Automatic analysis quantitatively measure method and automatic analysis quantitatively measure apparatus

A quantitative measurement and automatic analysis technology, applied in the analysis of materials, thermal excitation analysis, material excitation analysis, etc., can solve the problems of difficult automatic measurement, unrealistic coil length, etc., and achieve the effect of excellent mixed liquid decomposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

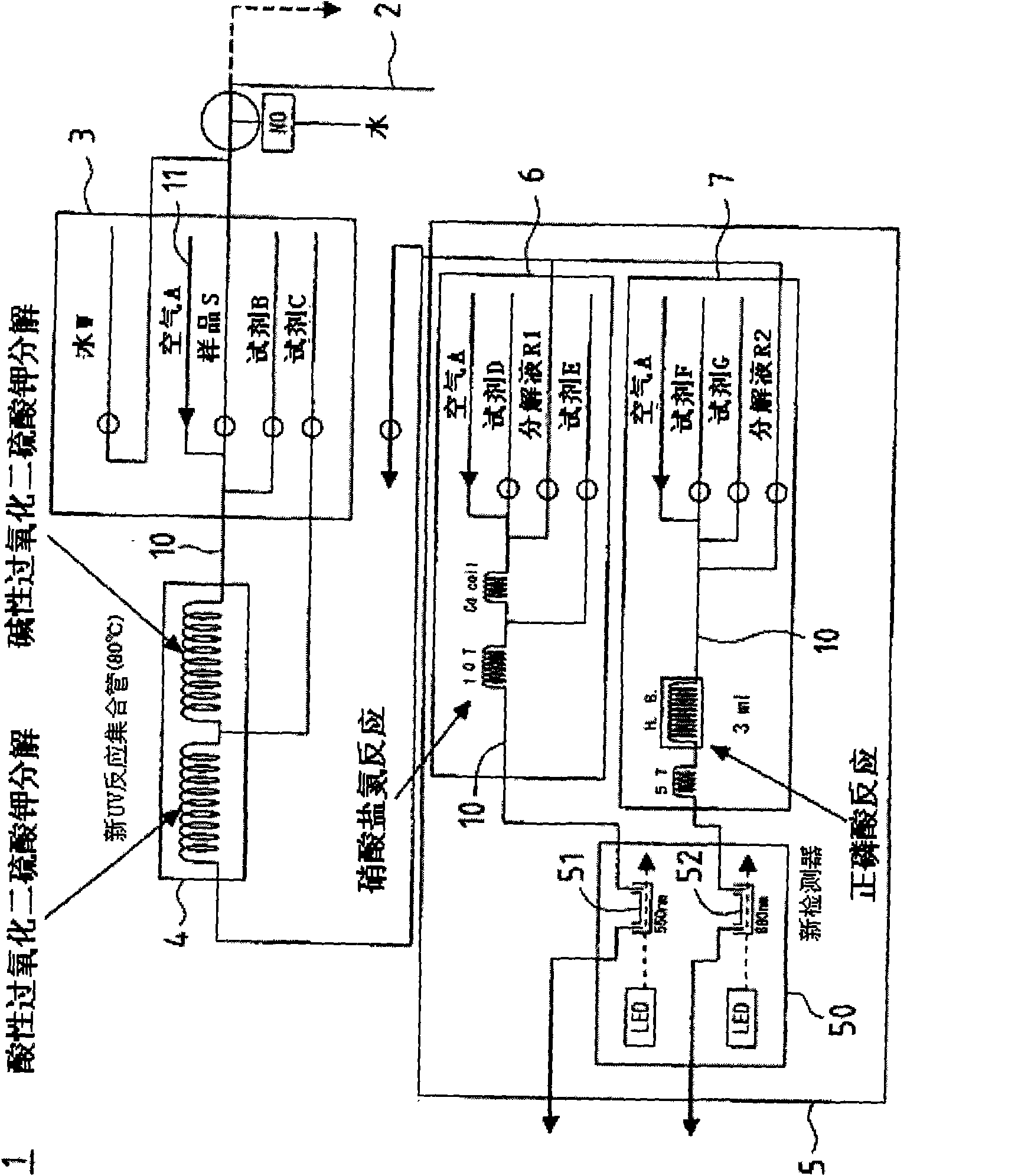

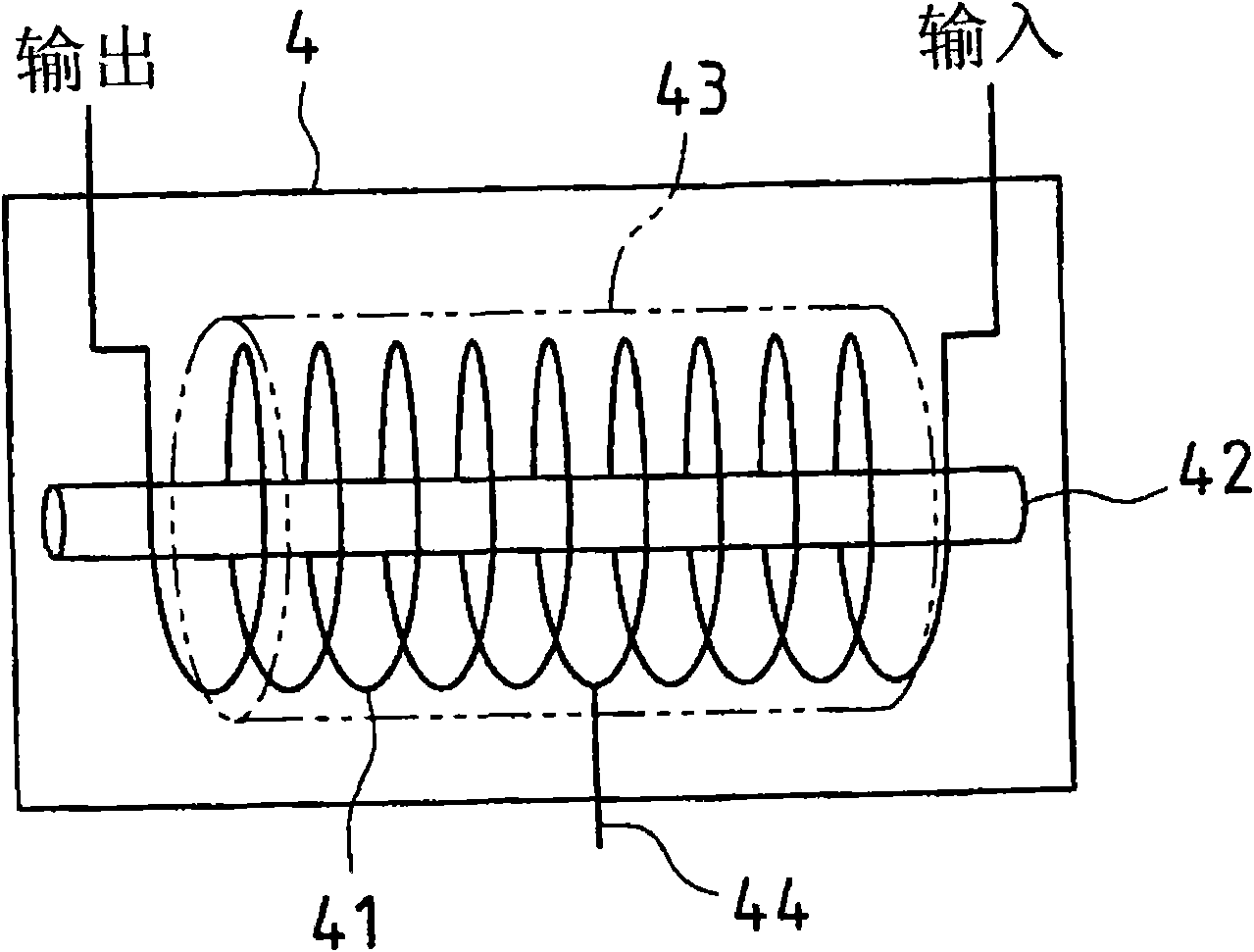

[0044] Prepare automatic analysis and quantitative measurement equipment. This equipment has a quartz tube with an inner diameter of 2mm and a length of 4m wound into a coil shape, a UV lamp is installed in the center of the coil, and a heating ring is wound around the quartz coil to heat the reaction set to 40-100°C. Tube.

[0045] Dissolve 40g of potassium peroxodisulfate and 4g of sodium hydroxide in 1000ml of pure water as a reagent, and dissolve 100ml of sulfuric acid in 1000ml of pure water as another reagent.

[0046] Dissolve 0.5 g of tripolyphosphoric acid in 1000 ml of pure water and use it as a sample.

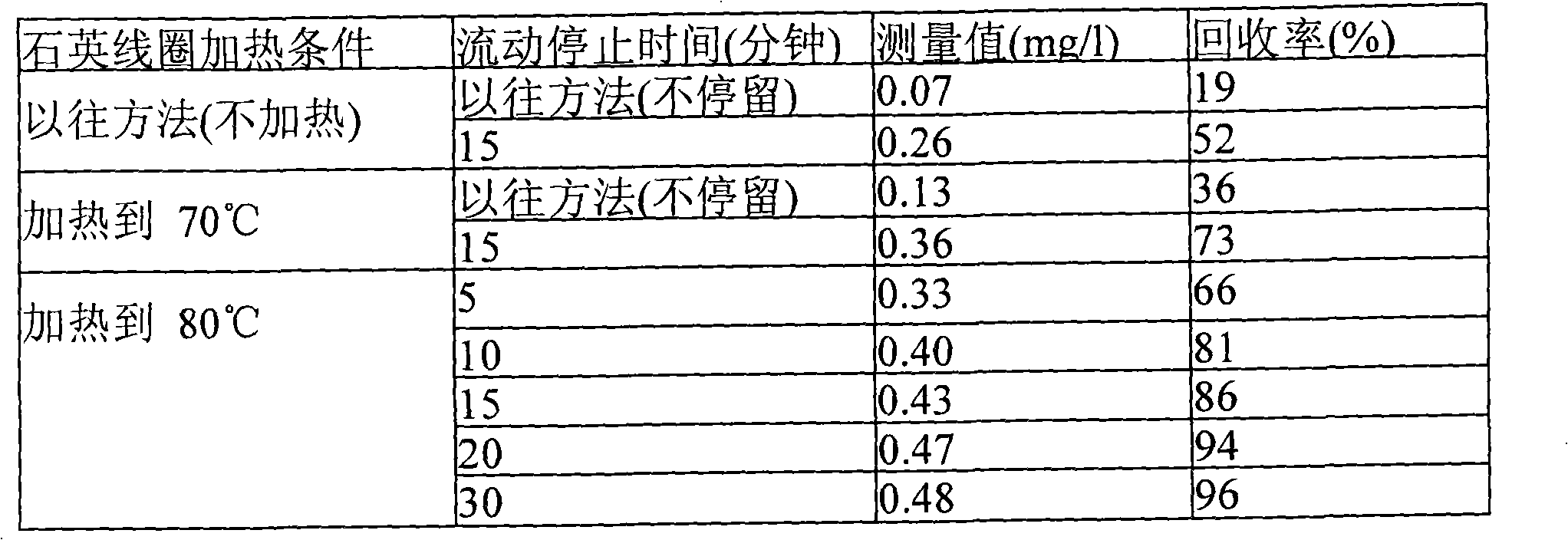

[0047] As shown in Table 1, the concentration of the aqueous solution of tripolyphosphoric acid as a sample was measured under the conditions of no heating, heating to 70°C, and heating to 80°C without stopping the mixed solution in the reaction manifold, and staying for 5 to 30 minutes. The results are shown in Table 1.

[0048] Table 1

[0049]

[0050] As c...

Embodiment 2

[0052] Various compounds shown in Table 2 were prepared as samples, and analyzed using the same reagents and reaction manifolds as in Example 1 above. Under the heating condition of 80° C., a test was carried out in the case where the reaction manifold was stopped for 20 minutes. The results are shown in Table 2.

[0053] Table 2

[0054] compound

Invention (mg / l)

Manual analysis (mg / l)

tripolyphosphate

0.95

0.99

1.0

1.0

ATP (adenosine triphosphate)

1.0

1.0

[0055] As can be seen from Table 2, excellent recoveries were achieved for all compounds in the table.

[0056] Industrialization prospect

[0057] The invention can be used for water quality management of waterways, seawater, rivers, lakes, ponds and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com