Casting flow tracking system of continuous casting machine

A technology of tracking system and continuous casting machine, applied in the field of casting strand tracking system, can solve problems such as unsafe measurement process, inaccurate measurement results, unsafe system, etc., to eliminate false overflow interference, improve tracking accuracy, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

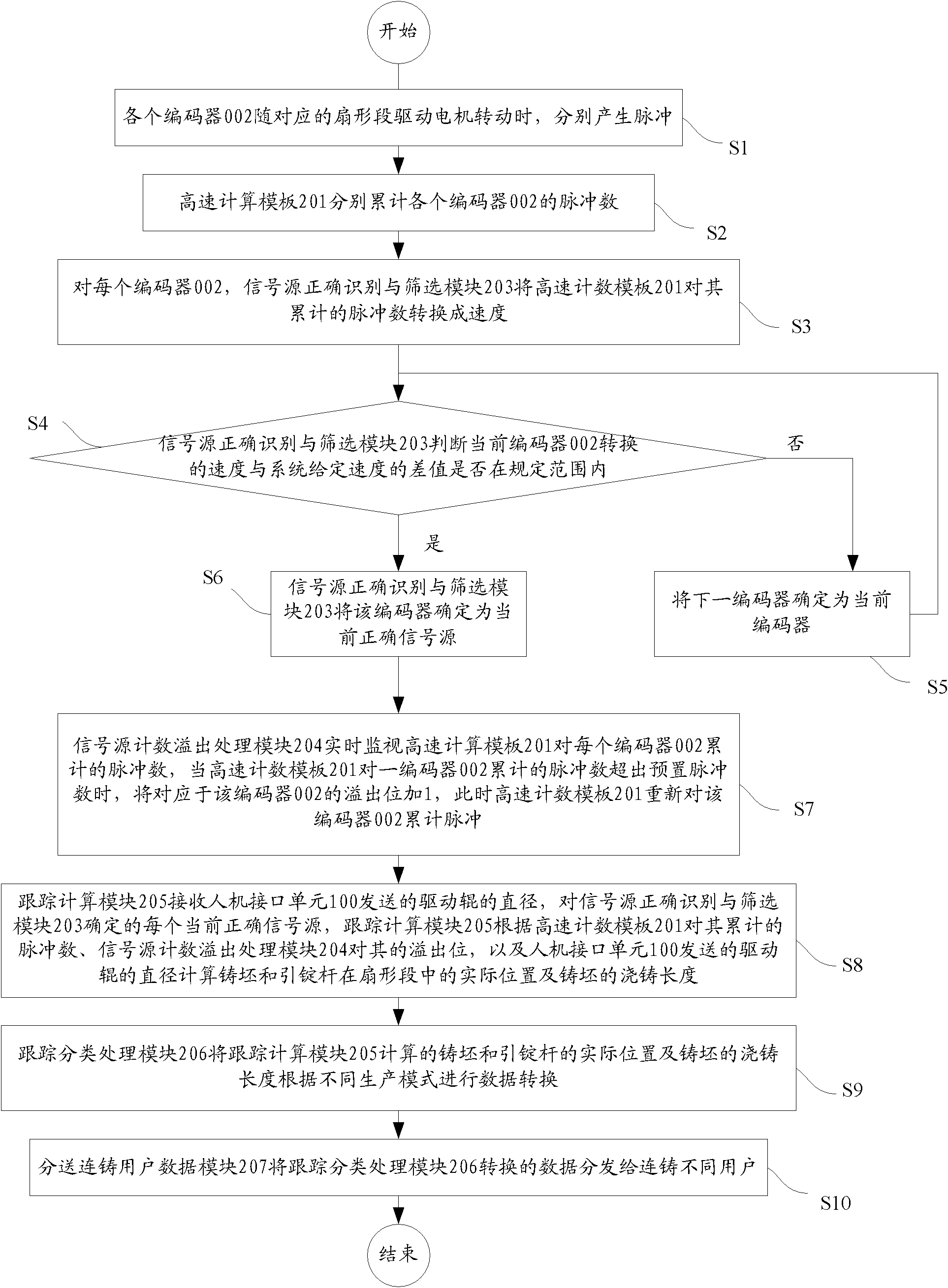

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0036] Before elaborating the strand tracking system of the continuous casting machine of the present invention, the technical background of the system will be described first.

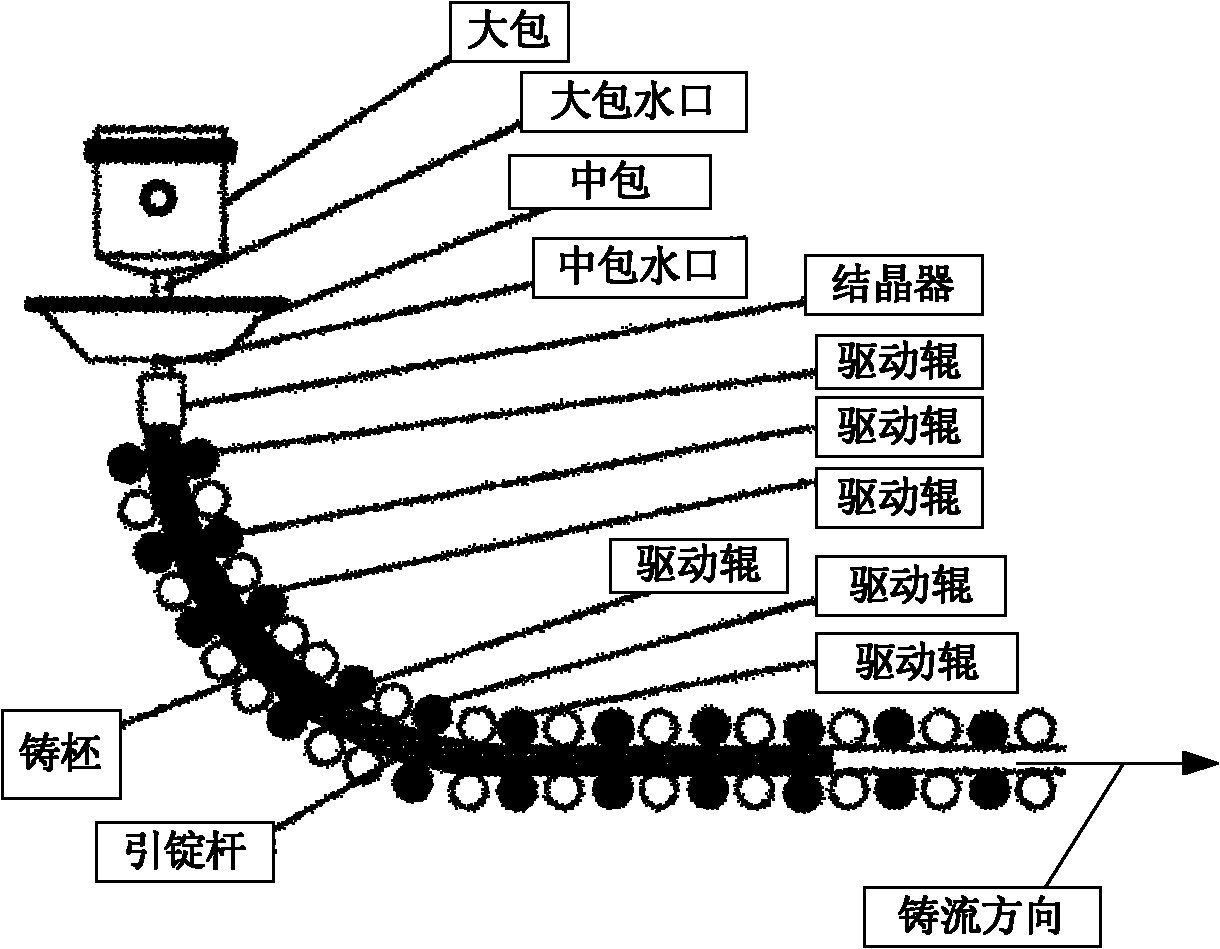

[0037] The segment is composed of a driving roller and multiple (generally 6, 3 before and after the driving roller) non-driving pressure rollers. figure 1 The composition of the sector is schematically shown, where the solid circle represents the drive roller of the sector, and the hollow circle represents the non-driven pressure roller of the sector. The drive rollers are connected by mechanical linkages to the drive motors outside.

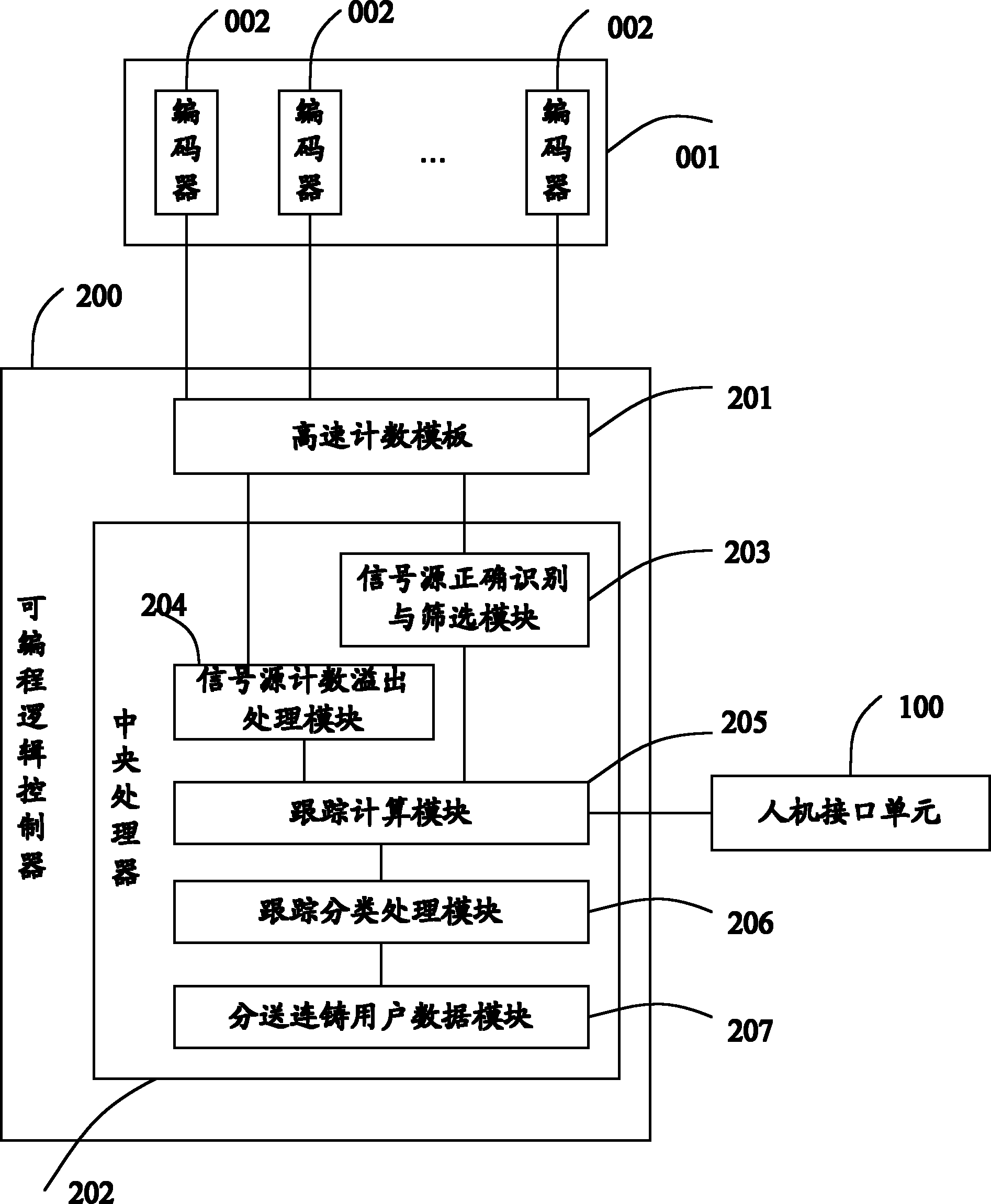

[0038] The casting flow tracking system of the continuous casting machine of the present invention is described below, as figure 2 As shown, the casting strand tracking system of the continuous casting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com