Banding machine

A technology for a wrapping machine and a case, which is applied to the parts of the wrapping machine, the packaging, transportation and packaging of paper products, etc., can solve the problems of low wrapping efficiency, wrapping firmness, inability to guarantee cleanliness, and small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

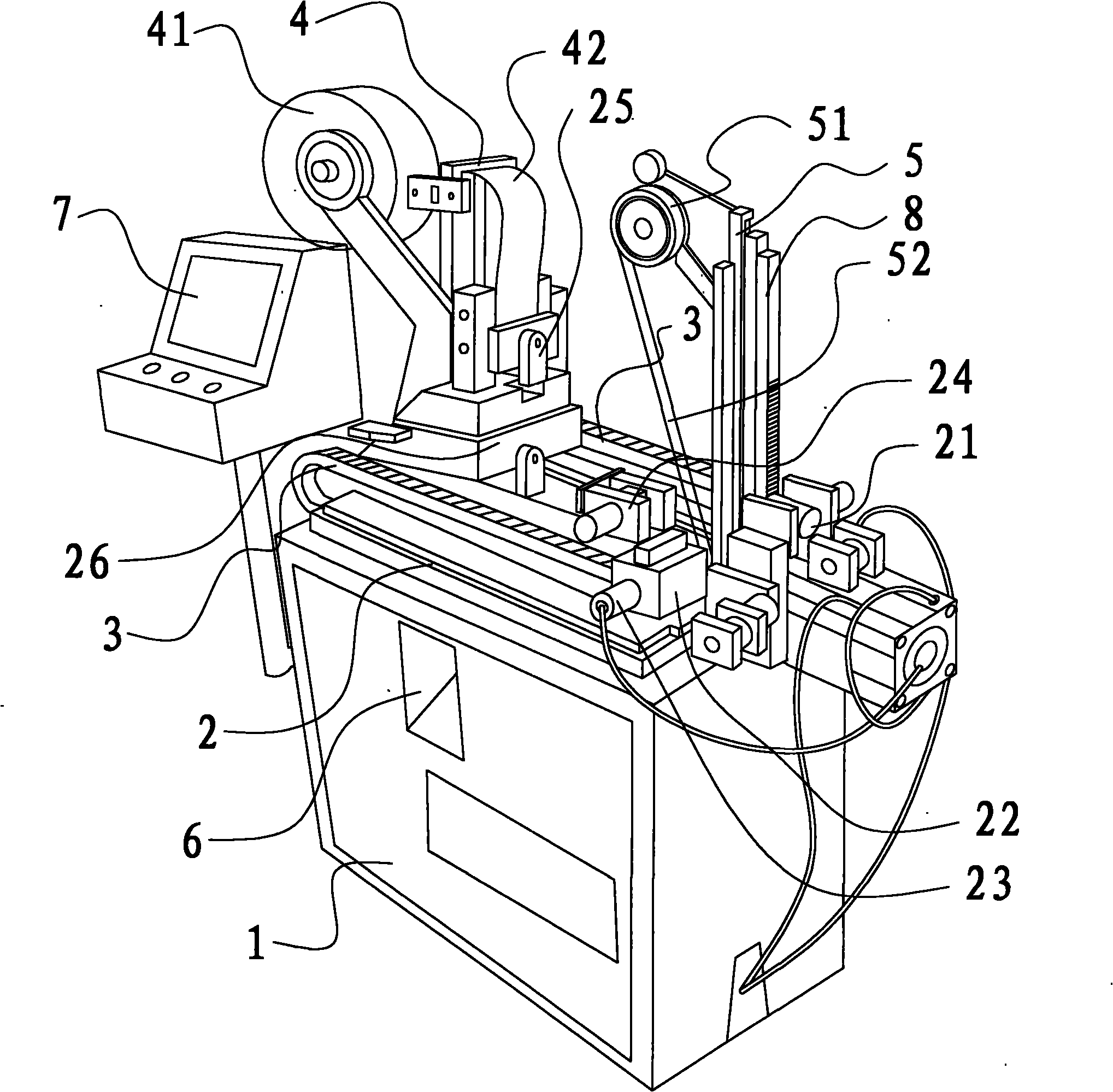

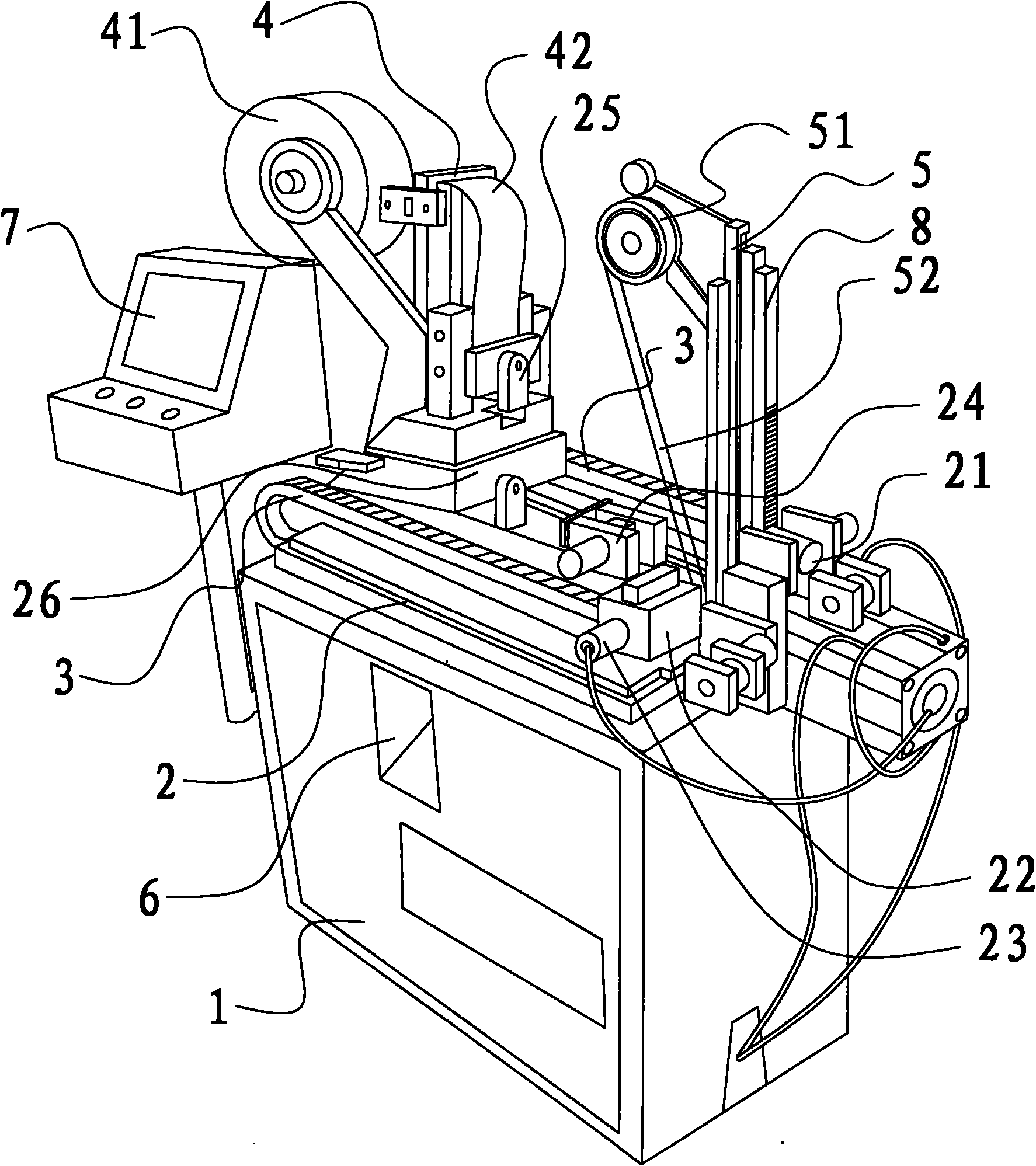

[0013] refer to figure 1 As shown, the present invention discloses a binding machine, comprising a case 1, a power assembly disposed in the case 1, and a workbench 2 arranged on the top of the case 1, and the workbench 2 is provided with two parallel transmission belts 3 and the slide rail between the two conveyor belts 3, the front end of the transmission belt 3 is provided with a discharge rack 8 and a tape holder 5 in sequence, and the rear end of the transmission belt 3 is provided with a material cutting mechanism 25 and a tape holder 4 in sequence, wherein the paper tape The frame 4 and the tape frame 5 are respectively provided with a paper tape wheel 41 and a tape wheel 51, and the paper tape 42 and the adhesive tape 52 in rolls are placed on the paper tape wheel 41 and the tape wheel 51, and the paper tape frame 4 is provided with Inverted paper cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com