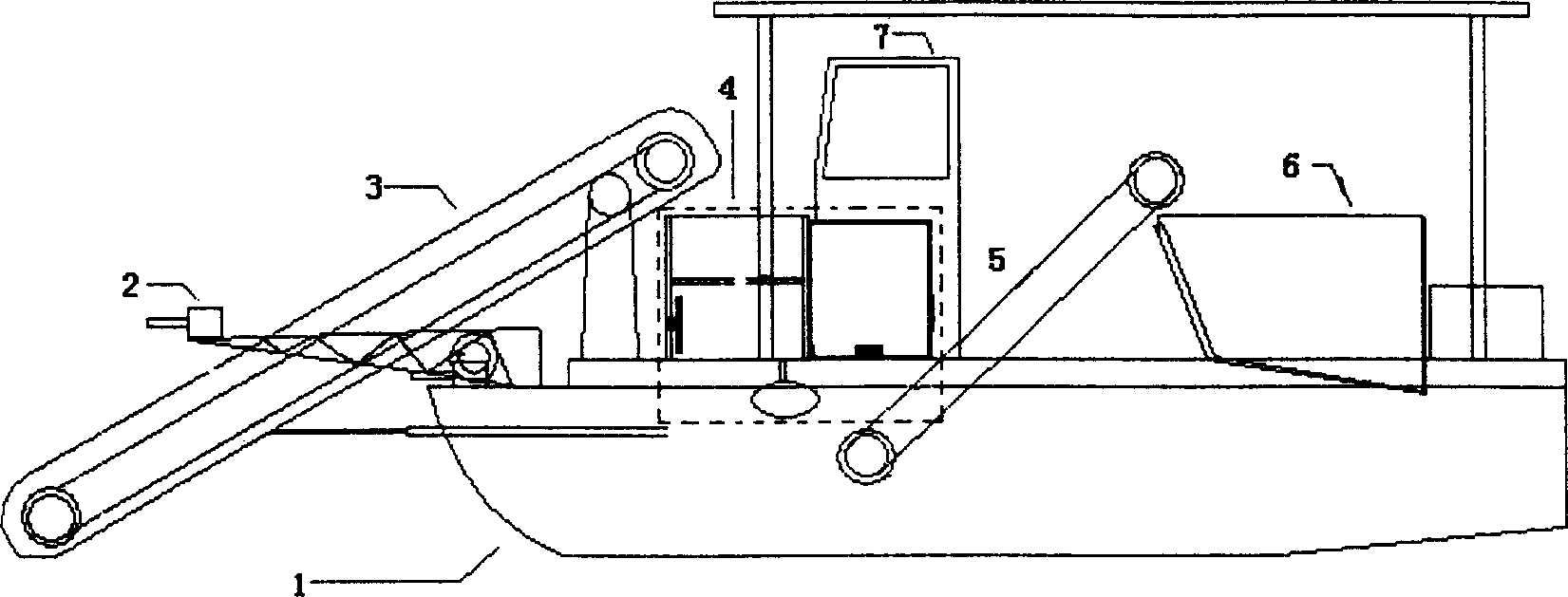

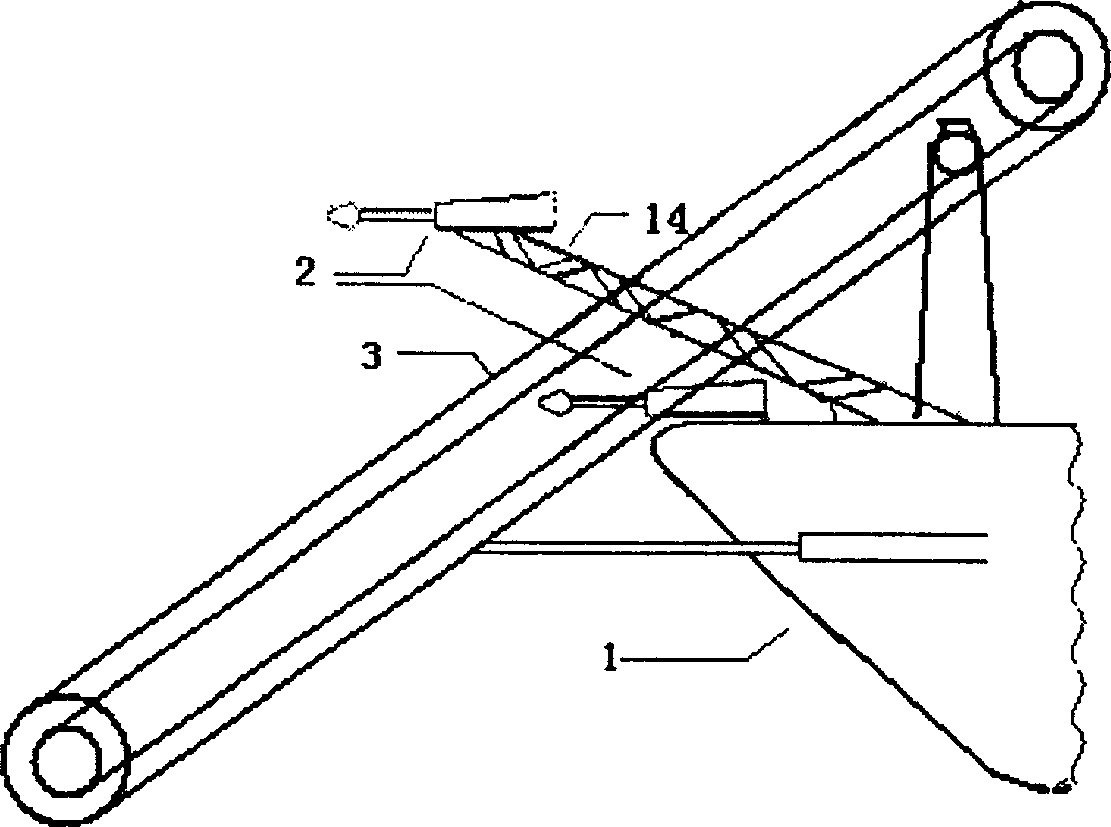

[0016] Such as figure 1 As shown, the present invention includes: a catamaran hull 1, a high-pressure water gun 2, a retractable track wheel 3, a filter cabin 4, a fixed track wheel 5, a storage cabin 6, and a cockpit 7. The connection method is as follows: the high-pressure water gun 2 is arranged on the bow, the front of the catamaran hull 1 is provided with a retractable track wheel 3, which is inclined, the end of the retractable track wheel 3 is provided with a filter press cabin 4, and a cockpit is arranged above the filter press cabin 4 7. Close to the filter press cabin 4 is a fixed track wheel 5, the end of which is connected to the storage cabin 6, and the bottom of the storage cabin 6 is inclined backwards and on both sides.

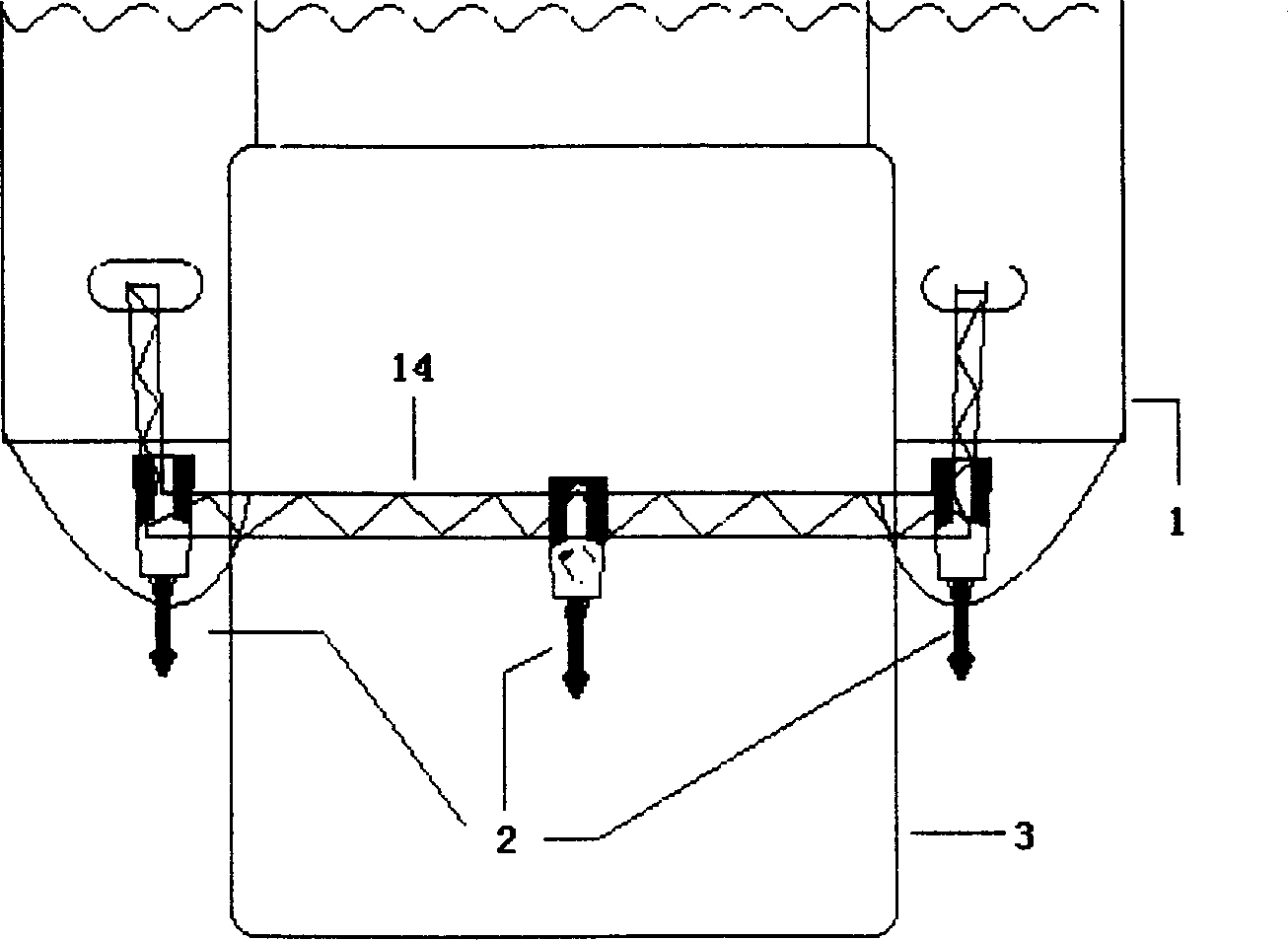

[0017] Such as figure 2 As shown, there are at least three high-pressure water guns 2, and the high-pressure water guns 2 are arranged on the gun frame 14, one is located at the center of the bow, and the other two are symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com