High-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and spinning method thereof

A nanofiber and composite filtration technology, applied in the field of electrospinning, can solve the problems of low strength, poor wear resistance, and the substrate and the nanofiber layer are not resistant to peeling, etc., and achieve high porosity, excellent performance, and excellent peeling resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

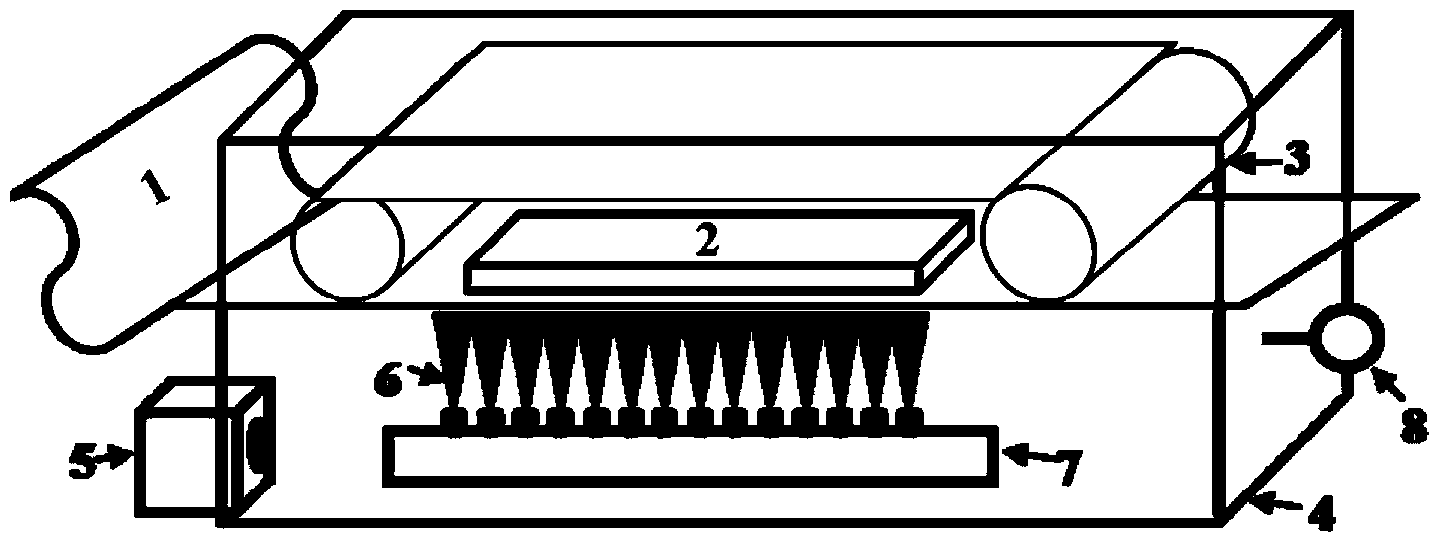

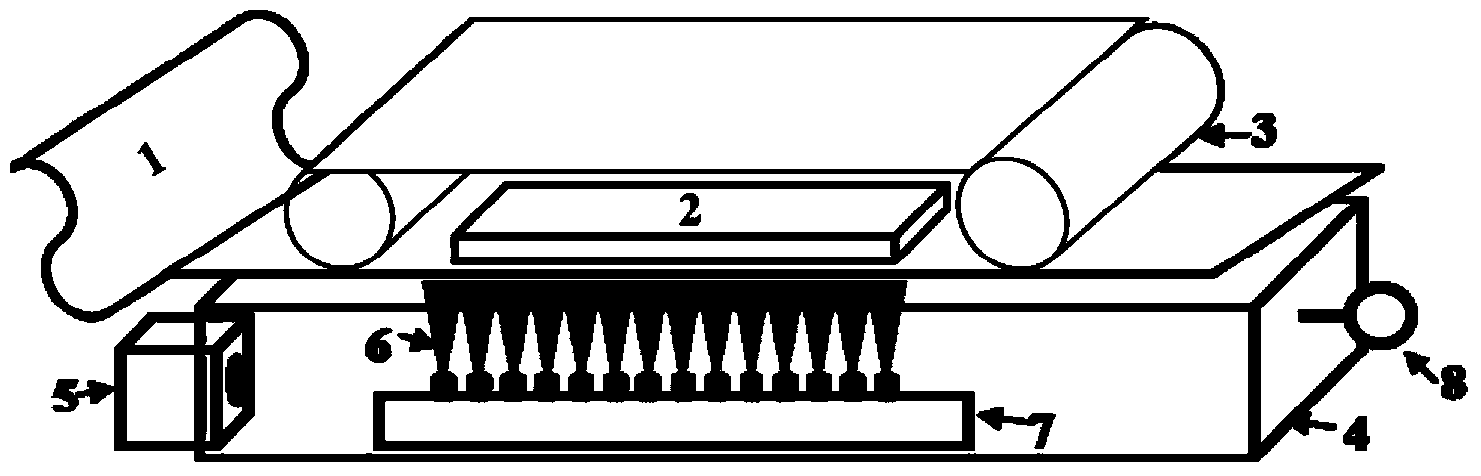

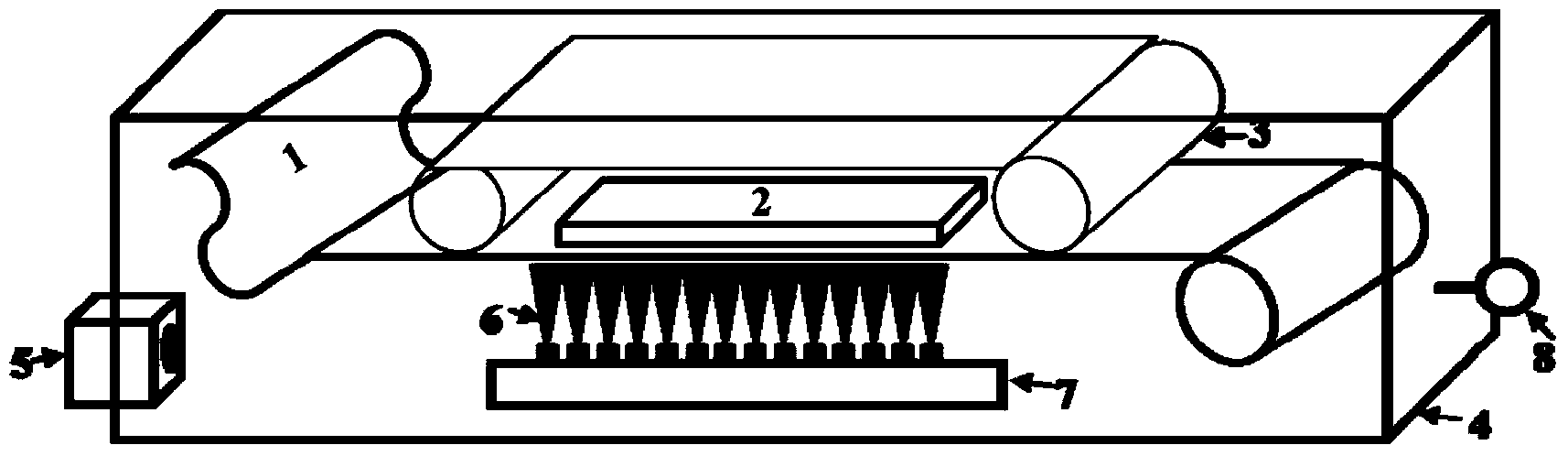

Image

Examples

Embodiment 1

[0047] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0048] Step 1: The polyacrylonitrile powder and the polysulfone resin particles were placed in a vacuum oven at 70°C for 1.5 hours and a vacuum oven at 110°C for 2.5 hours, respectively.

[0049] The second step: dissolve the dried polyacrylonitrile powder in the DMF solution, place the solution on a magnetic stirrer and stir for 15 hours respectively to form a homogeneous solution; in the homogeneous solution, the mass of polyacrylonitrile The fraction is 30%; while polysulfone resin particles are dissolved in DMF solution, the solution is placed on a magnetic stirrer and stirred for 15 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of polysulfone is 35% %

[0050] Step 3: Draw a certain amount of DMF solvent into a 10mL needle tube, and then electrostatically spray it onto the rece...

Embodiment 2

[0053] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0054] Step 1: Place the polyethylene oxide powder and polyurethane particles in a vacuum oven at 70°C for 1.5 hours and in a vacuum oven at 110°C for 2.5 hours, respectively.

[0055]The second step: dissolve the dried polyethylene oxide powder in the DMAc solution, place the solution on a magnetic stirrer and stir for 15 hours respectively to form a homogeneous solution; in the homogeneous solution, the mass of polyethylene oxide Fraction is 28%; Polyurethane particle is dissolved in DMF solution simultaneously, and described solution is placed on magnetic stirrer and stirs 15 hours respectively, forms homogeneous solution; In described homogeneous solution, the massfraction of polyurethane is 30%

[0056] Step 3: Draw a certain amount of DMAc solvent into a 10mL needle tube, and electrostatically spray it onto the rece...

Embodiment 3

[0059] A high wear-resistant and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method, the specific steps are:

[0060] Step 1: Place the polycaprolactone particles and the polyethersulfone particles in a vacuum oven at 40°C for 3.5 hours and in a vacuum oven at 150°C for 1.0 hour, respectively.

[0061] Second step: dissolve the dried polycaprolactone particles in acetone, place the solution on a magnetic stirrer and stir for 10 hours respectively to form a homogeneous solution; in the homogeneous solution, polycaprolactone The mass fraction is 20%; while the polyethersulfone particles are dissolved in the NMP solution, the solution is placed on a magnetic stirrer and stirred for 15 hours to form a homogeneous solution; in the homogeneous solution, the mass fraction of polyethersulfone 40%

[0062] Step 3: Draw a certain amount of acetone solvent into a 10mL needle tube, and electrostatically spray it onto the receiving substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com