Wettability-patterning method and designs for pumpless transport and precise manipulation of liquid volumes on and through porous materials

A liquid volume, porous substrate technology, used in chemical instruments and methods, fluid controllers, laboratory containers, etc., can solve problems such as unproven combinations, and achieve the effect of simple manufacturing process and improved delivery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

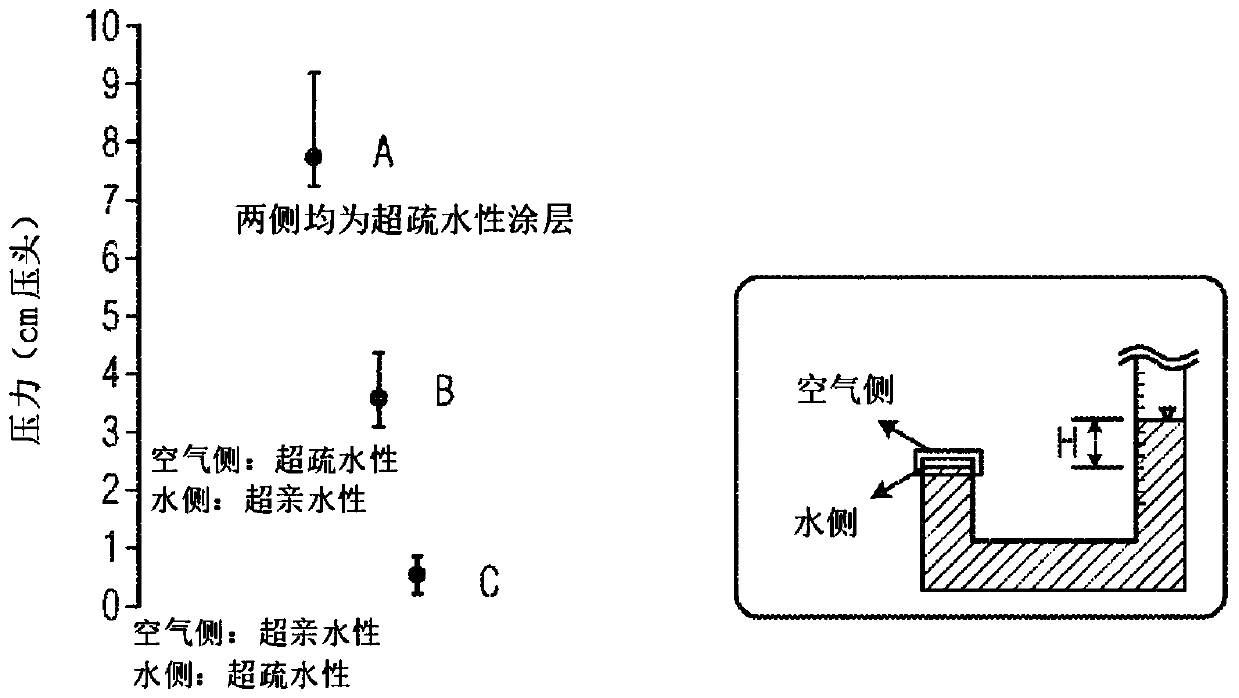

Method used

Image

Examples

Embodiment

[0082] The following contents are provided for the exemplary purpose of facilitating understanding of the present disclosure, and should not be construed as limiting the present disclosure to these examples. Other formulations and substrates may also be used within the scope of this disclosure and the claims set forth below.

[0083] In one specific example, TiO in a matrix of hydrophobic fluoroacrylic polymer (PMC) (20% by weight in water; DuPont, Capstone ST-100) was used by spraying. 2 Filler particles were applied to a porous substrate in the form of 38 gsm high density tissue (HDPT) KLEENEX 50606 brand rigid roll tissue (from Kimberly-Clark) to render the substrate superhydrophobic. Facile patterning techniques that have been previously deployed on solid substrates are applicable to HDPT. Surface preparation consists of two basic steps:

[0084] 1. Spray TiO on the substrate 2 The nanoparticles and PMC were then dried in an oven (Model 10GC; QuincyLab, Inc.) at 80°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com