Whirlwind type heat radiation LED lamp

A technology of LED lamps and LED lamps, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of bulky heat dissipation devices, speed up the flow of gas in the heat conduction sheet, etc., and reduce maintenance costs , Replacement and maintenance are light and convenient, and the method is ingenious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

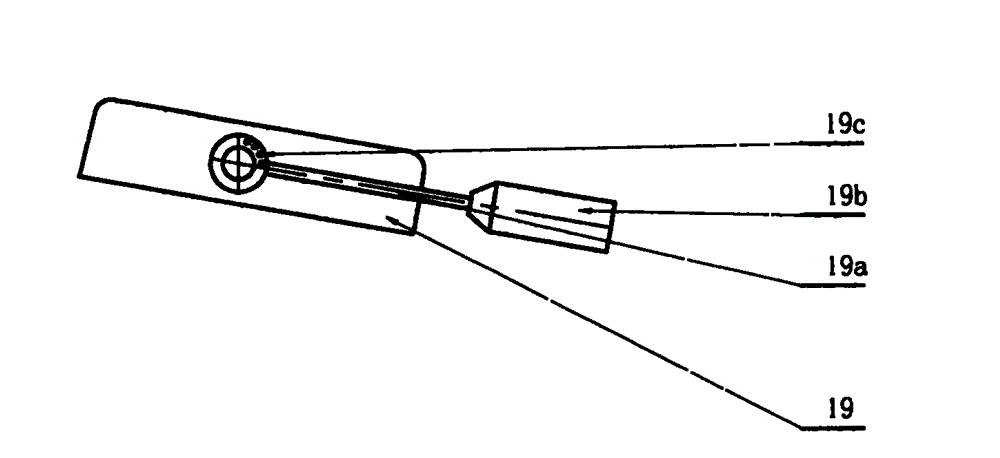

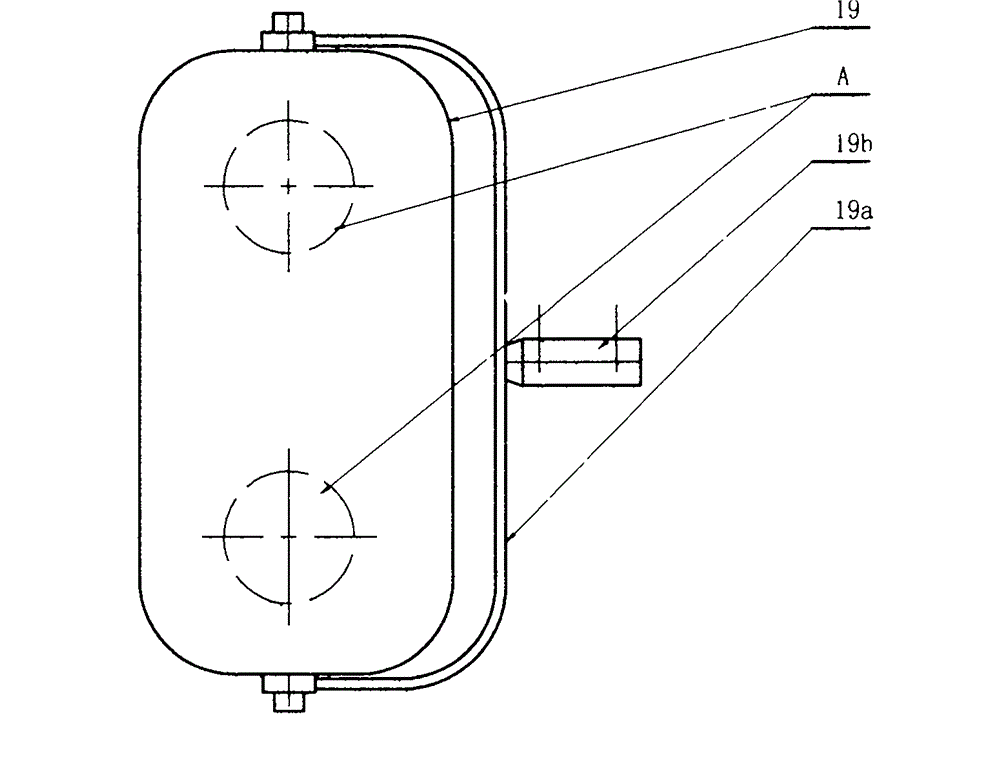

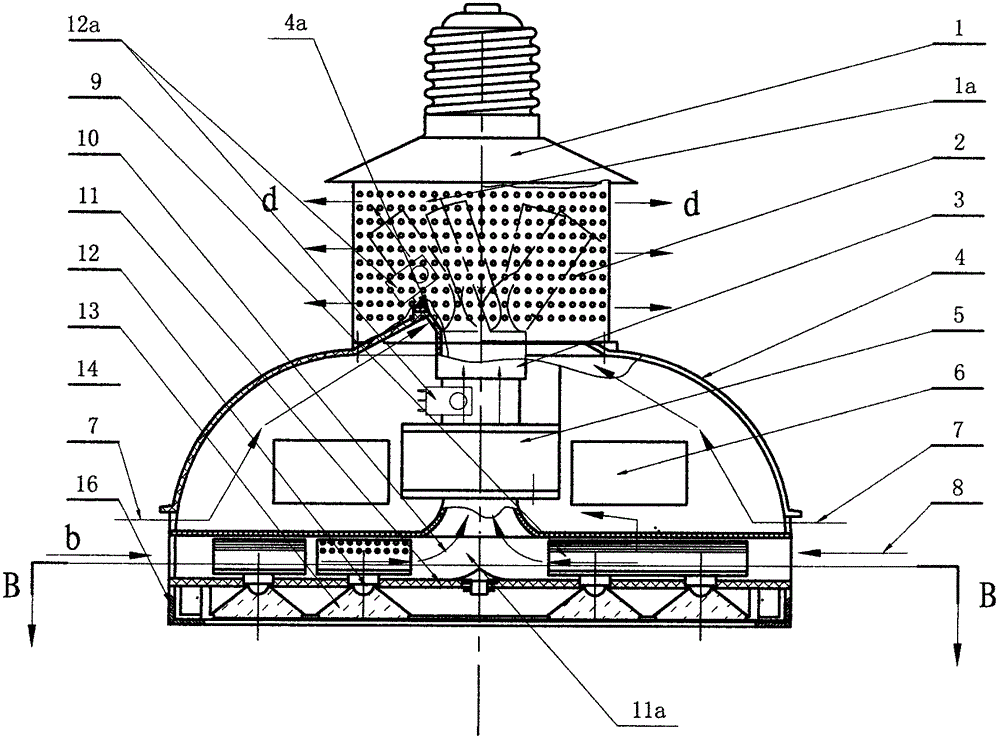

[0030] In order to further understand structure of the present invention, describe as follows with reference to accompanying drawing:

[0031] refer to figure 1 , 2 This whirlwind heat dissipation LED lamp is mainly composed of a heat conduction sheet 9 and an LED lamp 12, and is characterized in that its heat conduction sheet 9 is a conduction sheet 9 device mounted on an LED bulb lamp or an LED array chip 12a, and the heat conduction sheet 9 is shaped like; there are several vertical strips and elongated pieces on a horizontal piece, and there is no horizontal connecting piece in the straight piece made by different processes, which can make the air flow unimpeded. The heat dissipation hole group 9a, the heat conduction sheet 9 and the LED chip lamp 12 are fixed in the middle hole of the supporting plate seat 15, and the upper part of the heat conduction sheet 9 has a """-shaped long and narrow air duct taking into account heat preservation and protection. ""-shaped seat co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com