Bearing block for water supply pump station and repairing technology

A technology for bearing housings and pumping stations, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as unsuitable for batch repair, complex repair process, and misalignment of bearing holes, and achieve compact structure, The effect of firm connection and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

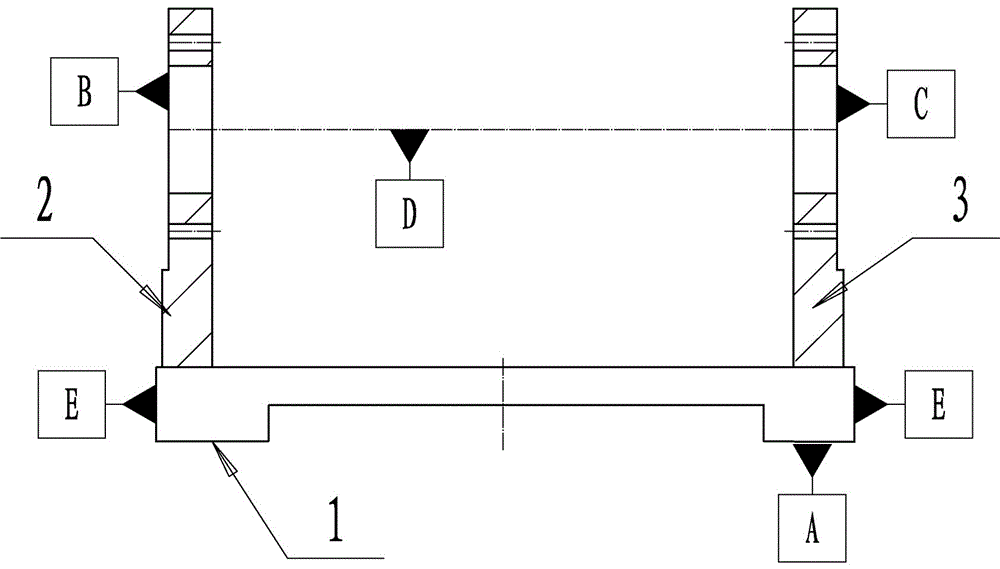

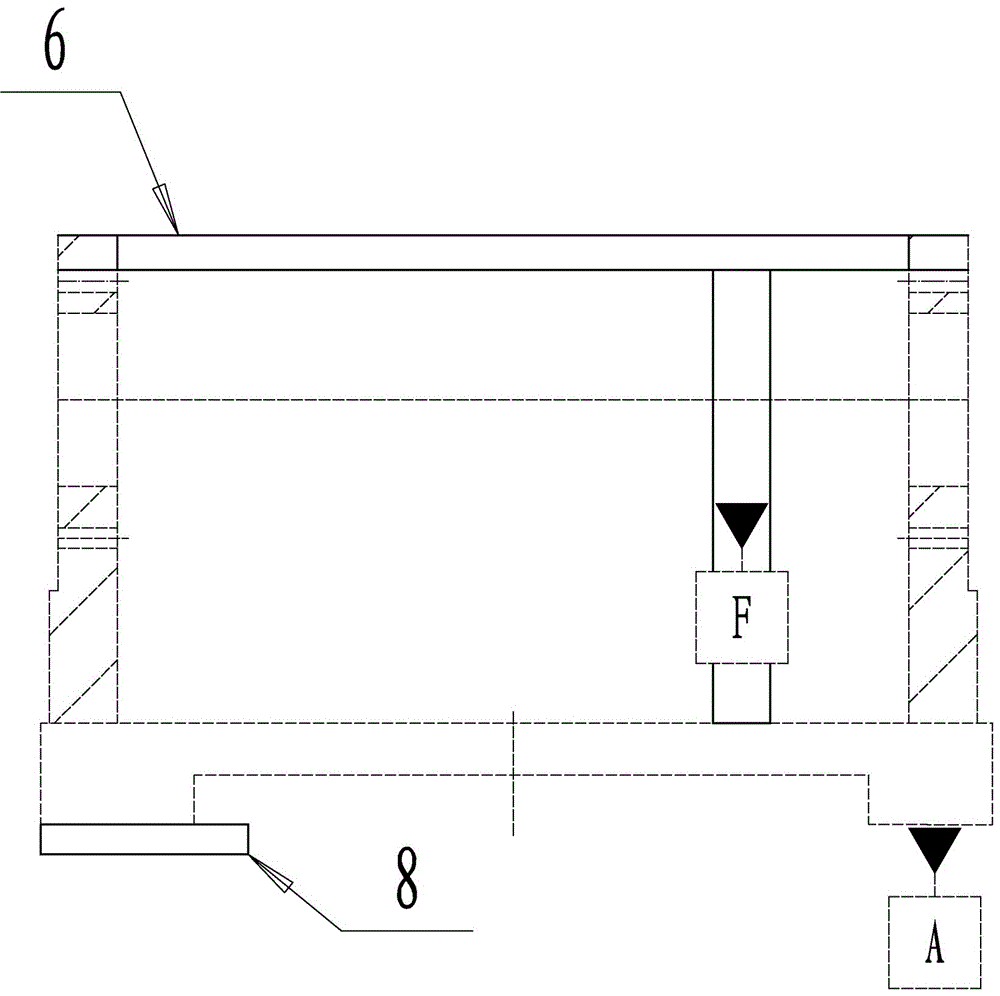

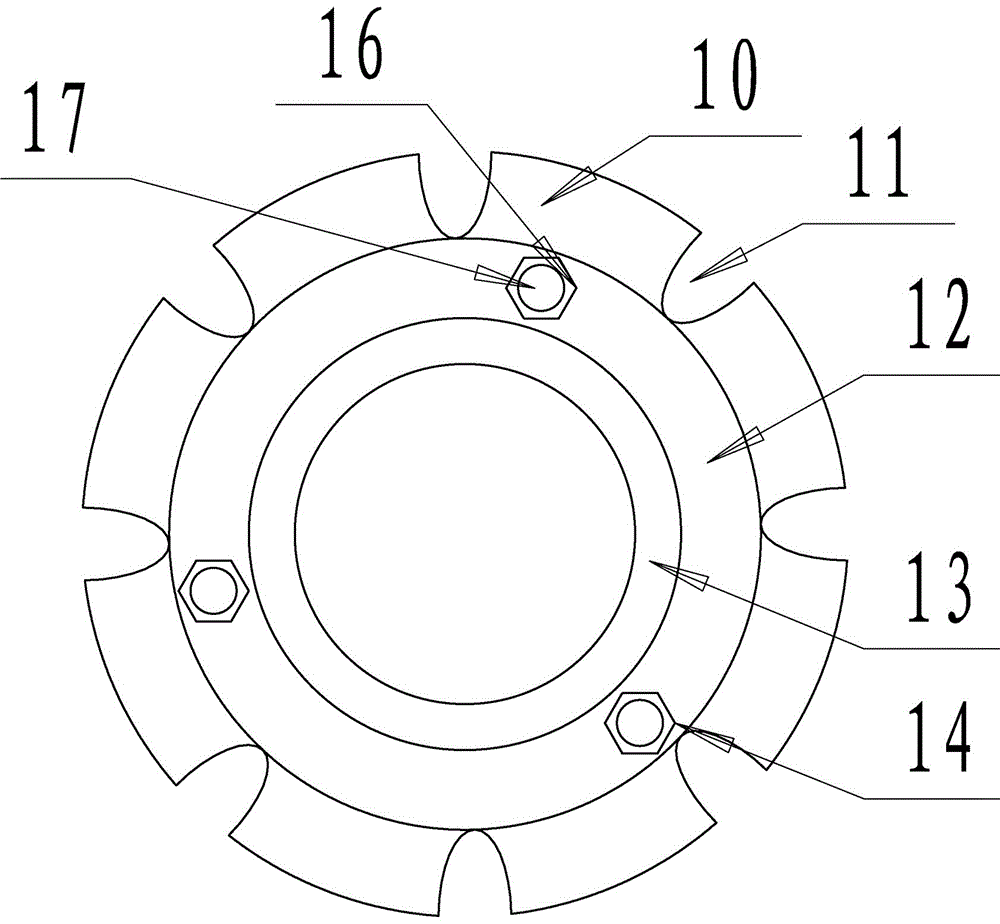

[0037] Such as Figure 1-6 As shown, the bearing housing for the water supply pump station of this embodiment includes a base 1 and a first bearing orifice plate 2 and a second bearing orifice plate 3 whose holes are coaxially arranged on the base 1;

[0038] The reference of the lower surface of the base 1 is A, the reference of the hole axis of the first bearing orifice plate 2 and the second bearing orifice plate 3 is D, the reference of the outer surface of the hole of the first bearing orifice plate 2 is B, and the reference of the second bearing orifice plate 2 is B. 3. The reference of the outer surface of the hole is C; the reference D is set parallel to the reference A, and the reference B and the reference C are vertically set relative to the reference D;

[0039] The lower surface of the base 1 is set on the water supply pump station by bolts or welding, the datum B is used to install the driving motor, the datum D is used to install the output shaft coaxial with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com