Pipeline cable conveying method with auxiliary supporting structure

A pipeline cable and auxiliary support technology, applied in the direction of cable installation, cable laying equipment, cable installation devices, etc., can solve the problems of affecting insulation performance, low work efficiency, slow dragging speed, etc., to prolong service life and improve transportation Efficiency and reduction of conveying resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

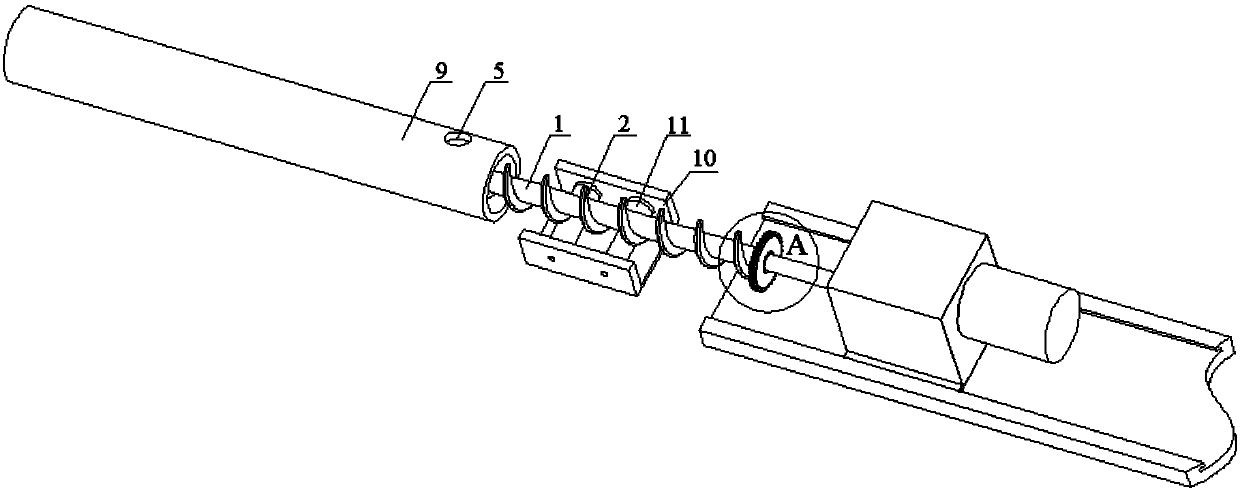

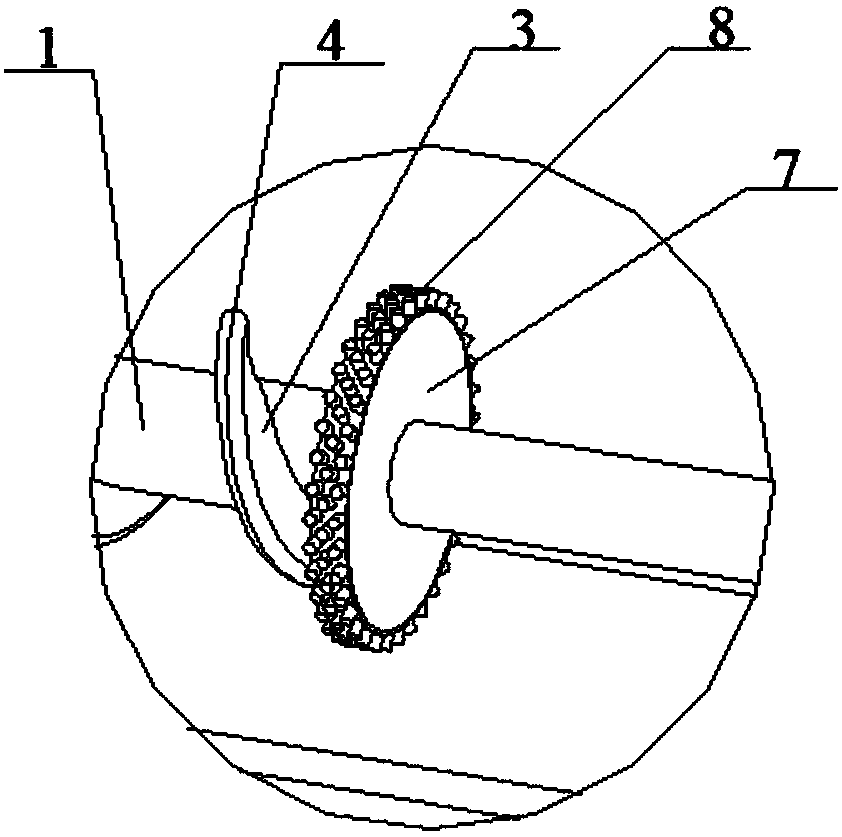

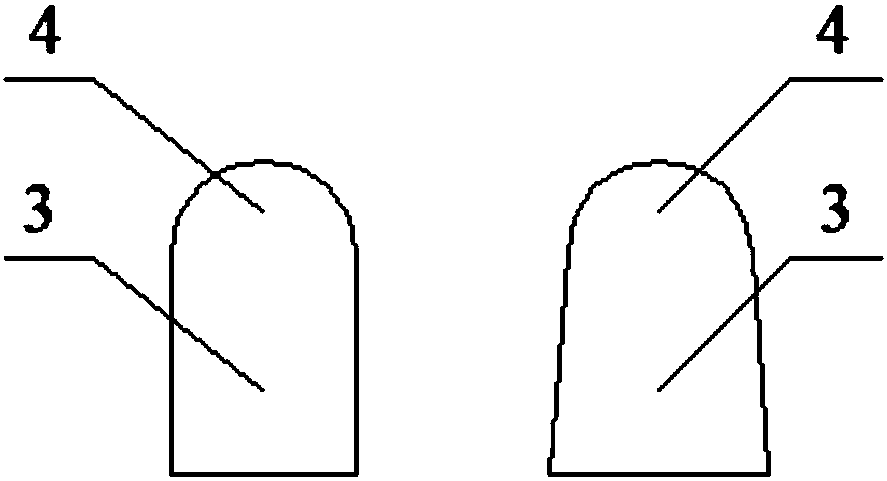

[0047] A pipeline cable conveying method with an auxiliary support structure, the method is completed by means of a cable conveying device, the cable conveying device includes a horizontal drilling machine, the cable 1 is fixedly connected to the drill pipe of the horizontal drilling machine, and the cable 1 is set and A helical blade 2 is fixed, and the helical blade 2 includes a blade root 3 and a blade tip 4 fixedly connected to the blade root 3. The cross section of the blade tip 4 is circular, and the ratio of the thickness L of the blade root 3 to the diameter D of the blade tip 4 is 1:1.1, the ratio of the outer diameter of the spiral blade 2 to the inner diameter of the pipe 9 is 0.8:1, both ends of the spiral blade 2 are discs 7, and the ratio of the diameter of the disc 7 to the inner diameter of the pipe 9 is 0.9:1, the periphery of the disc 7 is also provided with a brush ring 8, the outer diameter of the brush ring 8 is the same as the inner diameter of the pipelin...

Embodiment 2

[0052] A pipeline cable conveying method with an auxiliary support structure, the method is completed by means of a cable conveying device, the cable conveying device includes a horizontal drilling machine, the cable 1 is fixedly connected to the drill pipe of the horizontal drilling machine, and the cable 1 is set and A helical blade 2 is fixed, and the helical blade 2 includes a blade root 3 and a blade tip 4 fixedly connected to the blade root 3. The cross section of the blade tip 4 is circular, and the ratio of the thickness L of the blade root 3 to the diameter D of the blade tip 4 is 1:1, the ratio of the outer diameter of the spiral blade 2 to the inner diameter of the pipe 9 is 0.8:1, both ends of the spiral blade 2 are discs 7, and the ratio of the diameter of the disc 7 to the inner diameter of the pipe 9 is 0.8:1, the periphery of the disc 7 is also provided with a brush ring 8, the outer diameter of the brush ring 8 is the same as the inner diameter of the pipeline ...

Embodiment 3

[0057] A pipeline cable conveying method with an auxiliary support structure, the method is completed by means of a cable conveying device, the cable conveying device includes a horizontal drilling machine, the cable 1 is fixedly connected to the drill pipe of the horizontal drilling machine, and the cable 1 is set and A helical blade 2 is fixed, and the helical blade 2 includes a blade root 3 and a blade tip 4 fixedly connected to the blade root 3. The cross section of the blade tip 4 is circular, and the ratio of the thickness L of the blade root 3 to the diameter D of the blade tip 4 is 1:1.2, the ratio of the outer diameter of the spiral blade 2 to the inner diameter of the pipe 9 is 0.8:1, both ends of the spiral blade 2 are discs 7, and the ratio of the diameter of the disc 7 to the inner diameter of the pipe 9 is 0.8:1, the periphery of the disc 7 is also provided with a brush ring 8, the outer diameter of the brush ring 8 is the same as the inner diameter of the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com