Pure cotton yarn production method utilizing seamless joint of roving and finespinning

A production method and technology of thick and thin coupling, applied in the field of spinning, can solve the problems of high product price, intelligence, continuous level stability, reliability gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

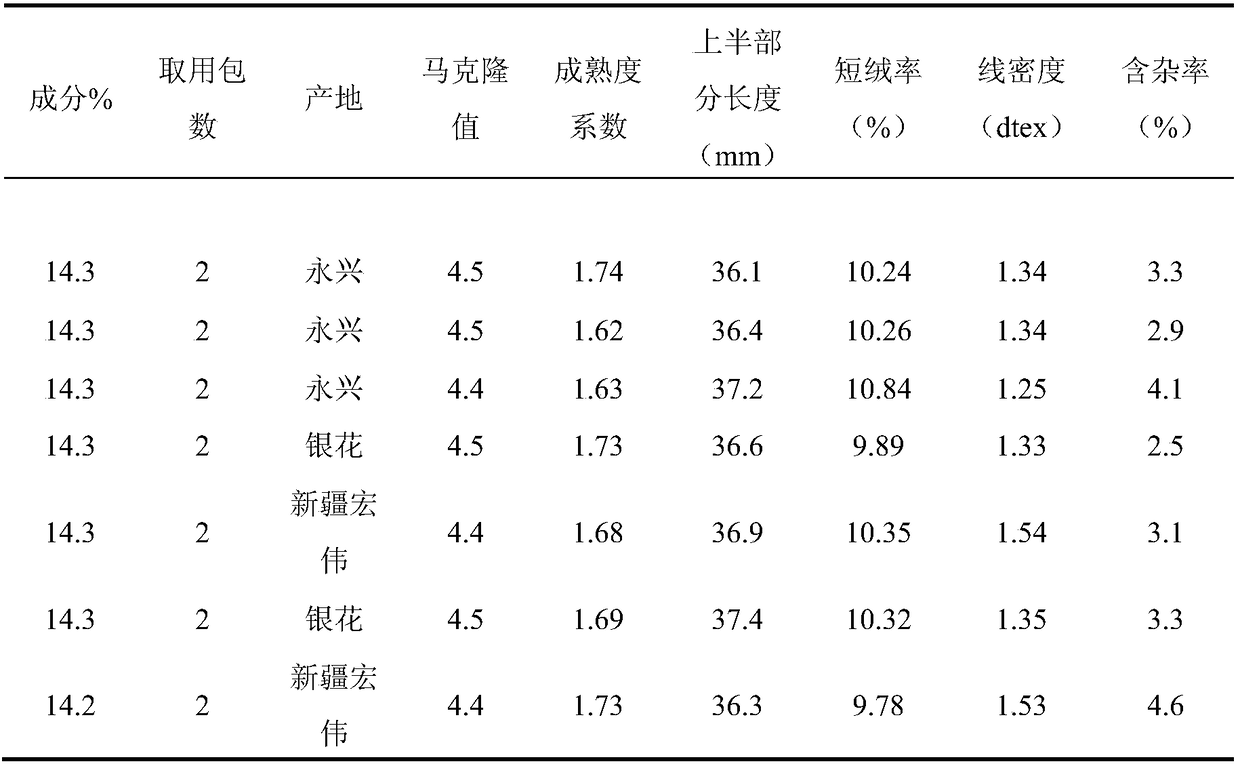

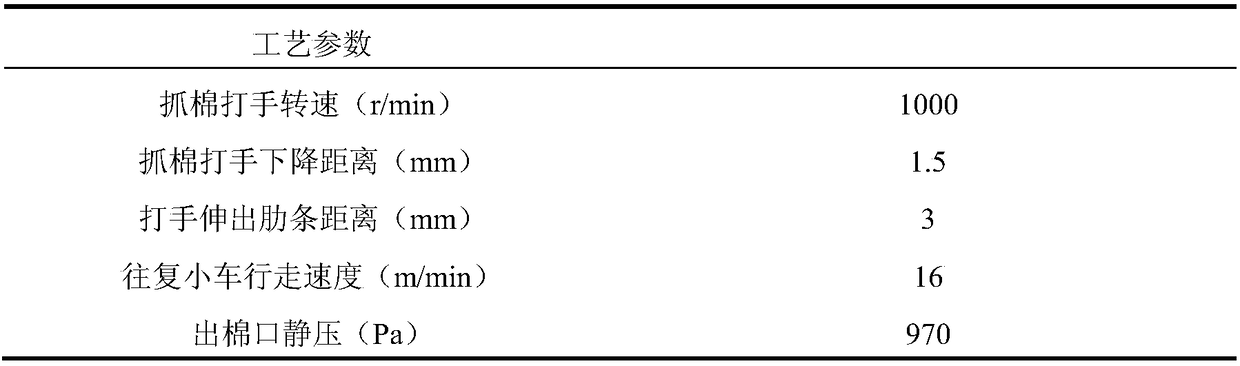

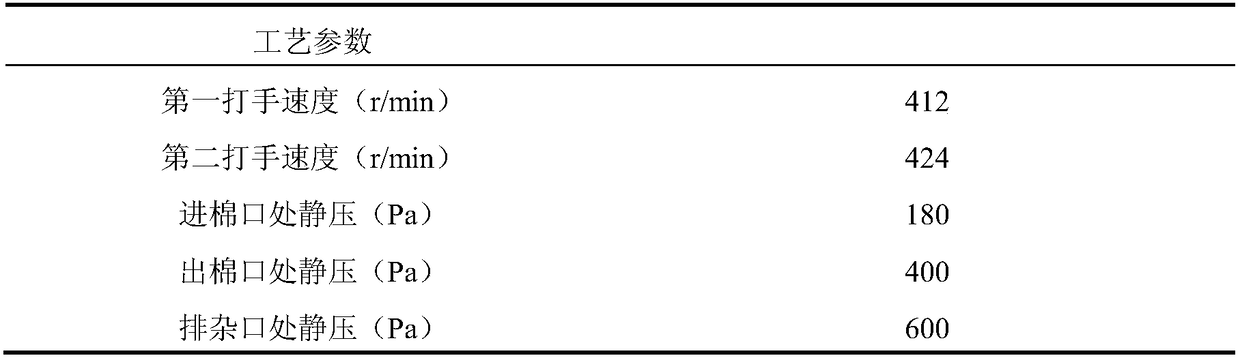

[0016] by 100 S Take the production of combed pure cotton yarn as an example. After the raw cotton is mixed with cotton, it will go through the opening and cleaning process, carding process, pre-drawing process, sliver and winding process, combing process, drawing process, roving process, spinning process and winding process. The bobbins are processed in the bobbin process, and the following production equipment are used in sequence in the bobbins: JWF1012 reciprocating plucking machine → TF27 bridge magnet → FA103A double-axial flow opener → FA028-160 multi-bin mixing machine Cotton machine + FA109-160 type three licker-in cotton cleaning machine → JWF0016C type foreign fiber sorting machine → JWF1054 type dust removal machine → 119A type spark detector → cotton box → JWF1211 type carding machine → JWF1310 type drawing frame →JWF1383 Combing Machine→Rieter E86 Automatic Combing Machine→JWF1312B Autoleveller Draw Frame→THC2015 Automatic Doffing Roving Frame→Thickness and Thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com