Technological method for preparing cake bases by using paper cake cups instead of steel moulds

A process method, cake embryo technology, applied in the field of food processing, can solve the problems of high mold purchase cost, lower product quality, large mold footprint, etc., to save mold footprint, save production labor, and improve labor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below in conjunction with specific embodiments.

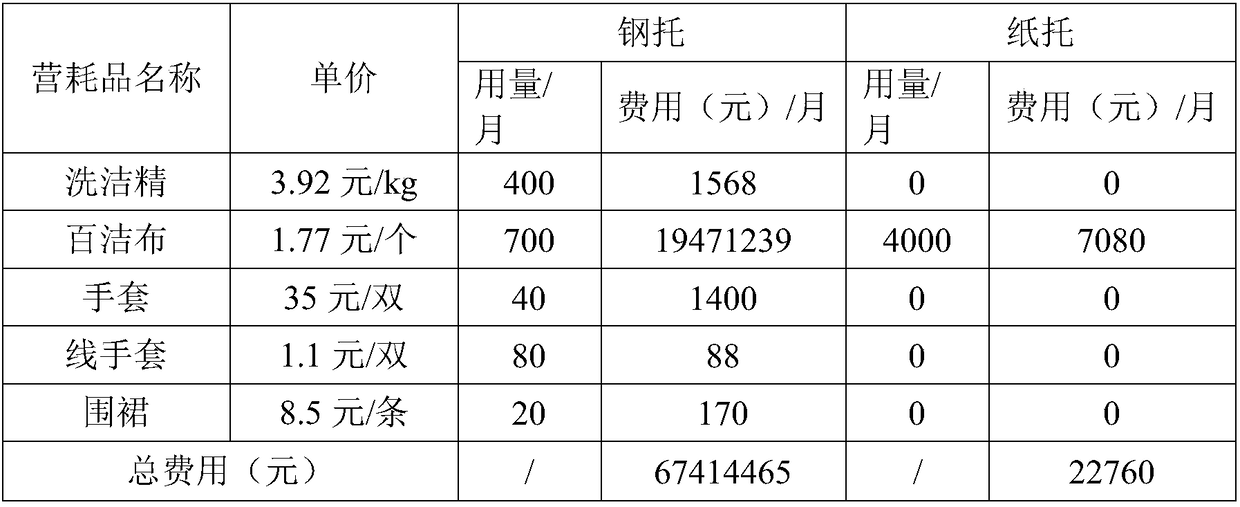

[0022] After repeated design, proofing, and machining tests, the invention team finally determined the process of using cake paper trays instead of tempered molds to make cake embryos. Take the 8-inch original chiffon hot noodles normal temperature cake embryo as an example, divide into two groups and carry out, one group is the iron mold, and one group is the paper holder of the present invention; Every group of experiments is done three times.

[0023] First, the production workshop uses the cake chiffon production line to complete the batter mixing; prepare the cake paper trays, separate them, and check whether there are foreign objects or damages in the paper trays; use the filling machine to fill the batter into the paper trays, and the weight of the batter is 250g , 260g, 270g;

[0024] Put the filled paper tray directly into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com