Magneto-rheologic liquid brake

A magnetorheological fluid and brake technology, applied in the direction of hydraulic resistance brake, brake type, mechanical equipment, etc., can solve problems such as inconvenient braking torque, improve braking safety, easy operation, reduce brake temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

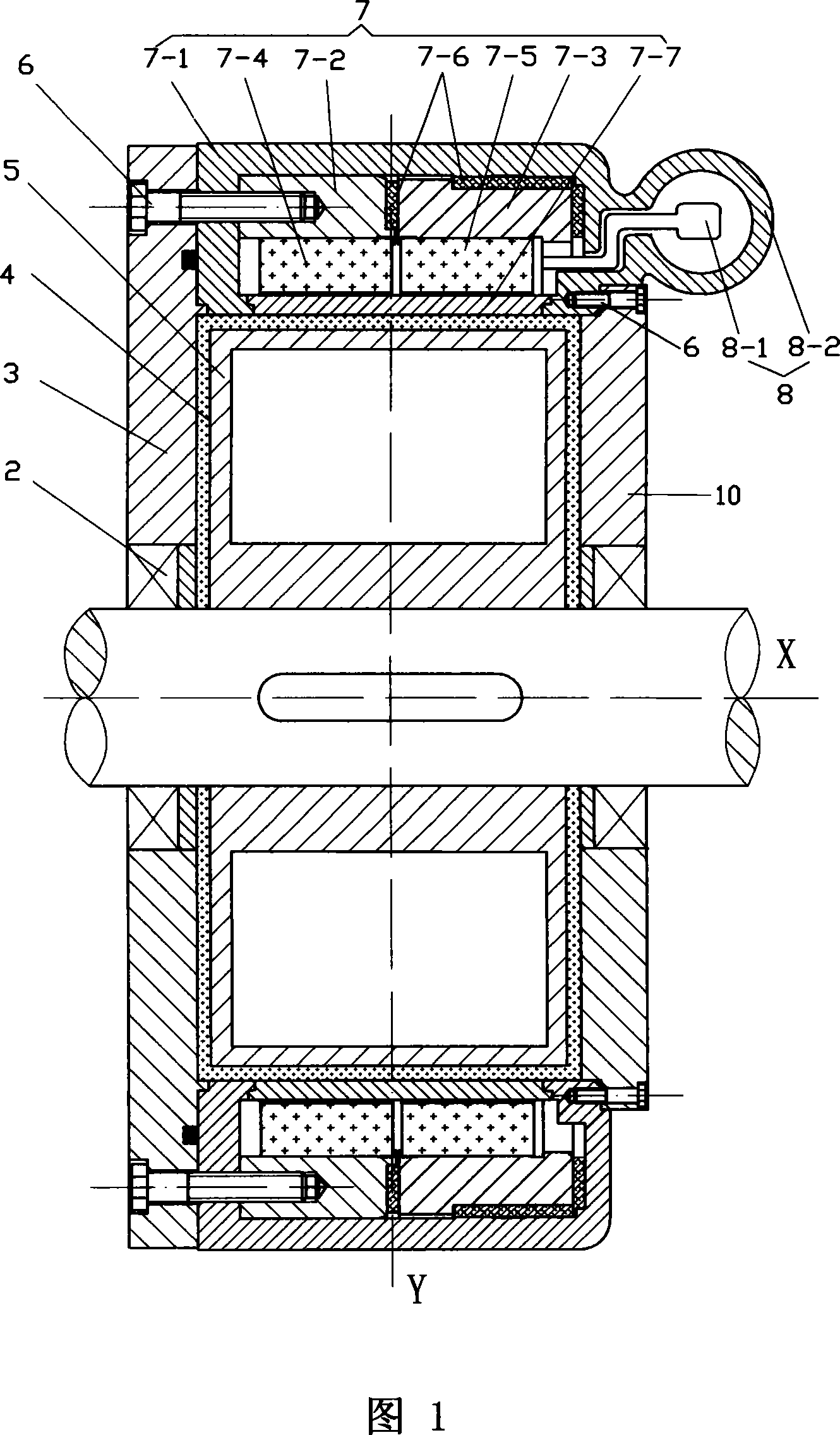

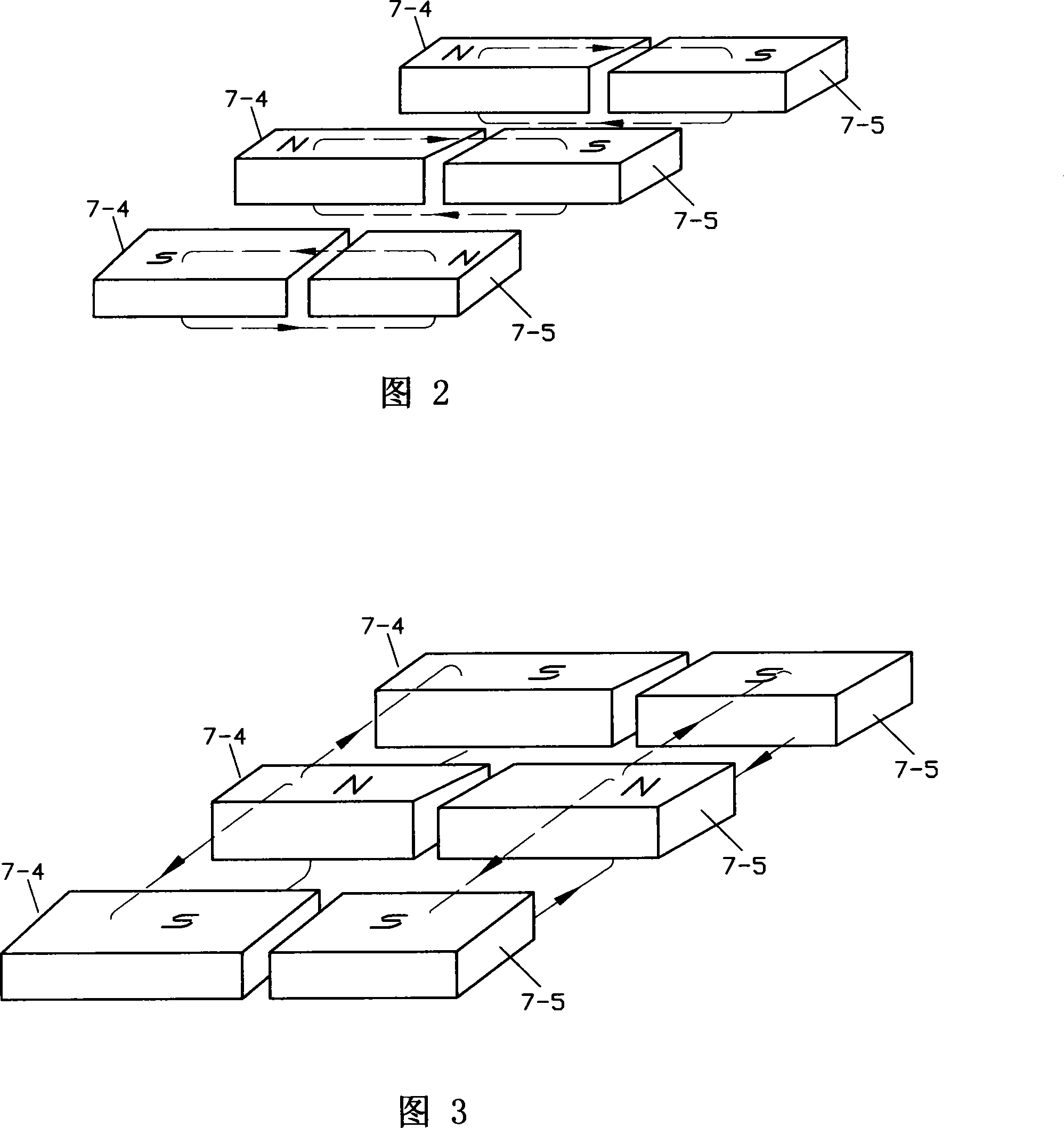

[0020] The embodiment shown in Figures 1 to 3 includes a rotor 5, a stator 7 on the outer circumference of the rotor 5, sealing covers 3, 10 covering both sides of the stator 7, and a fixed connection with the rotor 5 and fixed on the two sealing covers 3, 10 The drive shaft 1 supported by the upper bearing 2 has a closed cavity 4 between the rotor 5 and the surrounding stator part and the sealing covers on both sides, and the enclosed cavity 4 is filled with magnetorheological fluid. The stator 7 includes an annular hollow housing 7-1, an annular fixed holder 7-2 and an annular movable holder 7-3. The sealing covers 3 and 10 on both sides are fixed on both sides of the housing 7-1 by screws 6. The inner surface of the fixed cage 7-2 is fixed with permanent magnets 7-4 evenly distributed in the circumferential direction, the inner surface of the movable cage 7-3 is fixed with permanent magnets 7-5 evenly distributed in the circumferential direction, and the fixed cage 7- The arran...

Embodiment 2

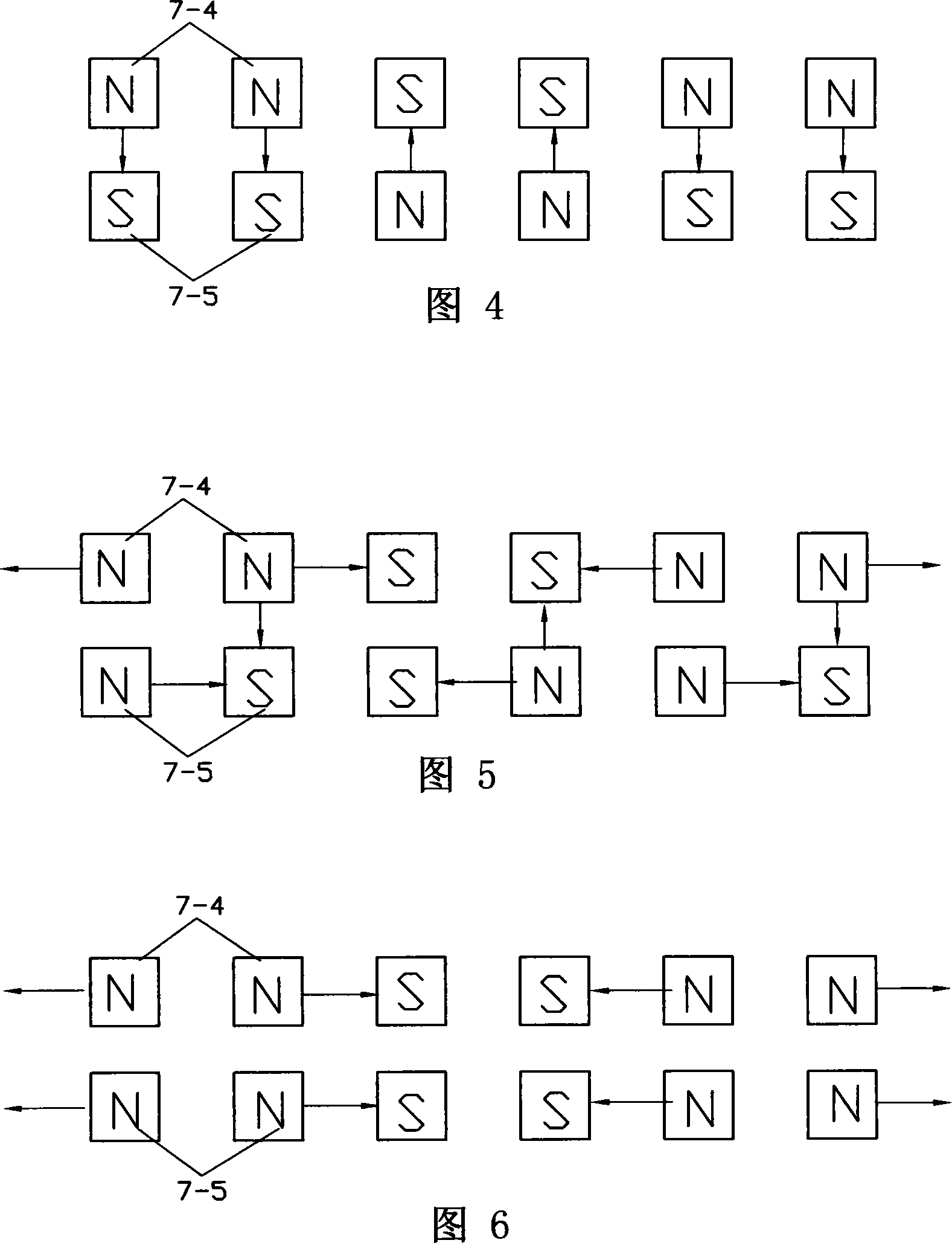

[0023] As shown in Figure 4, the polarity of the permanent magnets is set in the radial direction, that is, in the Y direction. Two permanent magnets in the same cage form a group, the polarity of the permanent magnets in the same group is the same, and the polarities of the permanent magnets of adjacent groups are different; Same as Example 1.

[0024] In this embodiment, when the permanent magnet group on the movable holder 7-3 and the permanent magnet group on the opposite fixed magnet holder 7-2 have different polarities, they belong to the axially adjacent permanent magnets on the two holders. The magnetic lines of force form a closed magnetic circuit. The direction of the closed magnetic circuit can be referred to the direction of the closed magnetic circuit in Figure 2. The magnetic lines of force do not pass through the magnetorheological fluid, and the brake is in a non-braking state.

[0025] When the movable cage 7-3 rotates one gear, the pitch between a permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com