Downhole steam flow and mass dryness fraction measurement method and measurement instrument

A technology of steam flow and measurement method, applied in the field of measurement, can solve the problems of inability to meet the needs of heavy oil thermal recovery process, difficulty in measuring dryness parameters, low measurement accuracy, etc., and achieves convenient measurement, wide measurement range and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

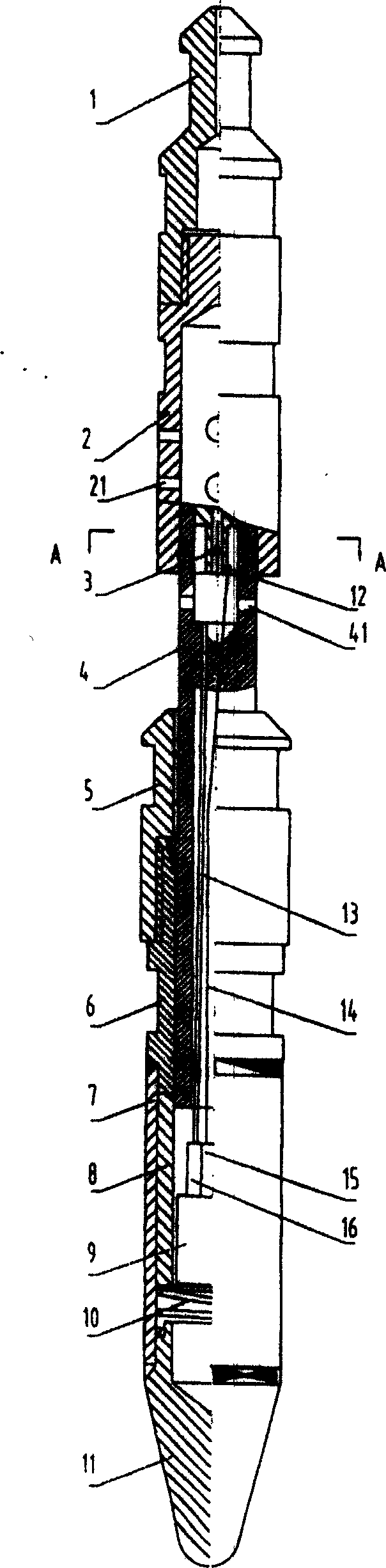

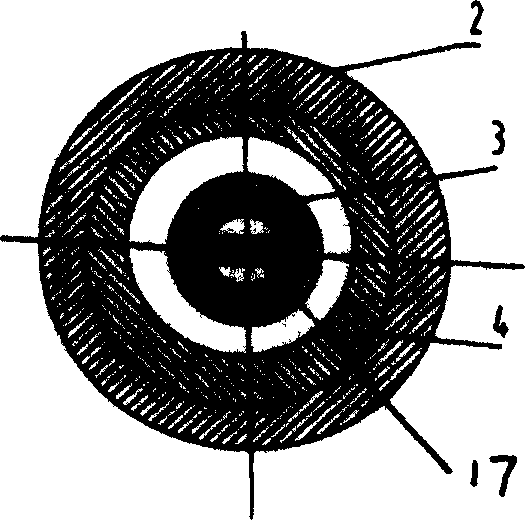

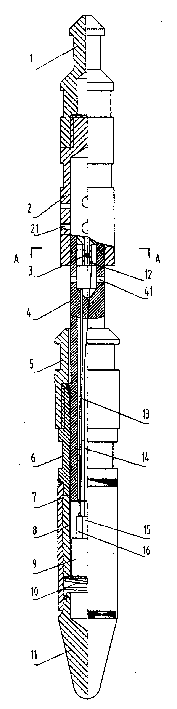

[0031] A method for measuring downhole steam flow and dryness, comprising measuring differential pressure and vortex shedding frequency, the measurement of the differential pressure and vortex shedding frequency described in step (A) is to use a vortex frequency generator, a differential pressure sensor, a vortex The measuring instrument of the combination body that sensor constitutes is carried out; Step (B) described differential pressure also is the differential pressure that measuring instrument itself produces to the throttling action of fluid, and described vortex shedding frequency is that vortex street frequency generating body produces to injection steam The vortex street frequency signal, the signal collected by the vortex street sensor is recorded in the downhole data acquisition system of the surveying instrument; step (C) stores the choke pressure difference and vortex street frequency data measured by the surveying instrument in the downhole data acquisition system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com