Seamless home textile kit with three sutureless sides and preparation method of kit

A seamless home textile and kit technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of high production costs, high labor costs, large waste of fabrics, and large demand for personnel to meet market trends. , the effect of improving production efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

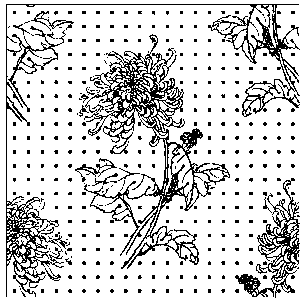

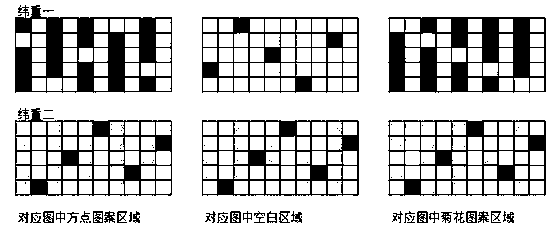

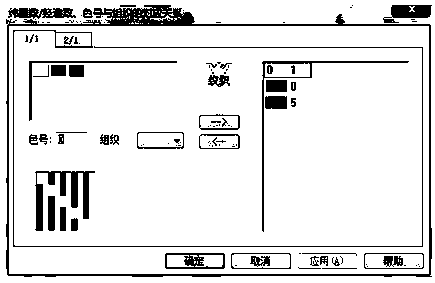

[0021] A three-side stitch-free seamless home textile kit product. The warp yarn of the upper fabric of the product adopts 60 combed pure cotton yarns, the weft yarn adopts 60 Tencel and 60 dyed bamboo fibers (pink); The warp and weft yarns are all 60 combed cotton yarns. The warp yarn density of the woven pillow cover and quilt cover product fabric is 173 yarns / inch, and the weft yarn density is 260 yarns / inch. The size of the finished pillowcase of the product is 44×66cm, the size of the finished quilt cover is 220×240cm, the fabric width of the woven pillowcase product is 118 inches, four horizontally opened, and the cutting line width is 0.8cm. The width of the quilt cover product is 98 inches, and the width of the cutting line is 1.1 cm.

[0022] The three-side stitch-free seamless home textile kit product includes steps including: home textile quilt cover / pillow cover pattern design, organizational structure design, pattern weaving process design → suit structure weaving →...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com