Patents

Literature

154results about "Manufacturing winding connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

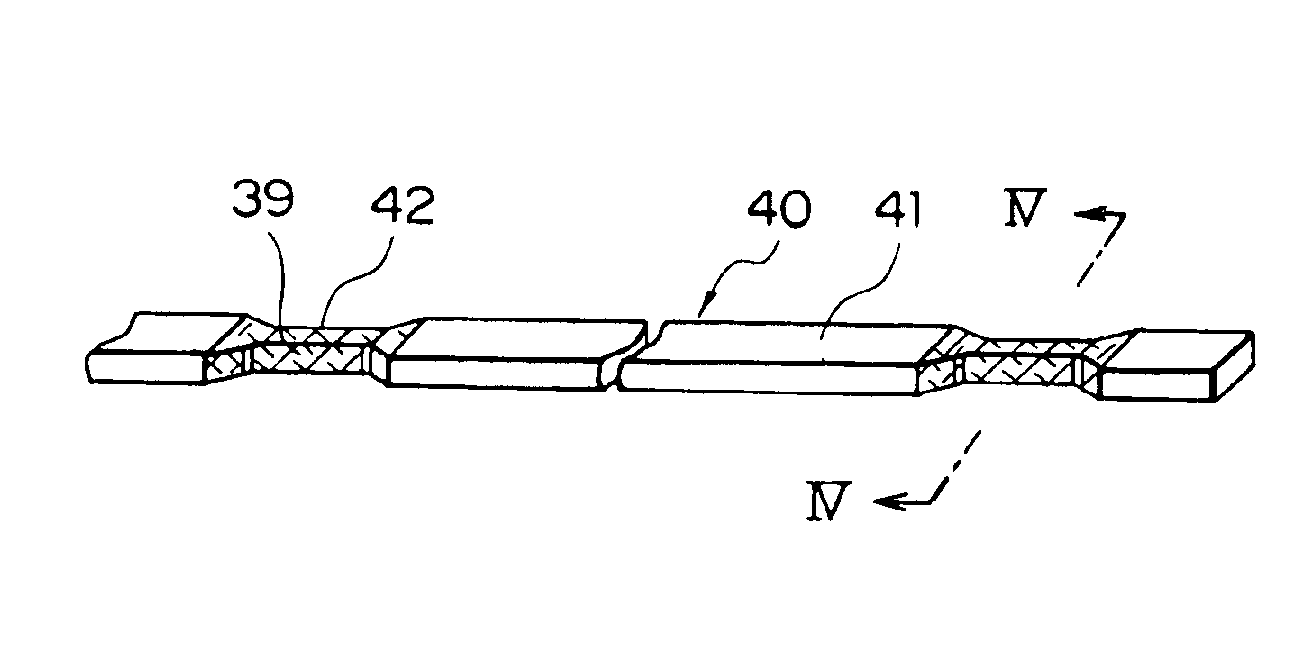

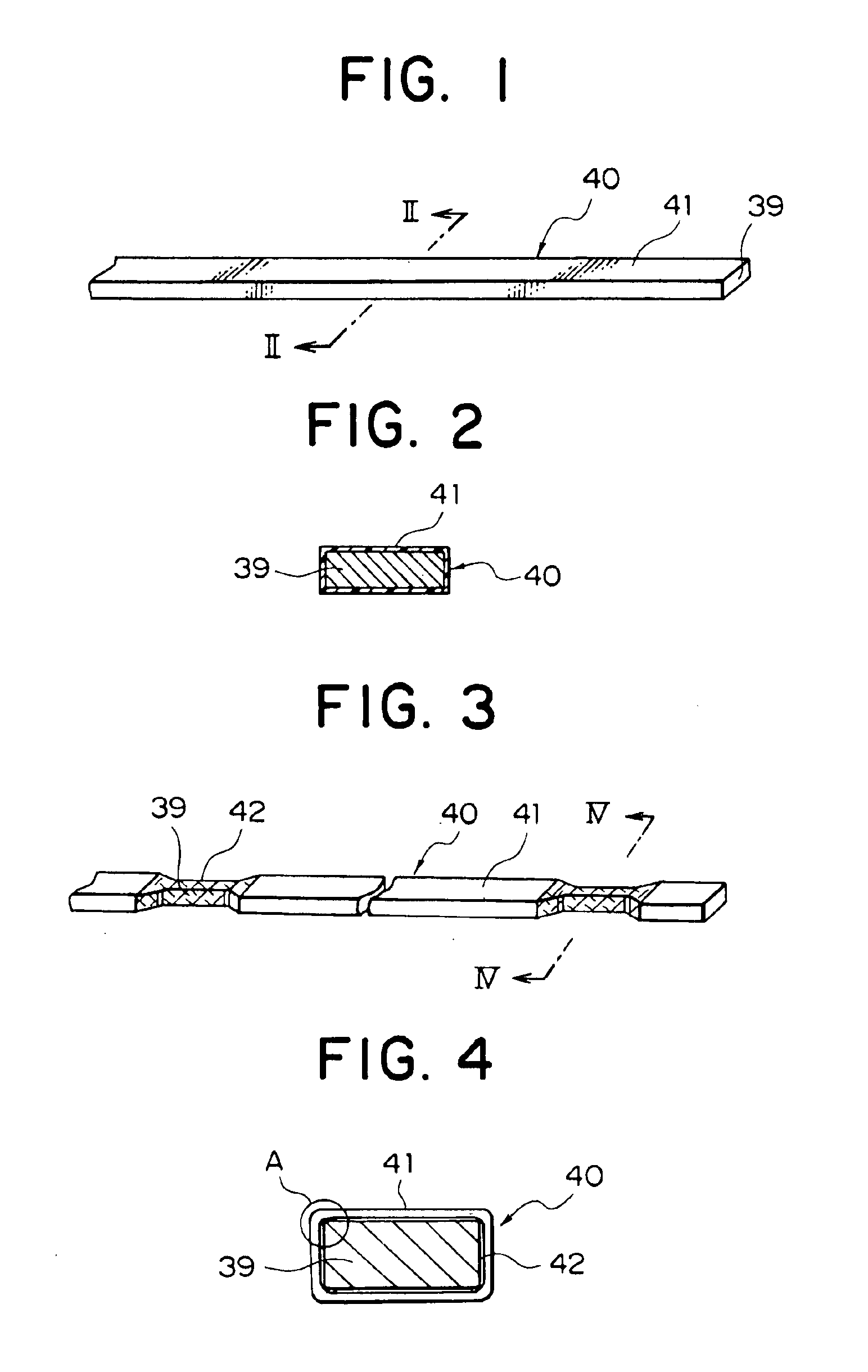

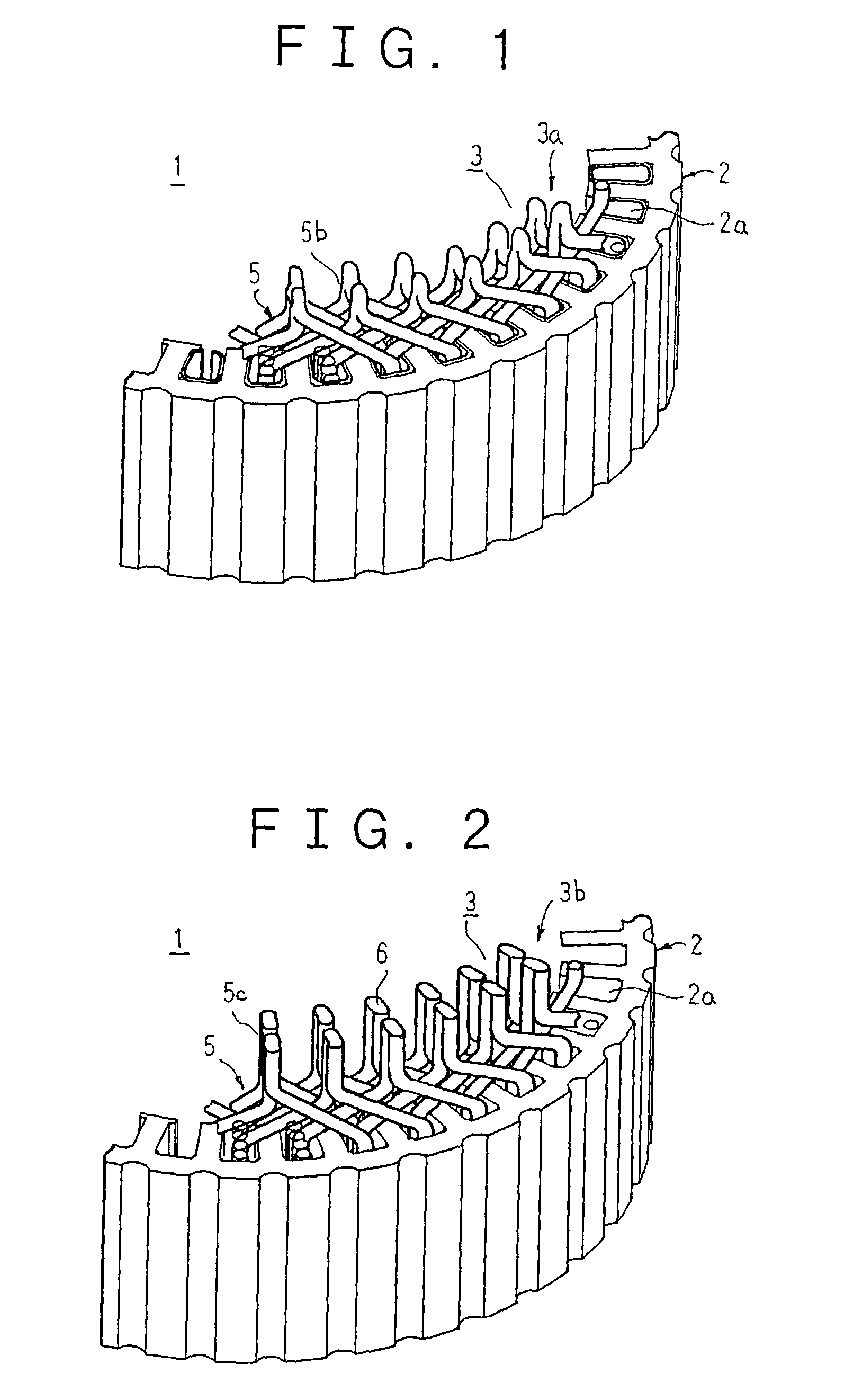

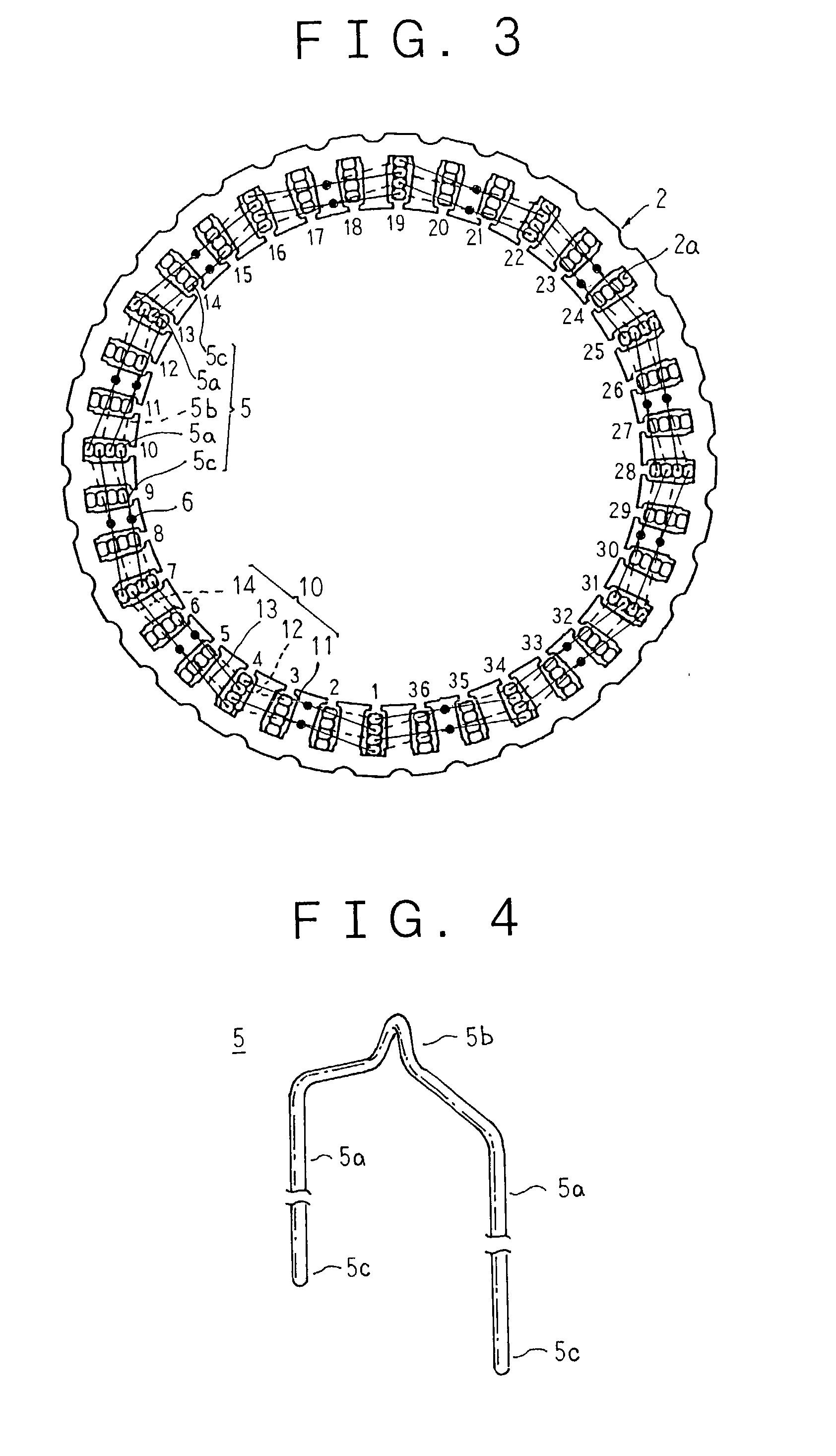

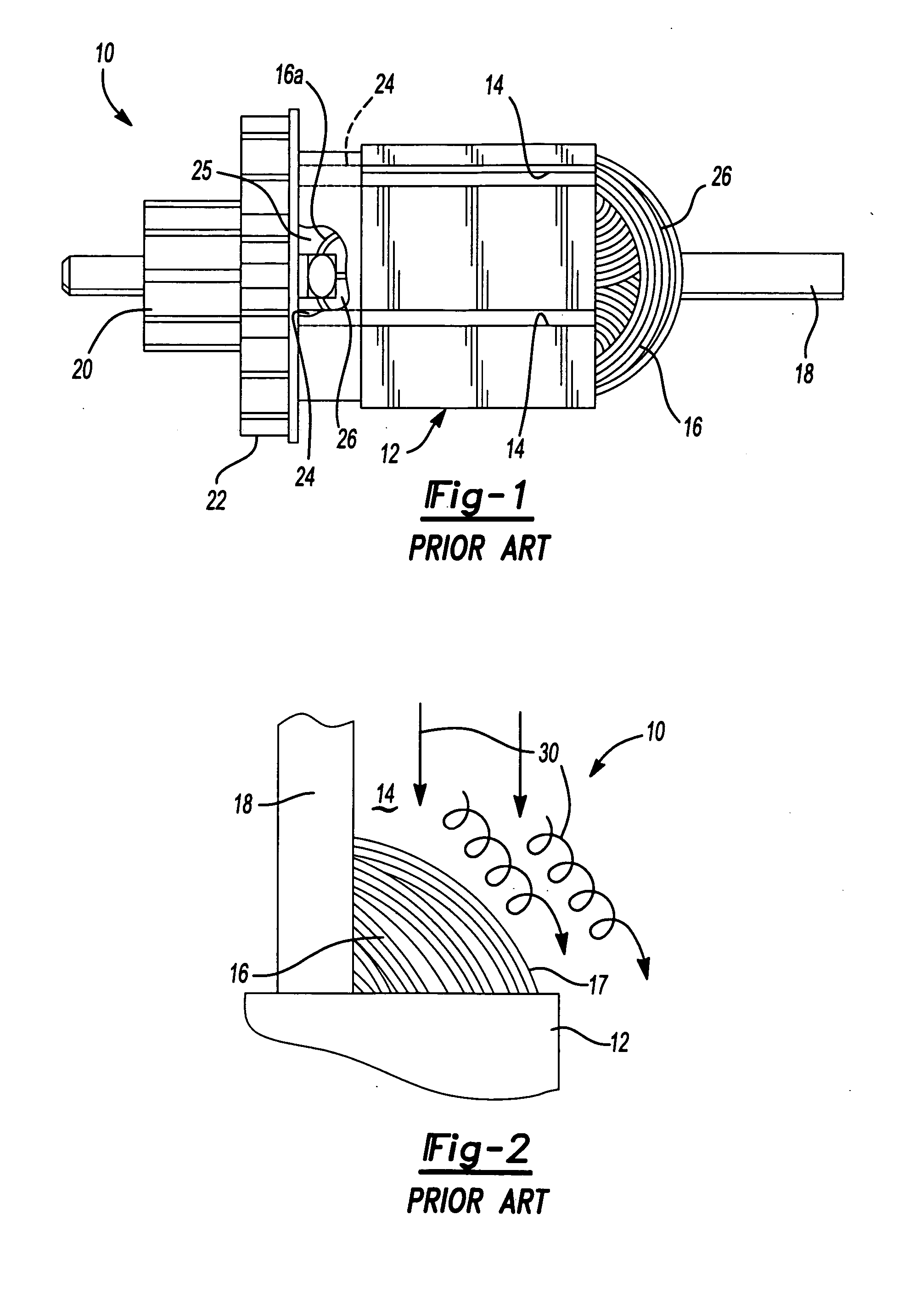

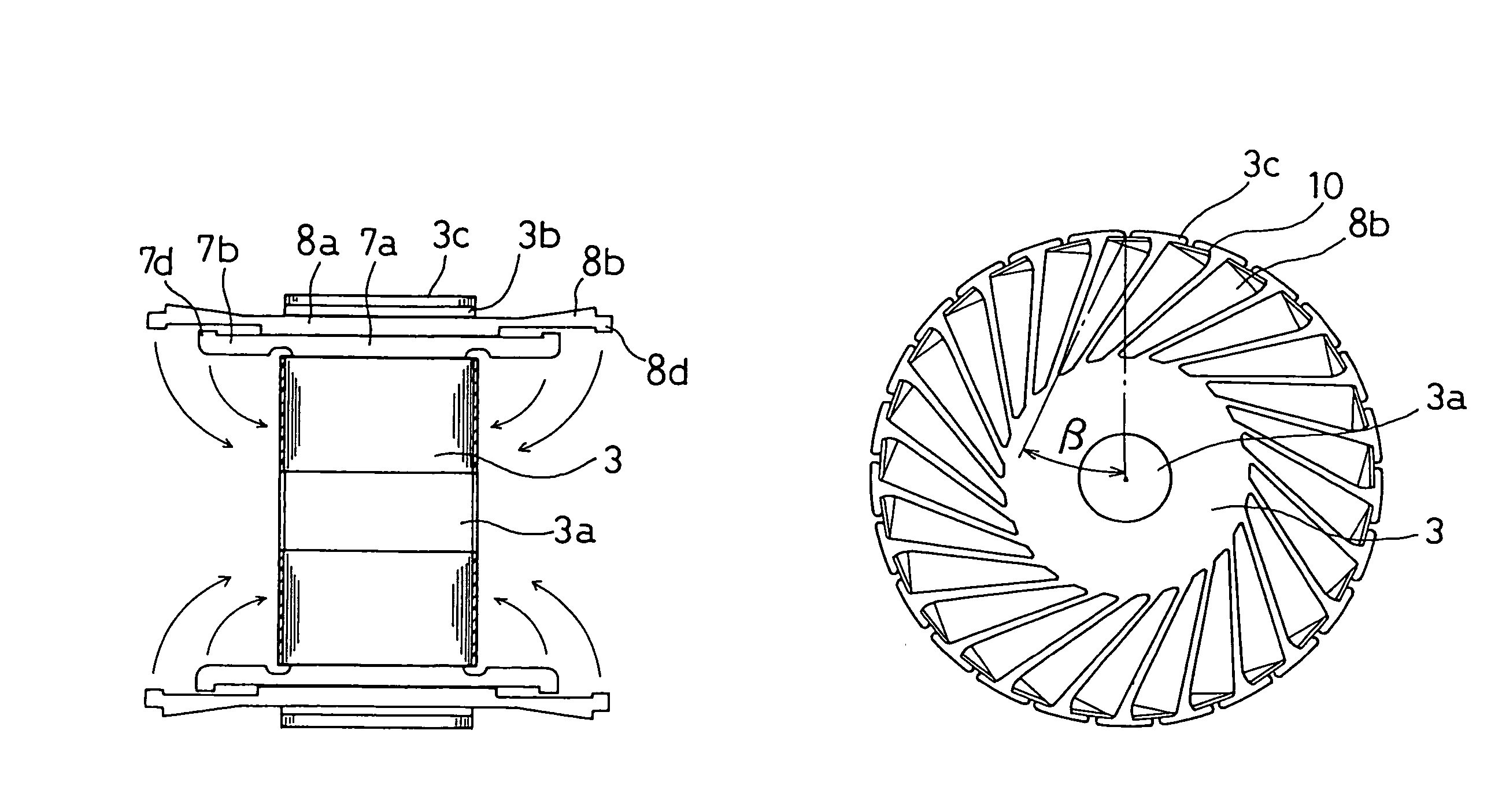

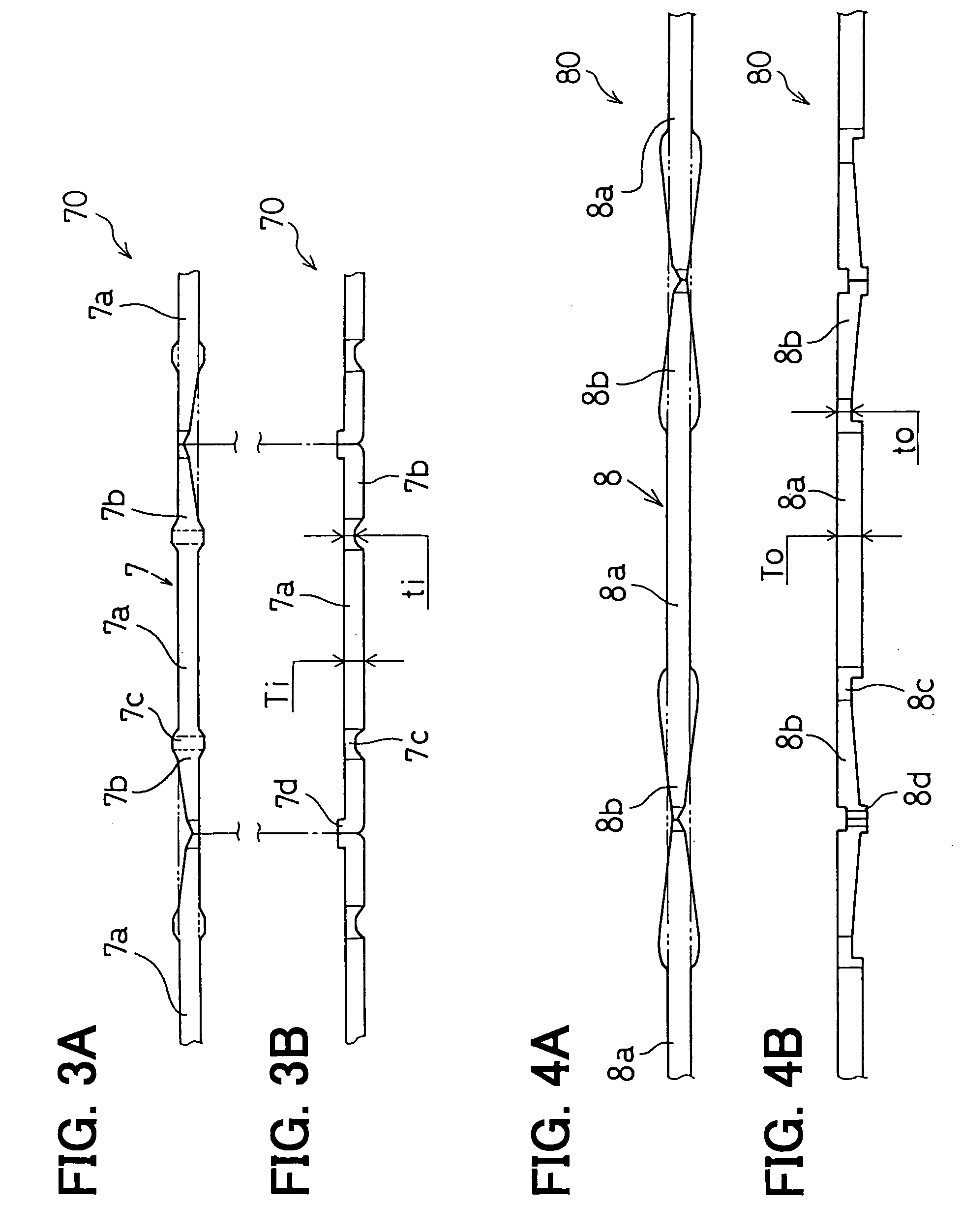

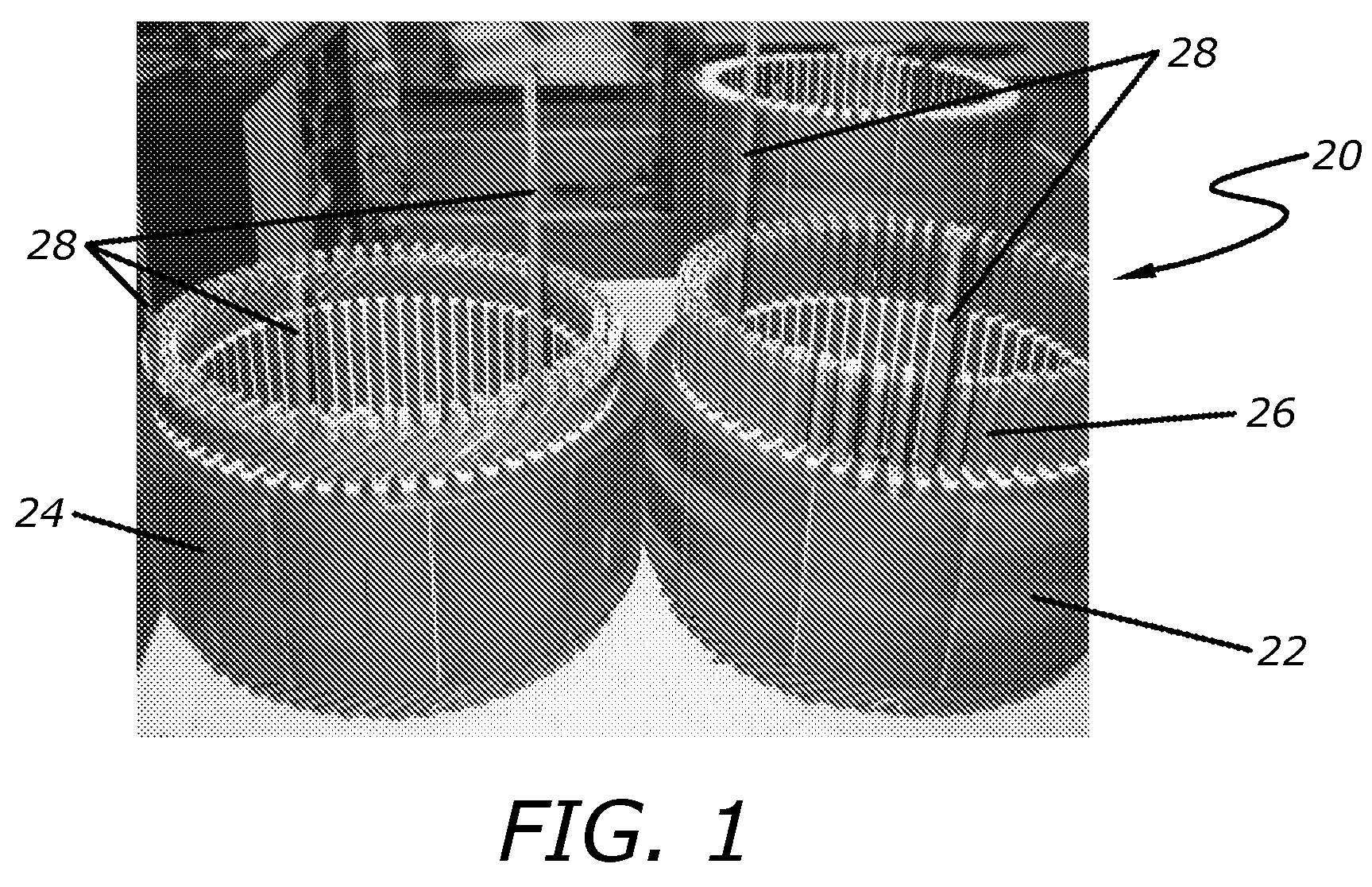

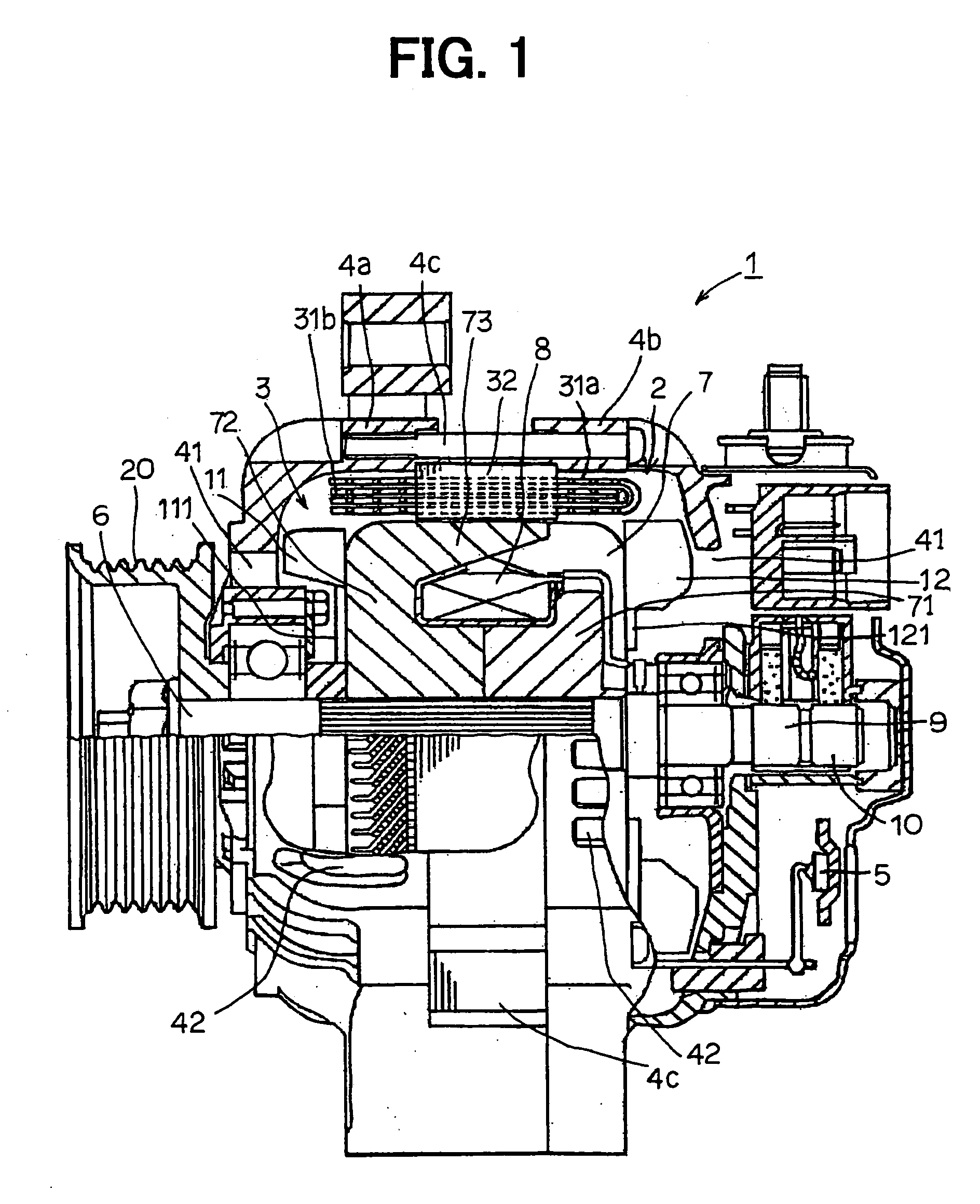

Method of manufacturing a stator for an alternator with reduced conductor portions

InactiveUS6865796B1Improve reliabilityImprove productivityWindings insulation shape/form/constructionManufacturing winding connectionsElectrical conductorAlternator

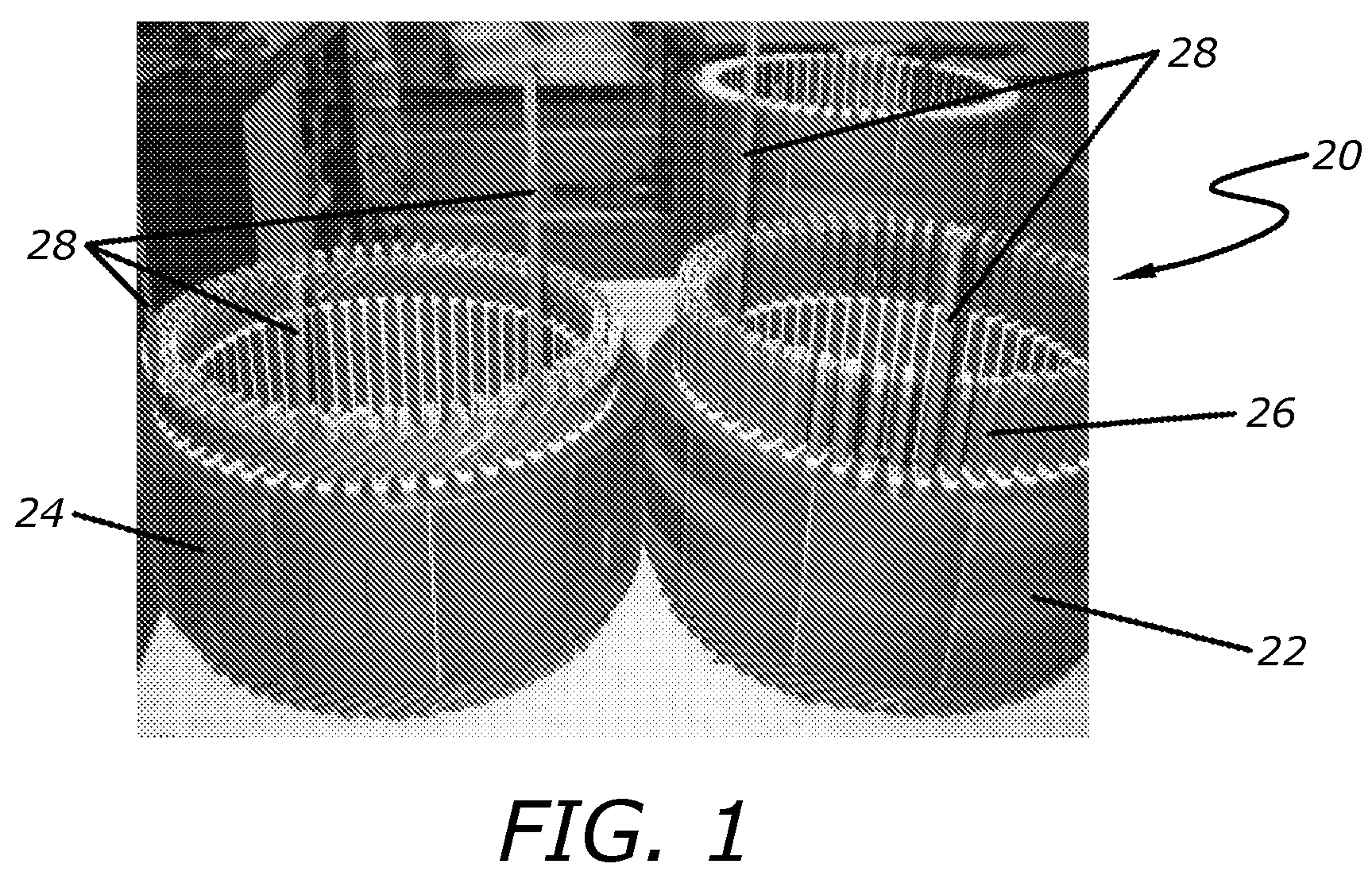

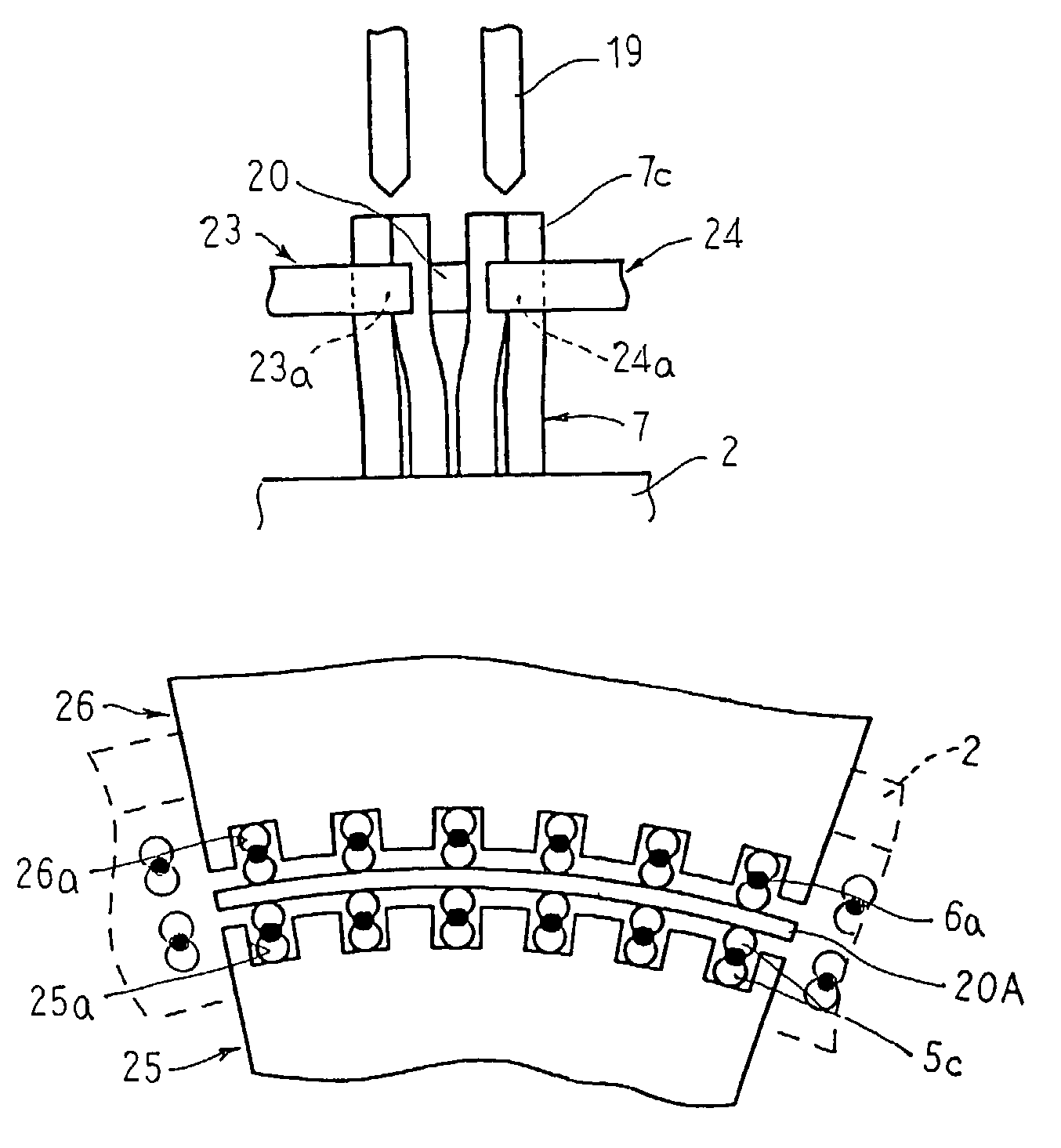

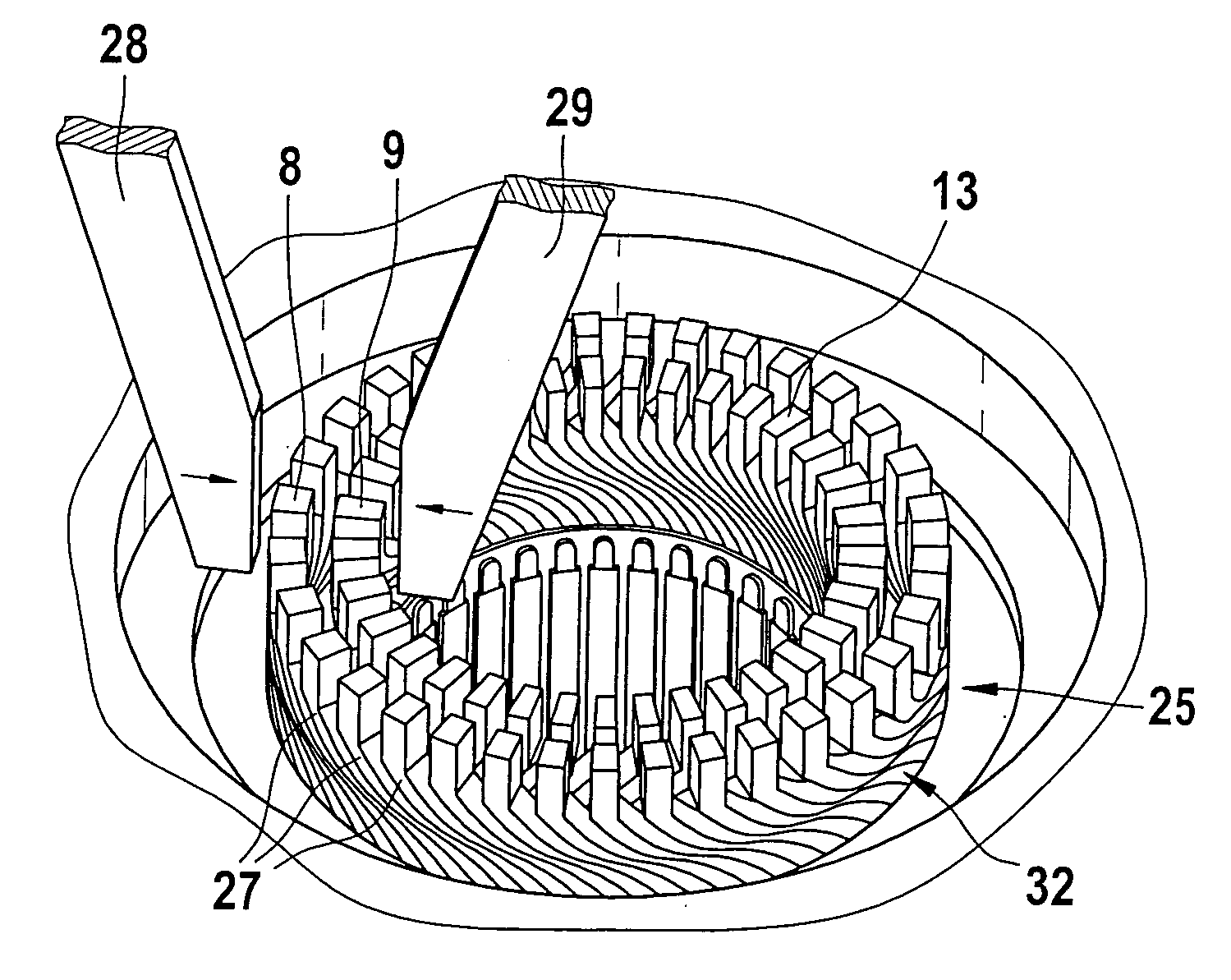

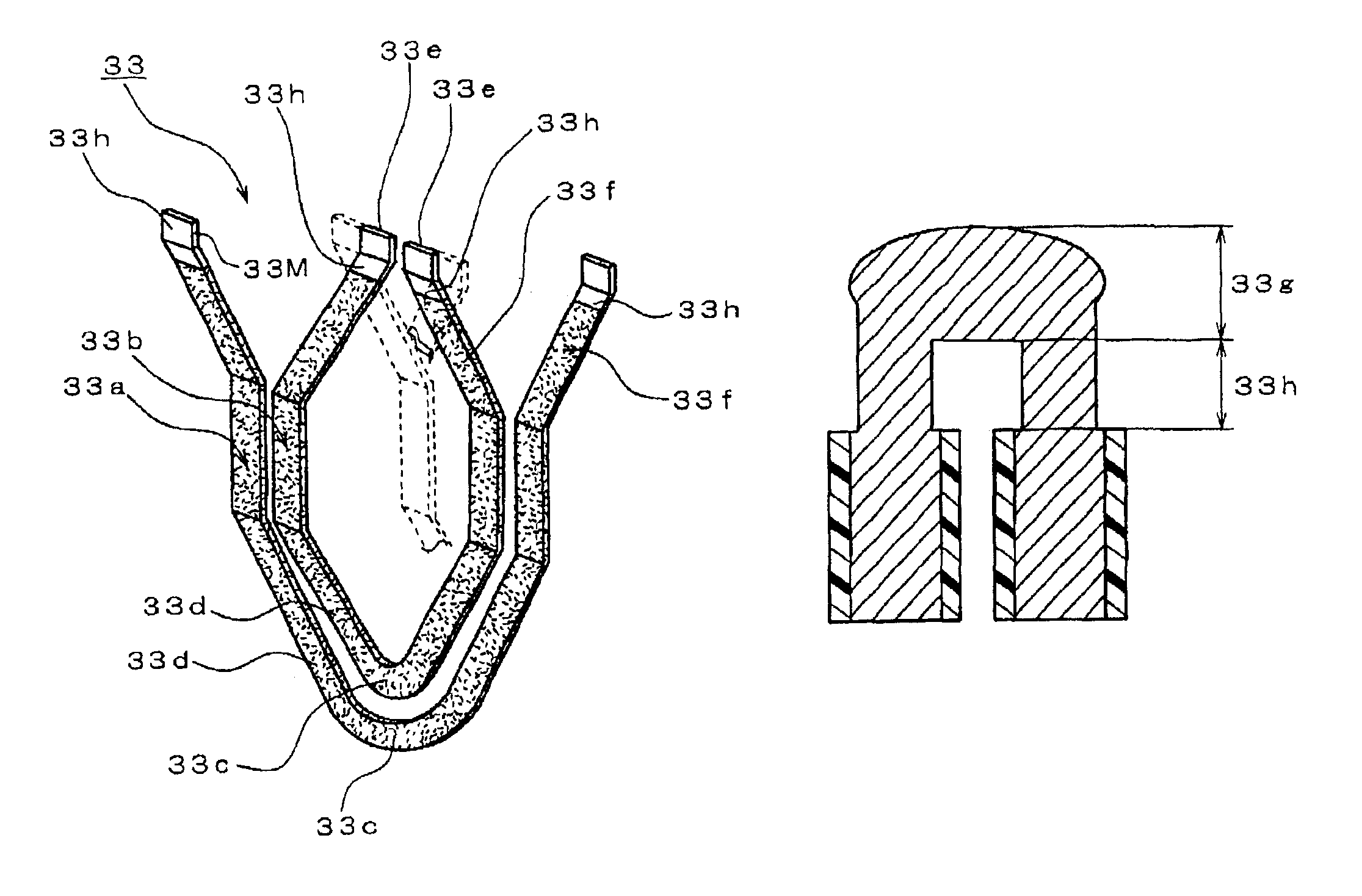

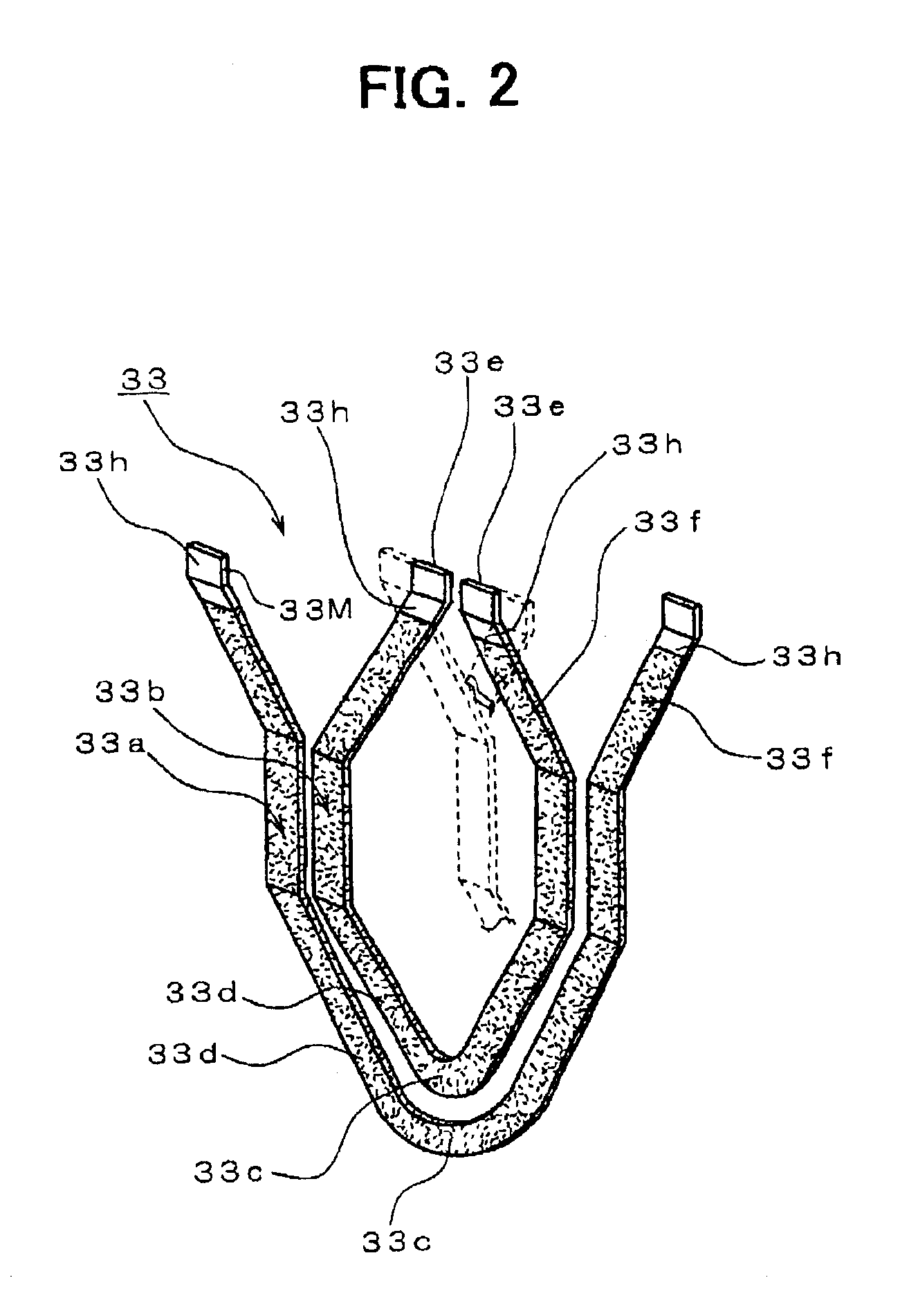

Coil members are obtained by forming width-reduced portions in a wire material over a predetermined longitudinal range generally centered on cutting positions, then removing an insulation coating from the width-reduced portions, and thereafter cutting the wire material at the width-reduced portions. Coil segments are prepared by bending the coil members into a general U shape. Then the coil segments are inserted into the slots in a stator core, and a stator is obtained by welding together the free end portions of the projecting coil segments.

Owner:MITSUBISHI ELECTRIC CORP

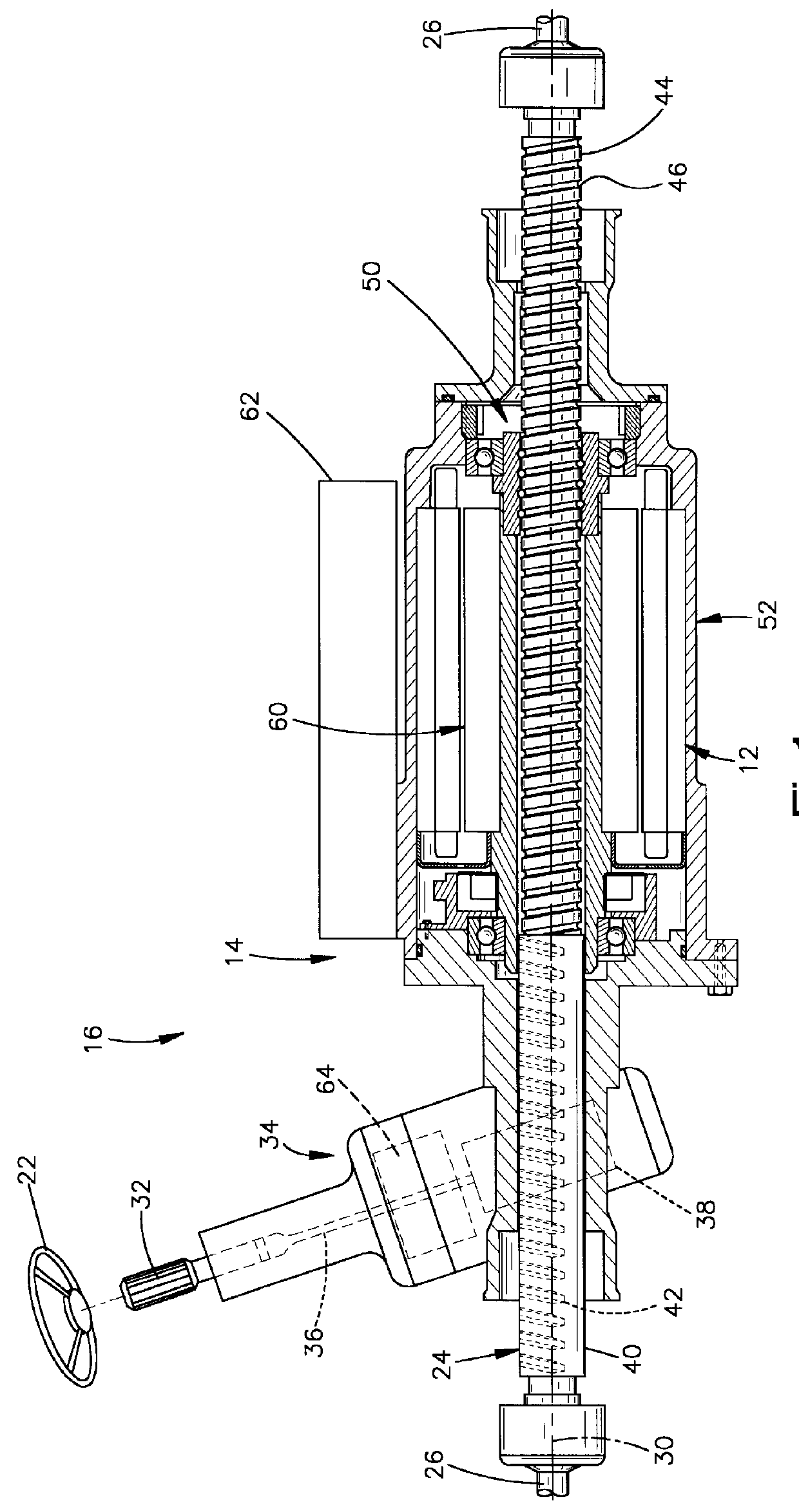

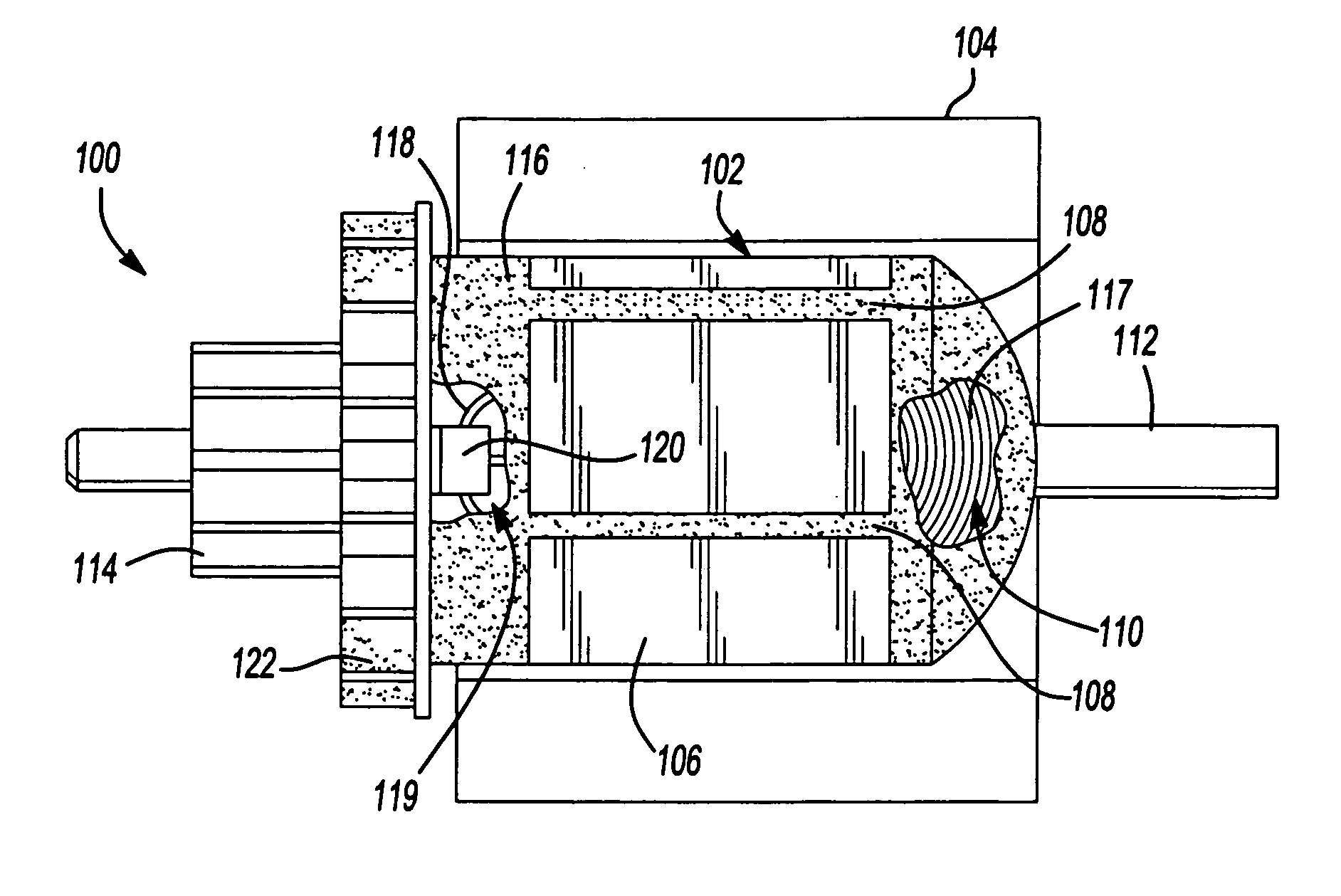

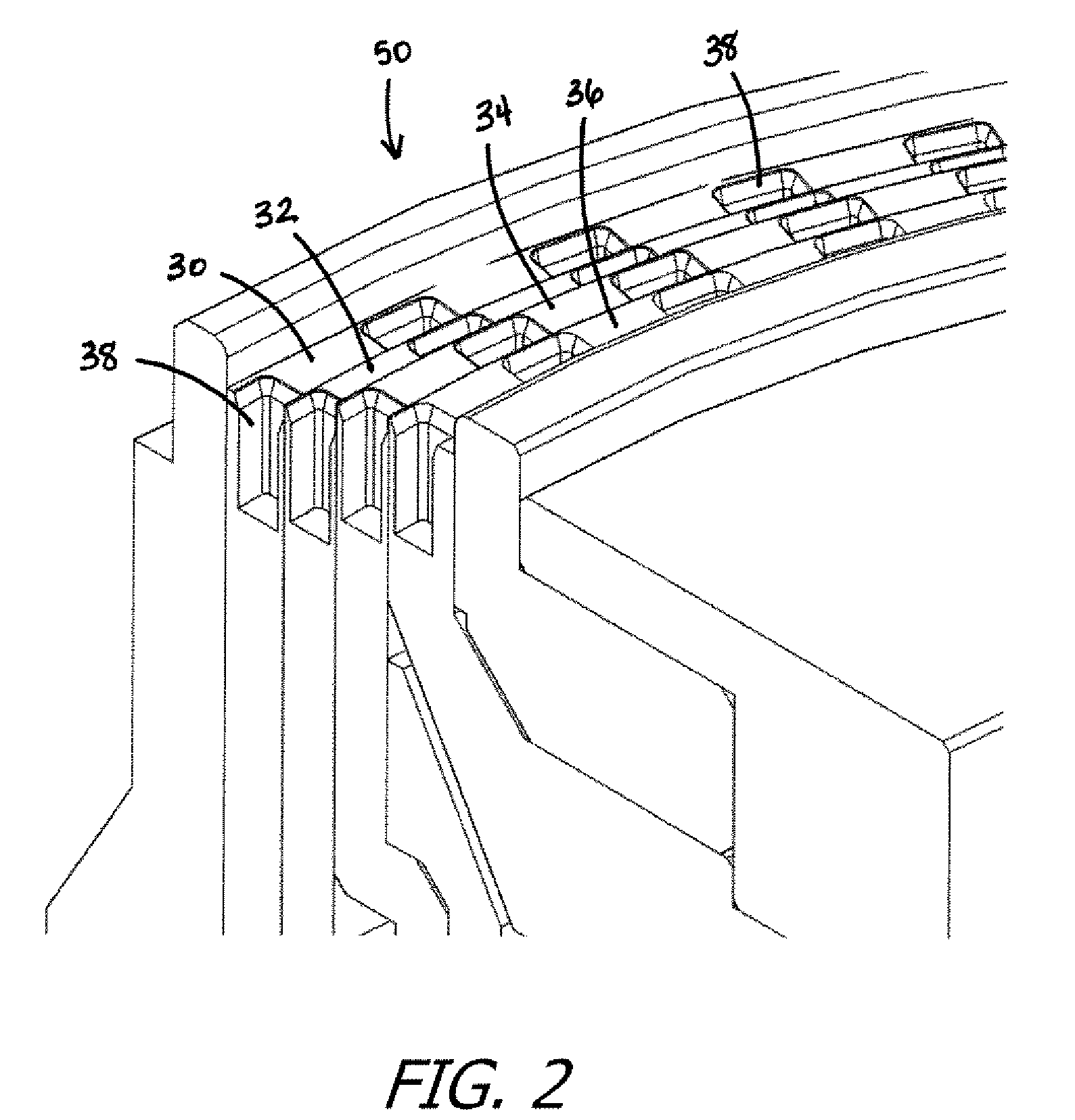

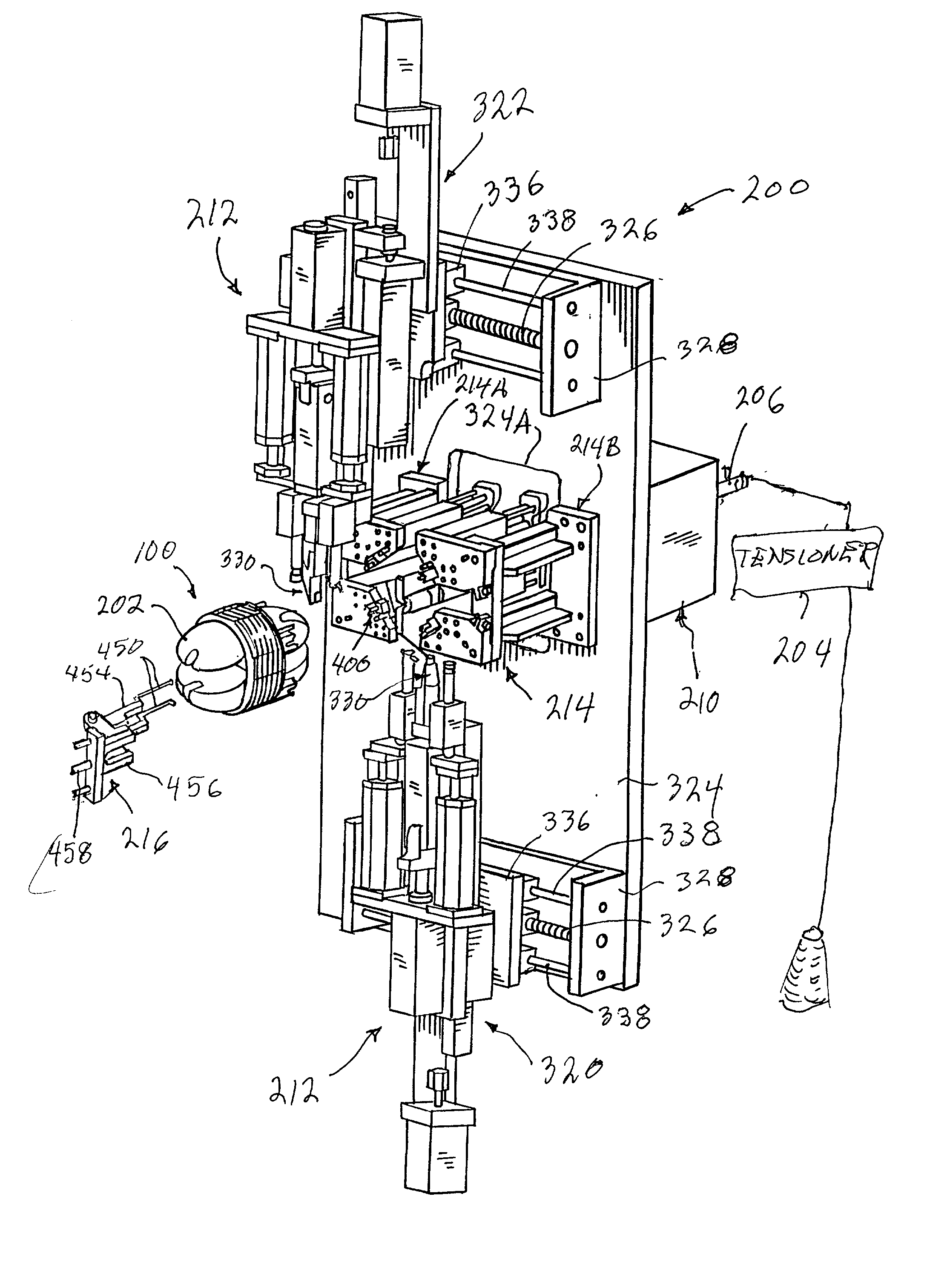

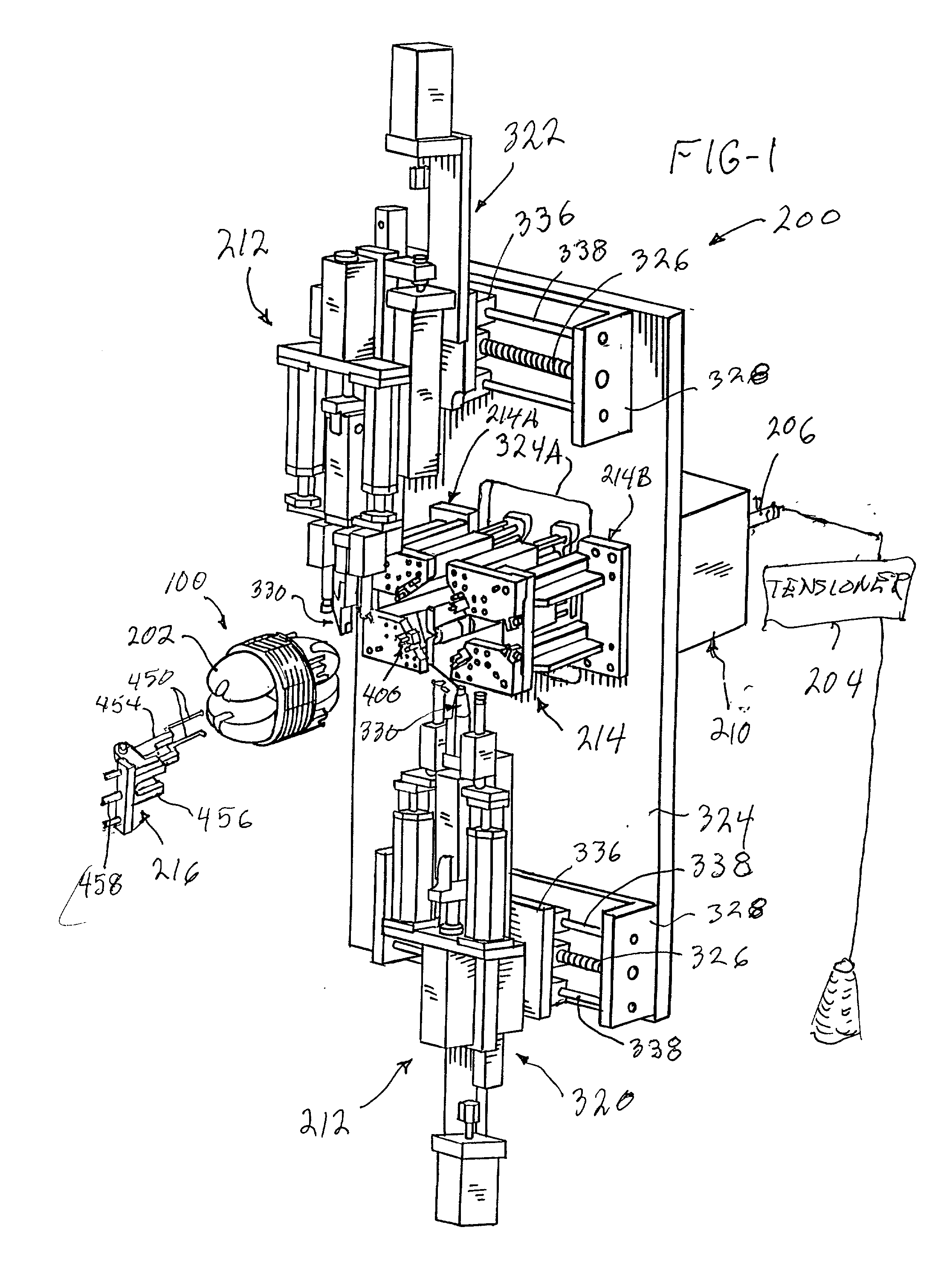

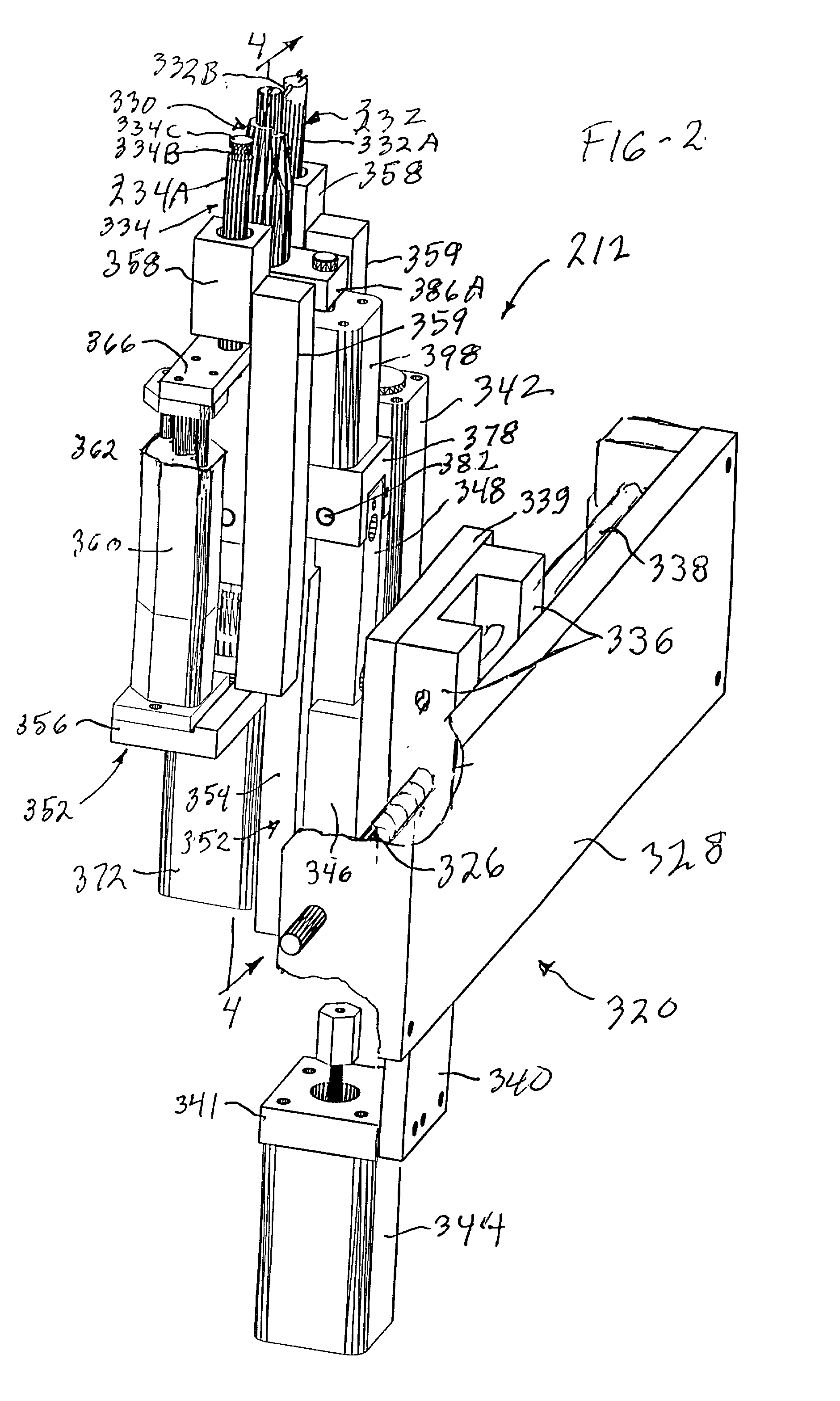

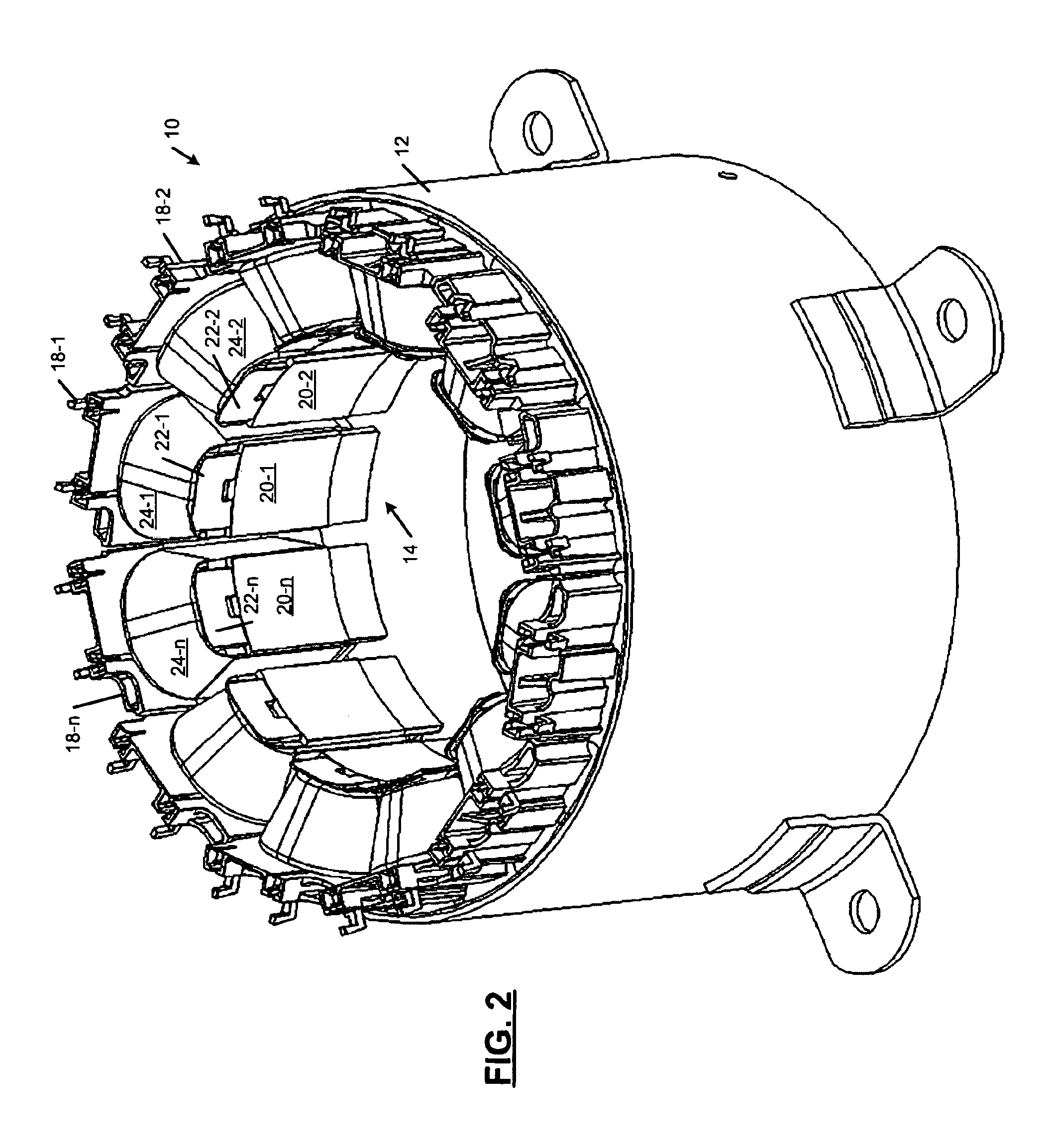

Methods and apparatus for twisting rotor and stator conductor ends

ActiveUS20090302705A1Magnetic circuit rotating partsSynchronous machinesElectrical conductorEngineering

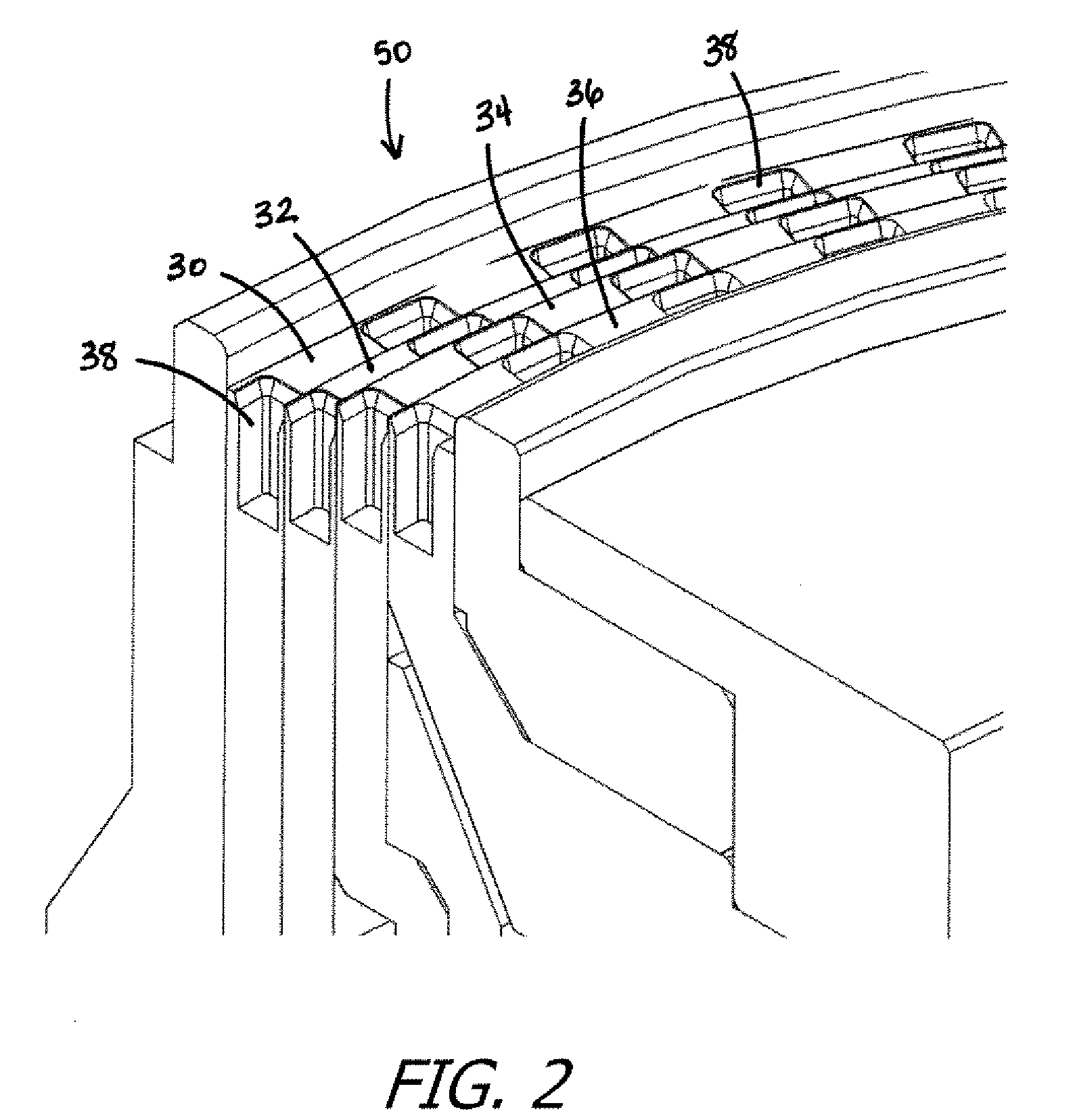

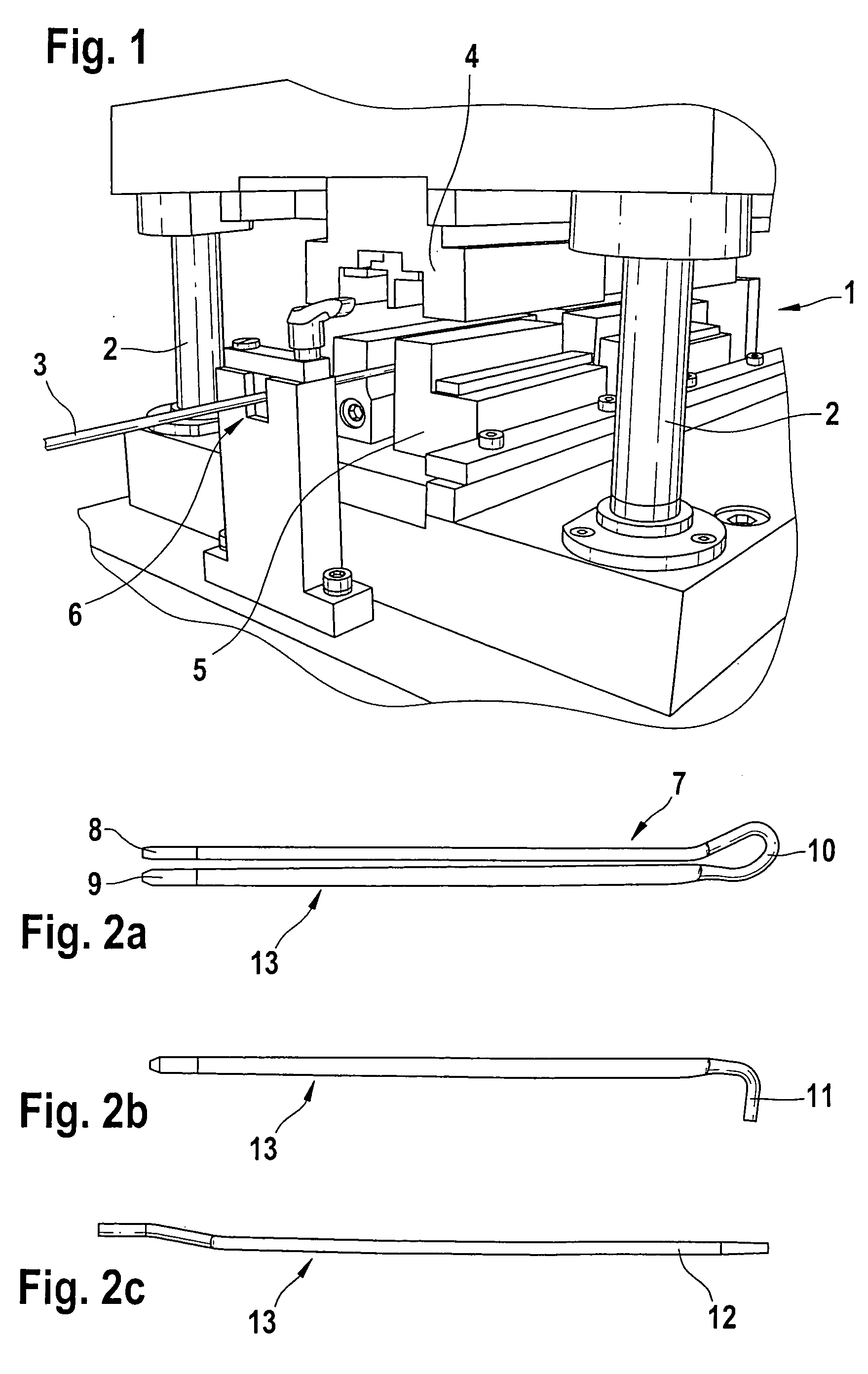

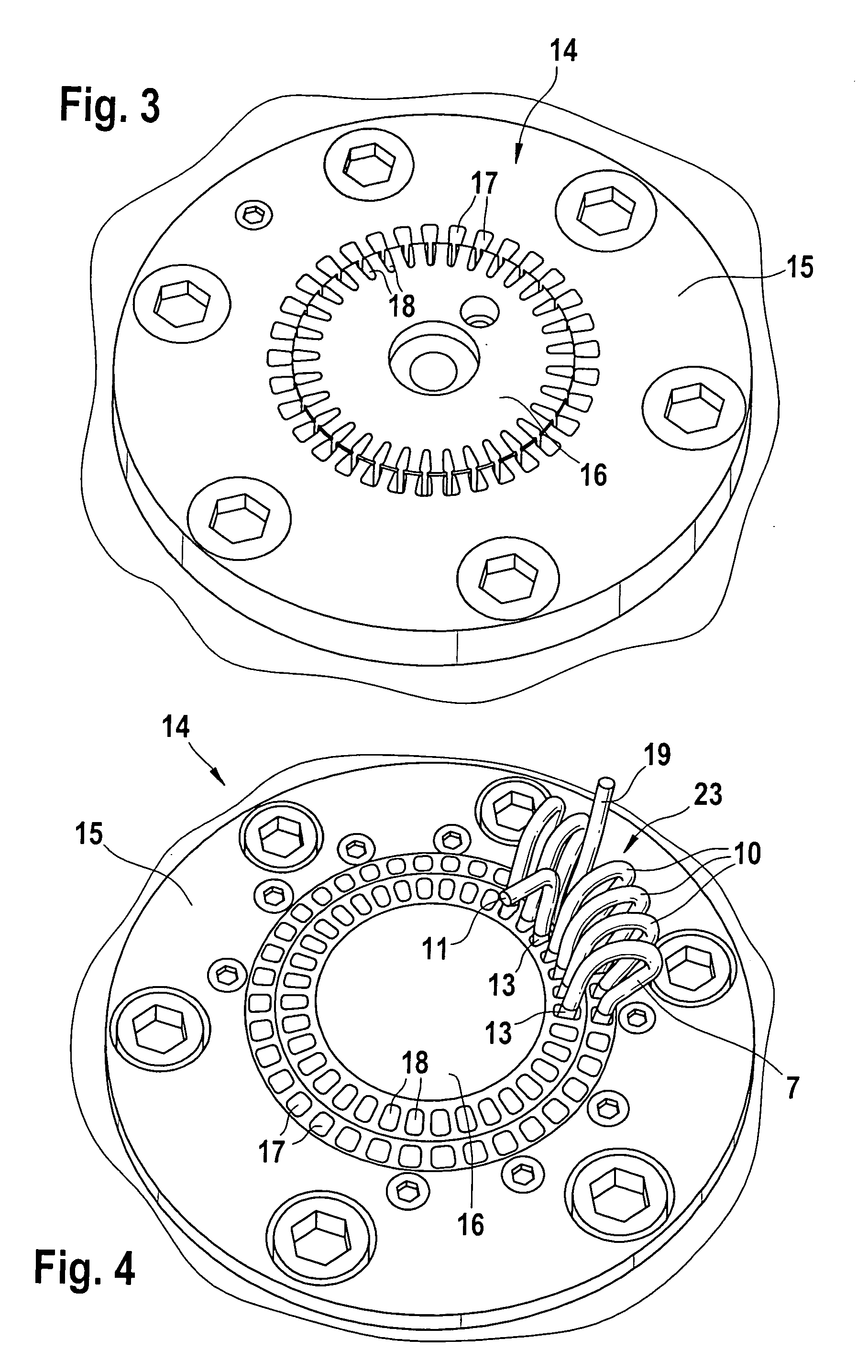

Methods and apparatus for twisting rectangular rotor and stator conductor ends whereby most if not all conductor ends are bent at once, radially adjacent ends being bent in opposite directions. A lost motion member may be used to bend selected conductors through lesser angles for such purposes as phase interconnection and power leads. The rectangular conductors are retained against twisting so that flat conductors will bend about an axis perpendicular to the larger dimension of the conductor cross section. Various features of the methods and apparatus are disclosed.

Owner:TECNOMATIC

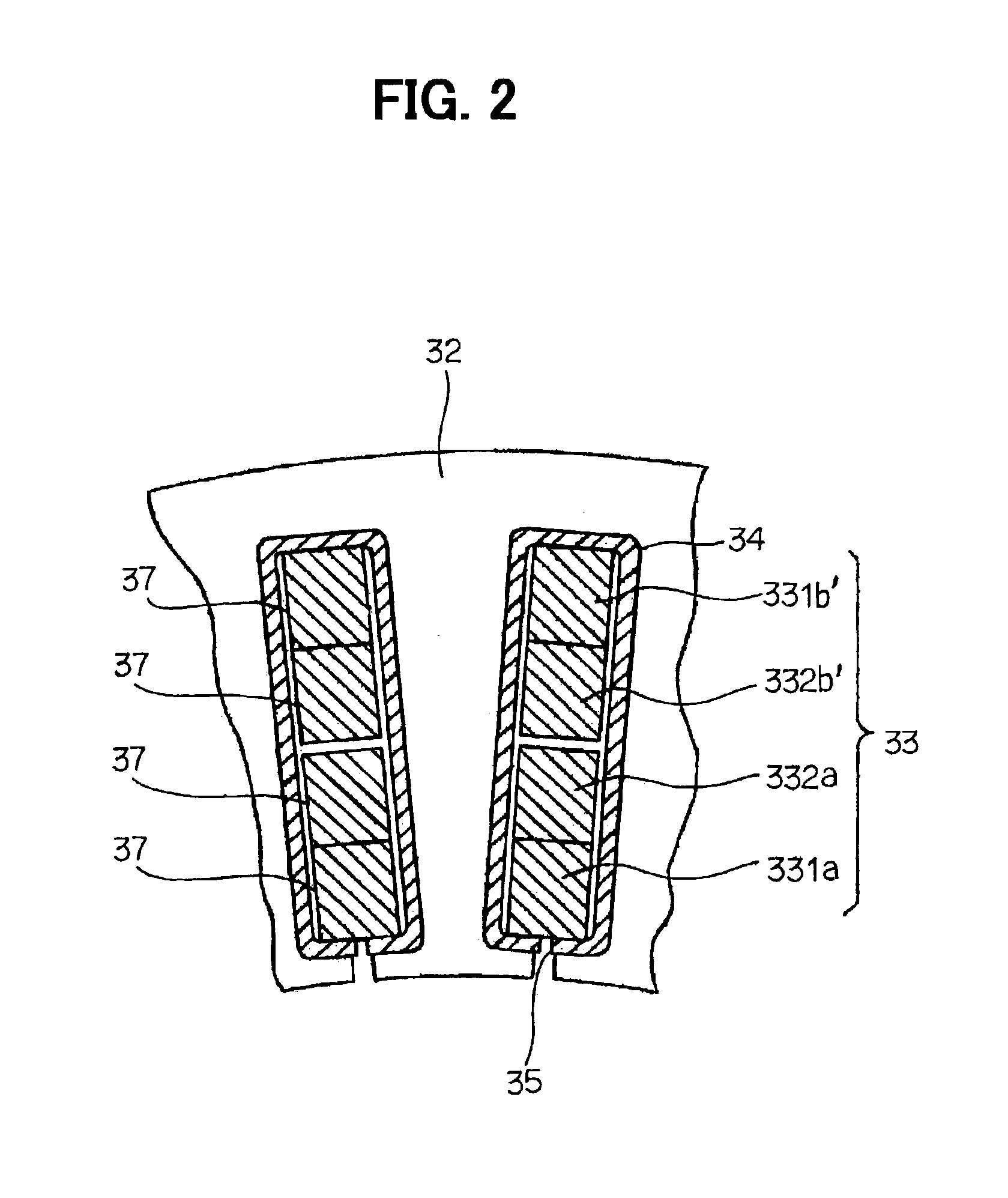

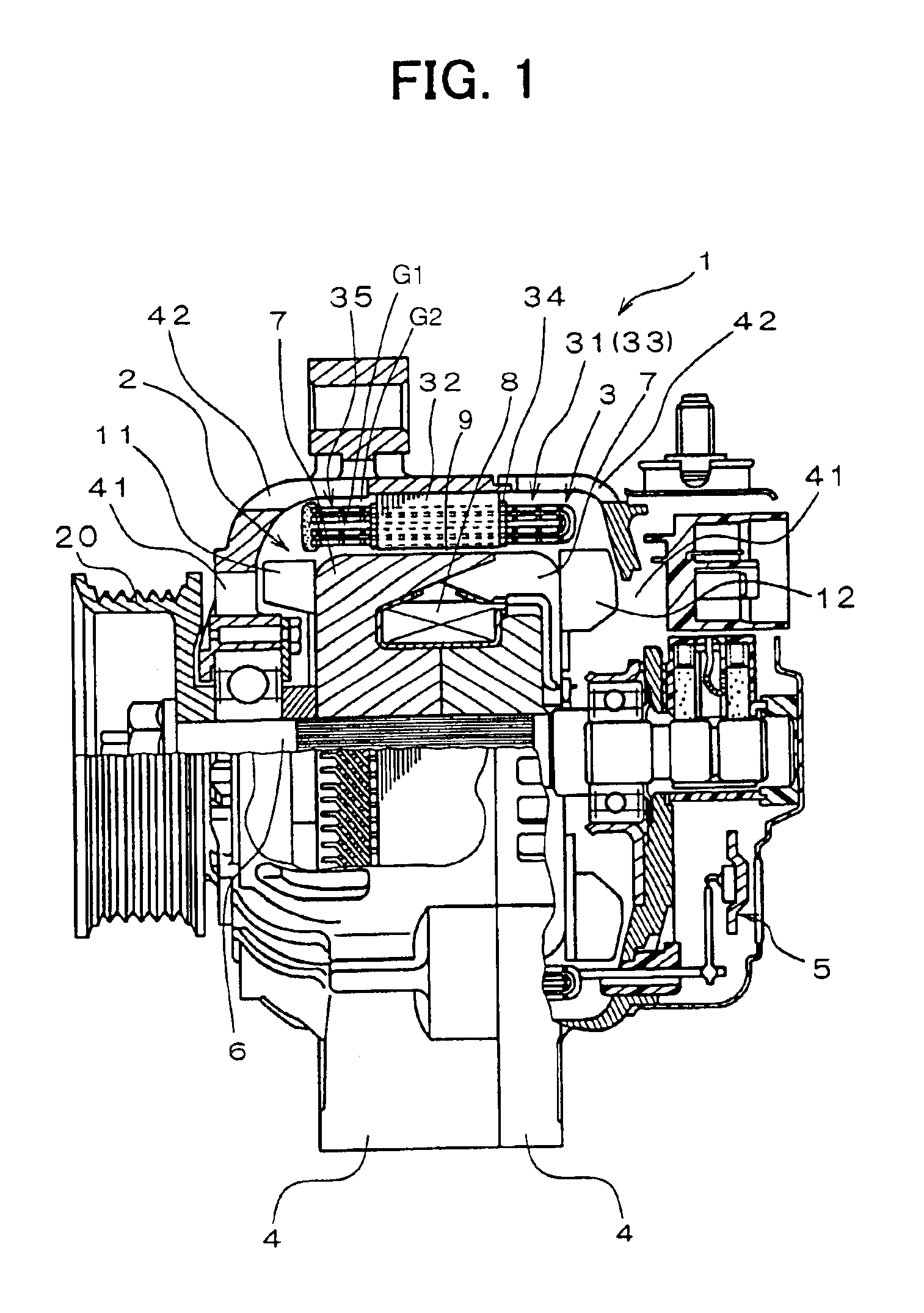

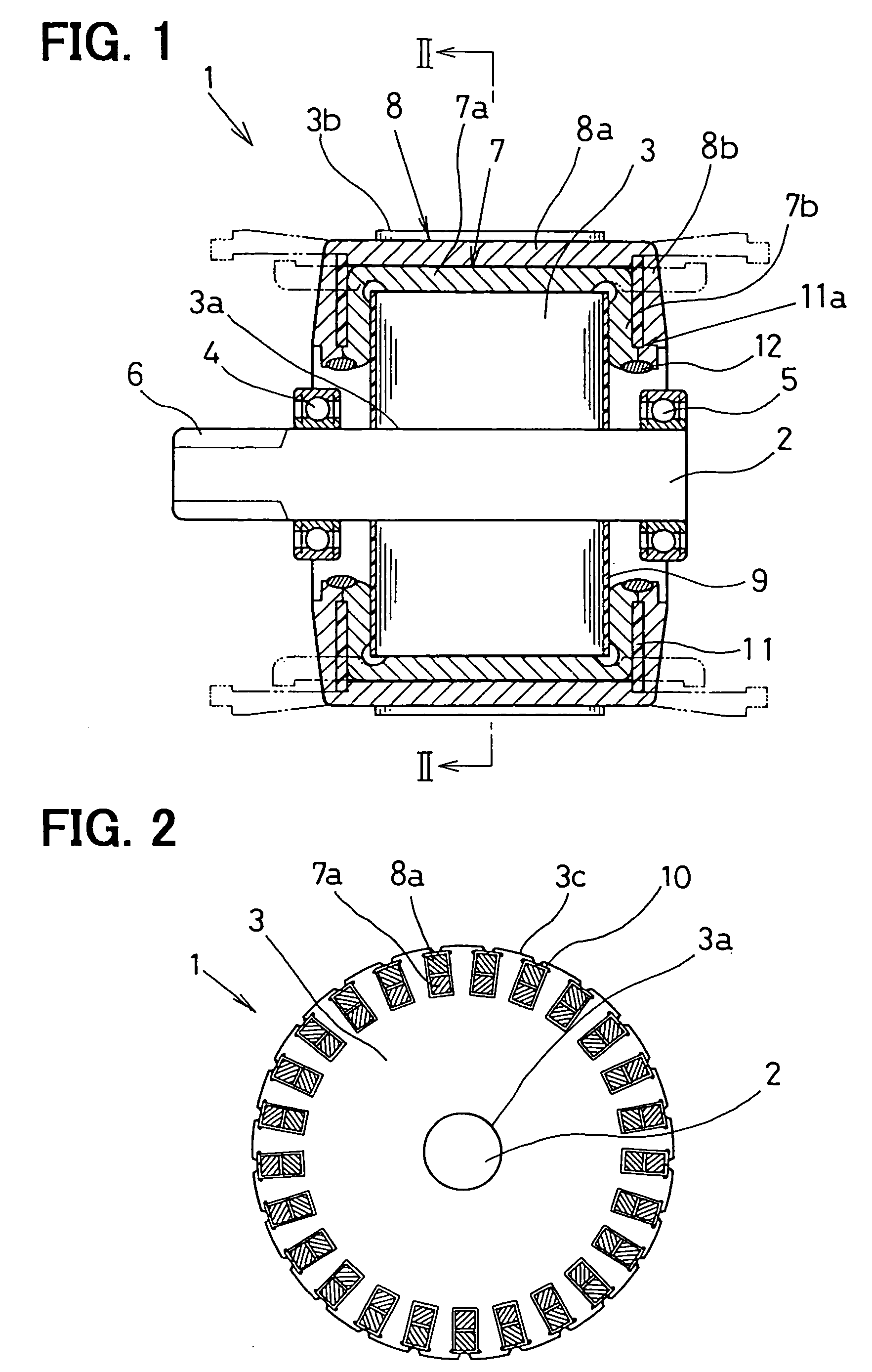

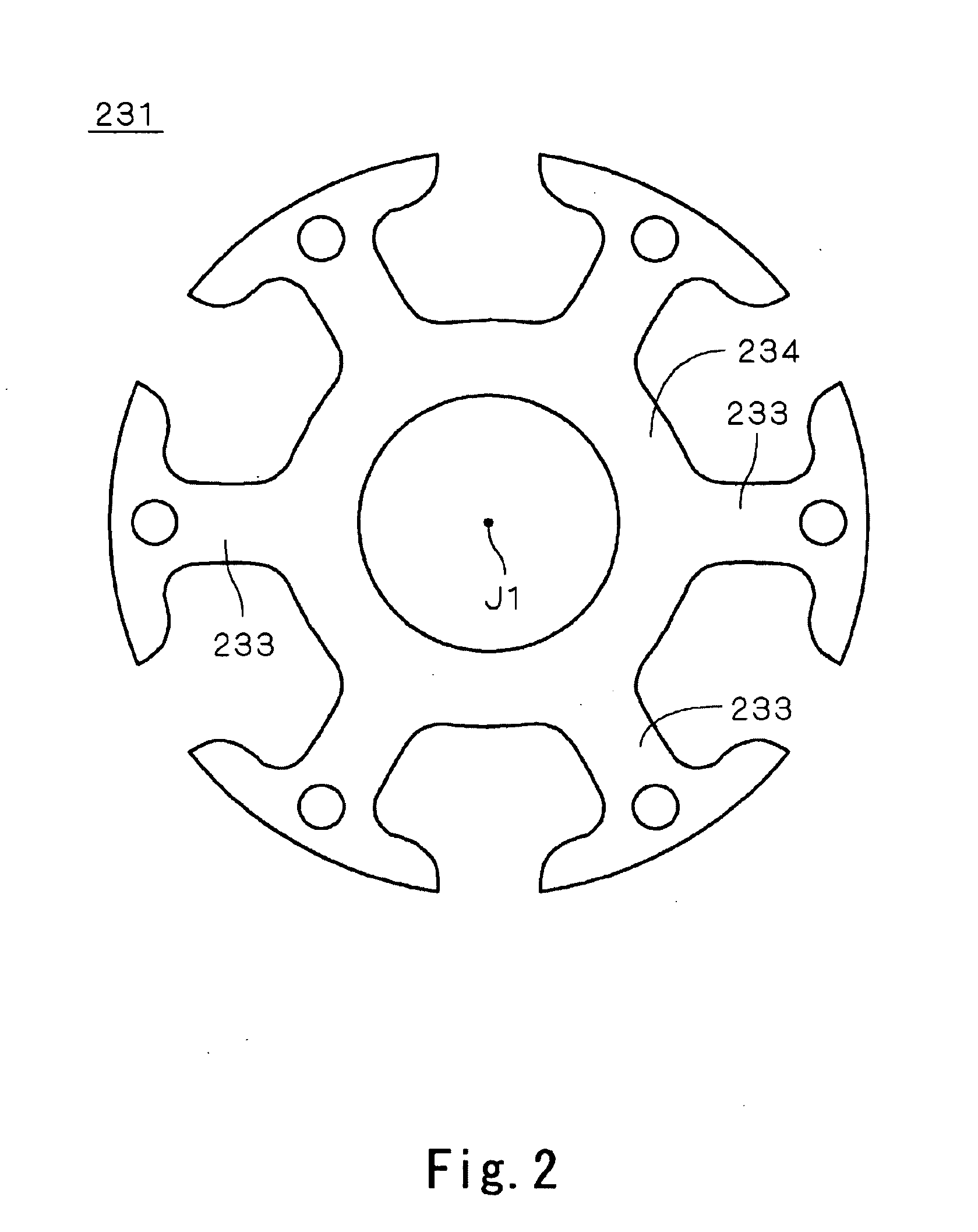

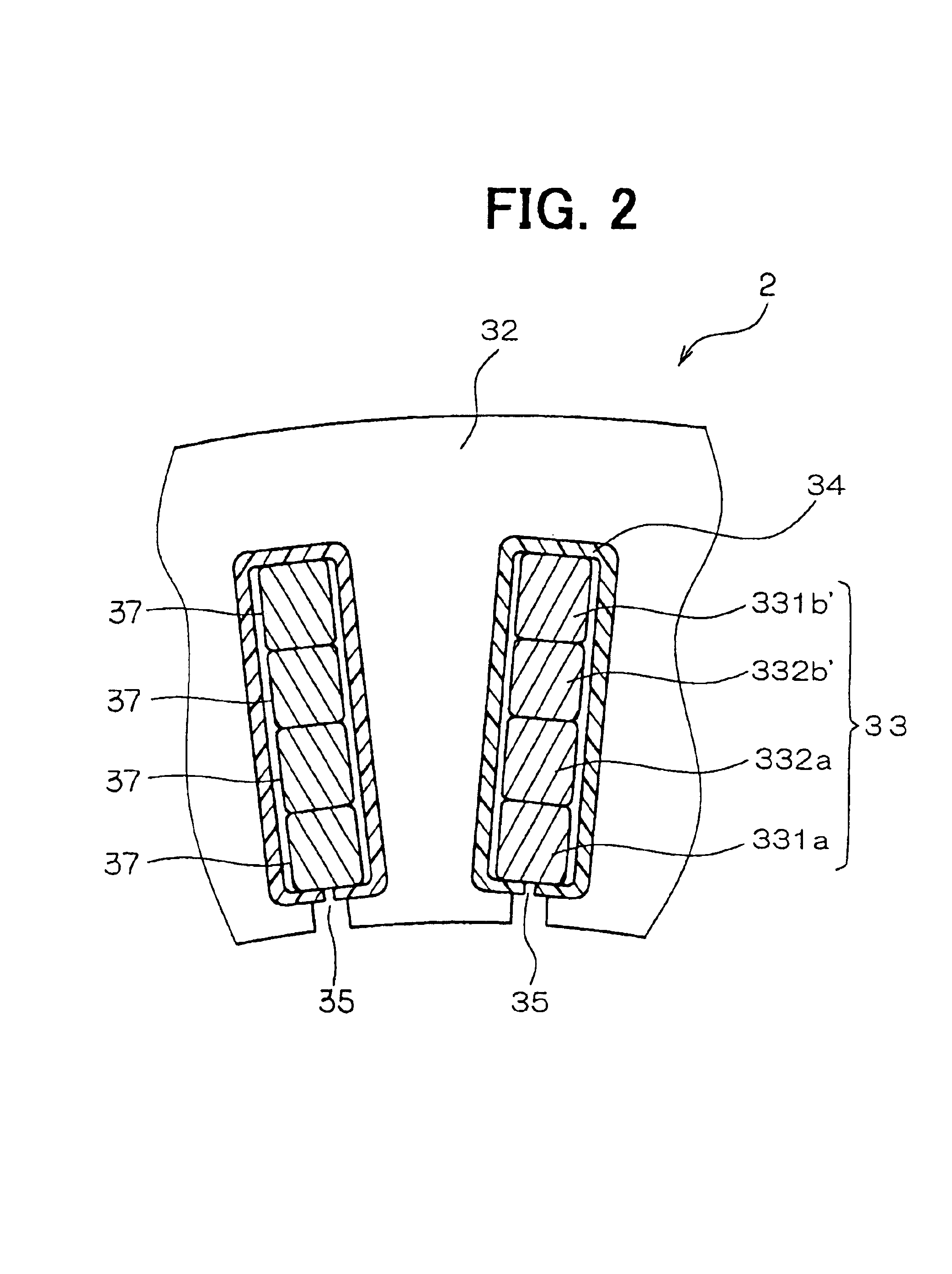

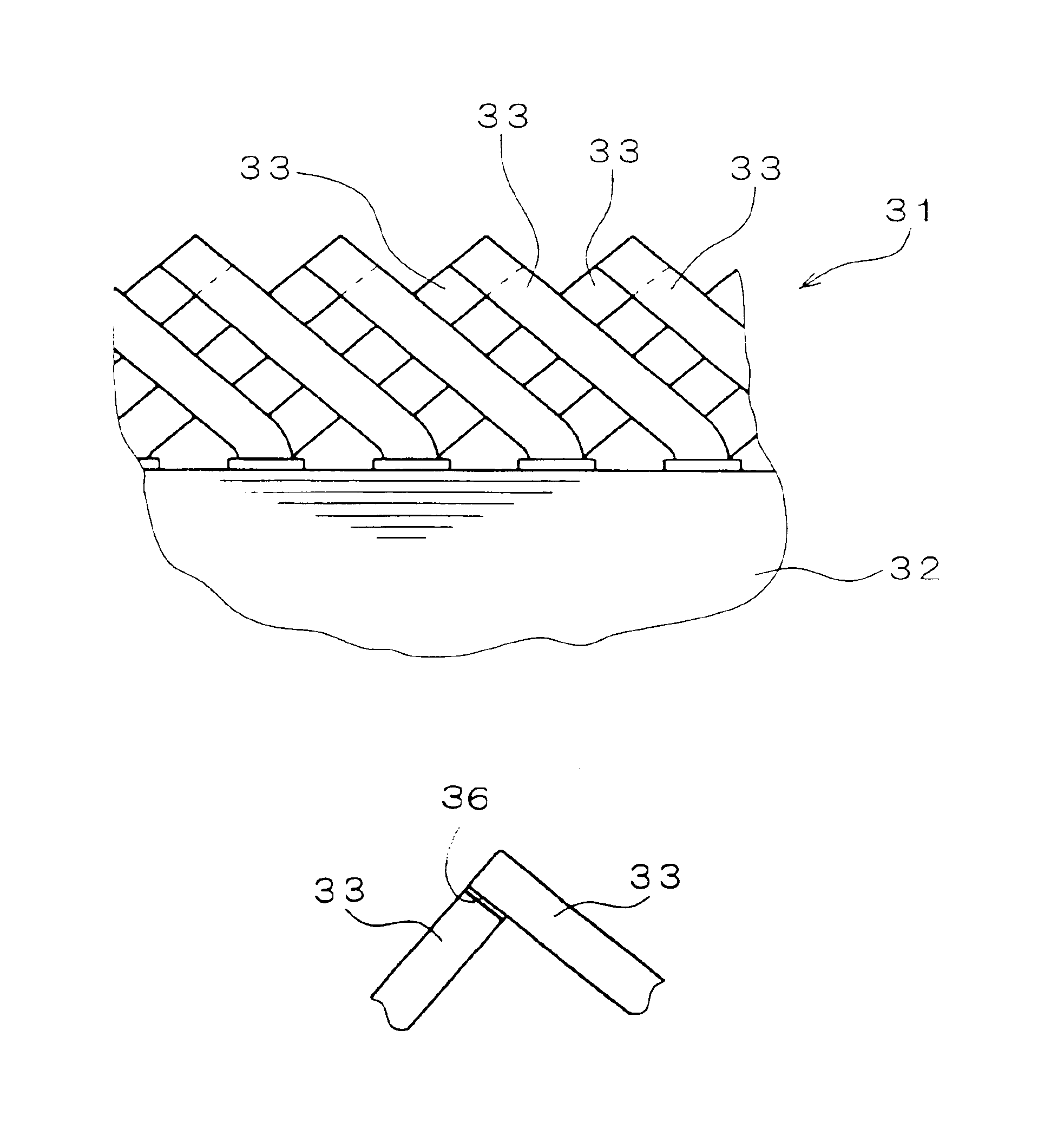

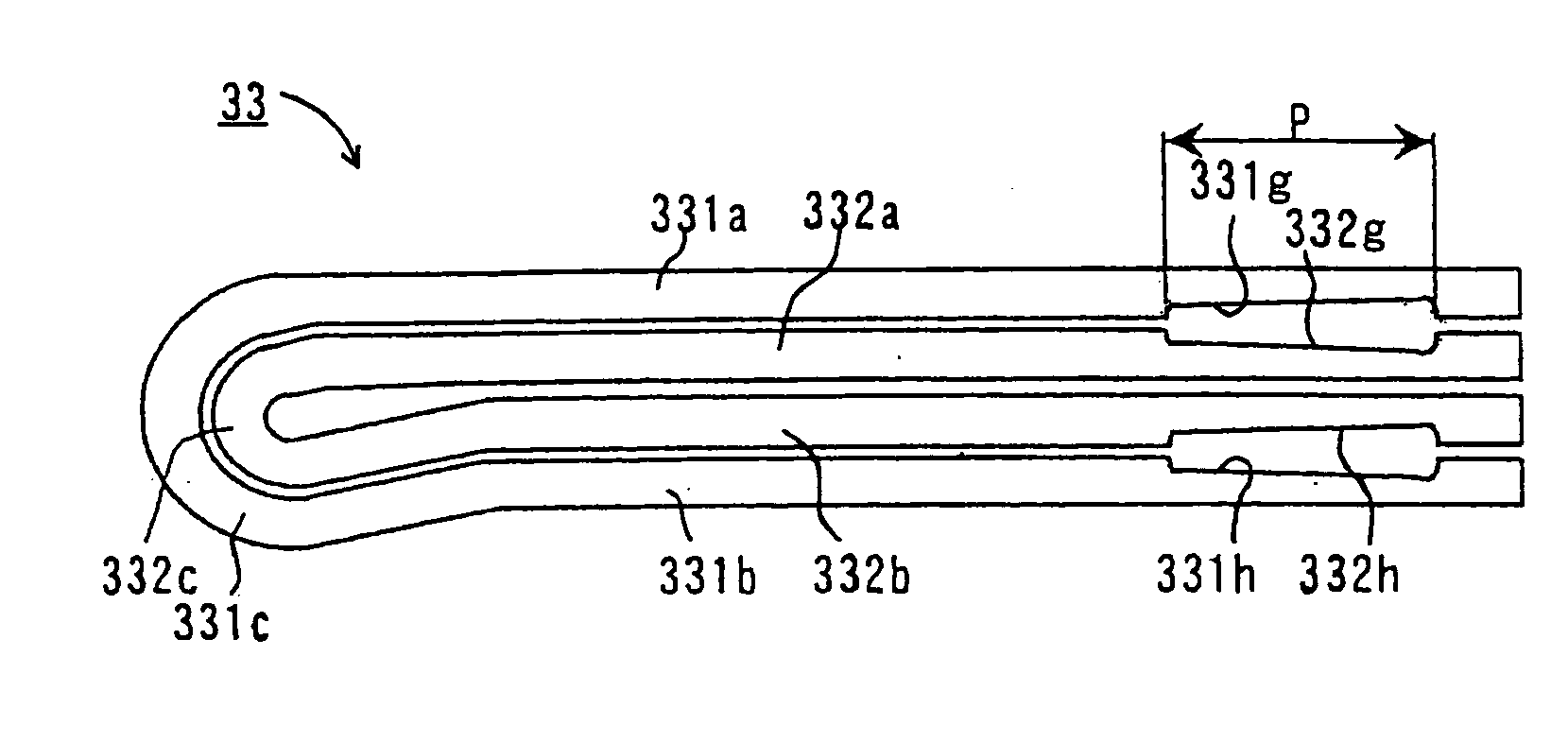

Stator for a vehicular rotary electric machine and a manufacturing method thereof

InactiveUS6897594B2Improve cooling efficiencySynchronous generatorsWindings insulation shape/form/constructionElectrical conductorElectric machine

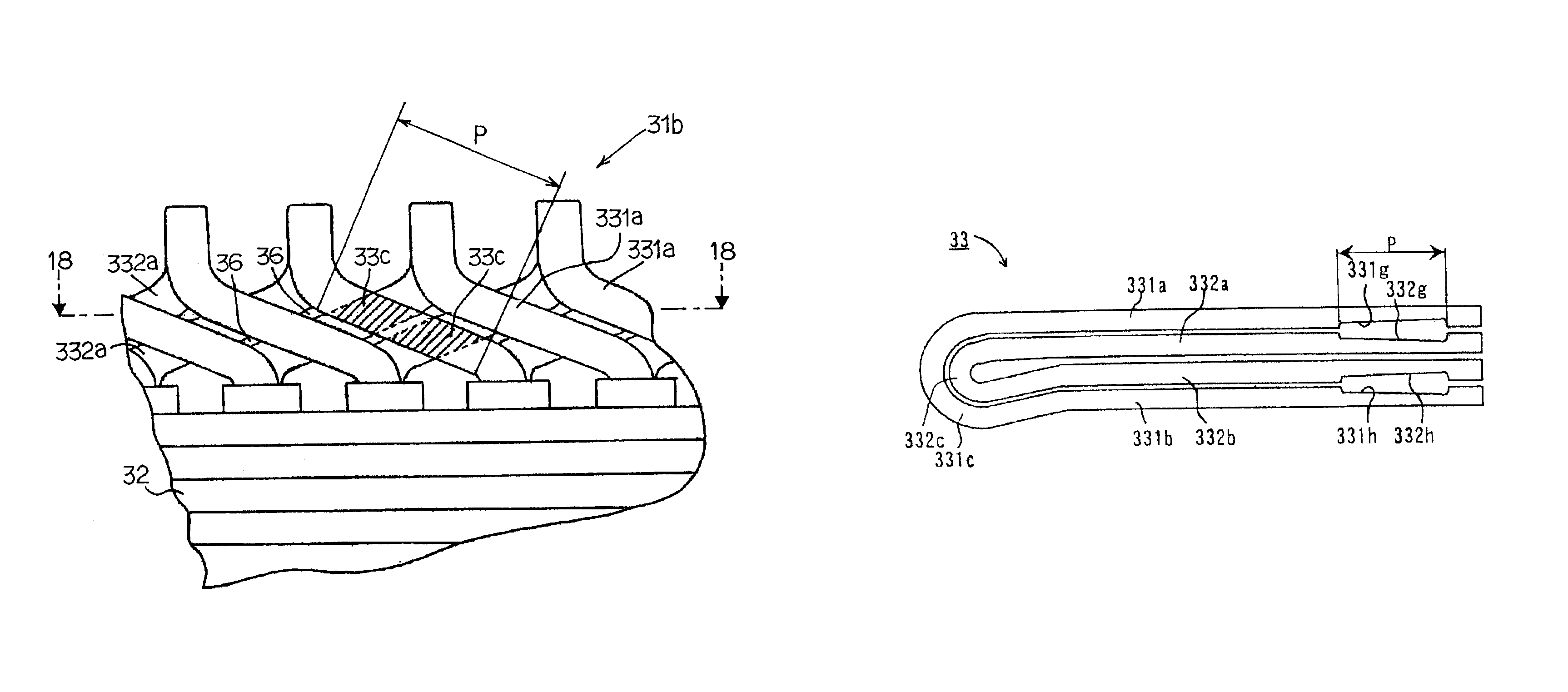

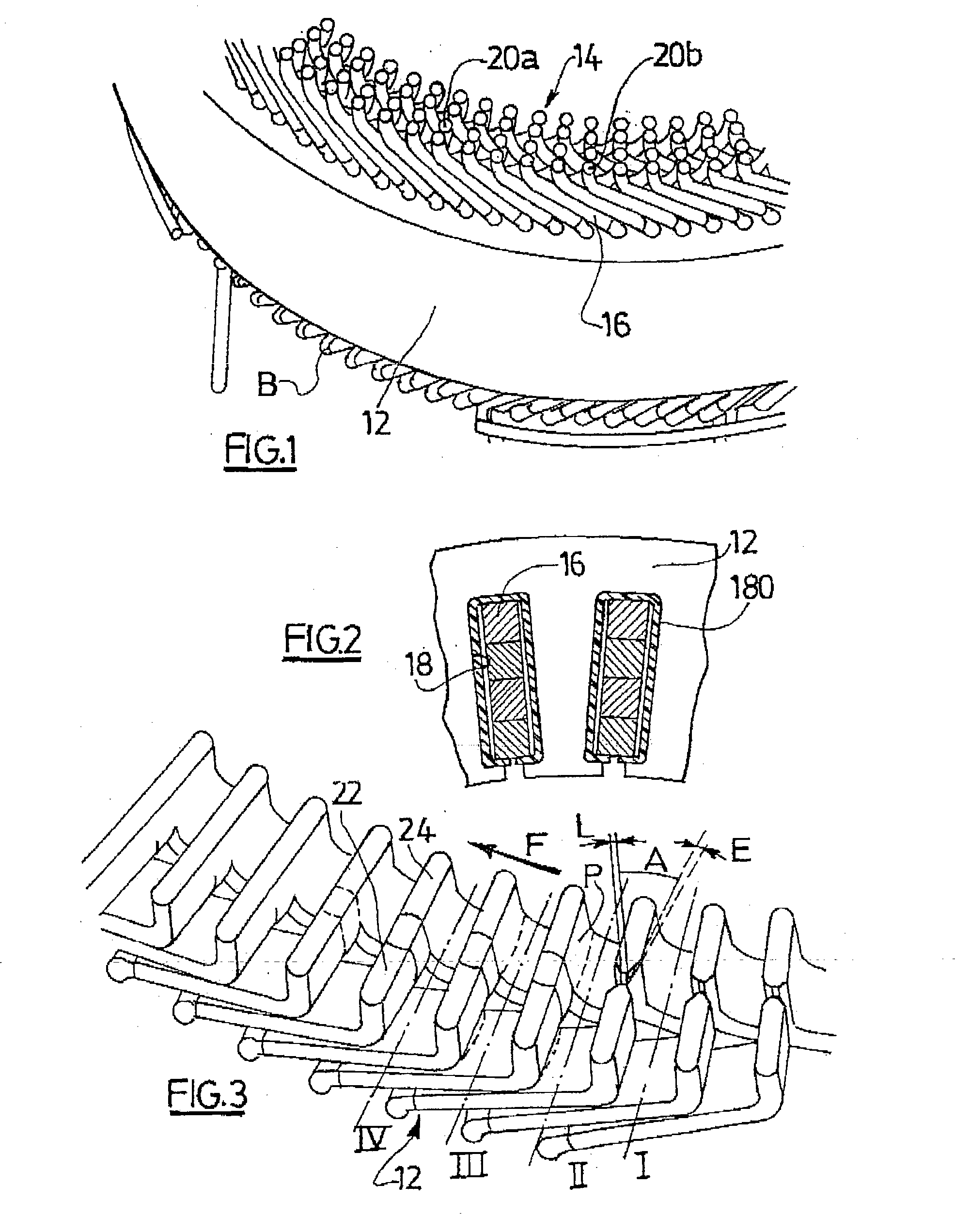

To secure insulation between electrical conductors at a coil end, a first electrical conductor at one coil end is arranged so as to intersect a radially adjacent second electrical conductor at one point or more. The electrical conductor is formed with radial indentations in side faces that are opposite side faces in opposing electrical conductors at any of the intersecting portions, the indentations having depths that increase toward the near end of the electrical conductors. Sufficient clearances are thereby secured between electrical conductors in their intersecting portions near their ends where the insulating films are susceptible to damage because of welding heat. Electrical insulation is thus ensured, and the cooling efficiency at the coil end is improved.

Owner:DENSO CORP

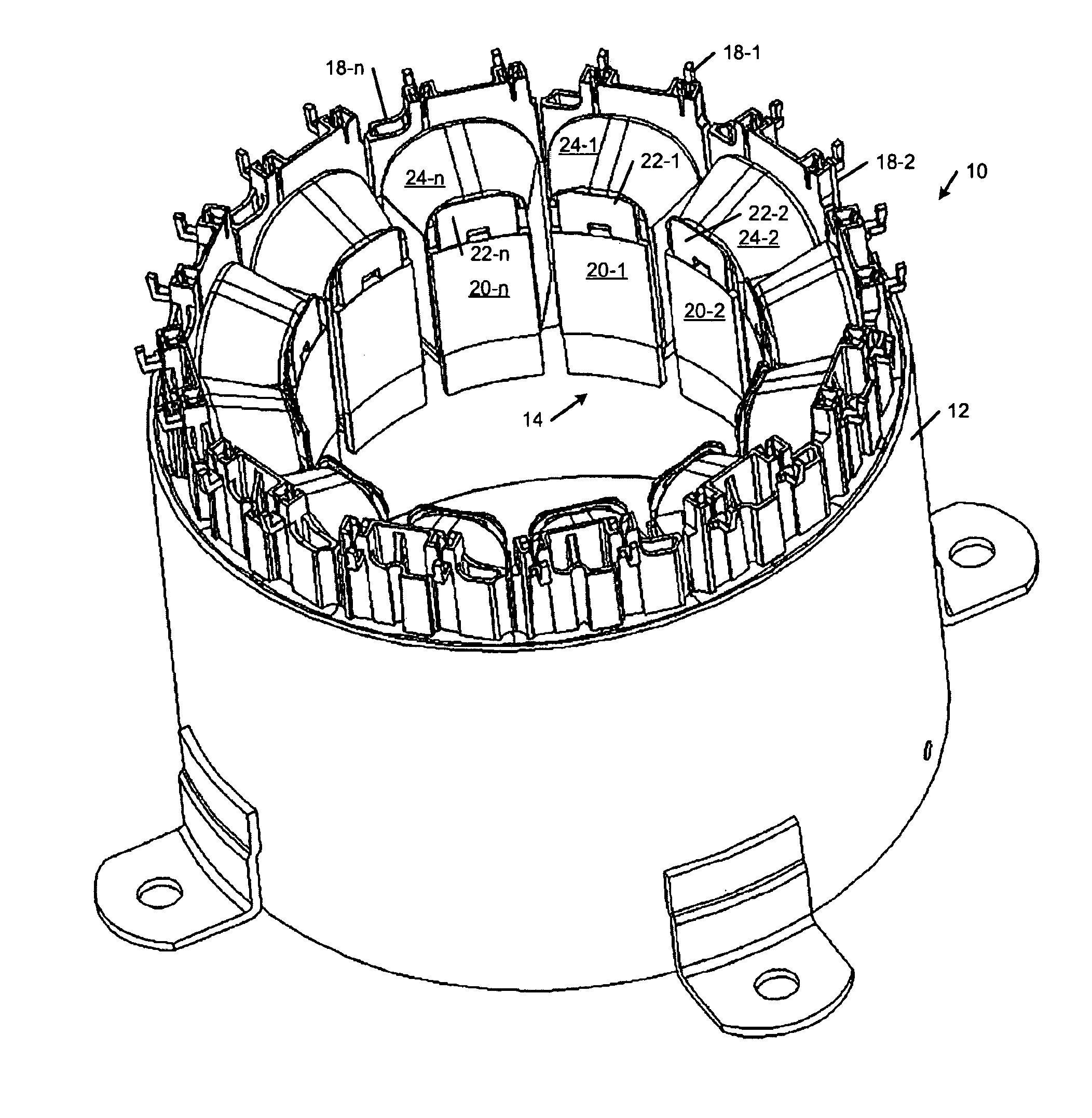

Rotary electric machine stator having individual removable coils

InactiveUS6531797B2Easy to buildEasy maintenanceMagnetic circuit stationary partsManufacturing winding connectionsElectric machineRemoving coil

Owner:MOTEURS LEROY SOMER

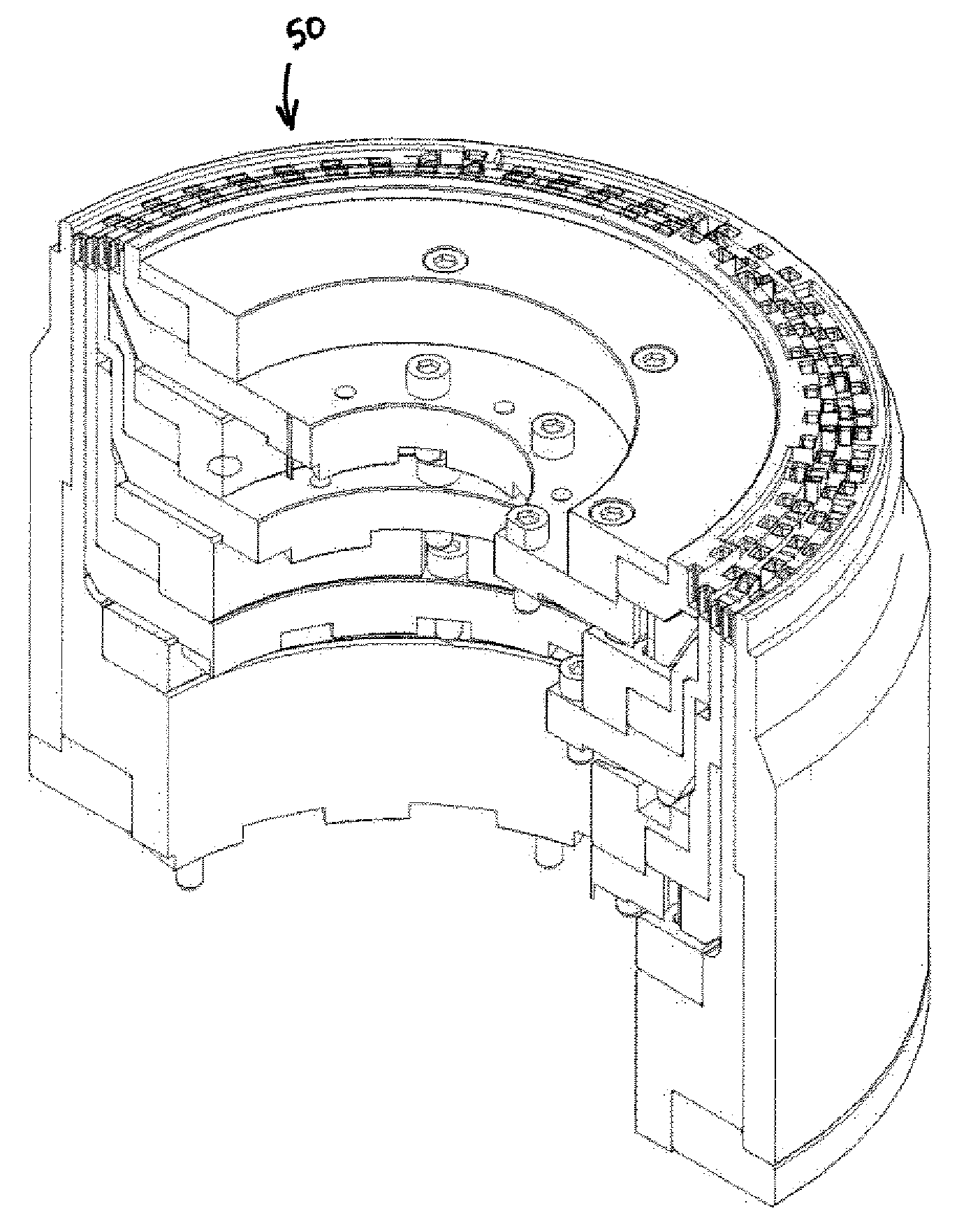

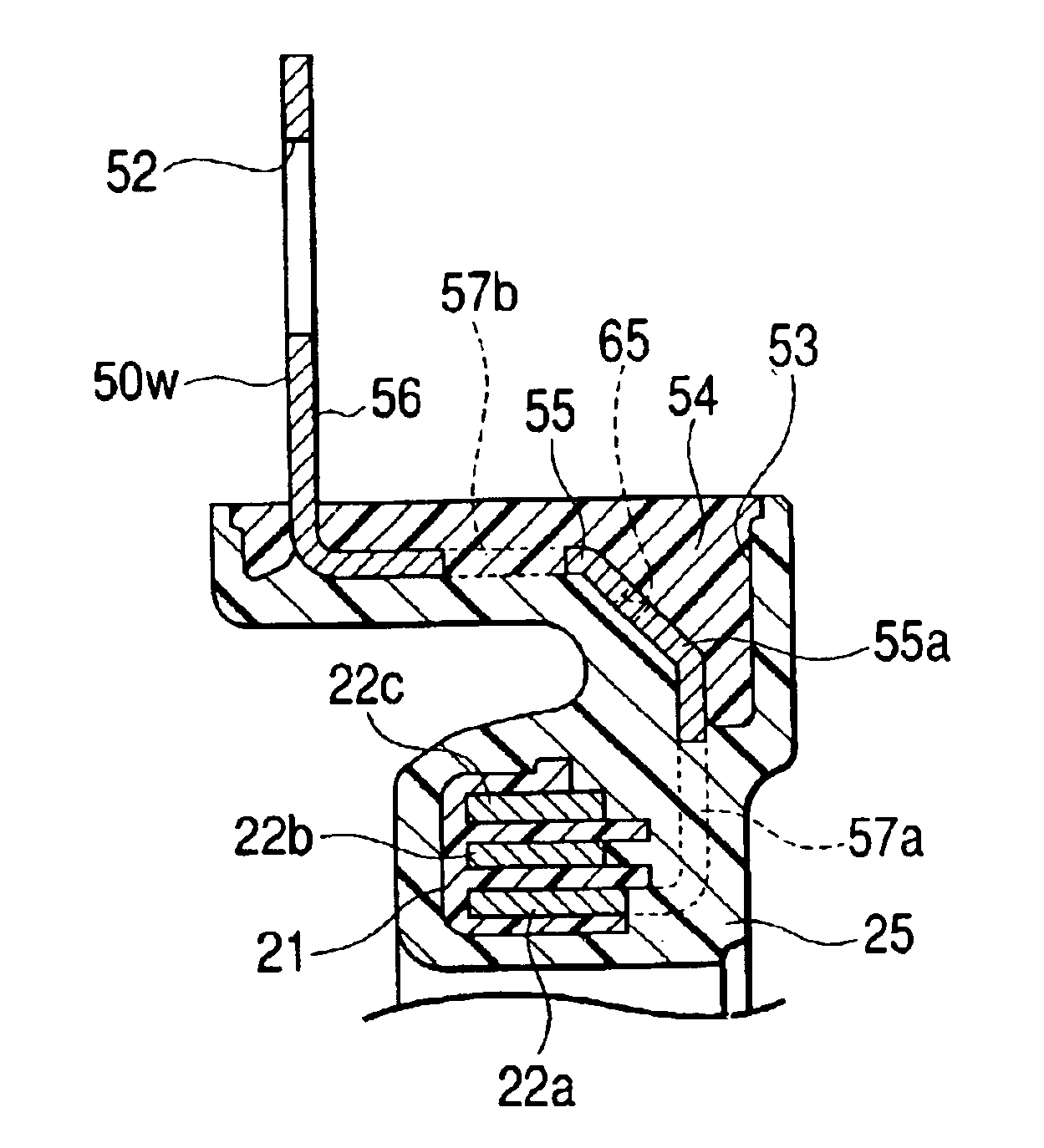

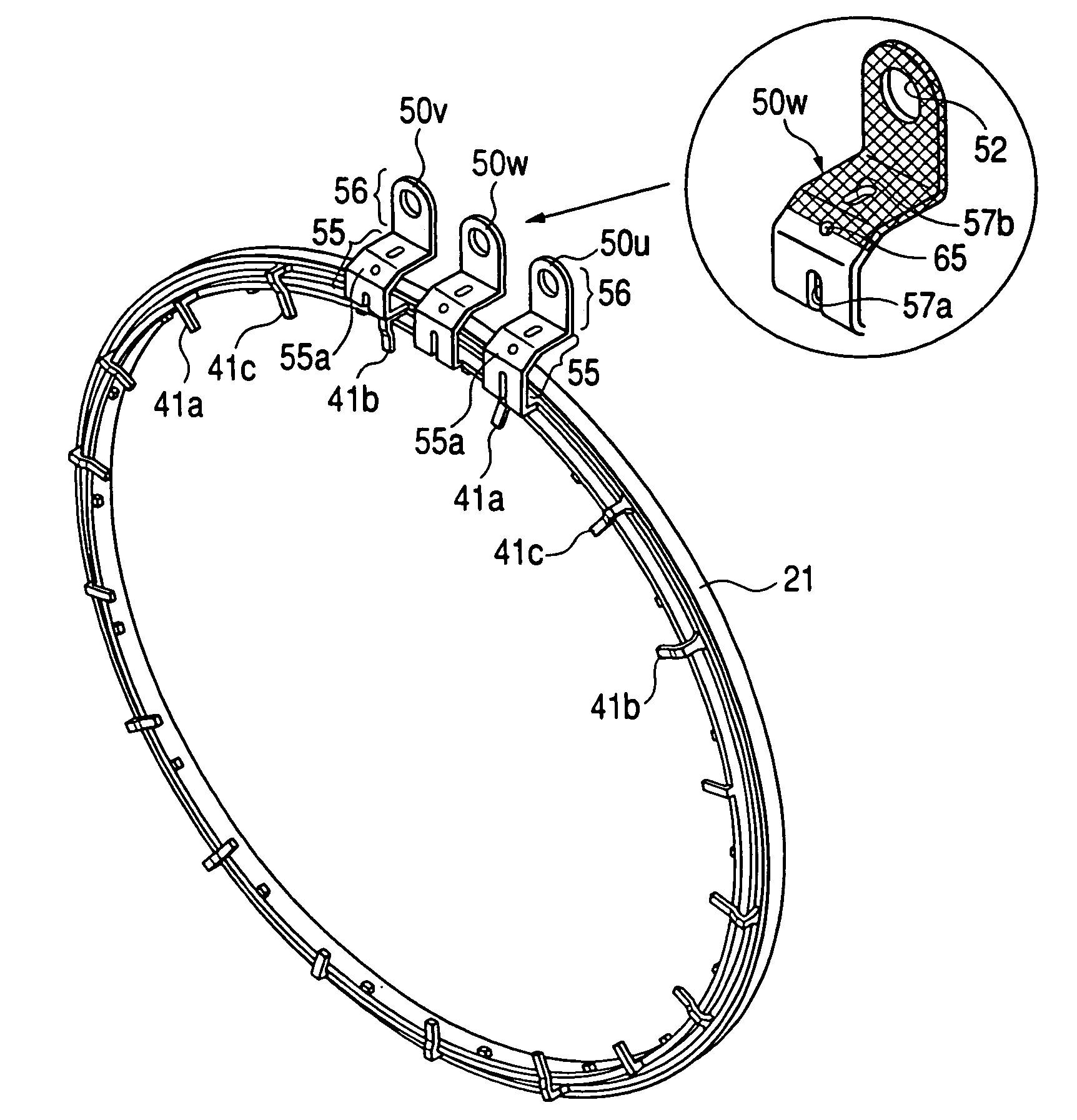

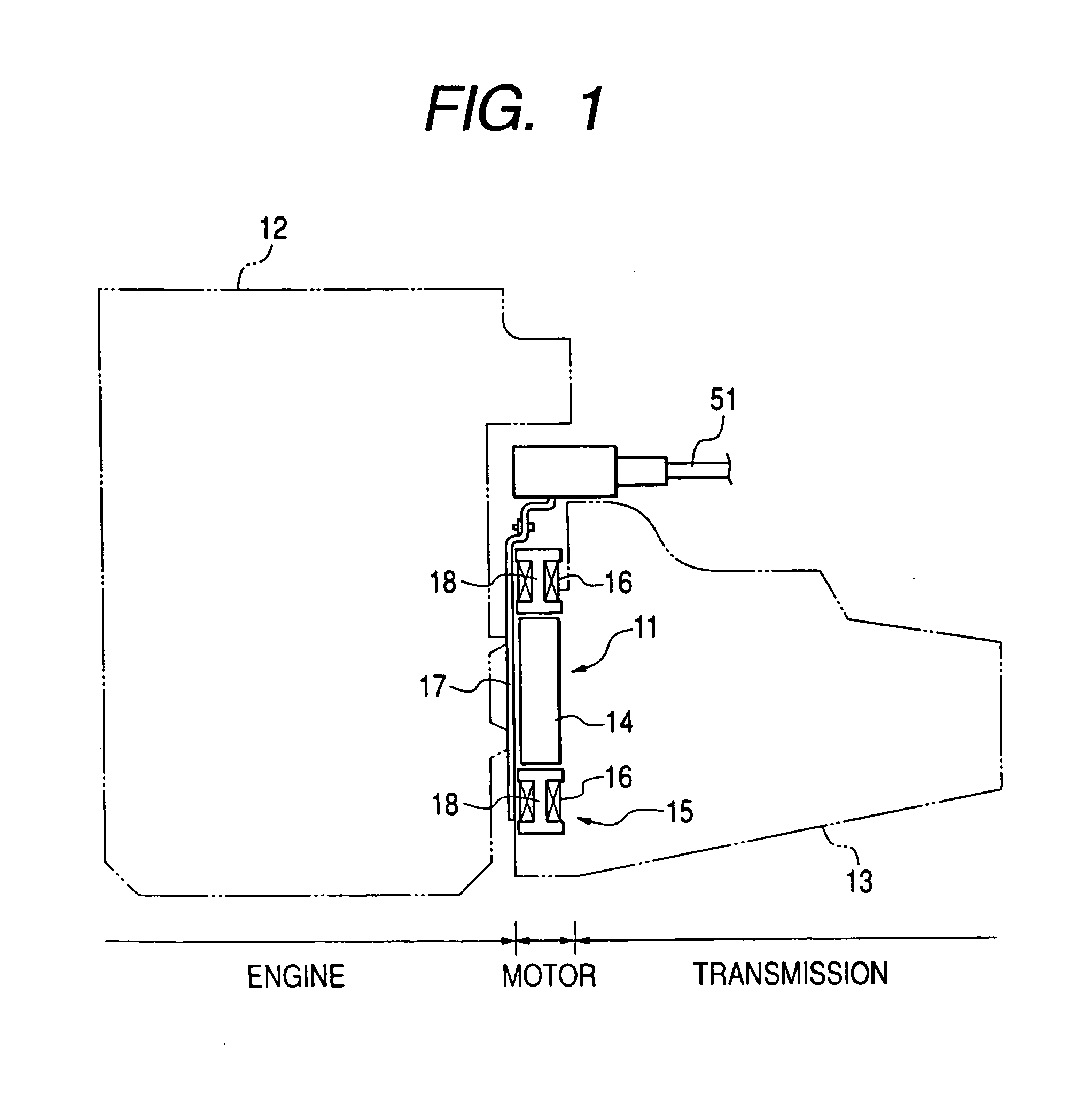

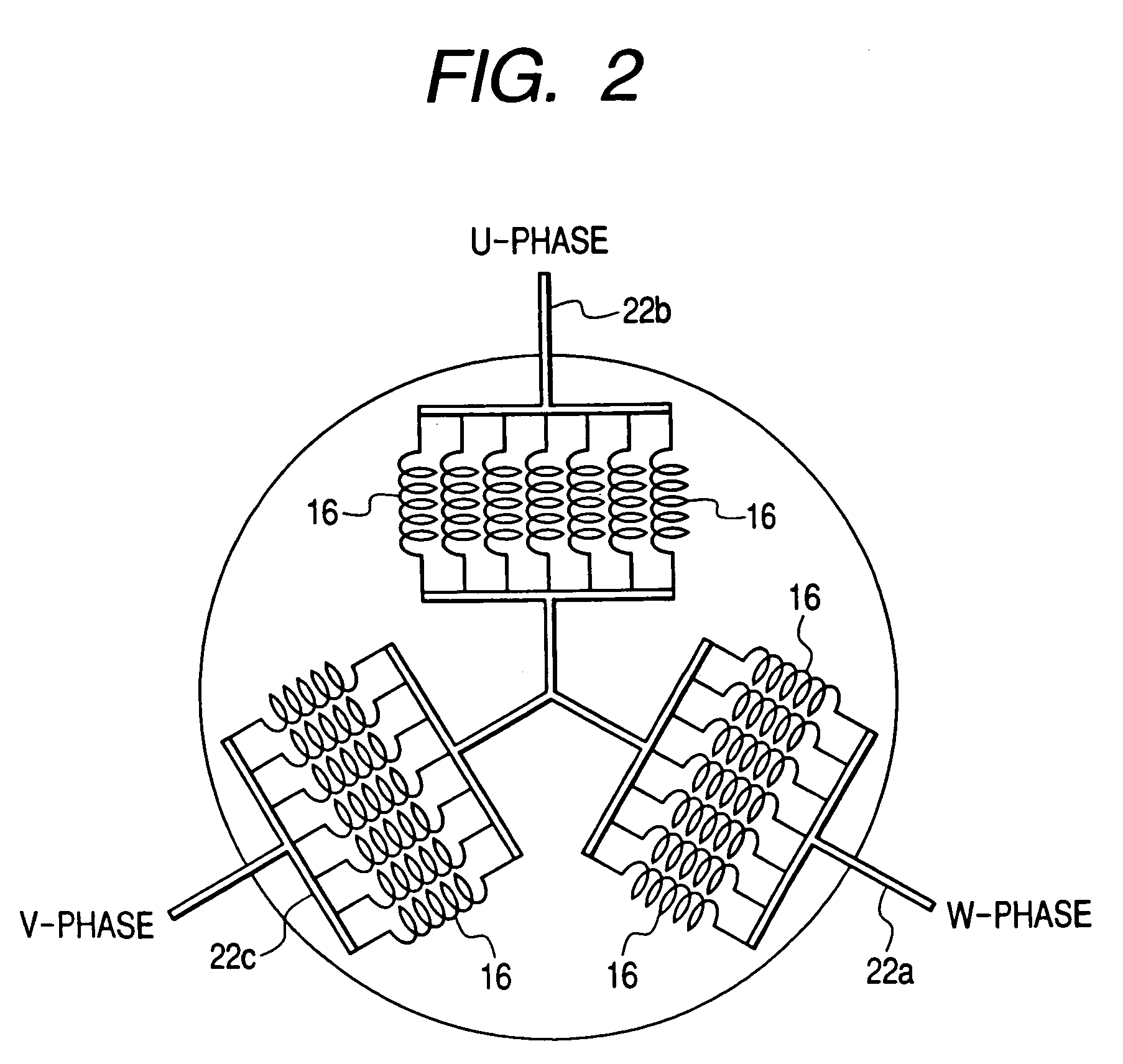

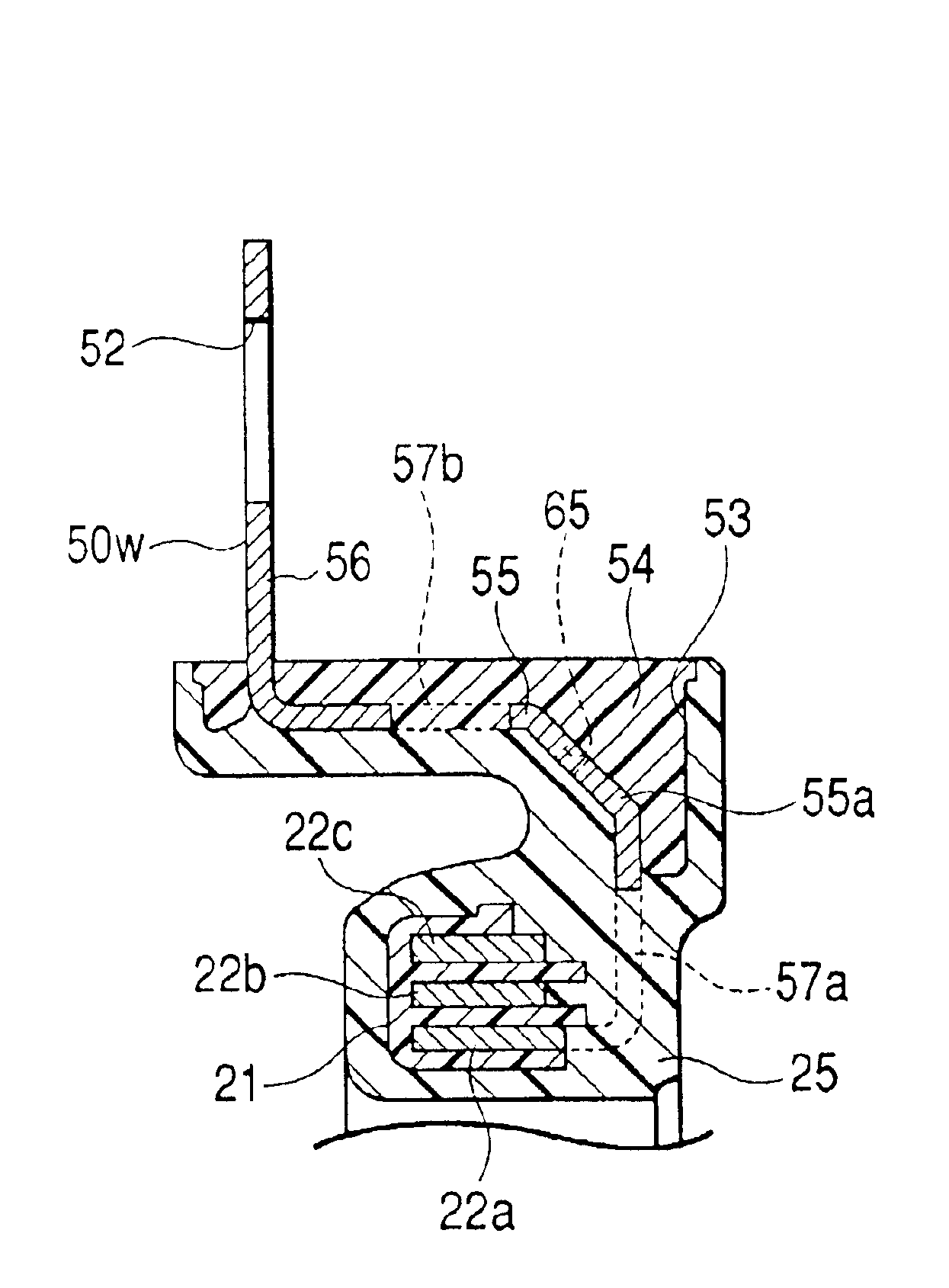

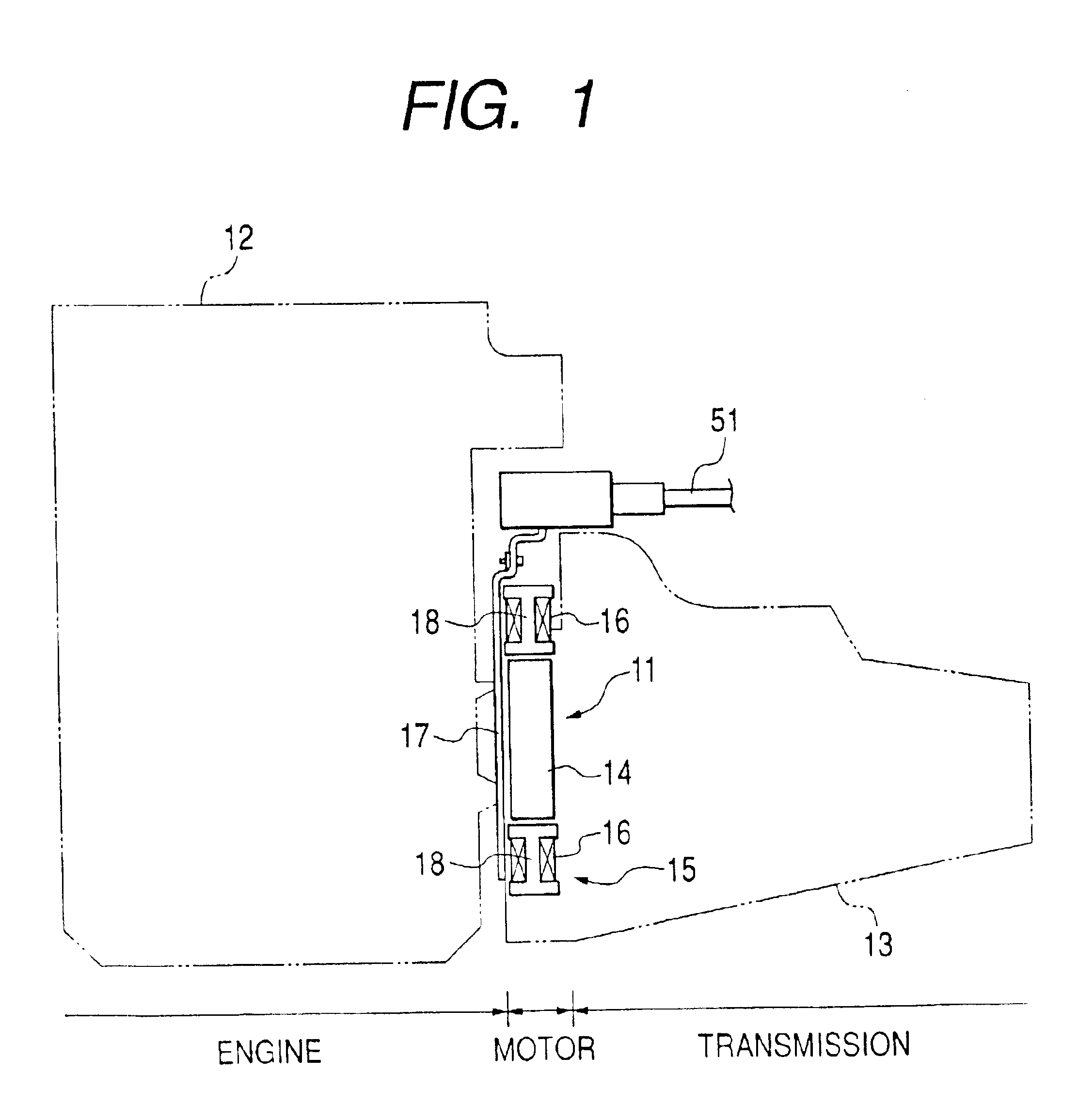

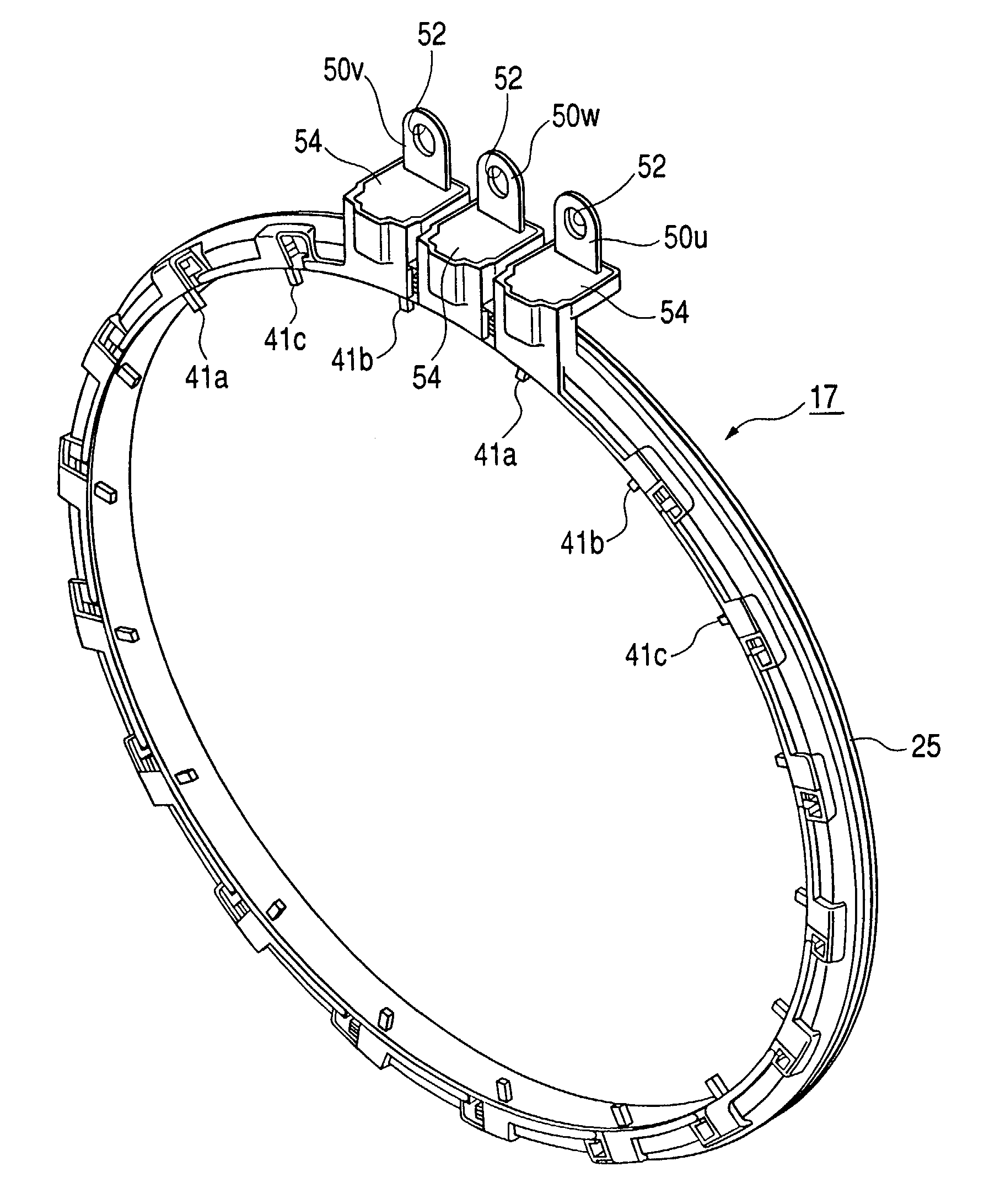

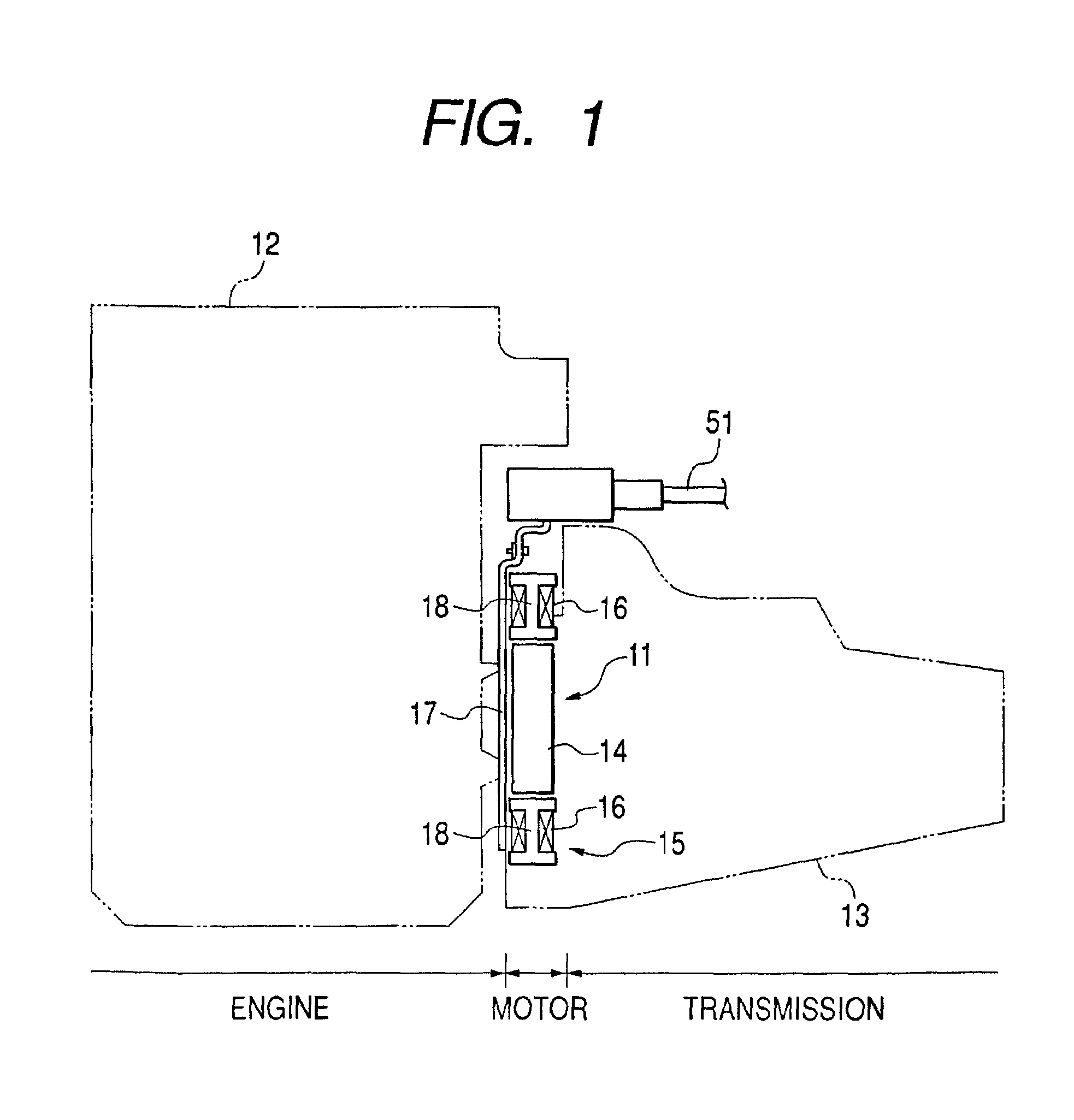

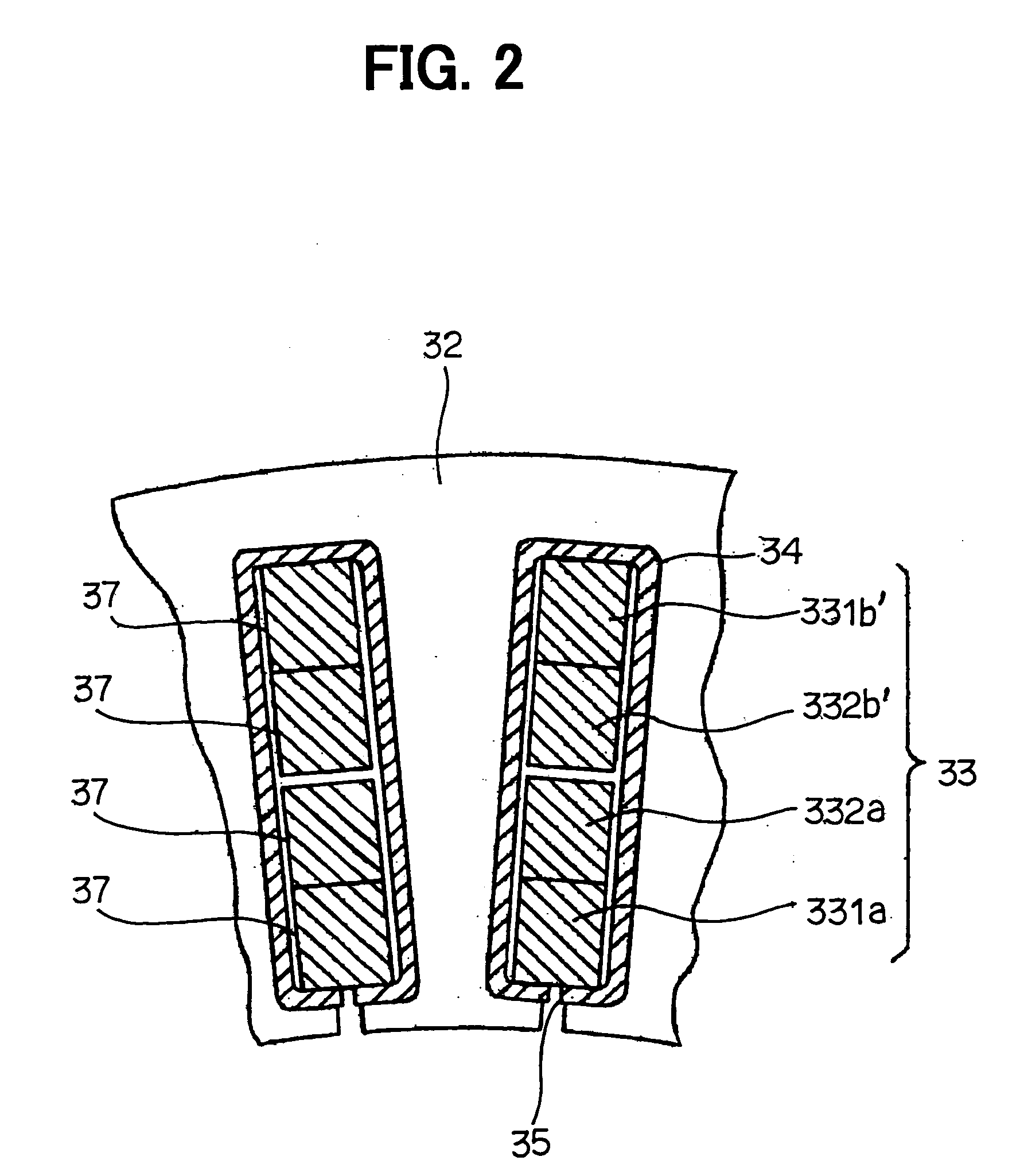

Thin brushless motor having resin-insulated concentric ring-shaped bus bars

InactiveUS6856057B2Improve heat resistanceHigh mechanical strengthRotary current collectorWindingsBrushless motorsInsulation layer

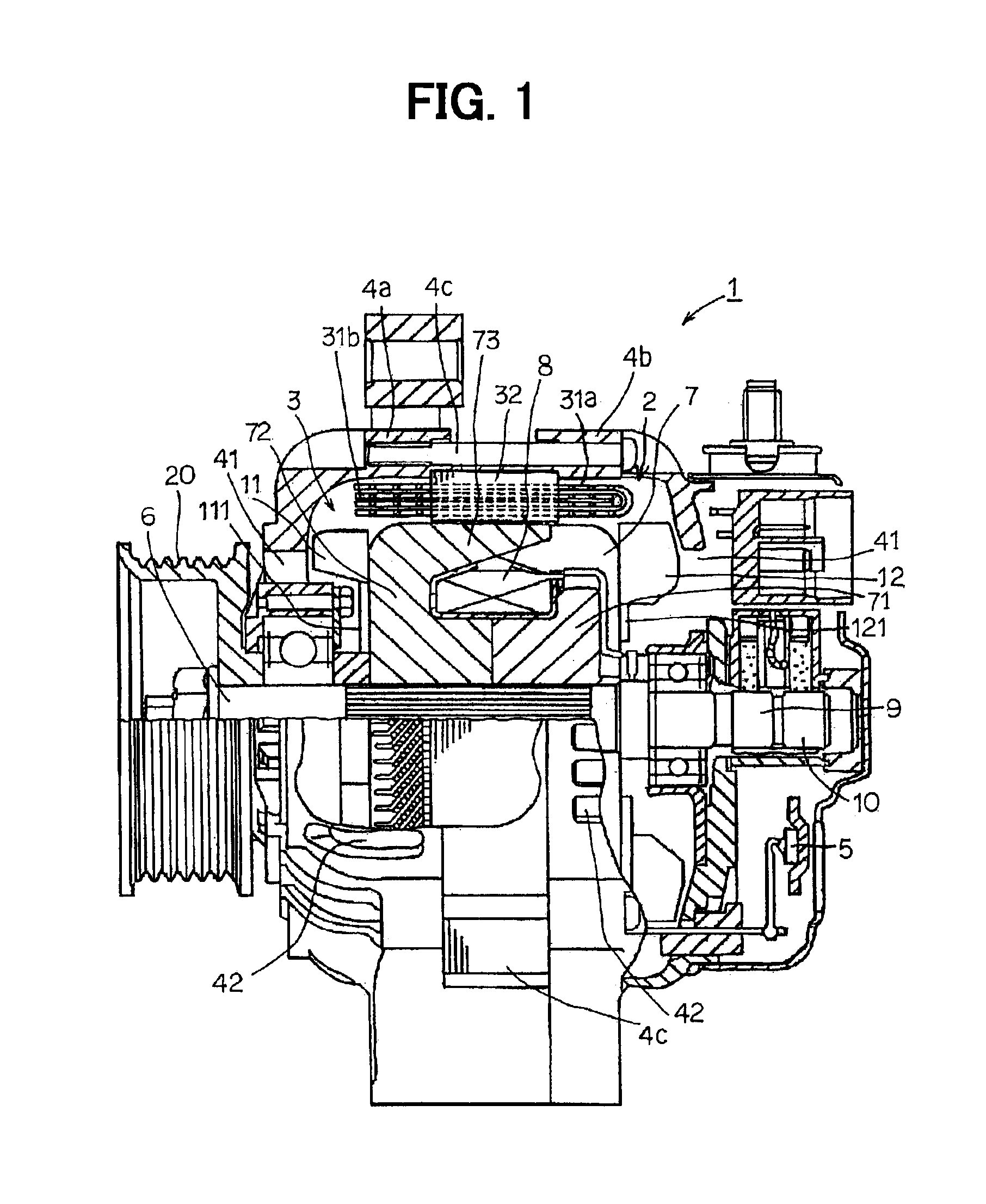

A centralized power distribution unit for a vehicular thin brushless motor includes a plurality of bus bars, a resin insulation layer that covers the bus bars, and an insulating holder having a plurality of holding grooves that hold the bus bars. The bus bars are pre-bent in a thickness direction to be formed into a substantially annular shape. Each of the bus bars is provided correspondingly with a phase of the motor. The holding grooves are formed in parallel extending along a circumferential direction of the centralized power distribution unit. The bus bars are respectively inserted into the holding grooves, and are thus stacked in a radial direction of the centralized power distribution unit. The insulating holder and the bus bars are covered by the resin insulation layer.

Owner:SUMITOMO WIRING SYST LTD +1

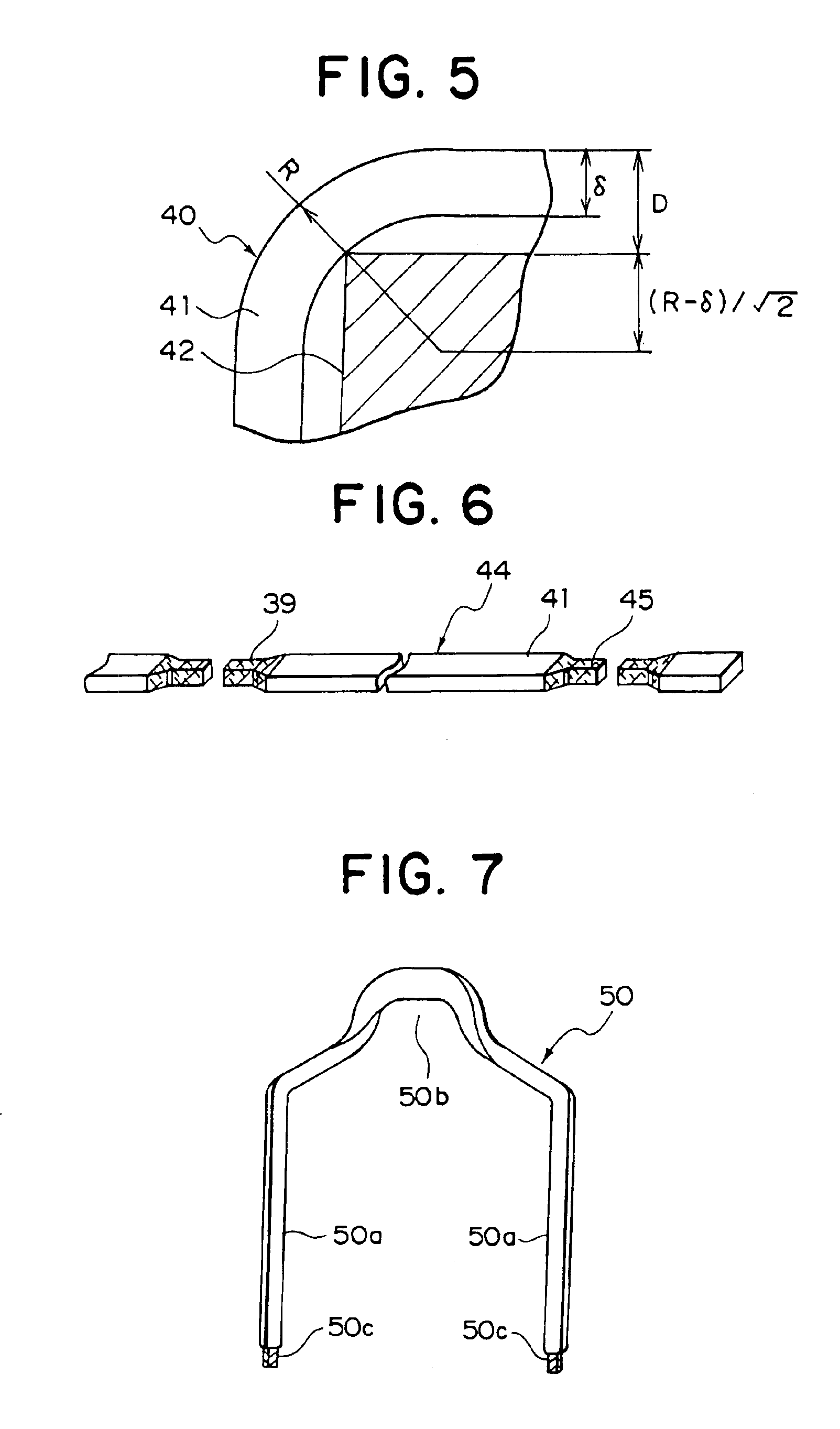

Method of producing bus bars for centralized power distribution unit

InactiveUS7219417B2Low costGood componentLine/current collector detailsWindingsStructural engineeringMechanical engineering

To produce bus bars, a conductive metal plate is stamped out into a plurality of strips simultaneously by press molding. Each strip has a tab having an L-shaped cross-section defined by a curved section and a distal end. The plurality of strips are bent in a thickness direction to obtain a plurality of rings, respectively. The rings are mutually different in diameter and have substantially the same center. The L-shaped tab of each of the rings is disposed such that the distal end of each tab is disposed substantially at a same distance from the center.

Owner:SUMITOMO WIRING SYST LTD +1

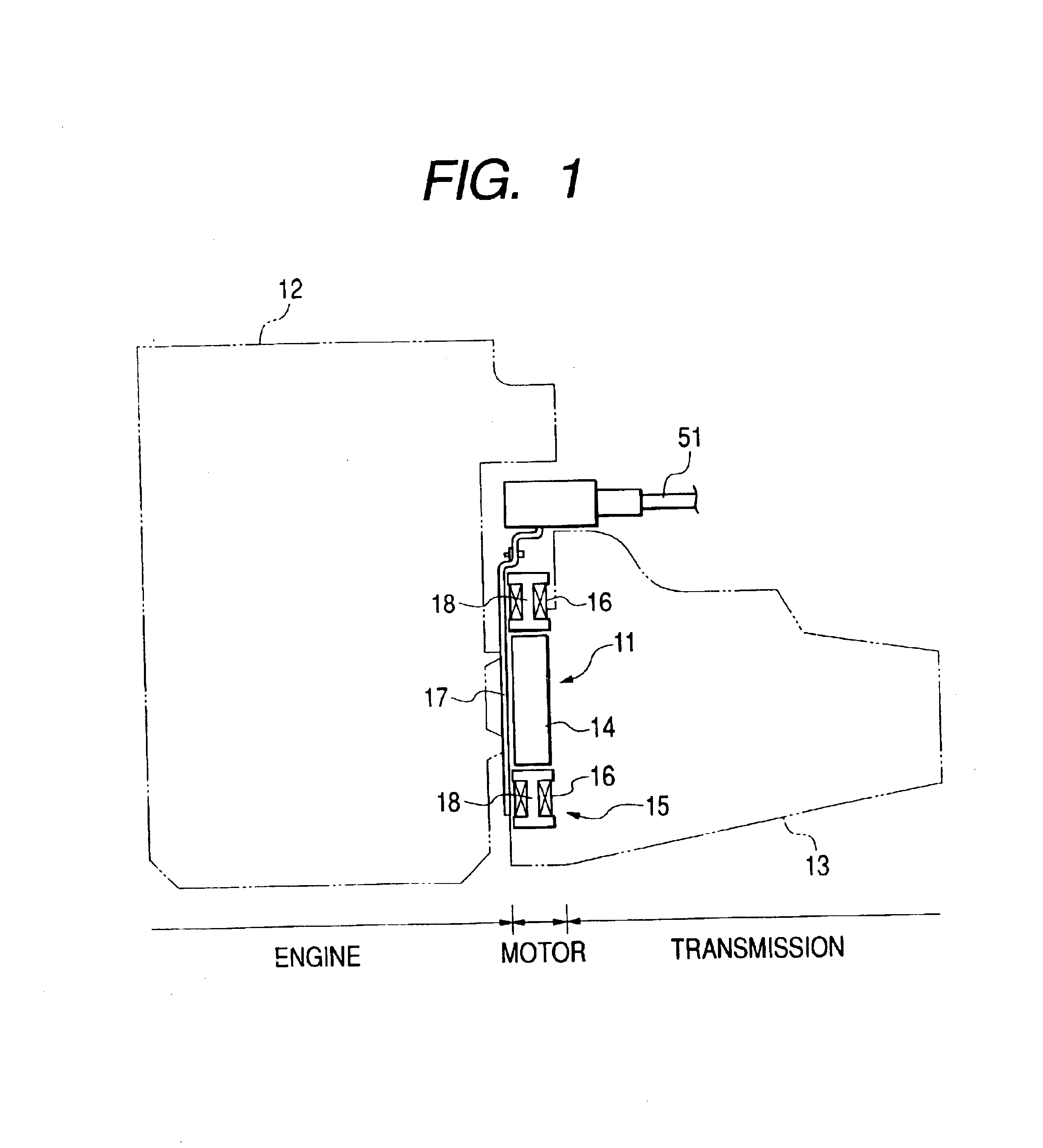

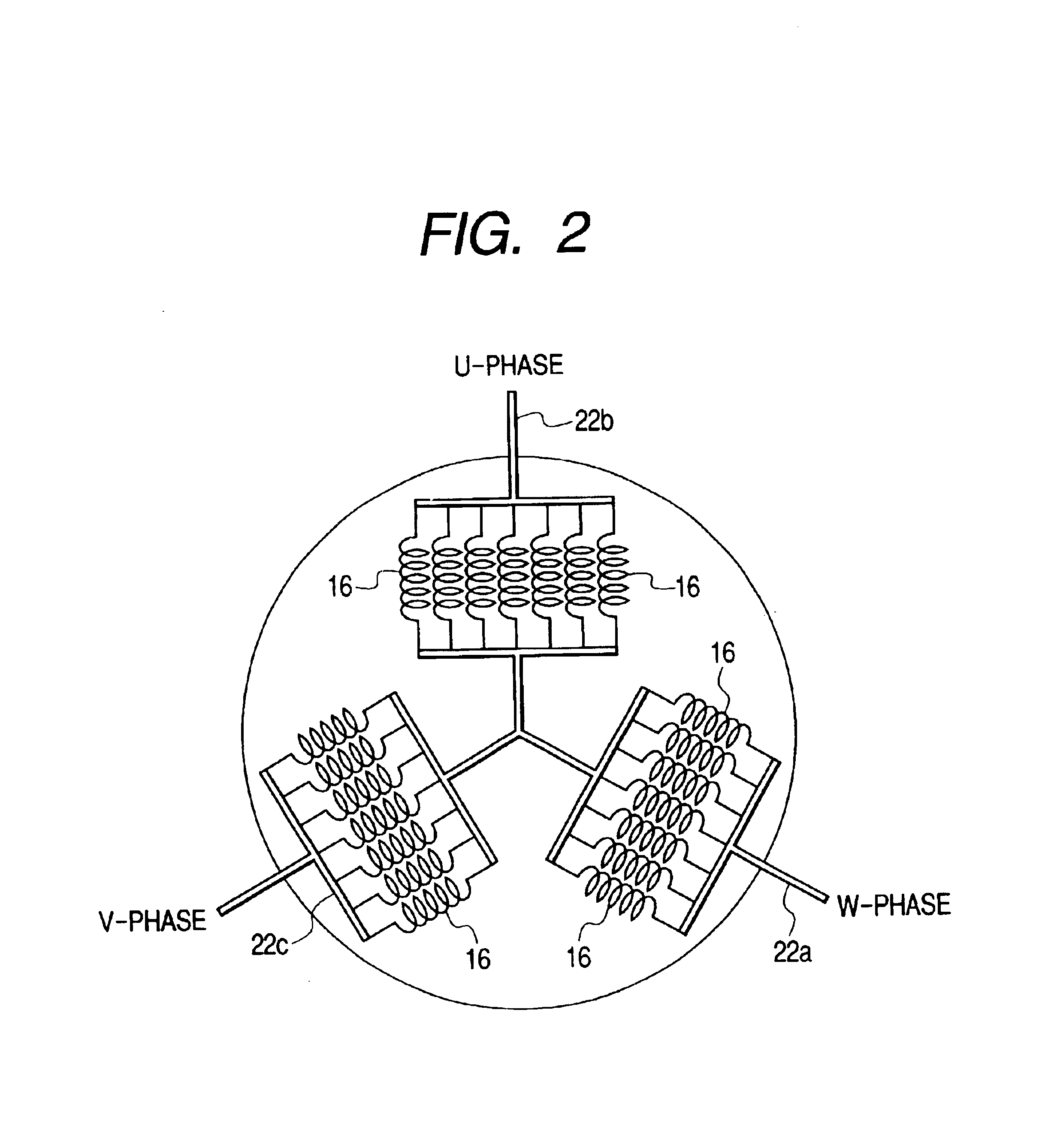

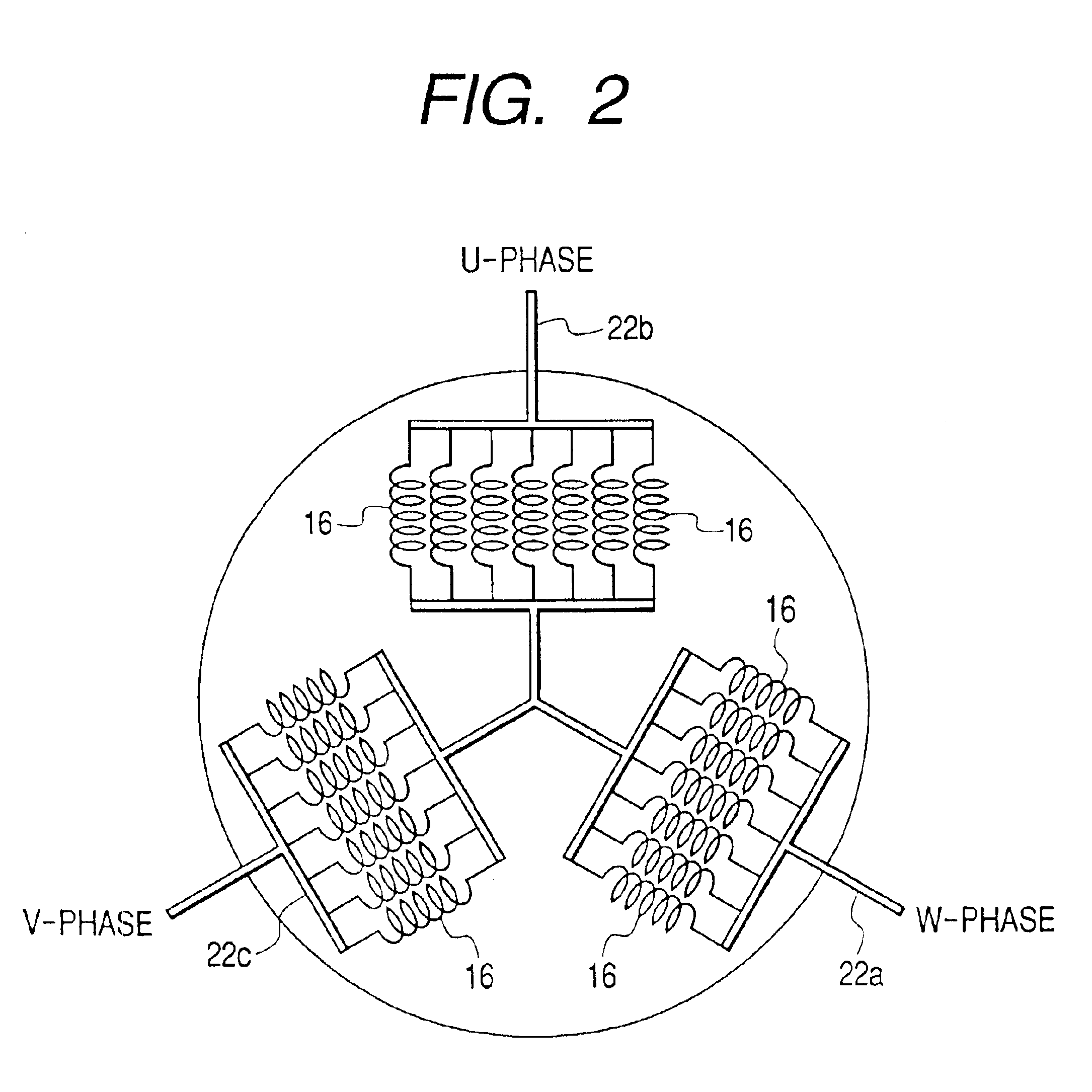

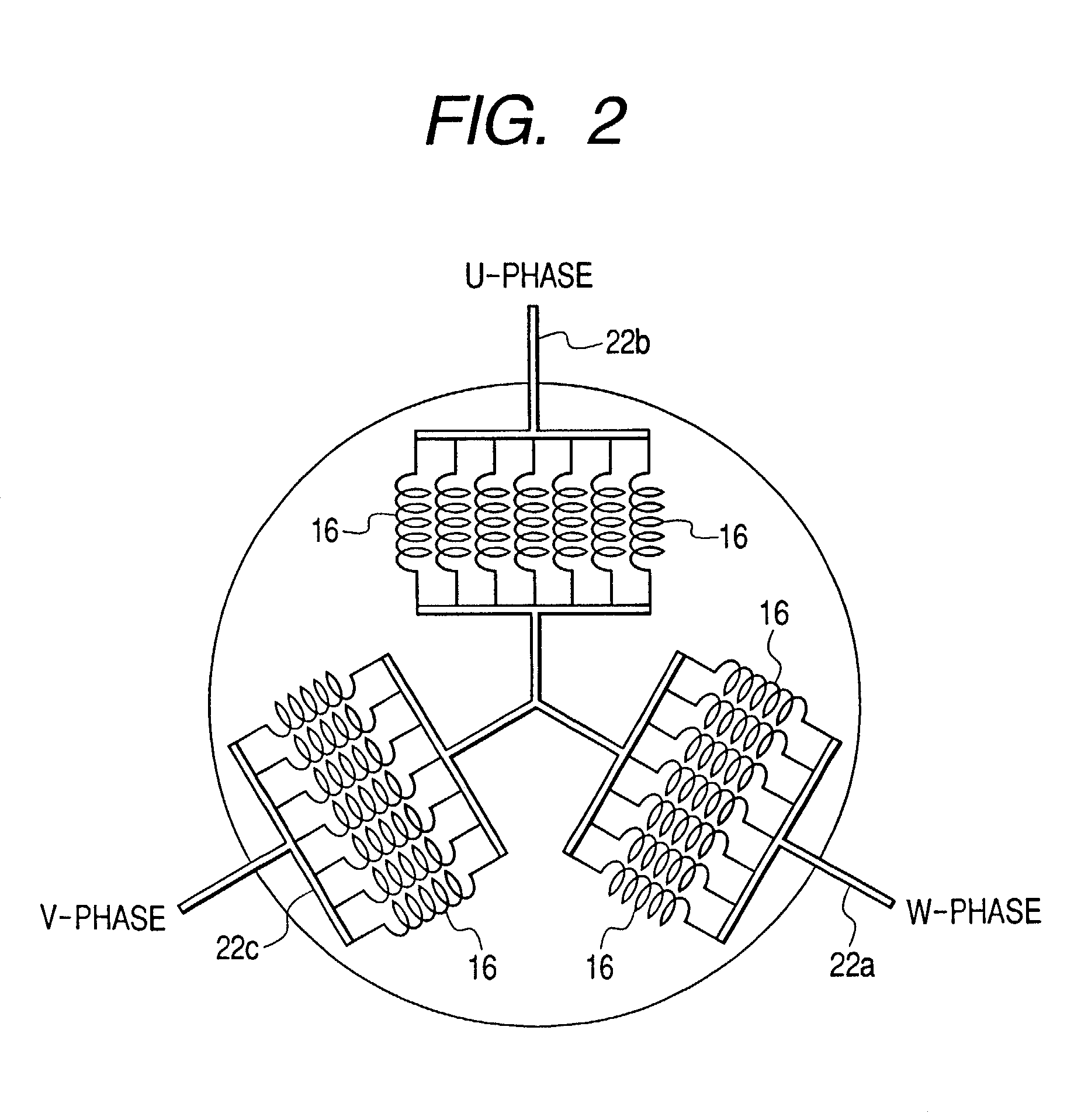

Thin brushless motor having ring-configured centralized power distribution unit

InactiveUS6894410B2Reduce material lossReduce material costsCoupling device connectionsManufacturing winding connectionsBrushless motorsConductor Coil

A centralized power distribution unit for a vehicular thin brushless motor includes a plurality of bus bars and a resin insulating layer that covers the bus bars. The bus bars are disposed correspondingly with phases of the motor. Each of the bus bars has a terminal portion to be connected to a battery and one or more tabs to be connected respectively to one or more windings of a stator. Each of the bus bars is shaped into a substantially annular shape by bending a molded material in a thickness direction. The molded material is obtained by stamping out a conductive metal plate into a strip-like shape. Diameters of the annular shapes of the bus bars are set to be different from one another depending on the corresponding phase of the motor. The bus bars are stacked in a radial direction of the centralized power distribution unit, mutually separated by a predetermined gap.

Owner:SUMITOMO WIRING SYST LTD +1

Method for producing centralized distribution unit of thin brushless motor for vehicle

InactiveUS6993829B2Superior waterproof-nessSuperior airtight-ness functionLine/current collector detailsWindingsBrushless motorsInsulation layer

In a method of producing a centralized distribution unit of a thin brushless motor for a vehicle having superior waterproof-ness and airtight-ness functions, and high dielectric strength, an insulating holder is provided with bearing recesses. Bus bars are bent from a substantially linear shape into a substantially annular shape, and inserted into holding grooves formed in the insulating holder. The insulating holder and bus bars are disposed in a molding cavity, and distal ends of holder supports that project from an inner wall of the molding cavity are engaged with the bearing recesses of the insulating holder. Resin is supplied into the molding cavity to form an insulation layer that covers the bus bars and an entire periphery of the insulating holder.

Owner:SUMITOMO WIRING SYST LTD

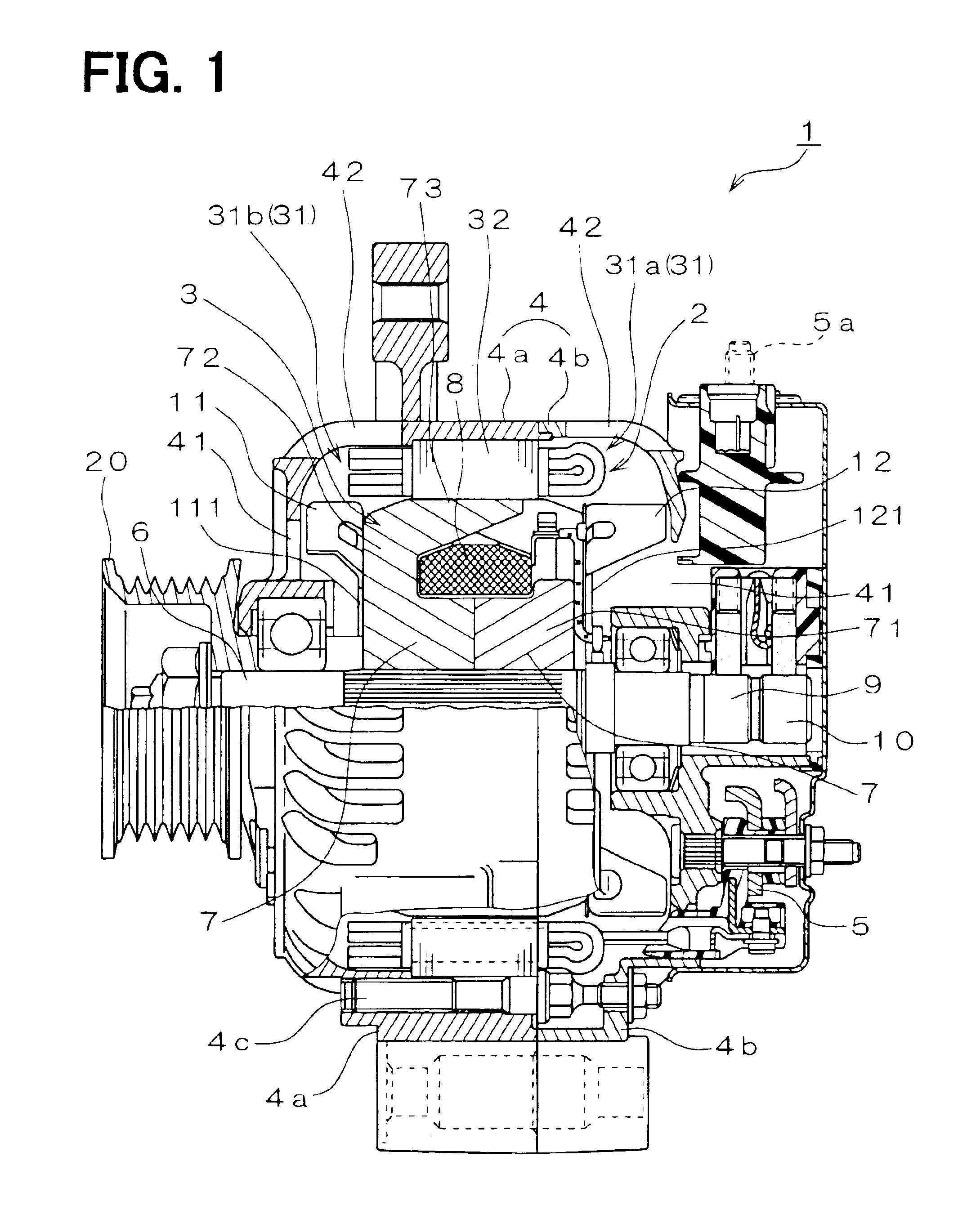

Dynamoelectric machine winding joining method

InactiveUS6990724B2Improving joining operationBroaden the fieldMagnetic circuitContainer/bottle contructionTorchEngineering

An intermediate holding member is inserted between a second free end and a third free end from an inner circumferential side in a radial direction, a first radial restraining member presses against a free end at an innermost circumference from radially inside, and a second radial restraining member presses against a free end at an outermost circumference from radially outside. Next, a voltage is supplied between a torch and the members, an inert gas is supplied to the torch, and an arc discharge is generated between the torch and the free ends, welding the radially-adjacent free ends.

Owner:MITSUBISHI ELECTRIC CORP

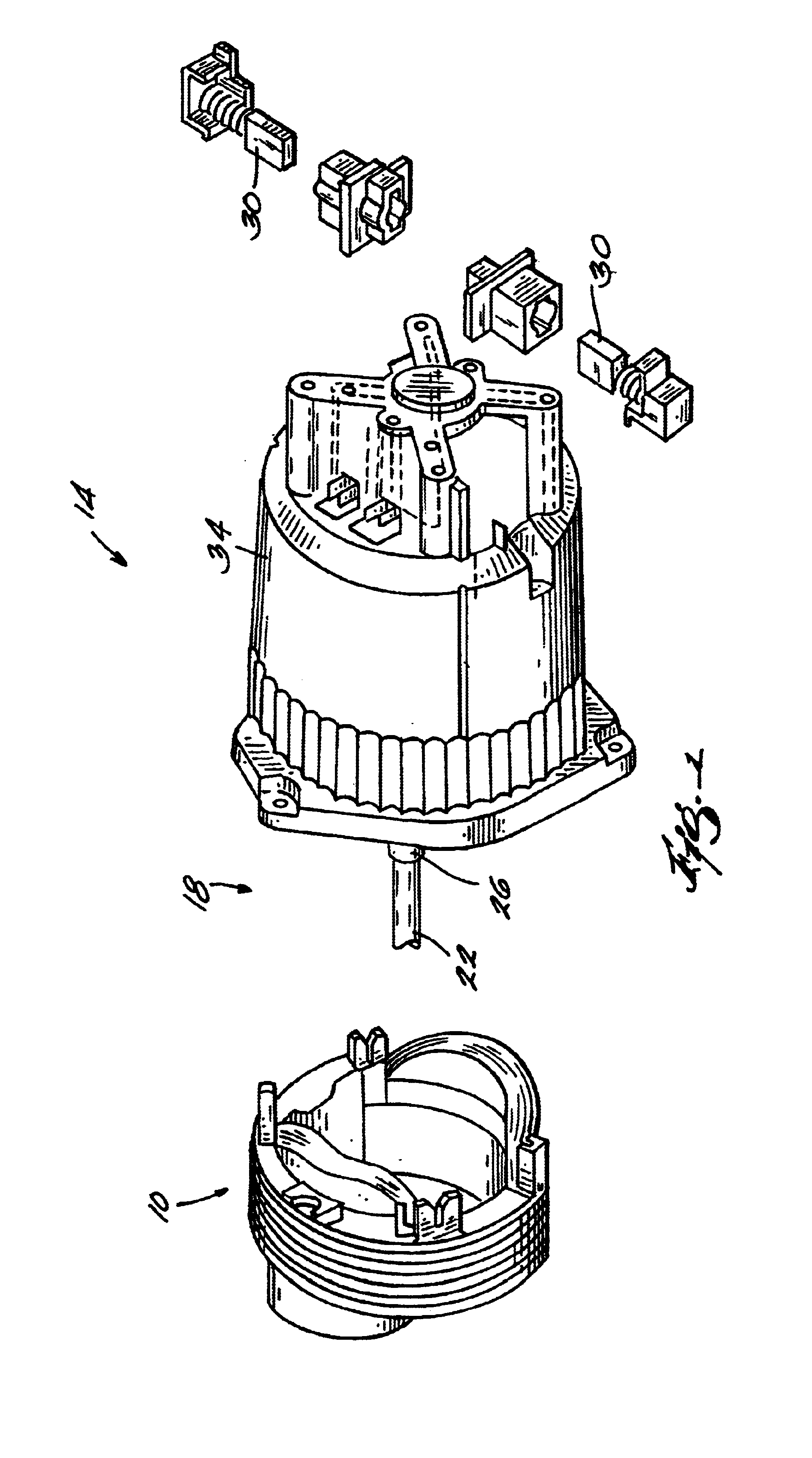

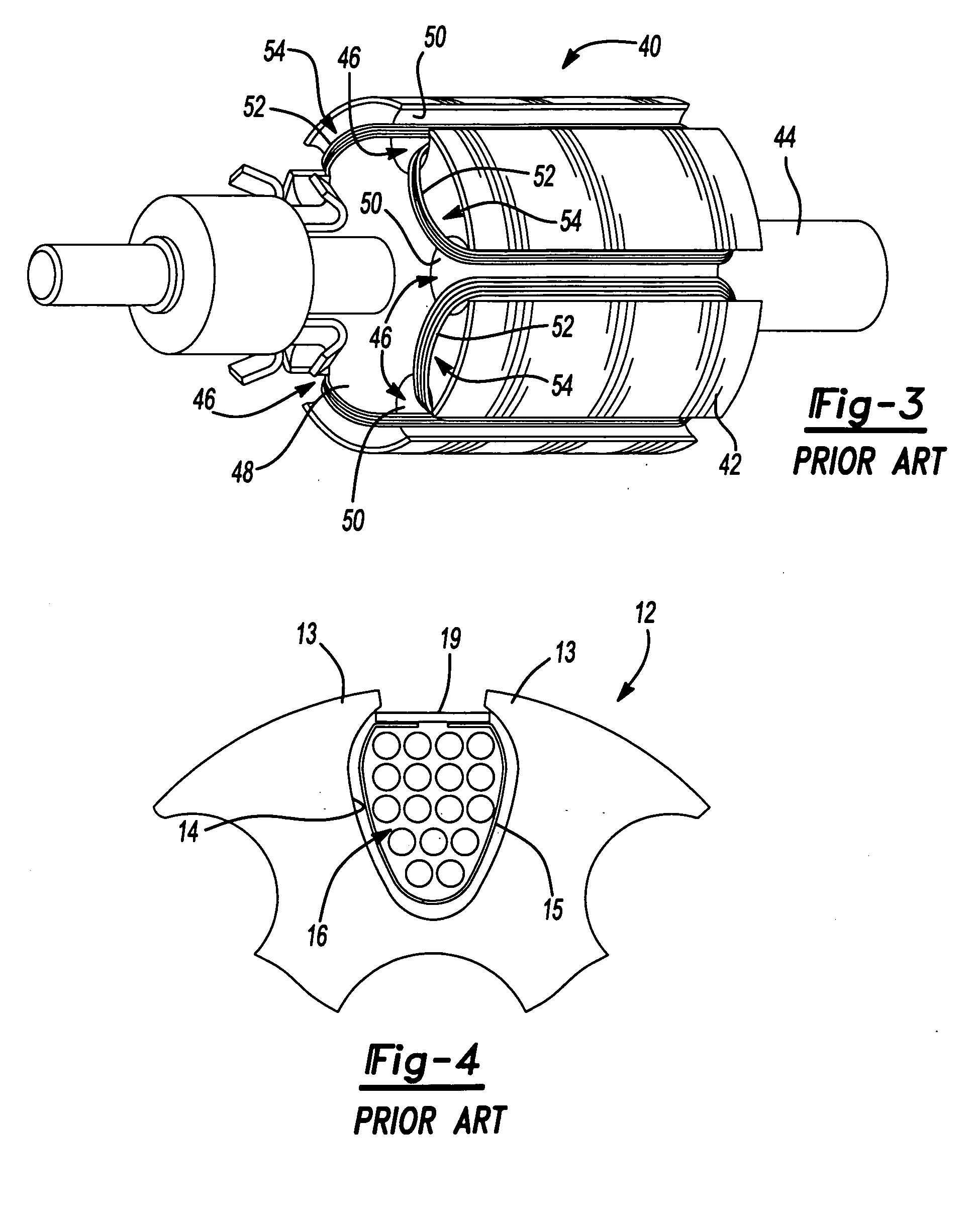

Field assembly and methods for assembling a field assembly

InactiveUS6847146B2Easy and economical to manufactureSynchronous generatorsWindingsEngineeringElectric motor

The present invention provides a field assembly for an electric motor and methods for assembling the field assembly. The field assembly includes a winding support and wire redirection structure. The field assembly may be used to manufacture motor assemblies having different polarities (both standard wound and reverse wound) for use with common motor housings, brushes, and wiring.

Owner:MILWAUKEE ELECTRIC TOOL CORP

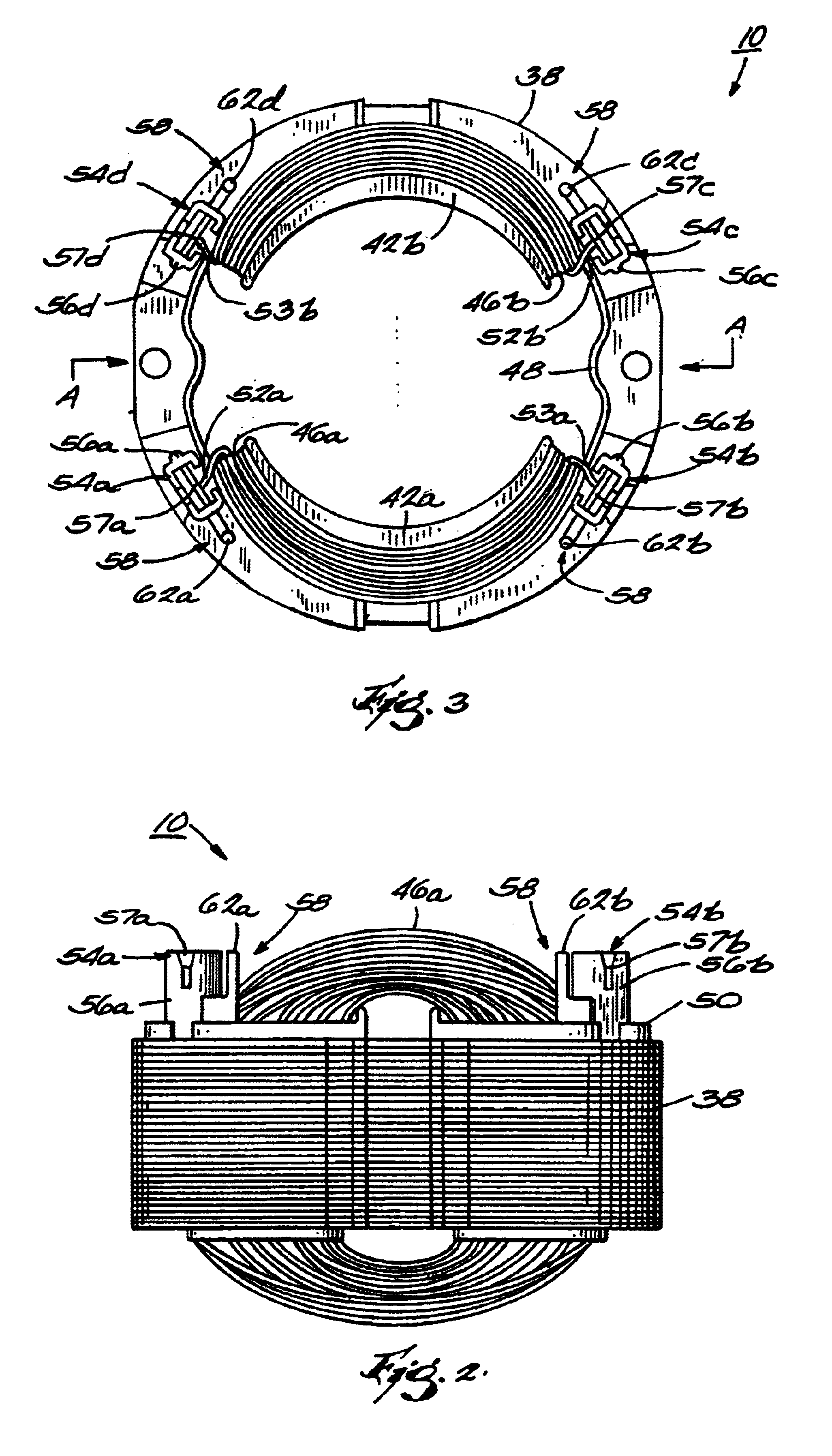

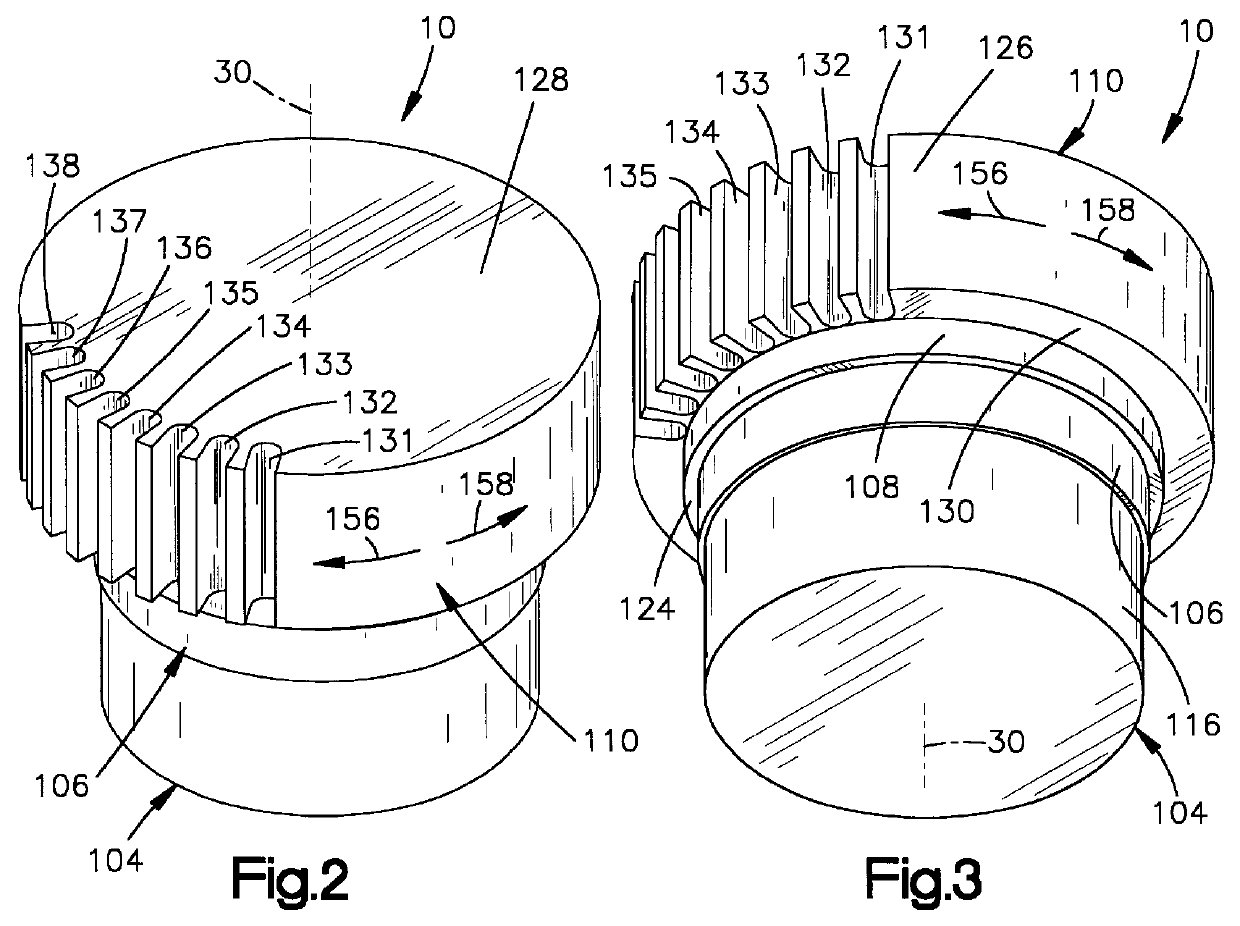

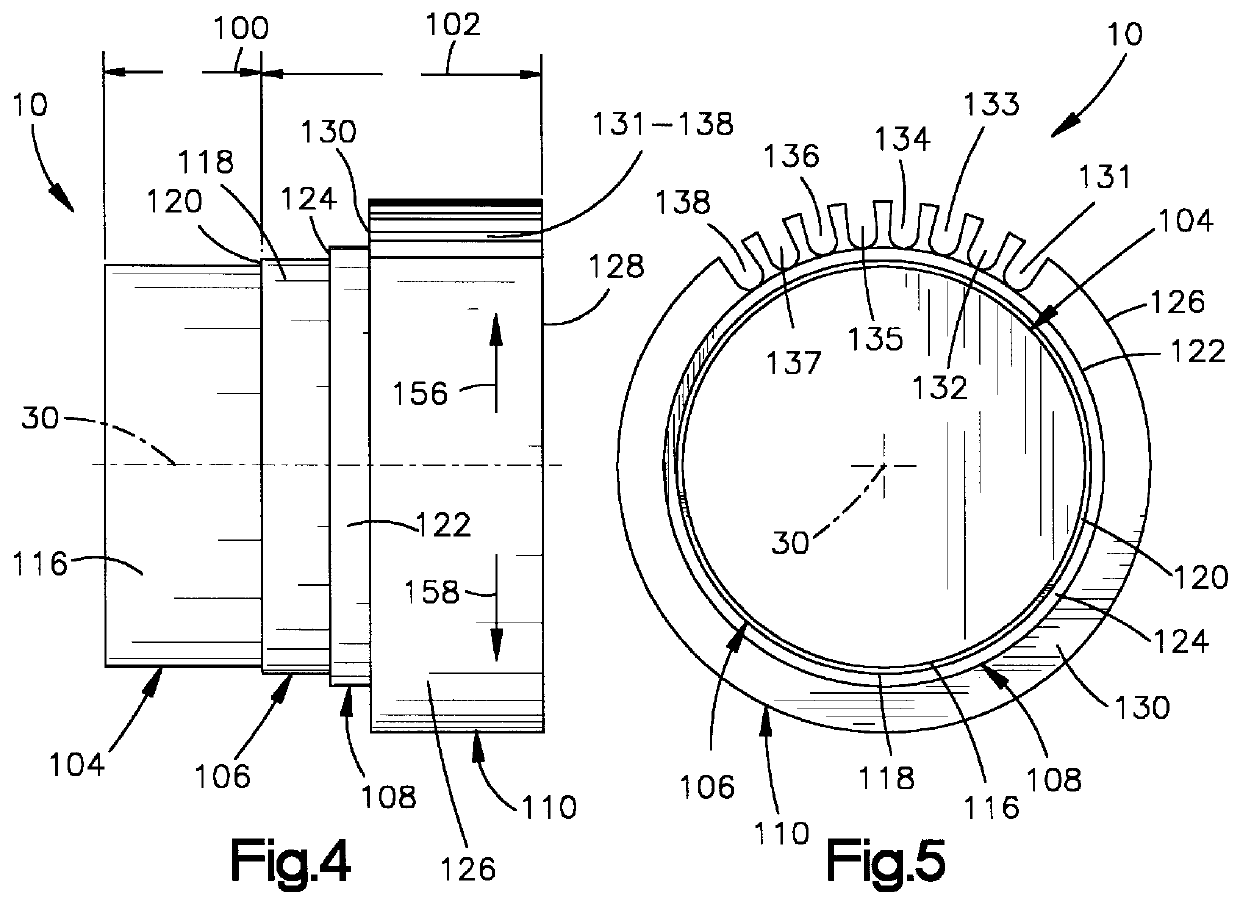

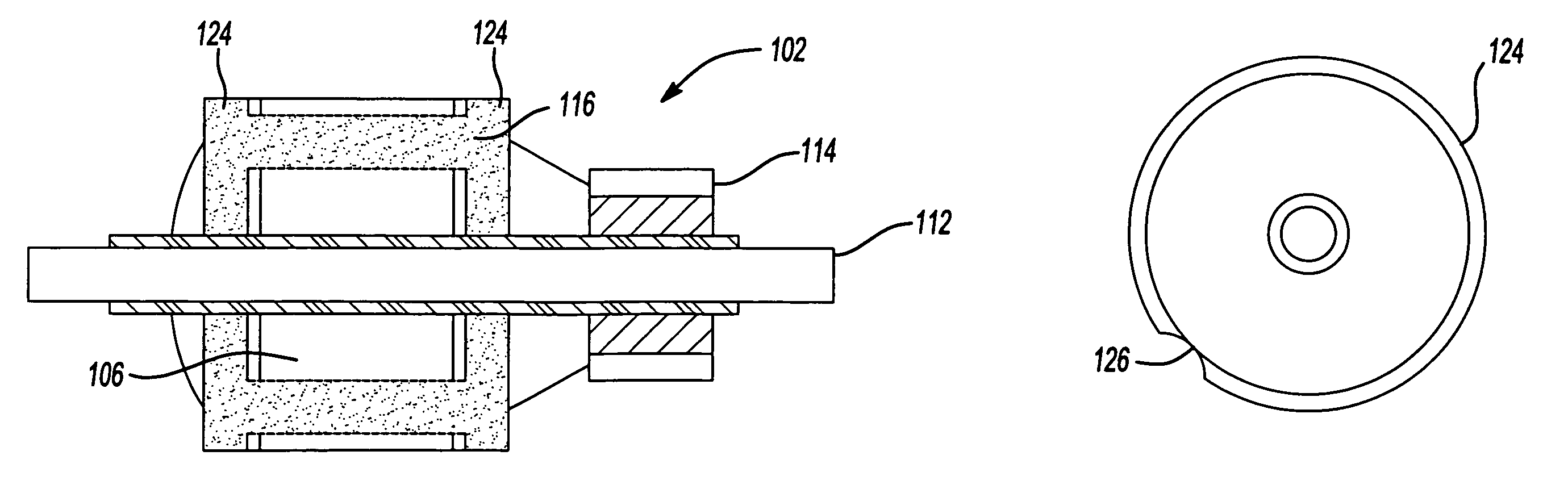

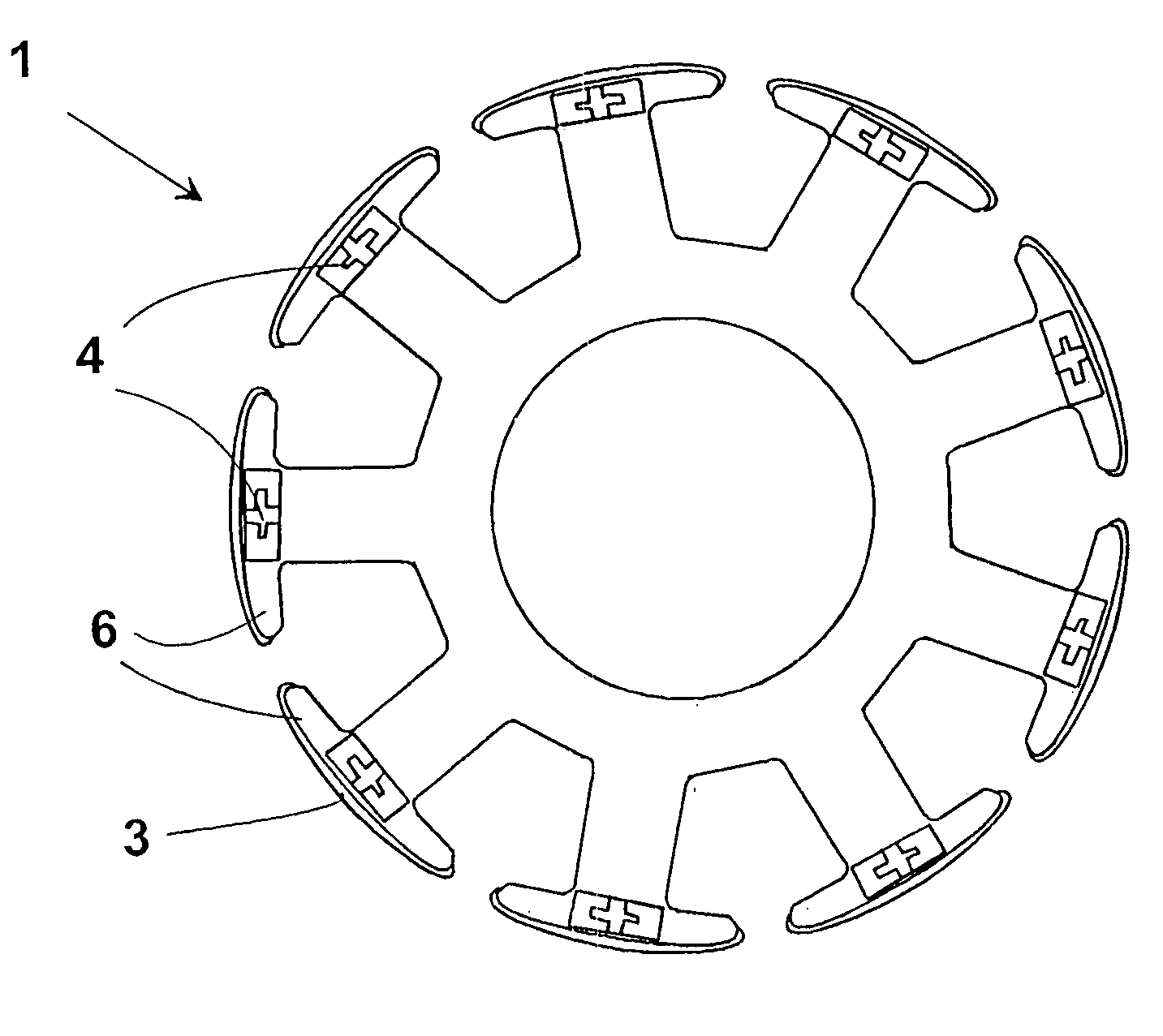

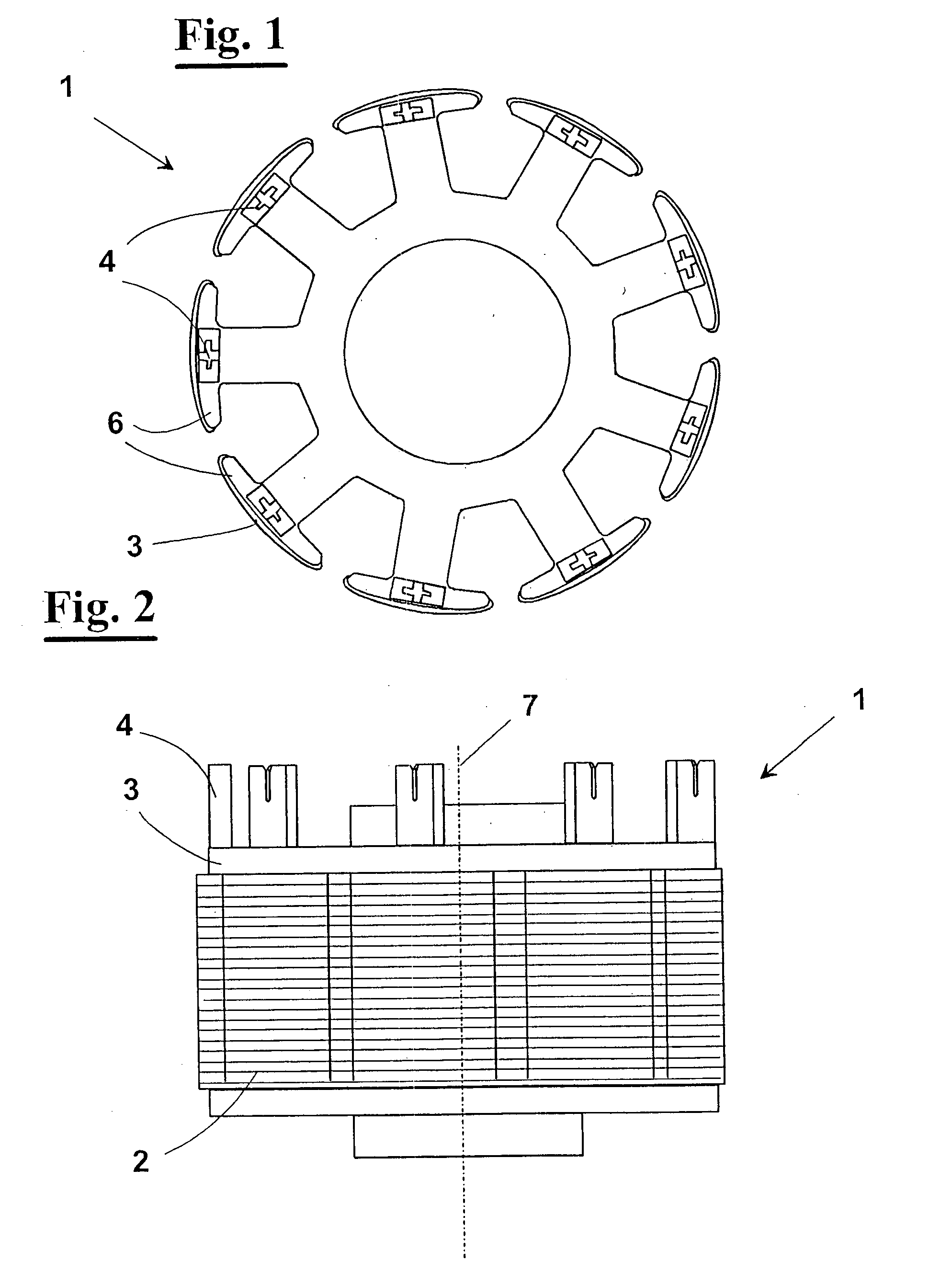

Motor stator winding tool

InactiveUS6141864AManufacturing winding connectionsMetal working apparatusInterference fitMagnetic poles

A winding tool (10) is used for connecting pairs of motor stator winding leads (91b-98b, 91c-98 c) and cutting of the connected pairs of leads to a predetermined length. The winding tool (10) includes a first part (100) received in the rotor space (88) in the motor stator (12) and a second part (102) projecting from a first end portion (72) of the motor stator. The first part (100) of the winding tool (10) has a cylindrical outer surface (116) engageable in an interference fit with a cylindrical inner surface (86) of the motor stator core (80) to resist radial and axial movement of the winding tool relative to the motor stator (12). The winding tool (10) has a plurality of slots (131-138) spaced circumferentially about an axis (30) and extending along an outer surface (126) of the second part (102) of the winding tool (10). The number of slots (131-138) is equal to the number of magnetic poles of the motor stator (12). The slots (131-138) have an axial length approximately equal to the predetermined length of the connected pairs of leads (91b-98b, 91c-98c).

Owner:TRW INC

Electric motor and method of making same and method of making a power tool

InactiveUS20060255678A1Speed up the processWindings insulation materialRotary current collectorPower toolMagnet wire

Owner:BLACK & DECKER INC

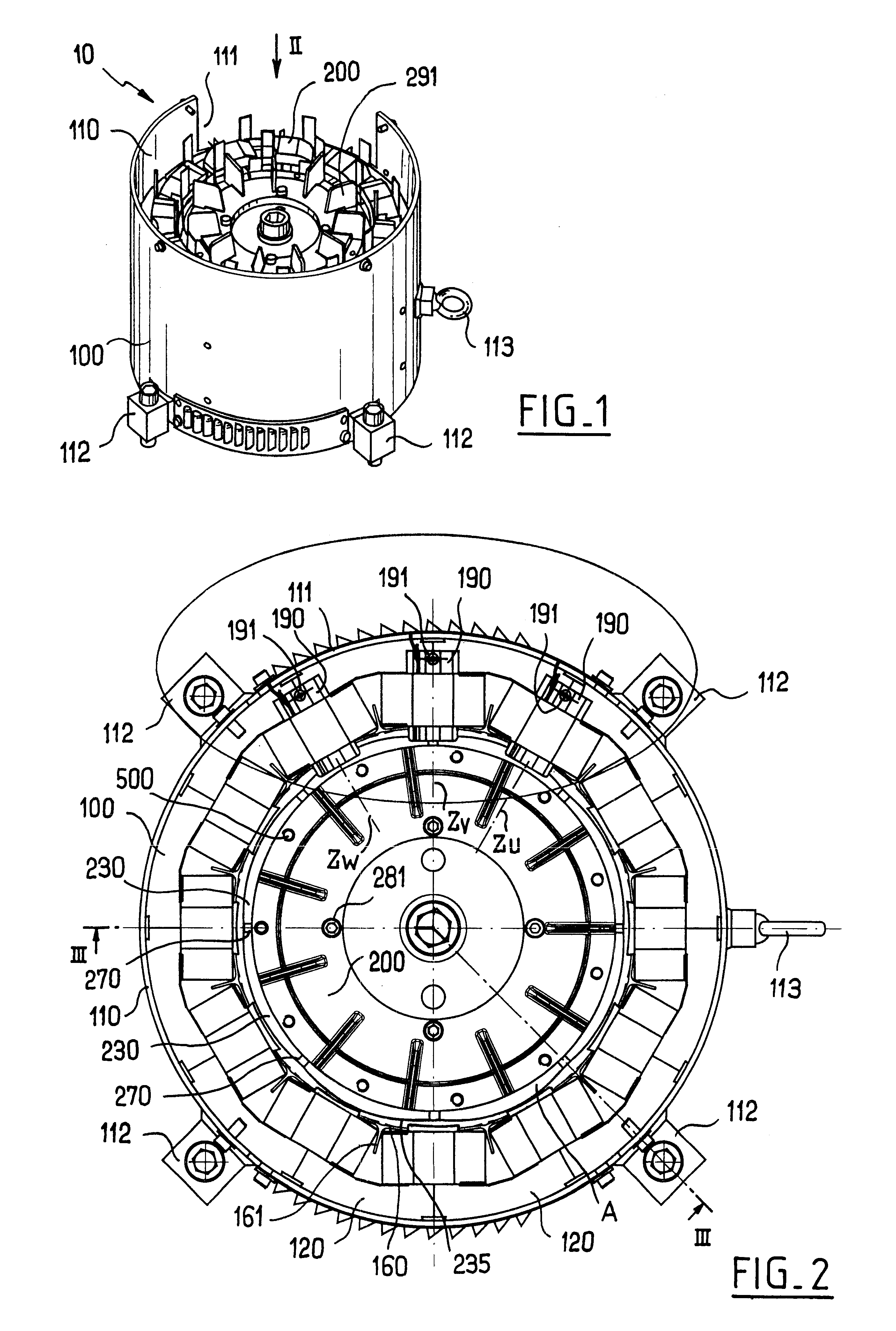

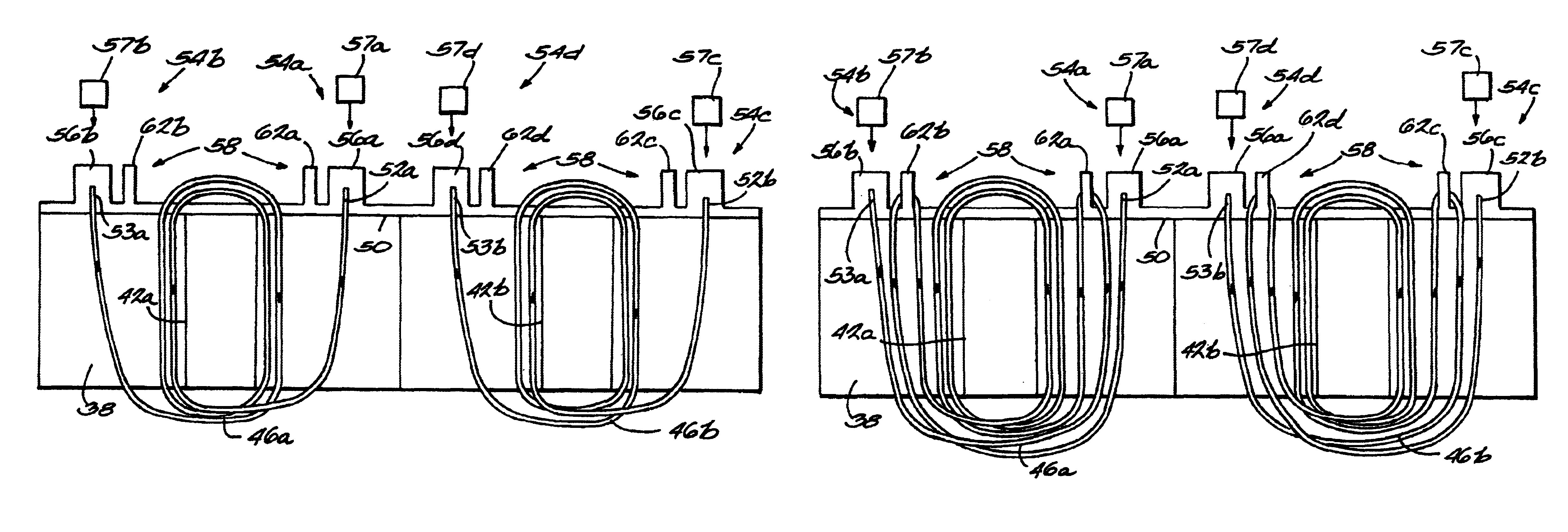

Method for producing coils and coil circuits

InactiveUS20060001327A1Reduced structureImprove space factorSynchronous machinesAsynchronous induction motorsElectric machineEngineering

The present invention relates to a method for manufacturing multiphase windings (32) of an electric machine, in which the following process steps are carried out. Cross-sectional profiles (13) that increase the slot space factor are stamped onto wire elements (7, 11, 12). Offsetting dies (14, 26) are loaded with stamped wire elements (7) to constitute the winding (32), stamped wire elements (11) to constitute an integrated star point (21), and stamped wire elements (12) for supplying current to the winding (32). The offsetting dies (14, 26) offset the stamped wire elements (7, 11, 12) in their end regions. An interconnection of the integrated star point (21) is produced by thermally attaching (30) the stamped wire elements (11) for the integrated star point (21)to a connecting ring (40) on an inside (41) of a finished winding head (20).

Owner:ROBERT BOSCH GMBH

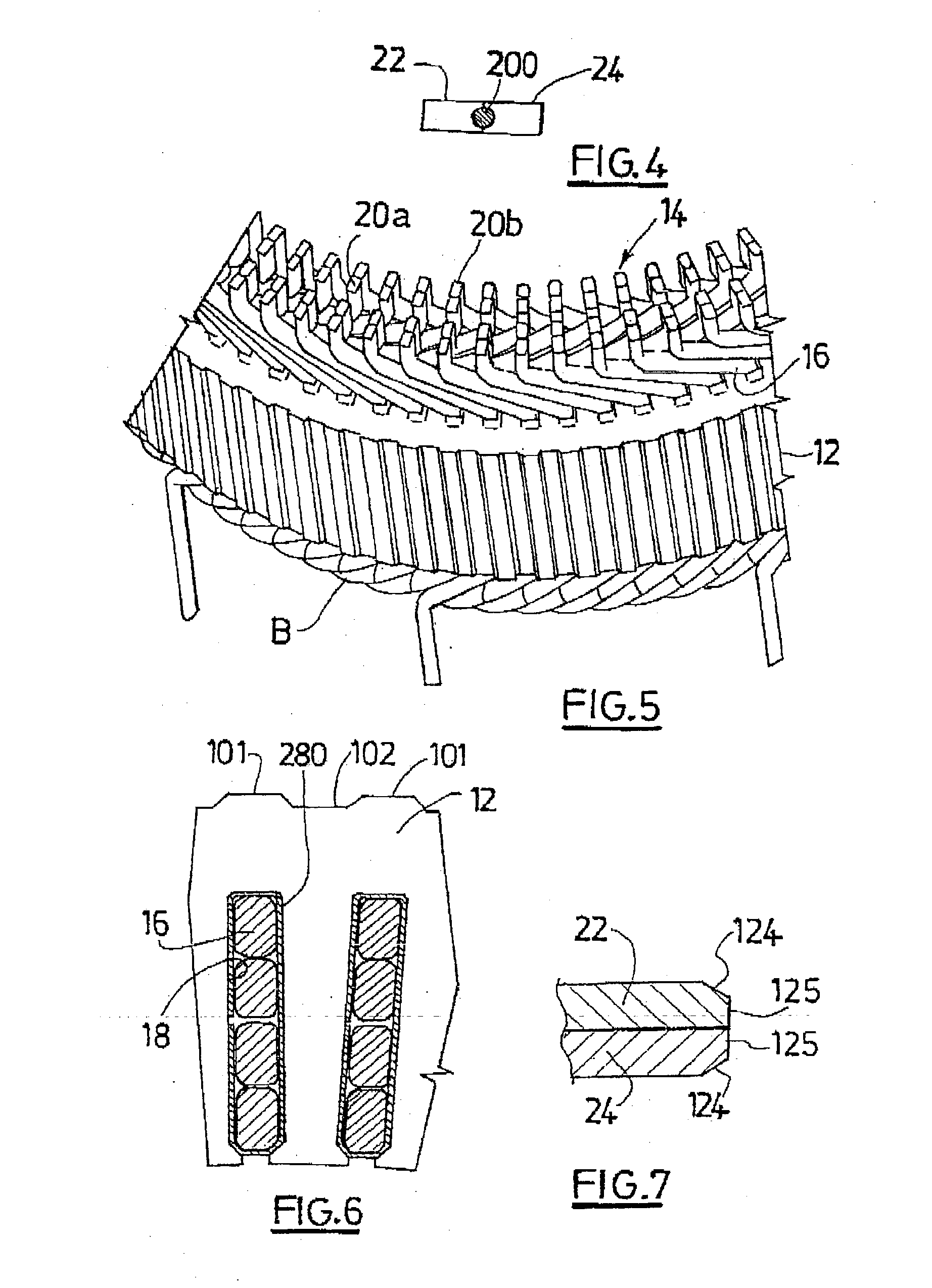

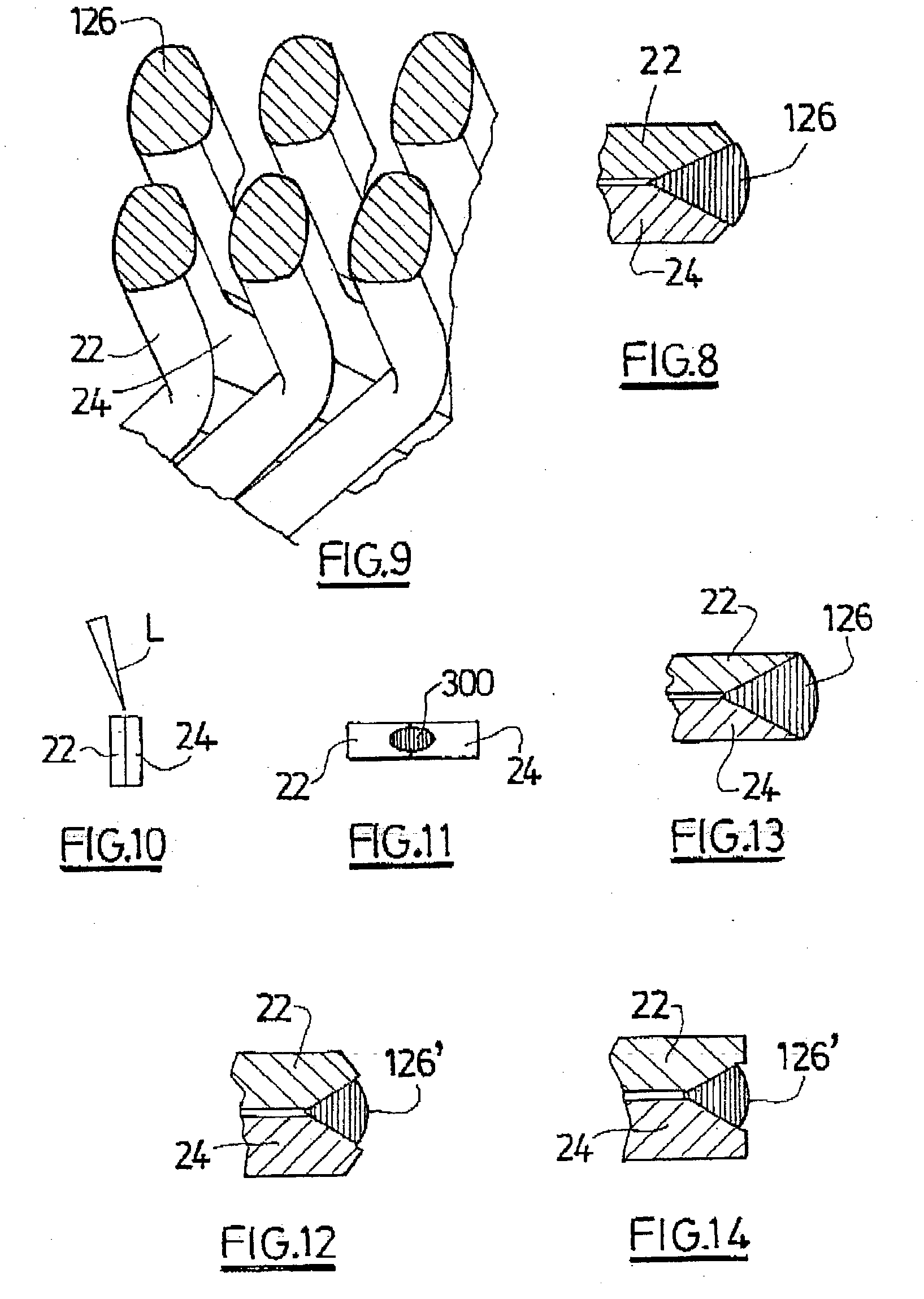

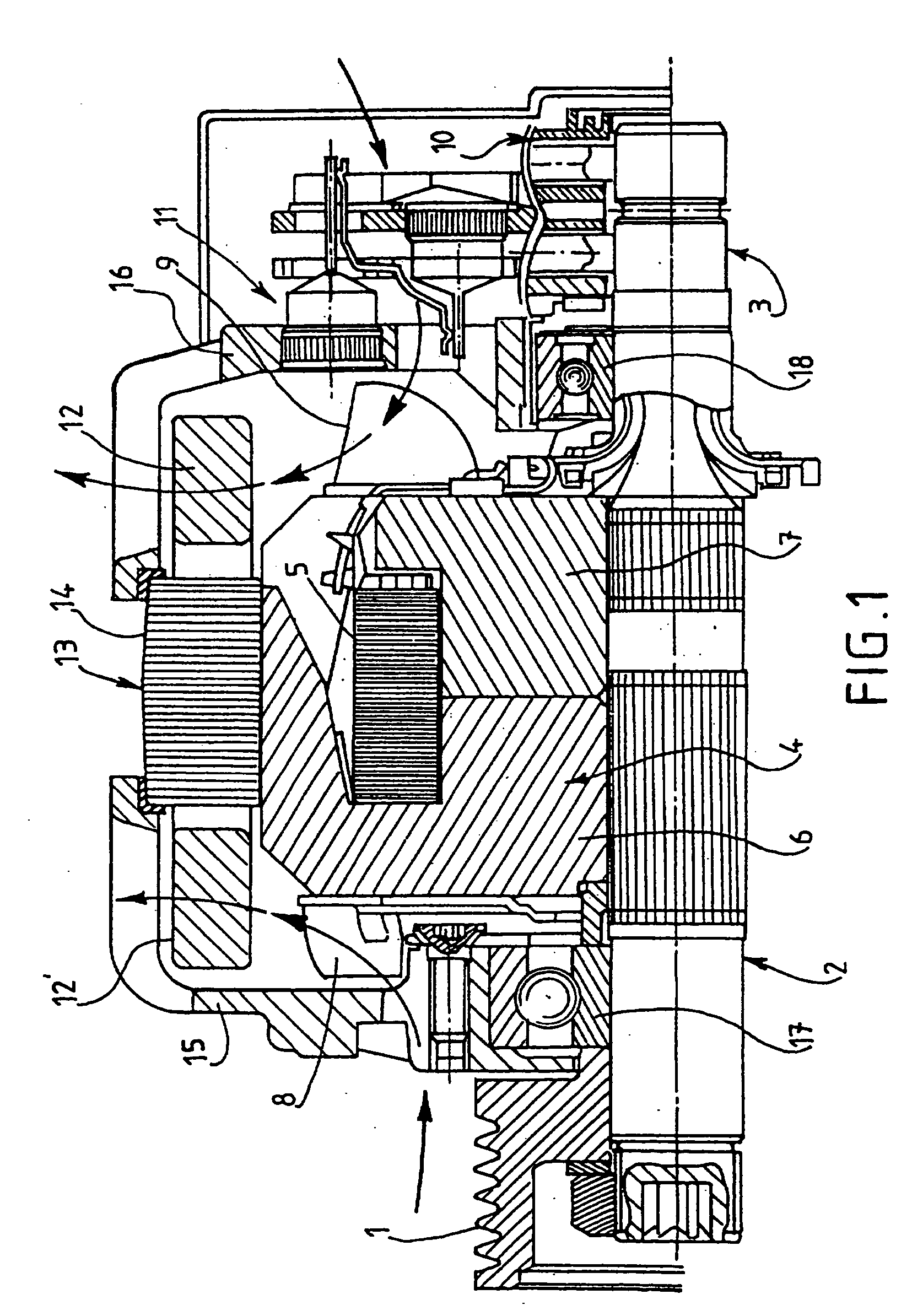

Method for assembling conductive segments of a rotor winding or stator winding in a rotary electric machine

InactiveUS20030159269A1Reduce assemblyRapid and simple and economicalMagnetic circuitSynchronous machinesElectrical conductorAlternator

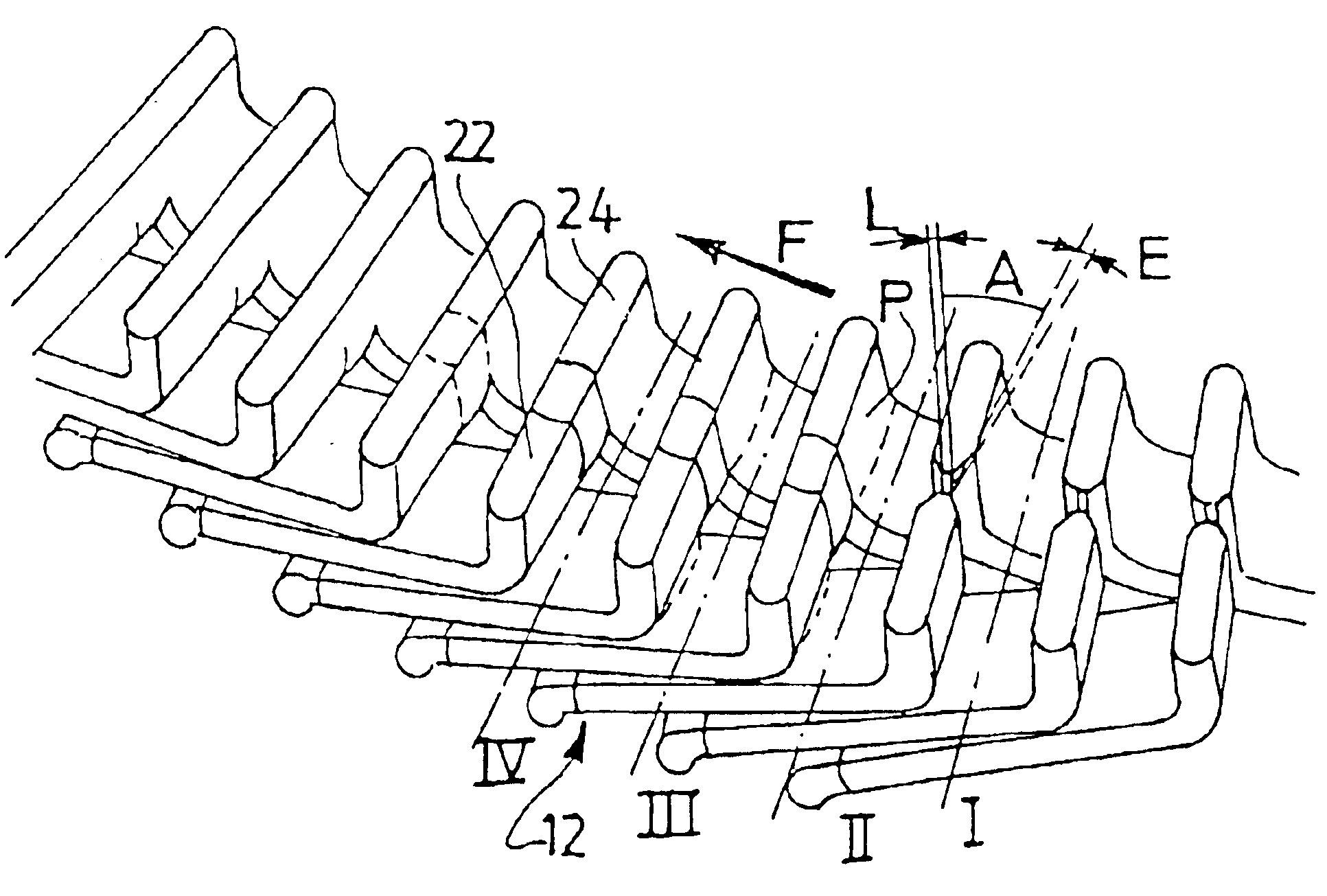

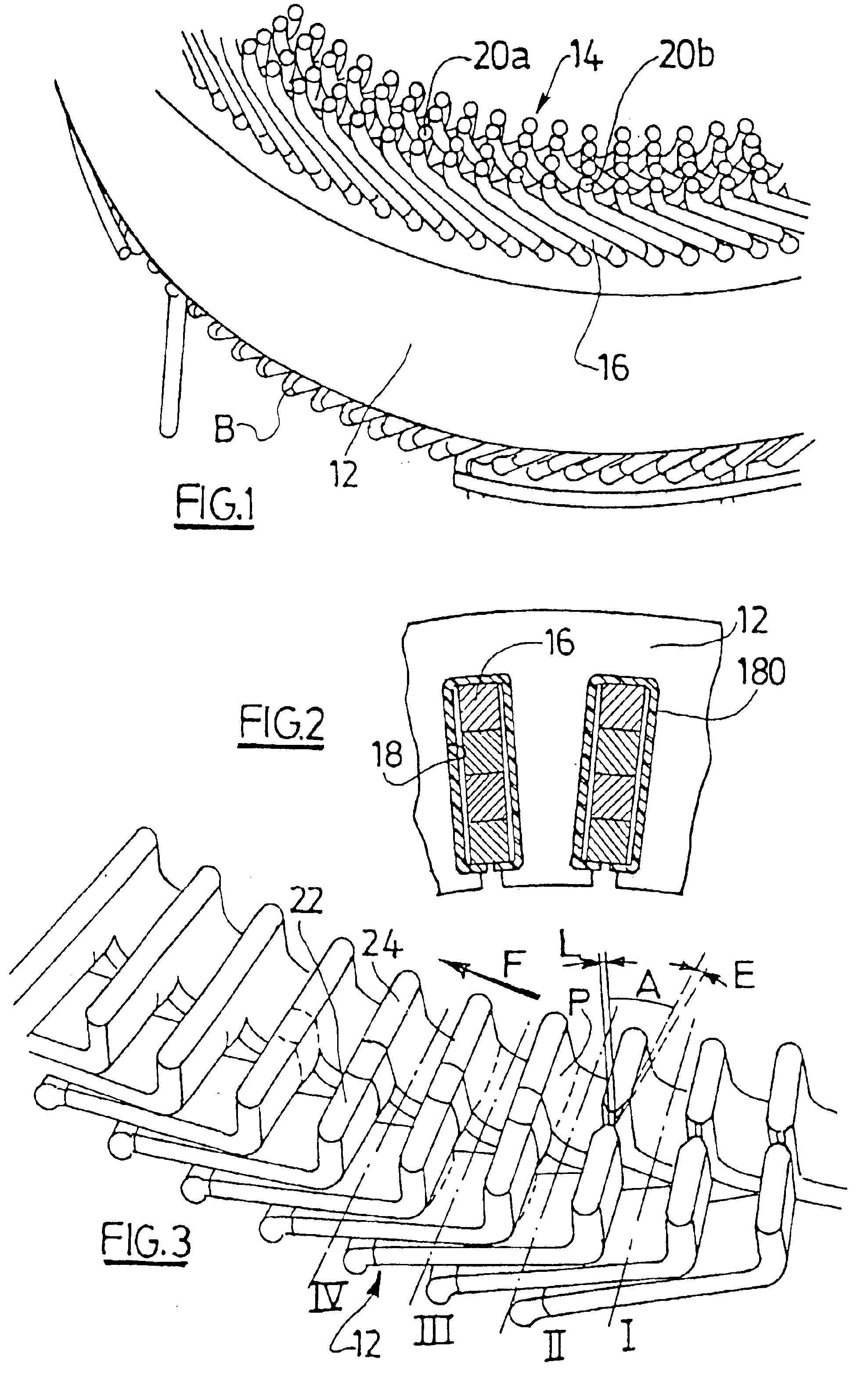

The inventive method of assembling conductive segments (16) of a rotor winding or a stator winding in a rotary electric machine comprises the following stages: insertion of the conductive segments (16) into slots made in a core (12) of the rotor or stator, whereby the free ends of the conductive segments protrude beyond the latter, and welding of the free ends of the conductive segments in groups of two in order to form a winding (14) around the rotor or stator. The conductor statements are both made of wire which is electrically conductive and coated with an electrically insulating material. The coating of electrically insulating material is removed in the welding zone of the conductive segments by the means used for welding the latter. The invention can be used for conducting segments of a rotor or stator winding in an alternator in a motor vehicle.

Owner:VALEO EQUIP ELECTRIC MOTEUR

Stator arrangement of rotary electric machine

InactiveUS6894415B2Avoid stayingEasy to stickSynchronous generatorsWindings insulation shape/form/constructionElectrical conductorElectric machine

A vehicle rotary electric machine includes a rotor, a stator having a stator core and a stator winding mounted in the stator core and a pair of frames for supporting the rotor and the stator. The stator winding has a plurality of conductor segments coated with insulation film. Each of the conductor segments has segment ends that are circumferentially aligned and form two or more rings. The segment ends that contact each other are welded and form joints of winding that have a bare surface. Therefore, electrolyte or foreign particles are prevented from staying at otherwise deteriorated insulation film.

Owner:DENSO CORP

Method for assembling conductive segments of a rotor winding or stator winding in a rotary electric machine

InactiveUS6915556B2Reduce assemblyRapid and simple and economicalMagnetic circuitSynchronous machinesAlternatorElectric machine

This process for assembling conductive segments (16) of a rotor or stator winding of a rotary electrical machine comprises the stages consisting in inserting the conductive segments (16) in slots arranged in a core (12) of the rotor or of the stator in such a way that the conductive segments project beyond the latter by their free ends, and in welding the conductive segments in pairs by their projecting free ends to form a winding (14) around the rotor or the stator.The conductive segments each being formed by a wire of electrically conductive material covered with a layer of electrically insulating material, the layer of electrically insulating material is eliminated, in the zone in which the conductive segments are welded, by the means used to weld the latter.Application to the assembly of conductive segments of a rotor or stator winding of a motor-vehicle alternator.

Owner:VALEO EQUIP ELECTRIC MOTEUR

Method of manufacturing armature of rotary electric machine

ActiveUS7302750B2Process can be speededSmall sizeWindings insulation shape/form/constructionMagnetic circuit rotating partsElectrical conductorElectric machine

An armature of a rotary electric machine composed of an armature core, an armature winding and a shaft is manufactured in the following manner. A conductor bar including plural conductors connected in line is formed, and each conductor is cut out from the conductor bar. The conductor in a straight shape is inserted into each slot of the armature core, and then both side portions of the conductor are bent at substantially right angle so that the side portions are positioned along axial end surfaces of the armature core. The side portions are further skewed and electrically connected to form the armature winding. An outer surface of the side portions circularly arranged on the axial end surface of the armature core is used as a commutator surface.

Owner:DENSO CORP

Methods for twisting rotor and stator ends

ActiveUS8215000B2Synchronous machinesAsynchronous induction motorsElectrical conductorInterconnection

Owner:TECNOMATIC

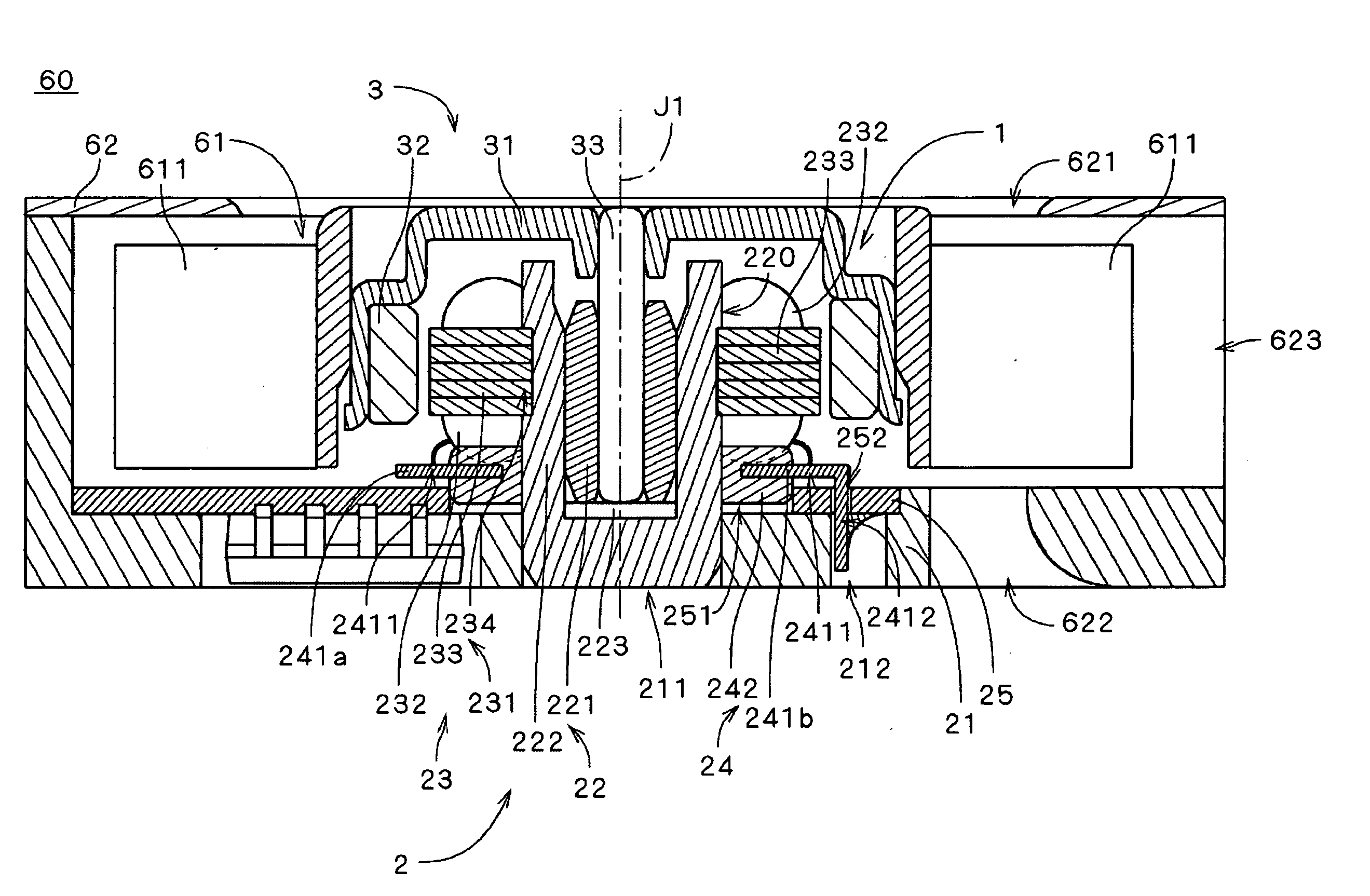

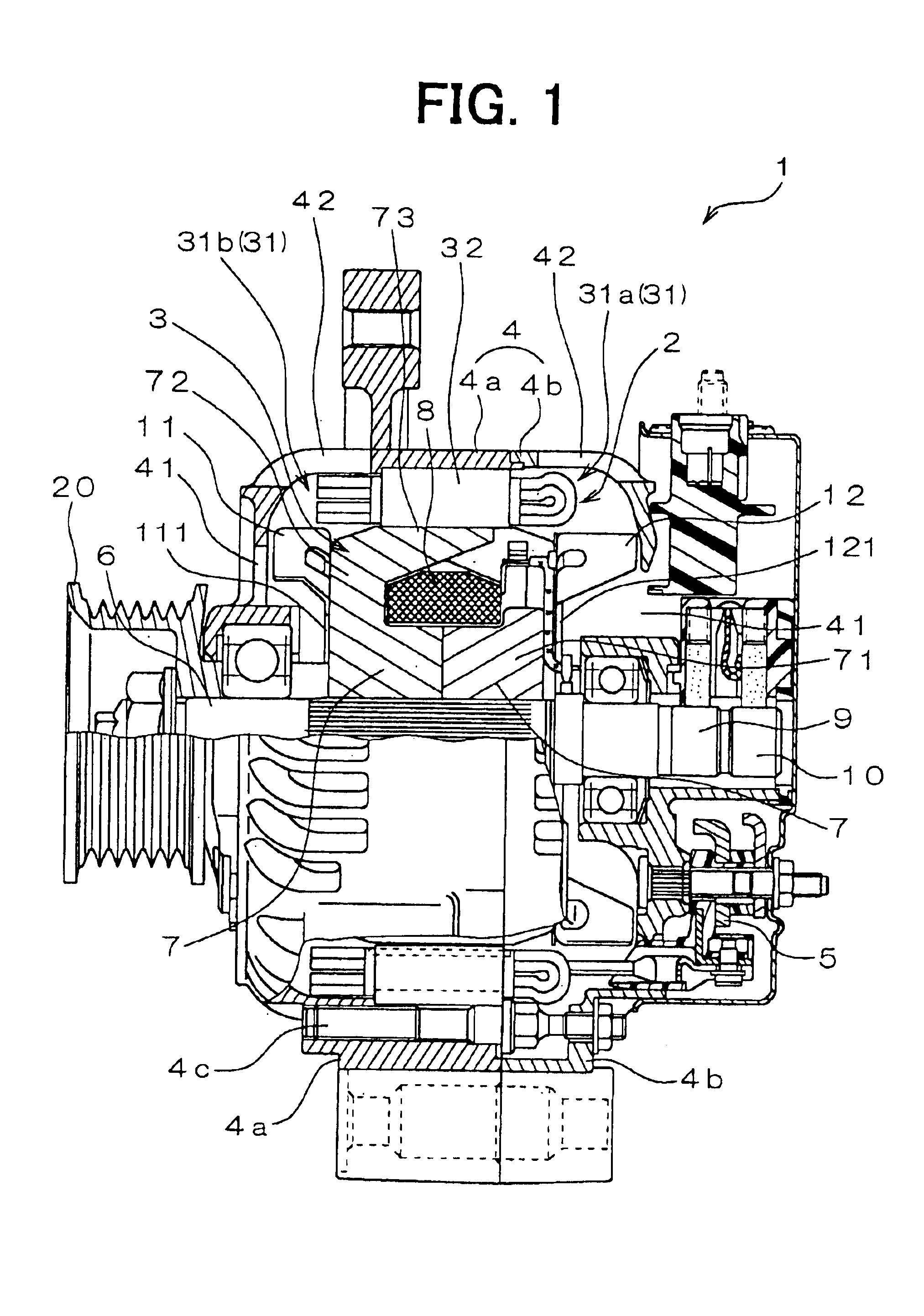

Method of manufacturing stator unit, and motor using the stator

ActiveUS20070007834A1Easy to manufacturePreventing open circuitWindingsMagnetic circuitEngineeringElectric motor

In manufacturing of the stator unit 2 according to one preferred embodiment of the present invention, a plurality of terminal pins are arranged in an axially spaced manner from a plurality of the coils during a twining process of the wires from the coils 232 to the terminal pins 241. Then, after the wire is twined to the terminal pins, the terminal pins connected to the coils are moved along the outer side face of the sleeve housing, functioning to as a guide portion for the terminal pins. By virtue of the configuration, the terminal pins 241 may be approximated to the coils without applying the tension on wire, and the stator unit may be made thin with preventing the open circuit of the wires.

Owner:NIDEC CORP

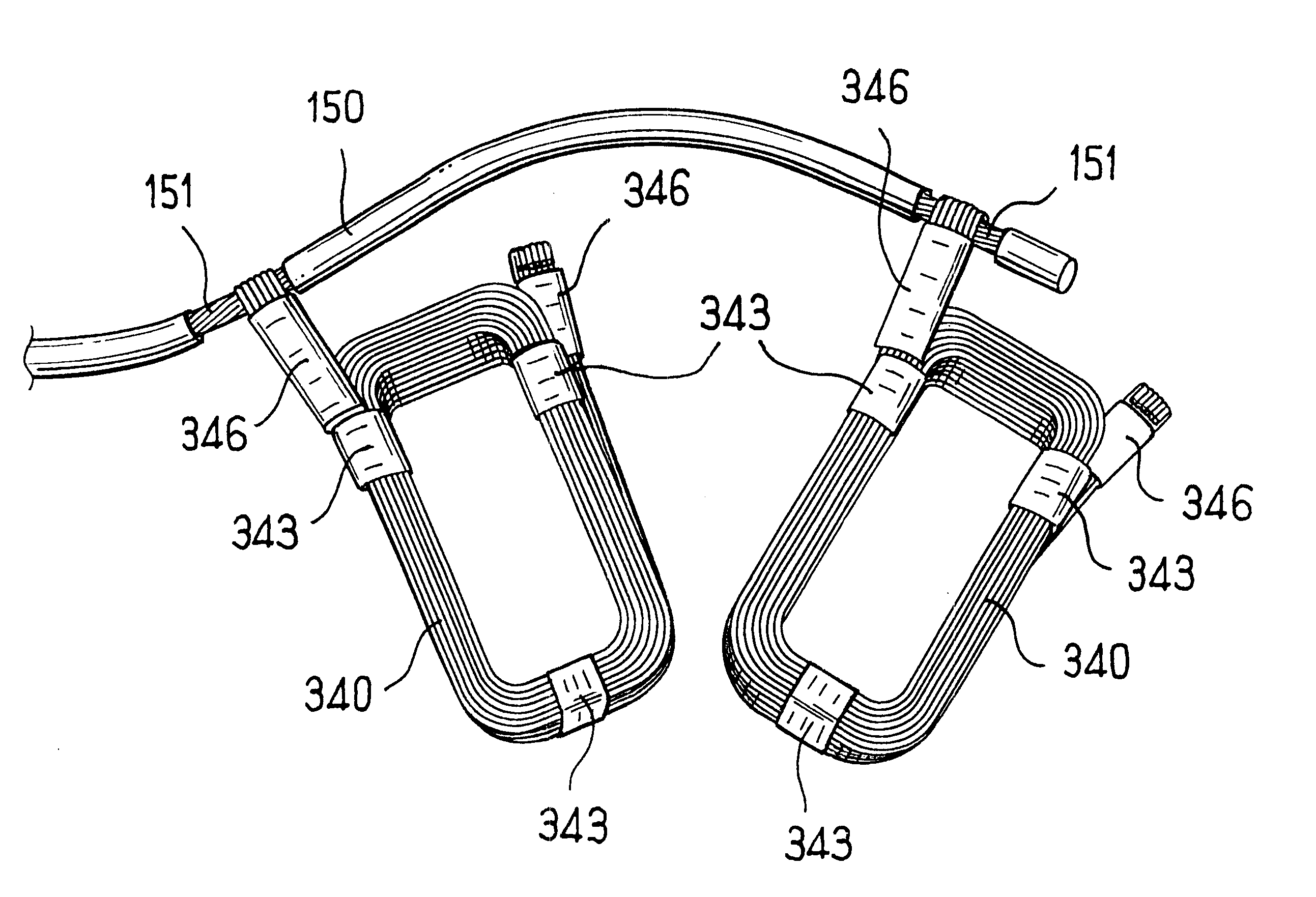

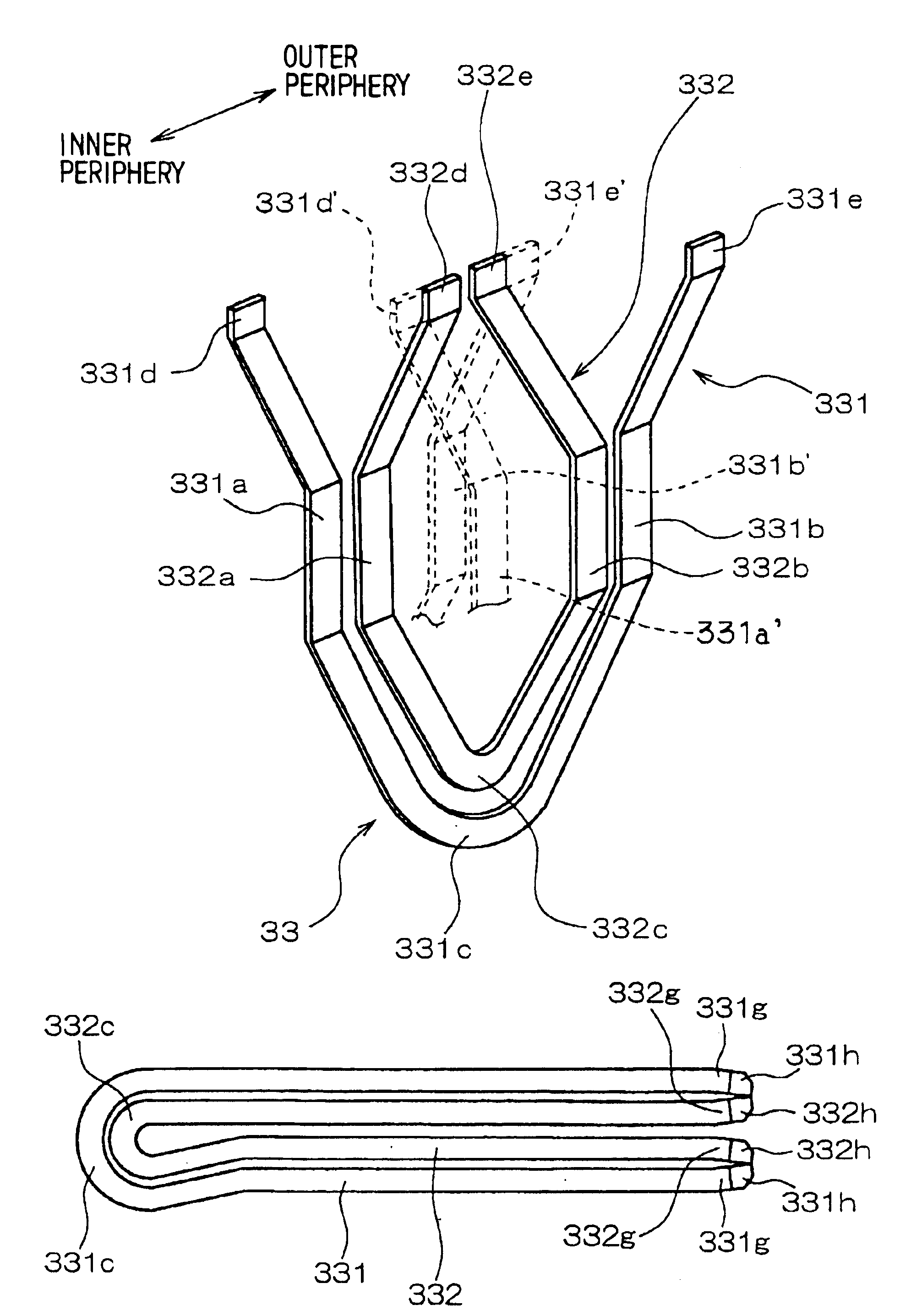

Winding for electric rotating machine and manufacturing method for the same

ActiveUS6903478B2ConnectionReduce distanceSynchronous generatorsMagnetic circuitConductor CoilMechanical engineering

A method for manufacturing a winding for an electric rotating machine includes steps of altering, passing, shaping, and connecting. In the altering step, connecting portions of conductor segments, a part of which is exposed, are altered in shape by a pressing die to provide good contact between the segments when they are connected. The altered segments are passing through slots of a stator core in the passing step. Ends of protruded portions of the segments are shaped so that they make an angle with respect to the radial section of the stator core in the shaping step. Adjacent segments are connected together at ends of the connecting portion in the connecting step.

Owner:DENSO CORP

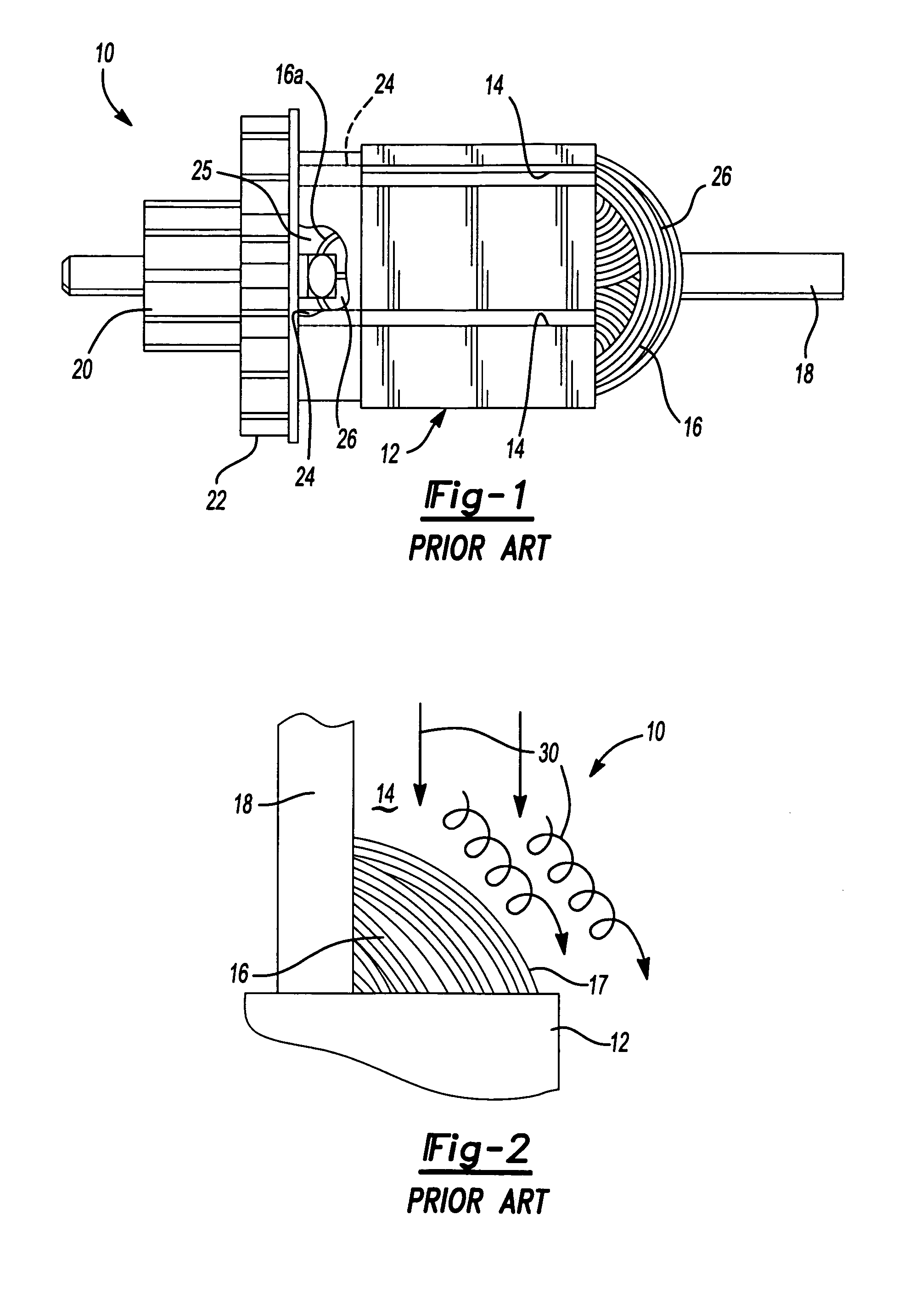

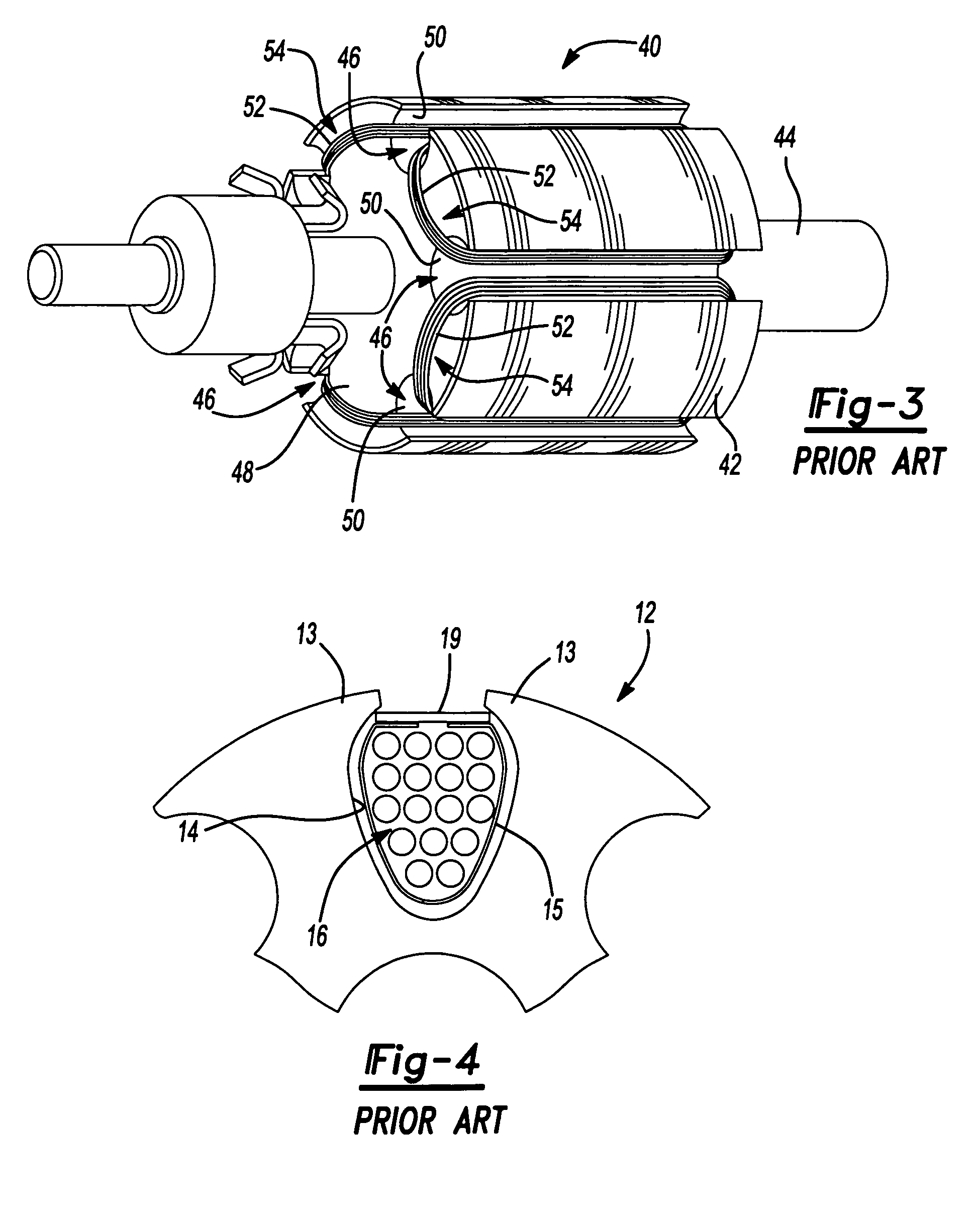

Stator winding and coil lead termination method and apparatus

The reciprocating and oscillating winding spindle of a stator winding machine is rotatable through 180.degree. to enable a stator winding and lead terminating method and apparatus for automatically winding a 2-pole stator having two pole pieces each with a coil wire wound from the same, single strand of wire. A cross-over wire segment between the two stator coils extends through the bore of the stator and is trapped against an inside wall of the stator by a cross-over wire retaining member. A stator coil lead terminating apparatus is capable of complex manipulations of stator coil lead wires at a winding station. Stator coil lead wires can be looped about wire guide posts on a stator core in the course of forming coil lead terminations, and the posts can be protected against bending or breaking by looping pins that partly receive the posts.

Owner:GLOBE PRODS

Method of forming a power tool

InactiveUS7814641B2Increase stiffnessIncrease critical speedWindings insulation materialRotary current collectorEngineeringPower tool

A method of forming a power tool includes forming and balancing an armature by securing a lamination stack having slots therein on an armature shaft securing a commutator on one end of the armature shaft, winding magnet wires in the slots in the lamination stack and securing ends of the magnet wires to the commutator, and molding plastic to at least partially encase the magnet wires in plastic and forming a balancing feature. Plastic is removed from the balancing feature during dynamic balancing of the armature. The armature is then disposed in a stator to form an electric motor and the electric motor is disposed in a power tool.

Owner:BLACK & DECKER INC

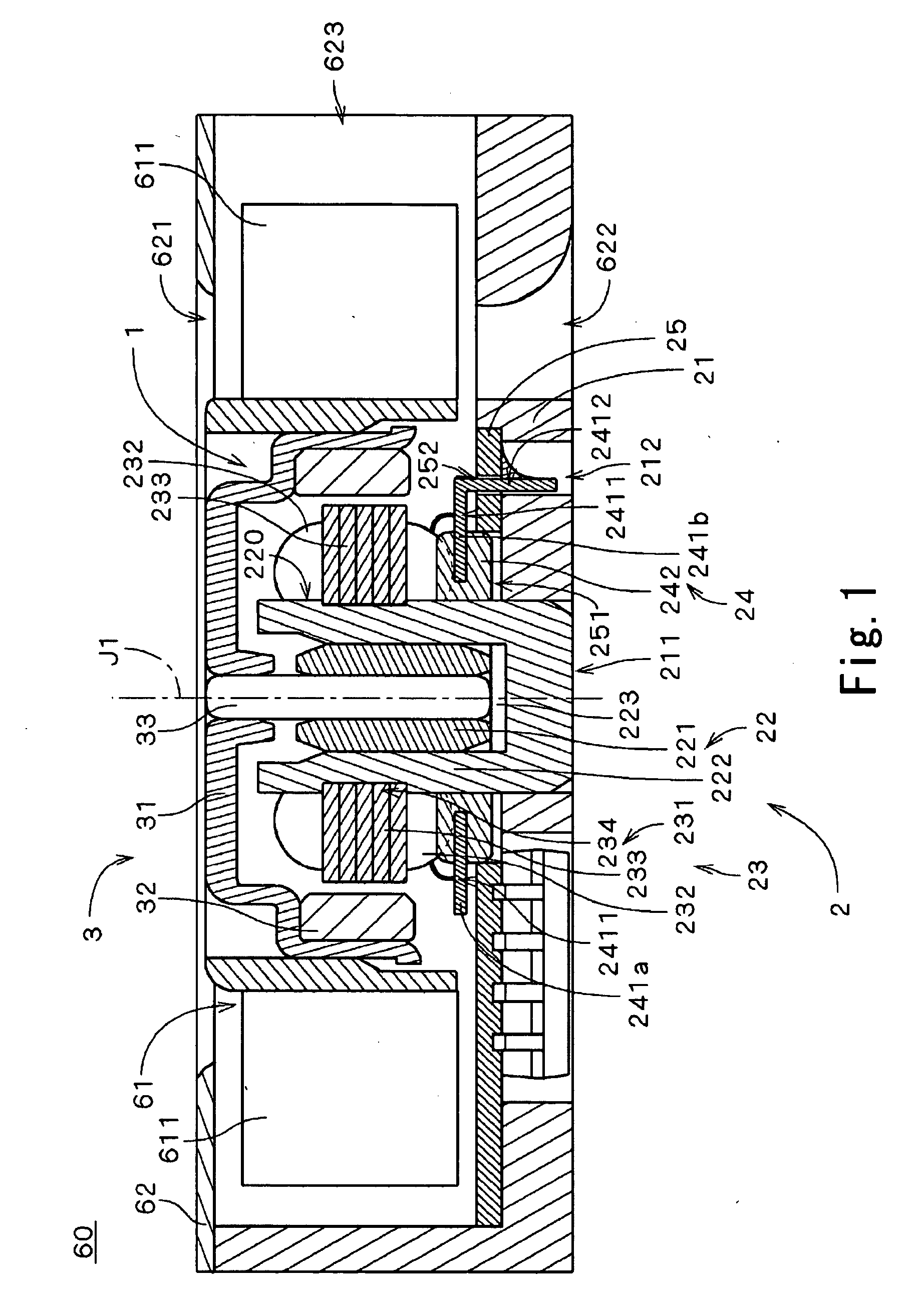

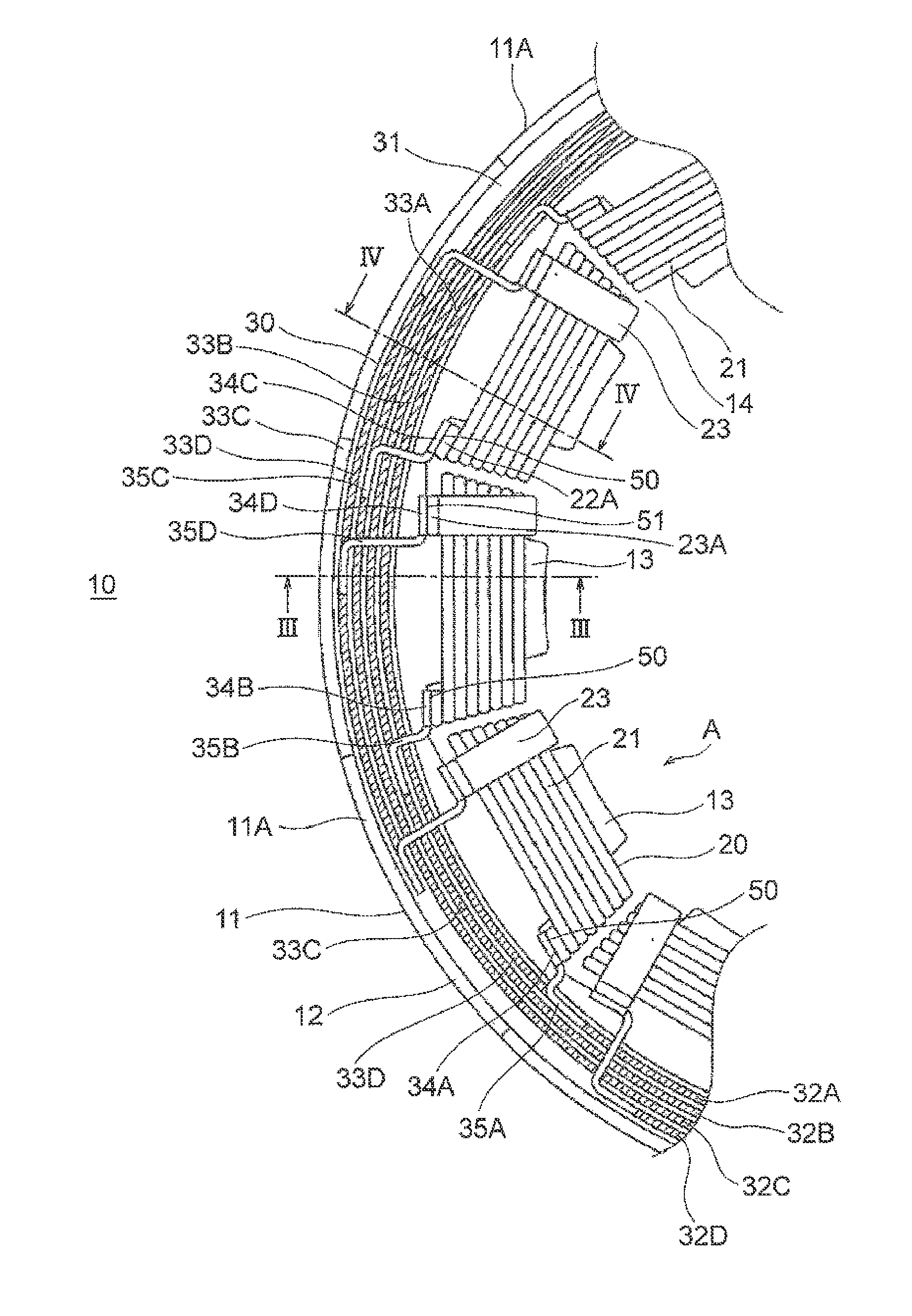

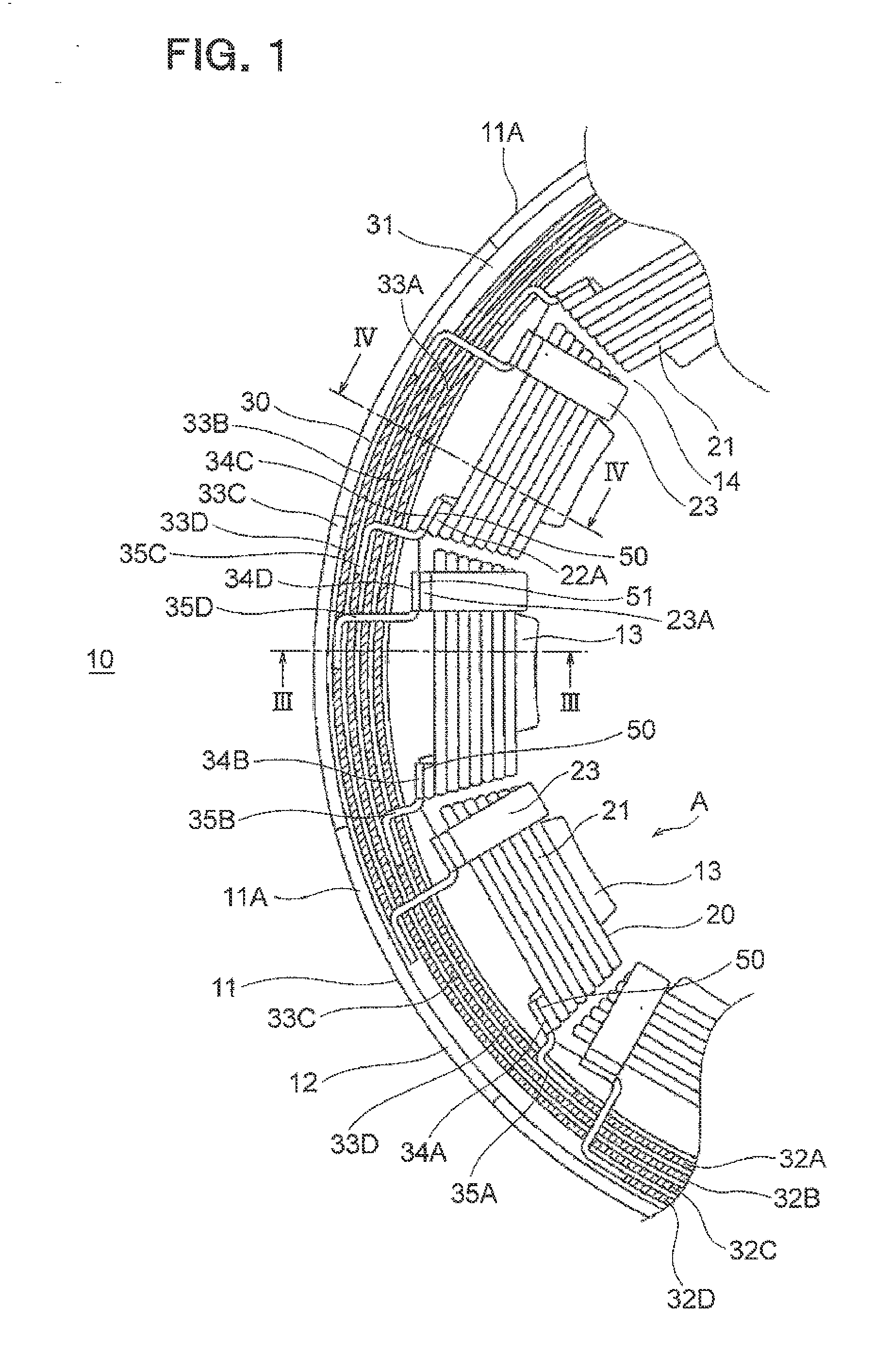

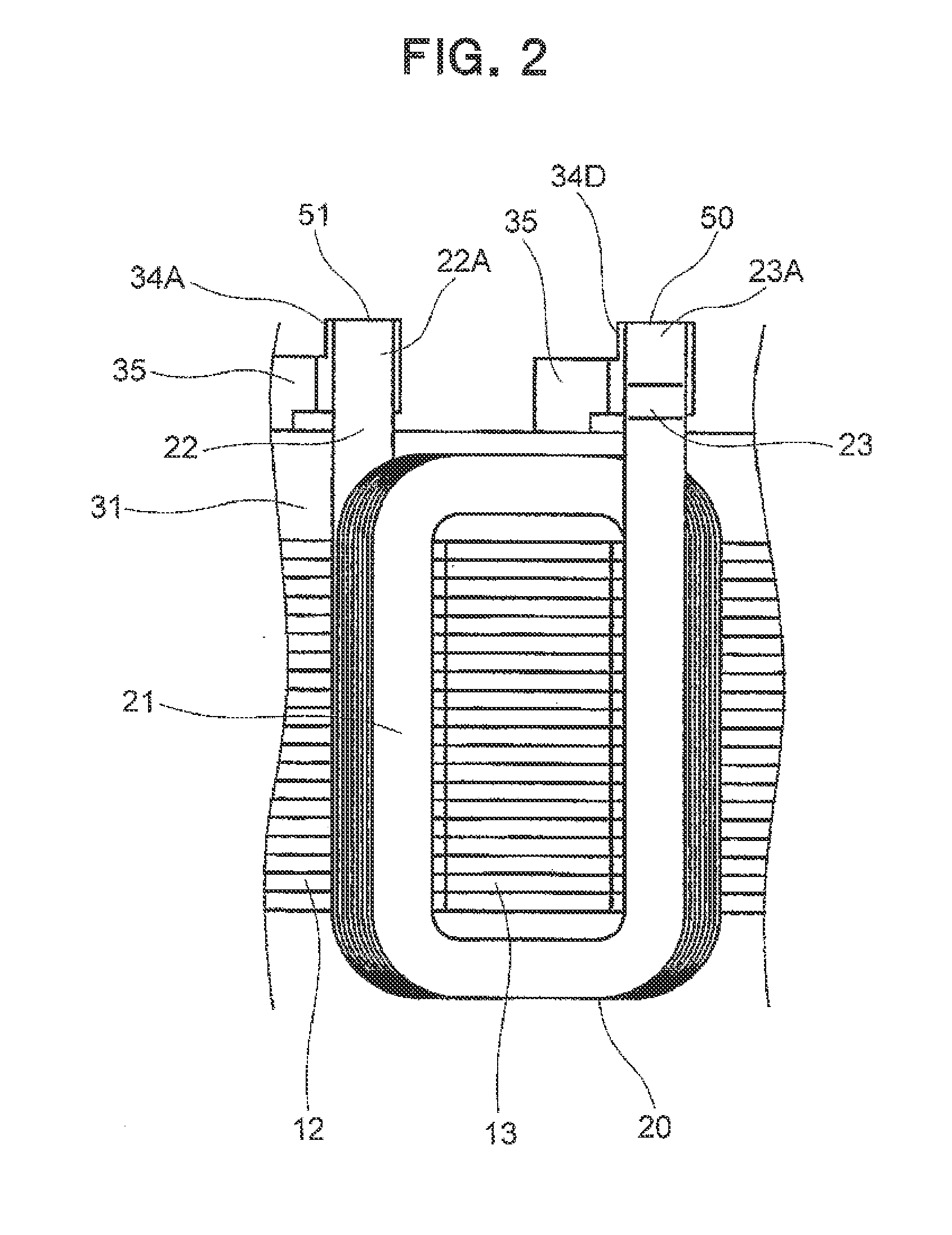

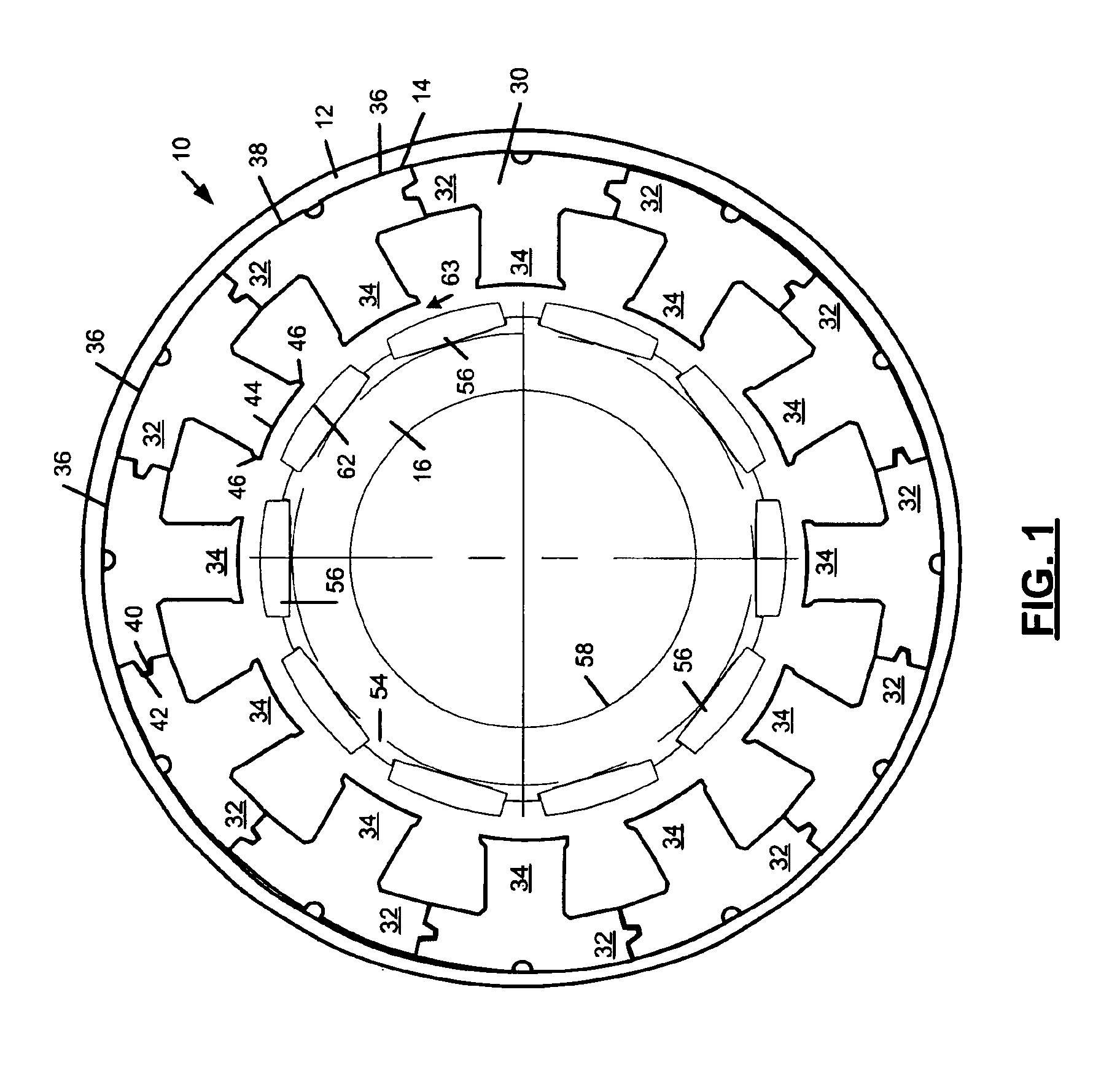

Stator for rotary electric machine and method for manufacturing the stator

ActiveUS20140070646A1Small sizeReduce spacingWindings insulation shape/form/constructionManufacturing winding connectionsMechanical engineeringElectric machine

Provided is a stator for a rotary electric machine, capable of reducing a space on an end surface of a stator core on an inner diameter side to reduce a size in an axial direction to realize a compact size by maintaining an insulating distance corresponding to a potential difference. In the stator for a rotary electric machine according to the present invention, a coil portion includes a coil main-body portion (21) and a second connecting wire (23). The second connecting wire (23) includes a first bent portion (24) and a second connecting-wire end portion (23A). The second connecting wire (23) is configured so that a differential value of a length z in the axial direction of the stator to a length r in the radial direction of the stator is Δz / Δr≧0.

Owner:MITSUBISHI ELECTRIC CORP

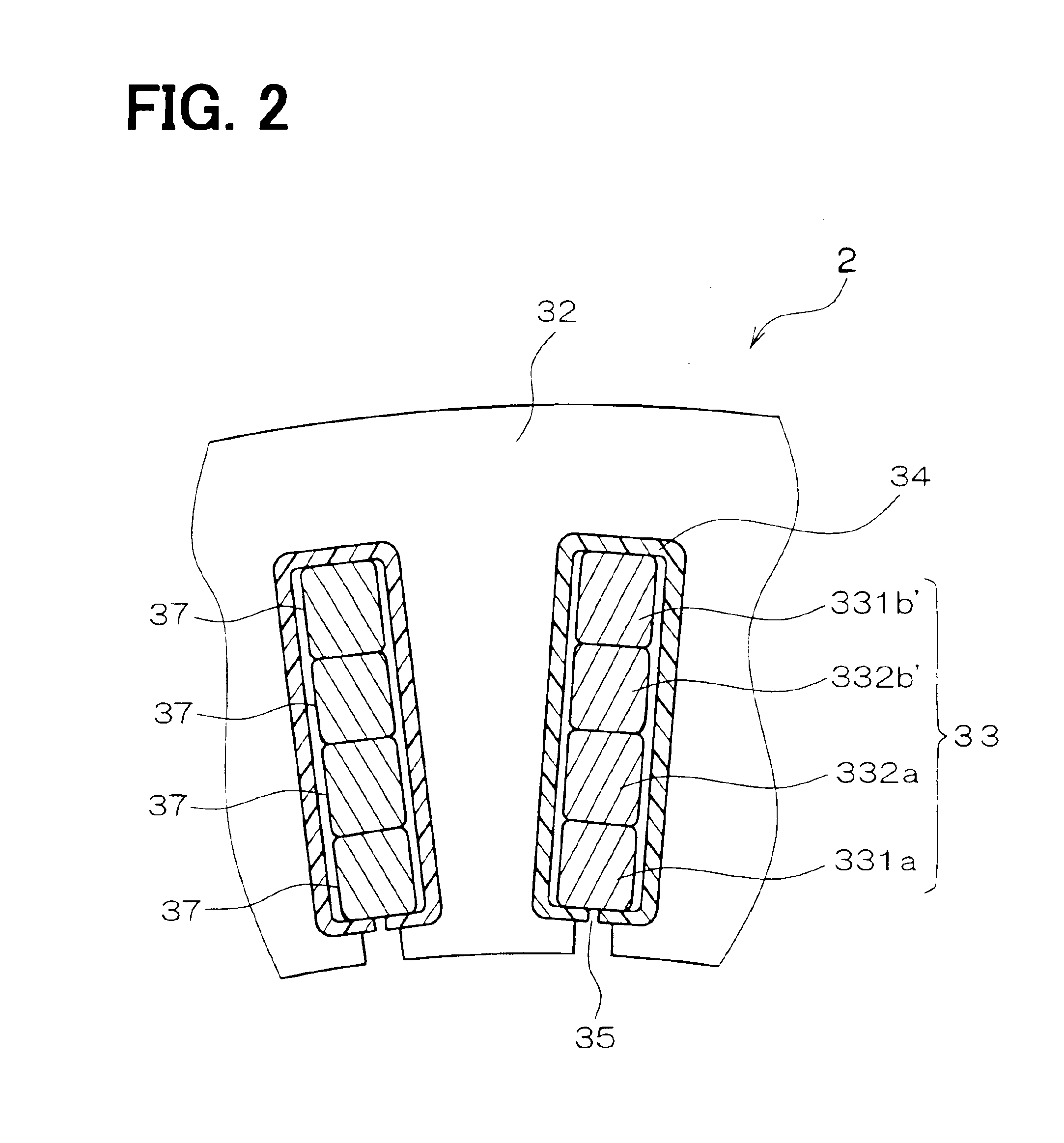

Rotary electric machine stator and method of manufacturing the same

A rotary electric machine stator includes a stator core having plural slots and a stator winding that is composed of plural conductor segments. Each conductor segment has a straight portion disposed in the slot and connection ends projecting from the slots and welded to another. The connection ends to be welded cross each other at an angle larger than zero degree.

Owner:DENSO CORP

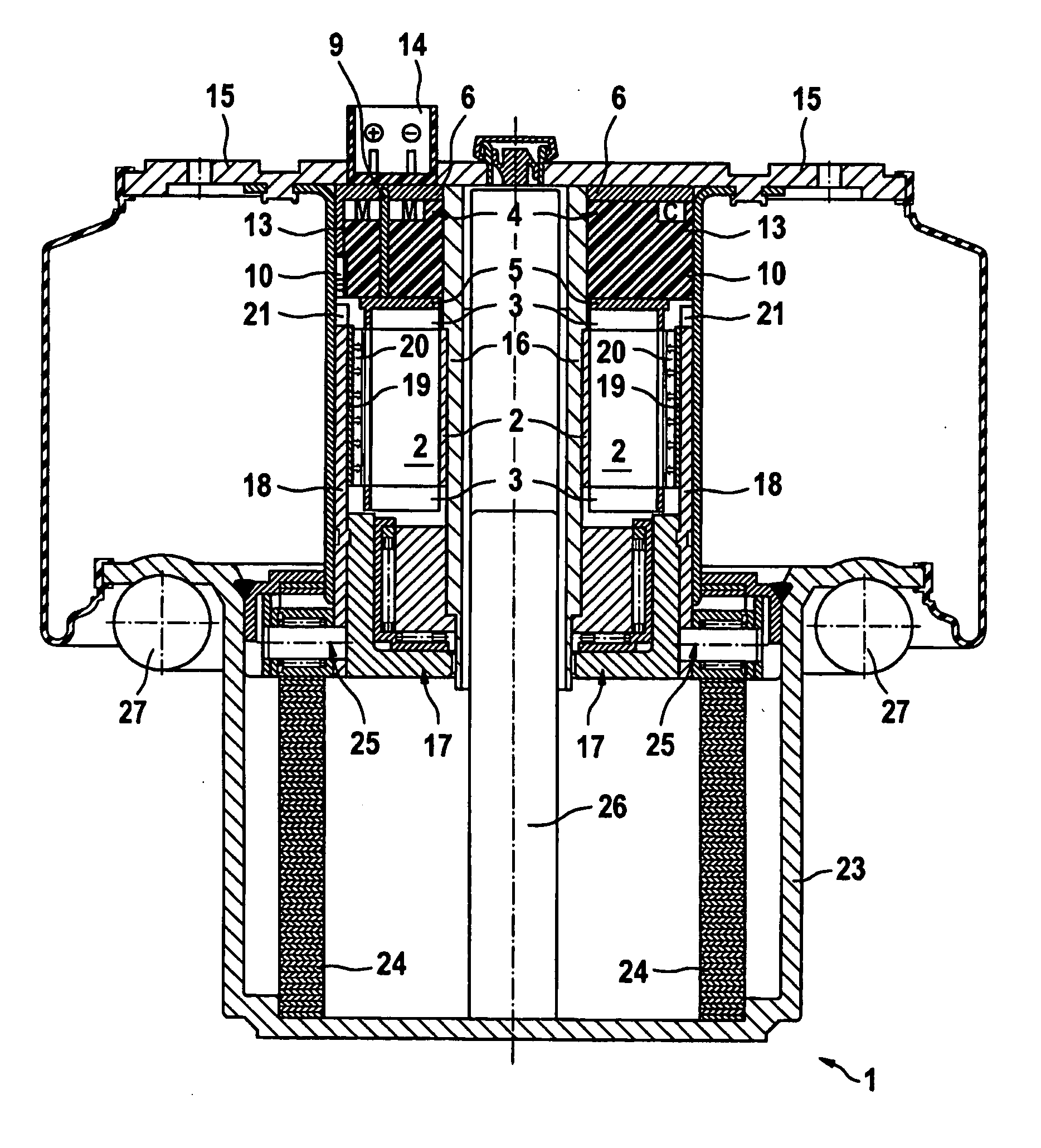

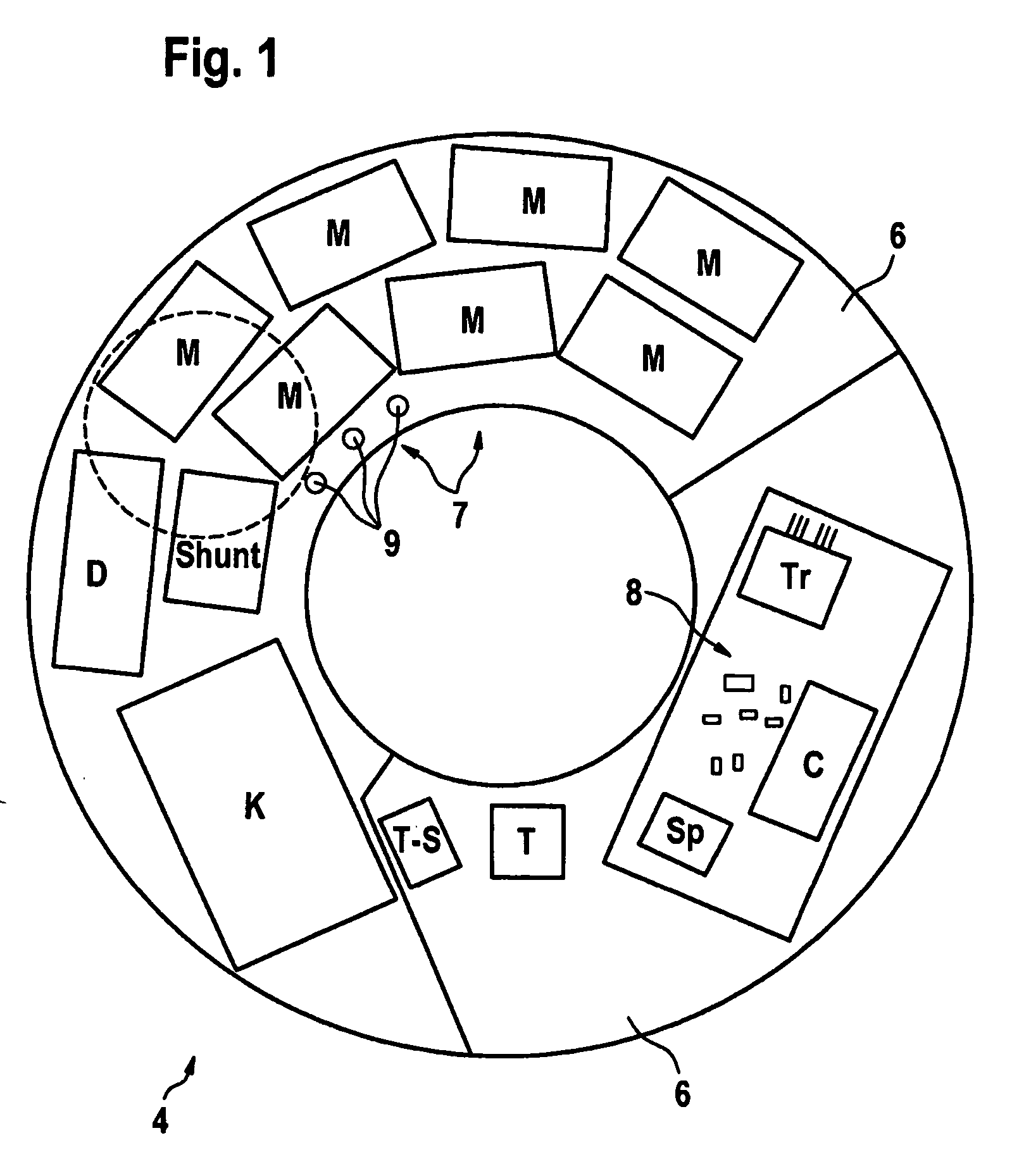

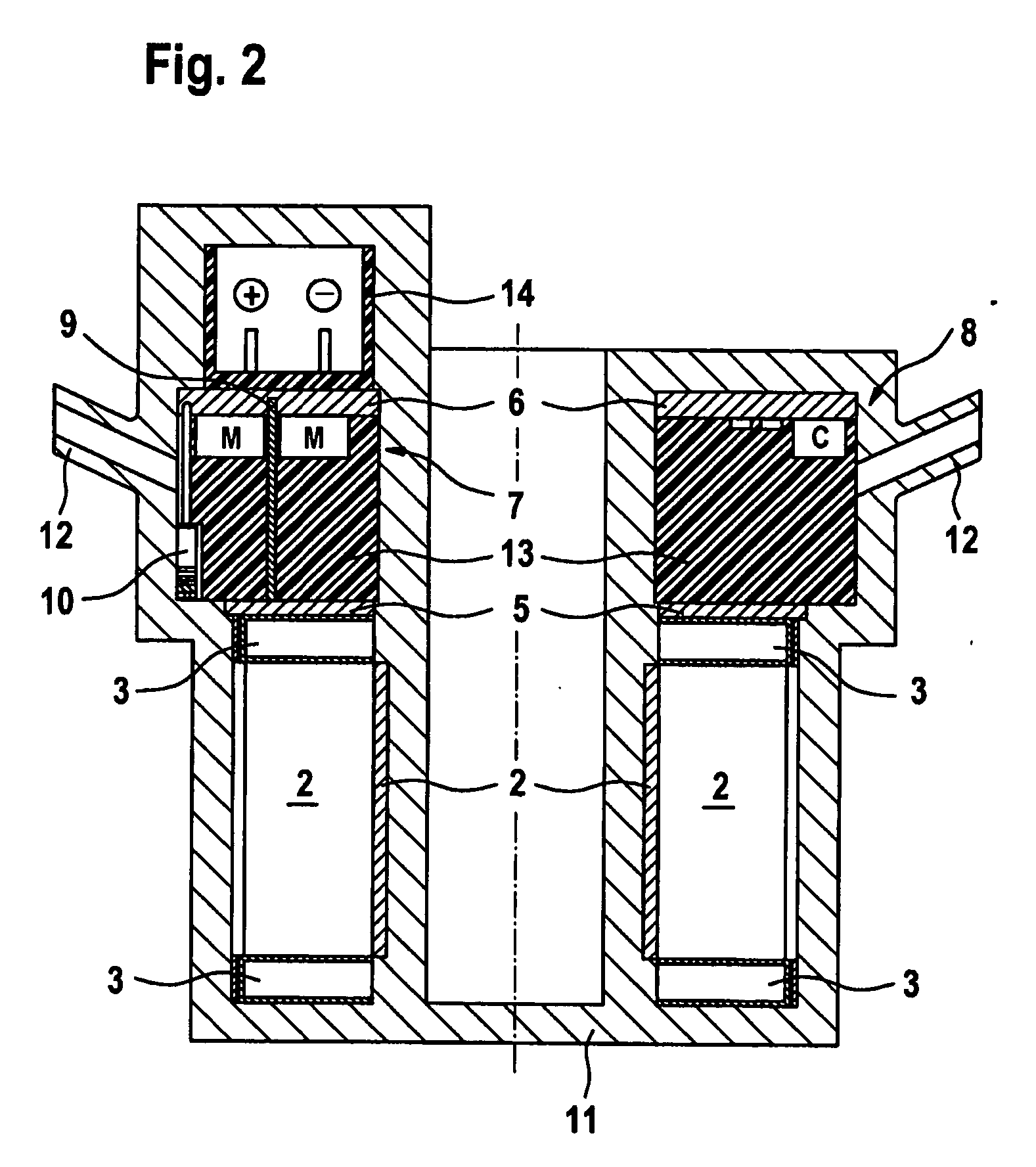

Electric actuation and process for making the same

InactiveUS20060192448A1Simple and reliable final assembly operationSimple and reliable processAssociation with control/drive circuitsManufacturing winding connectionsElectricityEngineering

In a method for manufacturing an electric drive, an electric motor having a stator, a drive electronics for the winding of the electric motor, and a housing are provided. Before being installed in the housing, the drive electronics and the stator are positioned against each other. Connection points of the drive electronics are electrically connected to the winding of the electric motor. A sealing compound is then brought into contact with the stator and the drive electronics and thereby joins the drive electronics to the stator. The sealing compound is subsequently solidified. Thus, the formed subassembly made up of the stator, the drive electronics and the sealing compound is installed in the interior cavity of the housing.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

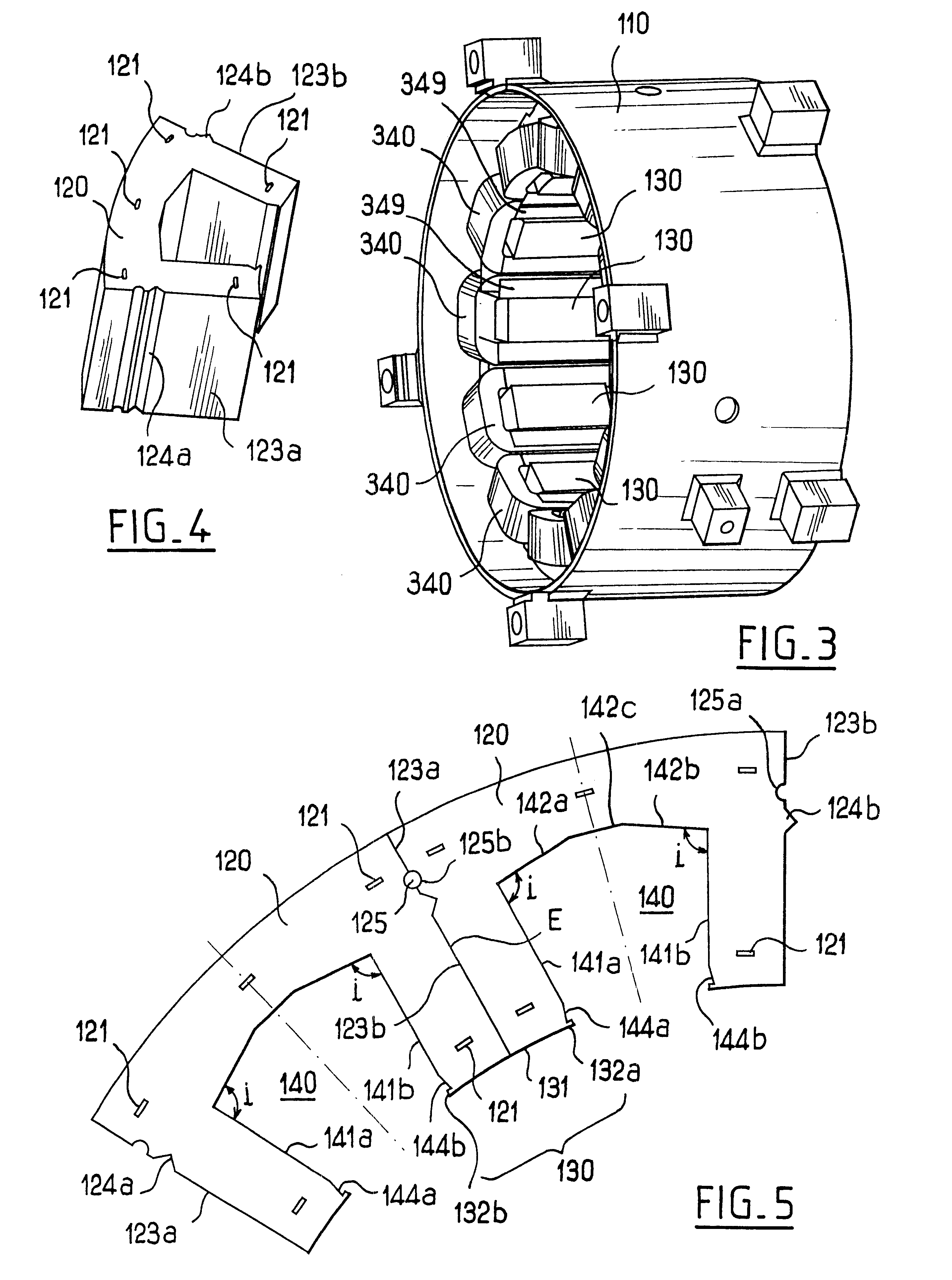

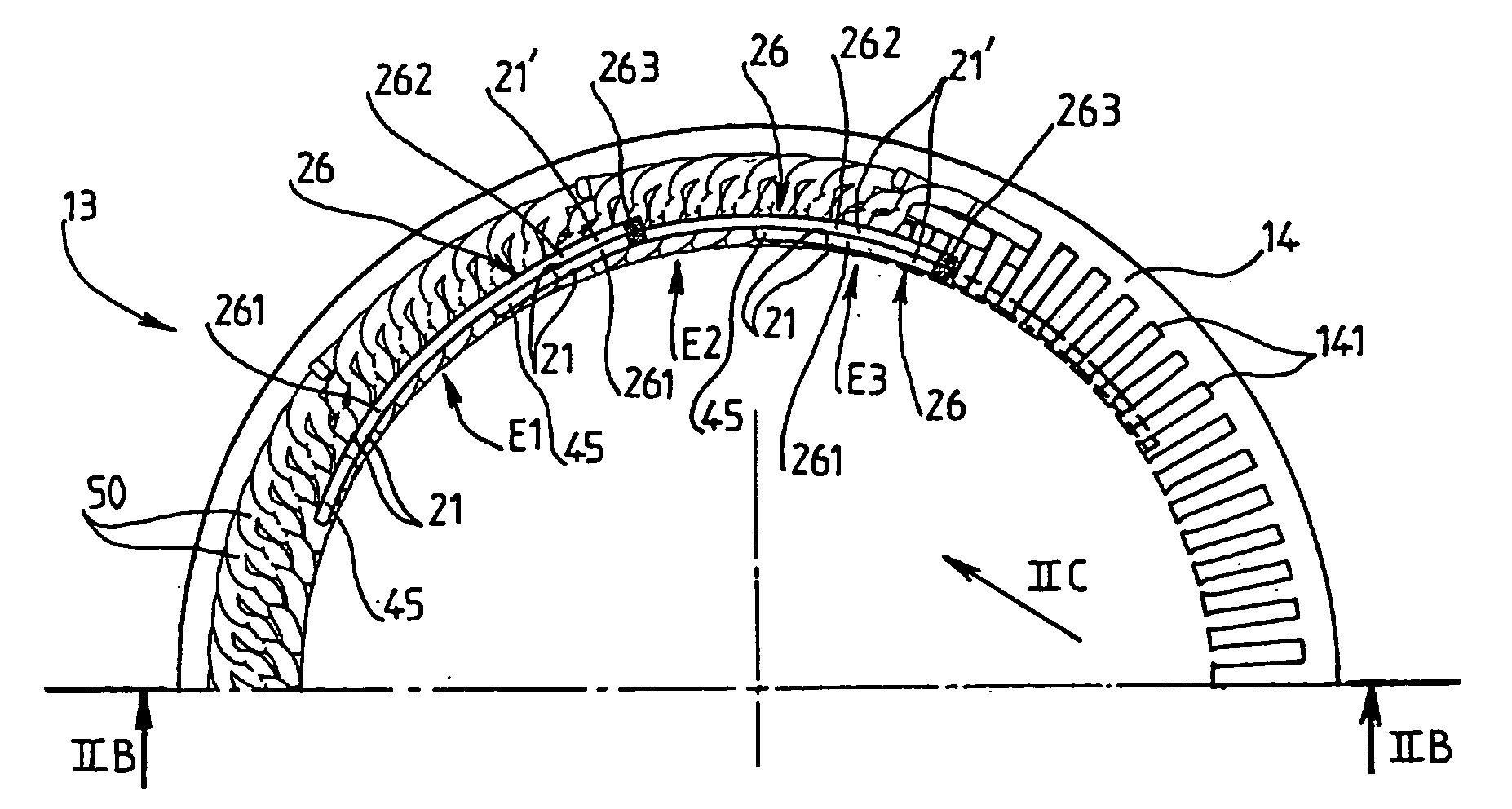

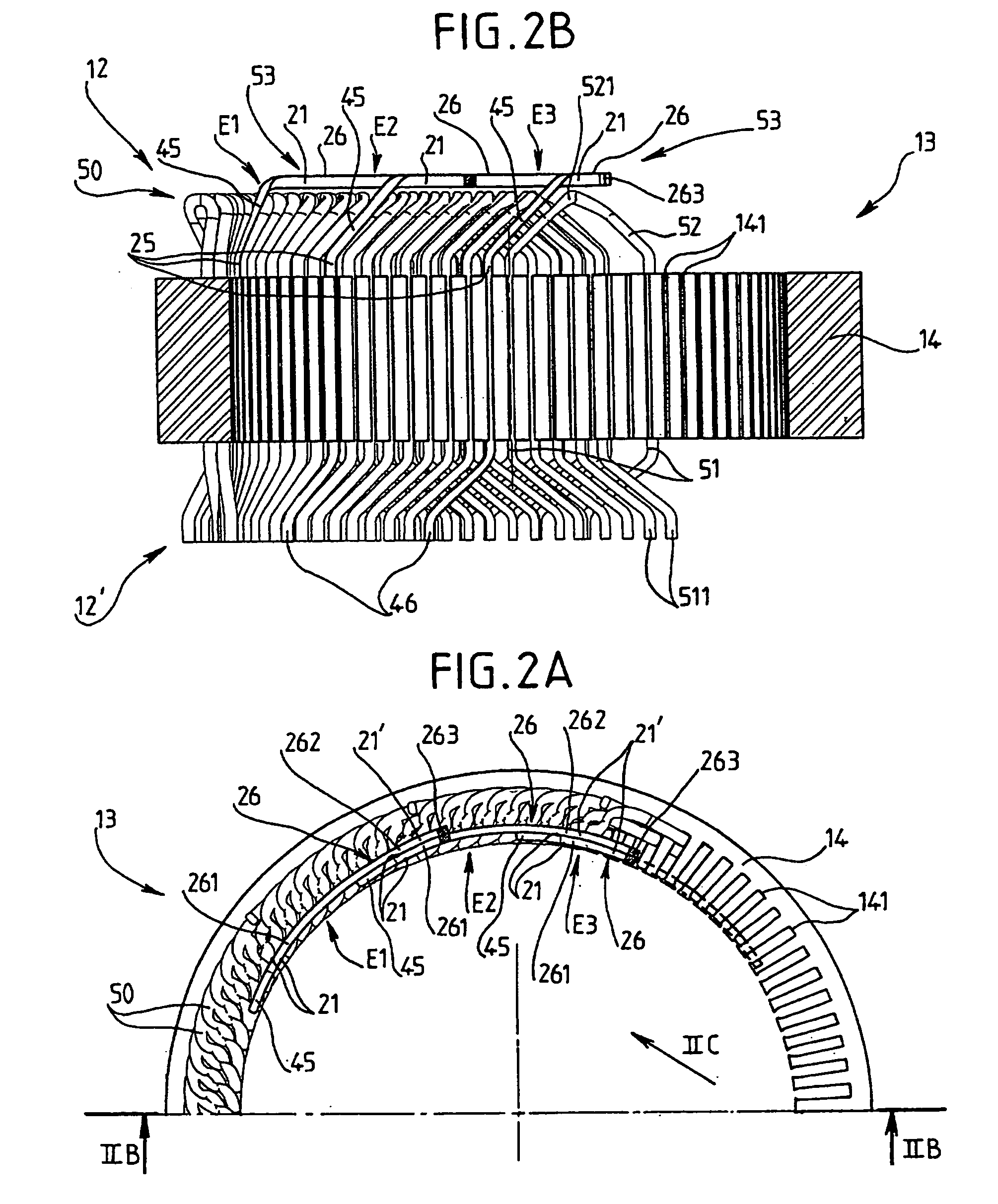

Alternator equipped with stator having twisted inputs

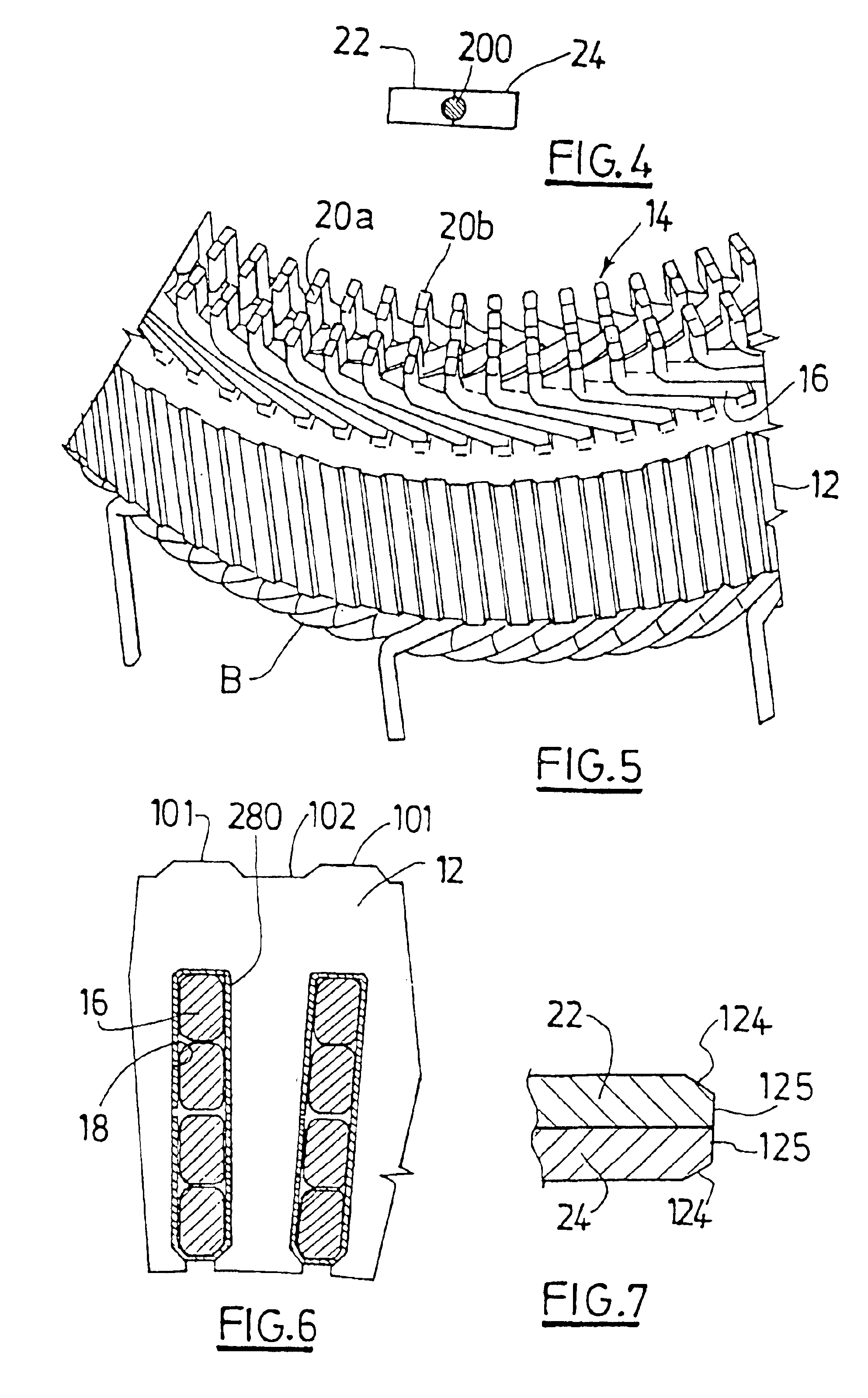

InactiveUS20060001326A1Defect correctionEasy inputSynchronous generatorsMagnetic circuitAlternatorRadial plane

The invention concerns an alternator, in particular for motor vehicle, comprising a stator (13) provided with a cylindrical body (14) bearing several phases (P), each phase comprising an input (E1 to E3) and an output, and electrically conductive interconnected elements (50) connecting the phase inputs to the phase output, the inputs (E1 to E3) consisting of rods having at least one longitudinal flat surface (21), each input including a first segment (25) passing through the body (14) of the stator (13) and a second end segment (26) extending from an axial side of said body (14), the second segments (26) of the inputs (E1 to E3) are twisted, the flat surface (21) of each input (E1 to E3) extending along the first segment (25) in a radial plane, and extending along the second end segment (26) either to form a cylindrical portion coaxial with the body (14) of the stator (13) or in a plane tangential to a cylinder coaxial with the body (14) of the stator (13).

Owner:VALEO EQUIP ELECTRIC MOTEUR

Interconnecting method for segmented stator electric machines

A method of connecting phases of a segmented stator electric machine includes providing a stator core. An end cap assembly is attached to the stator core. Winding wire is wound around the end cap assembly and the stator core to form a stator segment assembly. A plurality of the stator segment assemblies are assembled into a stator including first, second and third phases. A phase wire stitching machine is used to connect opposite ends of the winding wire of each of the stator segment assemblies to form the first, second and third phases of the stator. The phase wires can be attached to the stator segment assemblies using terminals, IDCs, hook terminals, and / or directly to the winding wire.

Owner:HERMETIC MOTORS LP

Stator for vehicular rotary electric machine and a manufacturing method thereof

InactiveUS20050116571A1Improve cooling efficiencySynchronous generatorsWindings insulation shape/form/constructionElectrical conductorElectric machine

To secure insulation between electrical conductors at a coil end, a first electrical conductor at one coil end is arranged so as to intersect a radially adjacent second electrical conductor at one point or more. The electrical conductor is formed with radial indentations in side faces that are opposite side faces in opposing electrical conductors at any of the intersecting portions, the indentations having depths that increase toward the near ear of the electrical conductors. Sufficient clearances are thereby secured between electrical conductors in their intersecting portions near their ends where the insulating films are susceptible to damage because of welding heat. Electrical insulation is thus ensured, and the cooling efficiency at the coil end is improved.

Owner:DENSO CORP

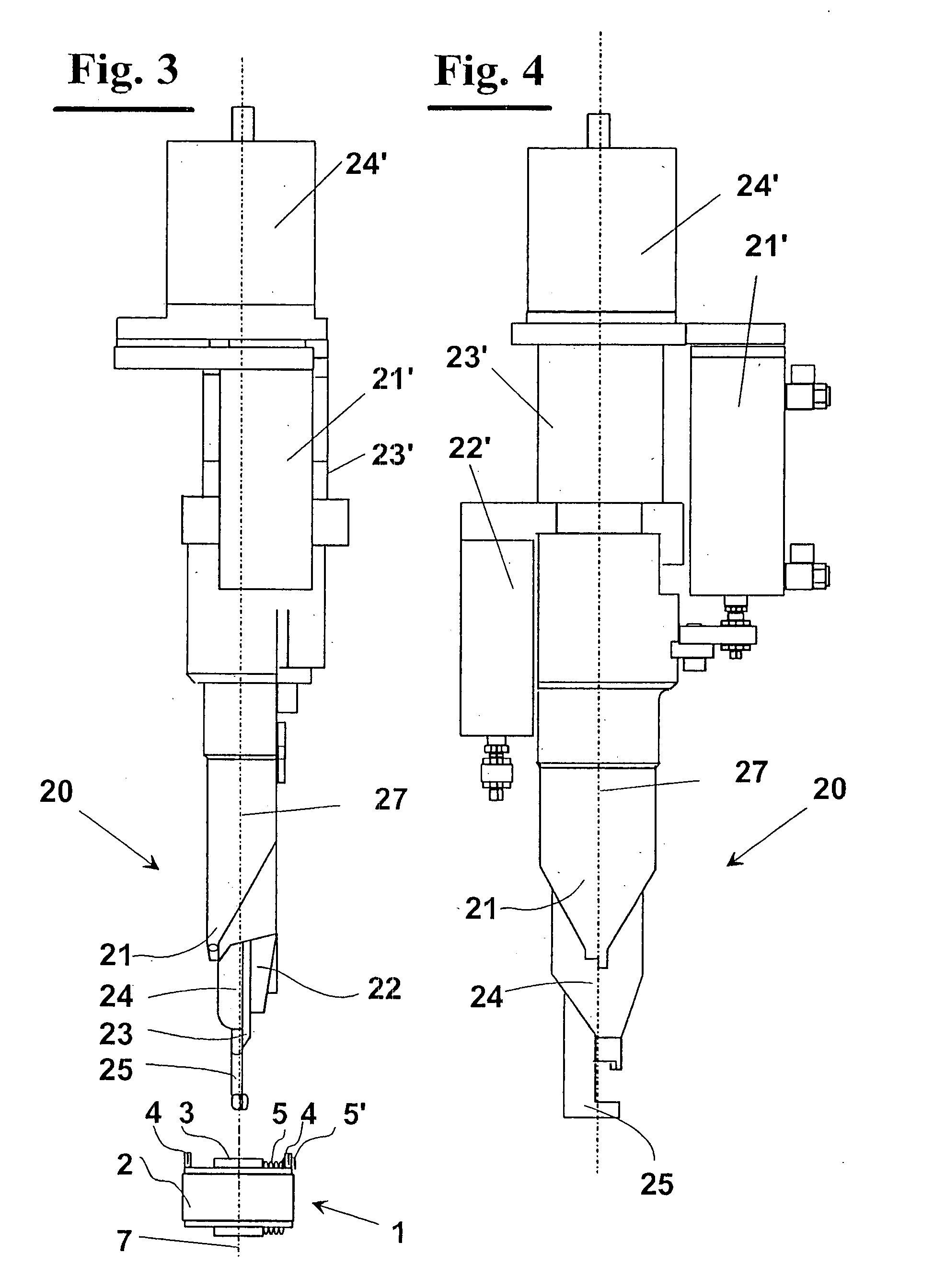

Method and apparatus for wire termination on outwardly spooled multi-pole stators

A method and device for wire termination on stators (1) wherein the wire (15) is wound about poles (6) distributed by a flier (10), guided by shrouds (16) that move radially with respect to the stator (1) overlapping the respective pole (6). Wire termination operations are provided on the wire ends (15) into the terminals (4) with the aid of the flier (10), carried out by an apparatus equipped with a termination device (20), comprising a first deflector (21), a second deflector (22), a blade (23), and a clamp formed by a movable gripper (24) and a fixed gripper (25). The movable gripper is suitable for closing onto the fixed gripper for gripping the wire (15). The device (20) can carry out the steps of catching, moving, introducing and cutting the wire (15) with movements parallel to its own axis (27), or to the axis (7) of the stator (1).

Owner:PONZIO MASSIMO +1

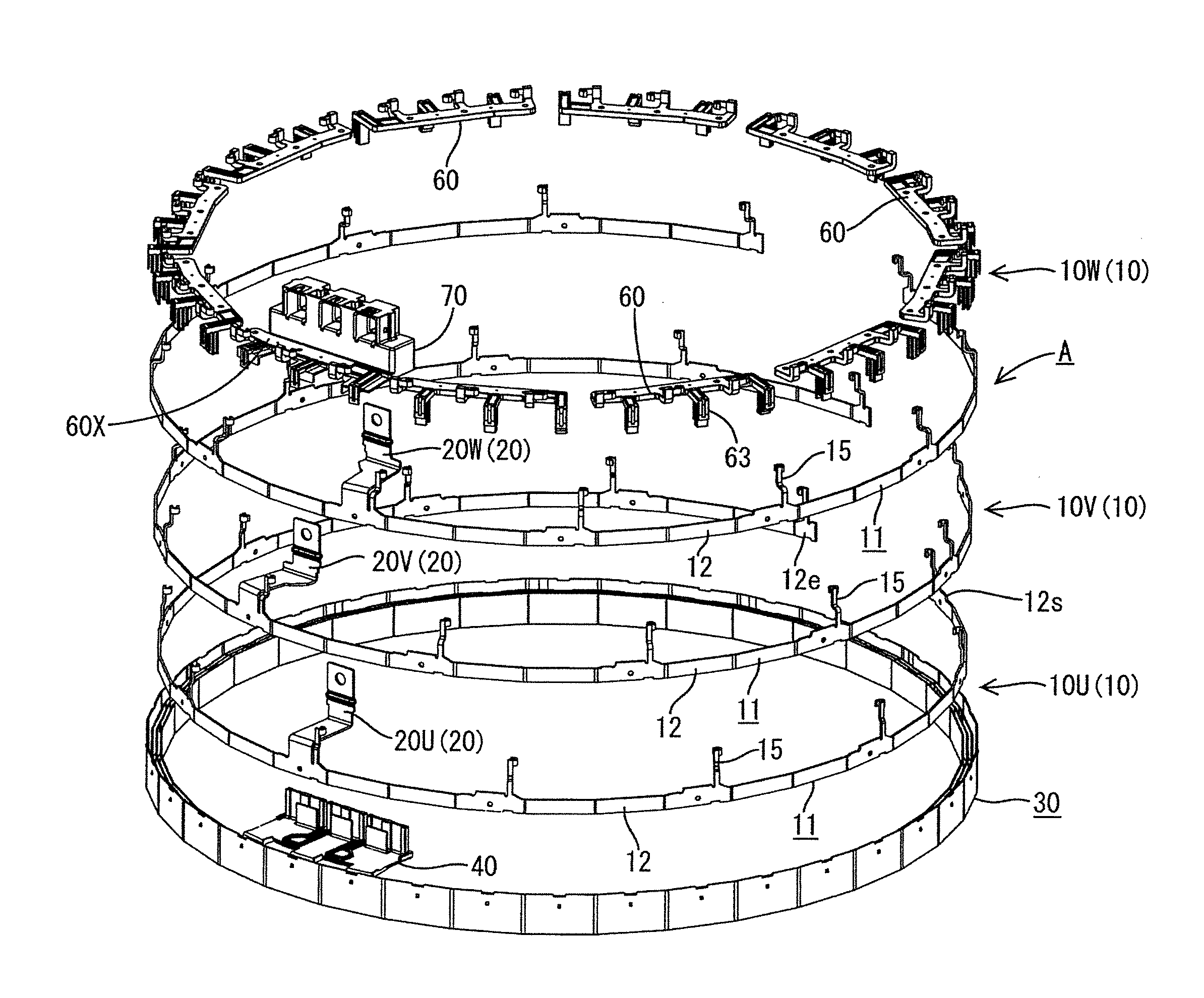

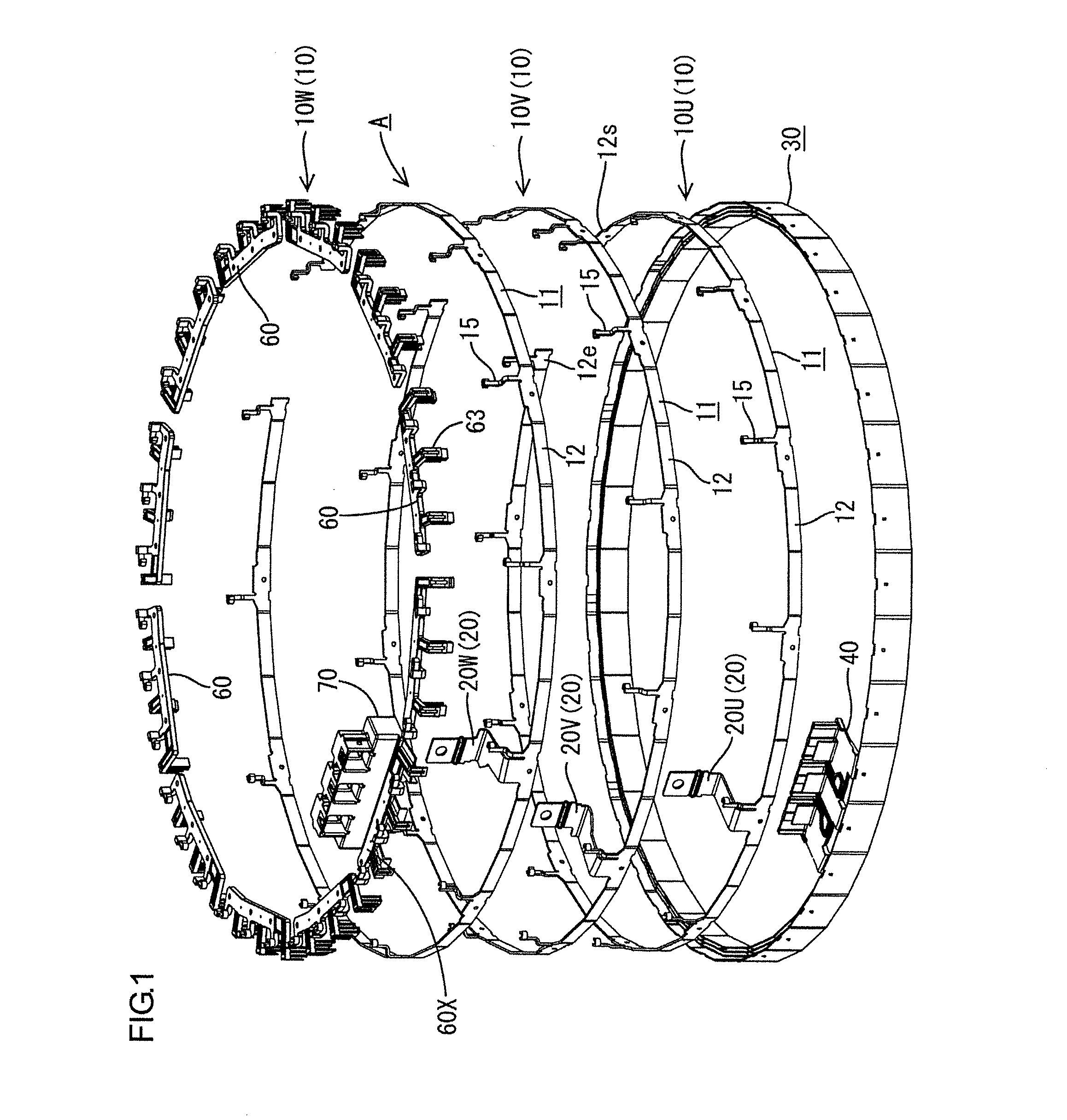

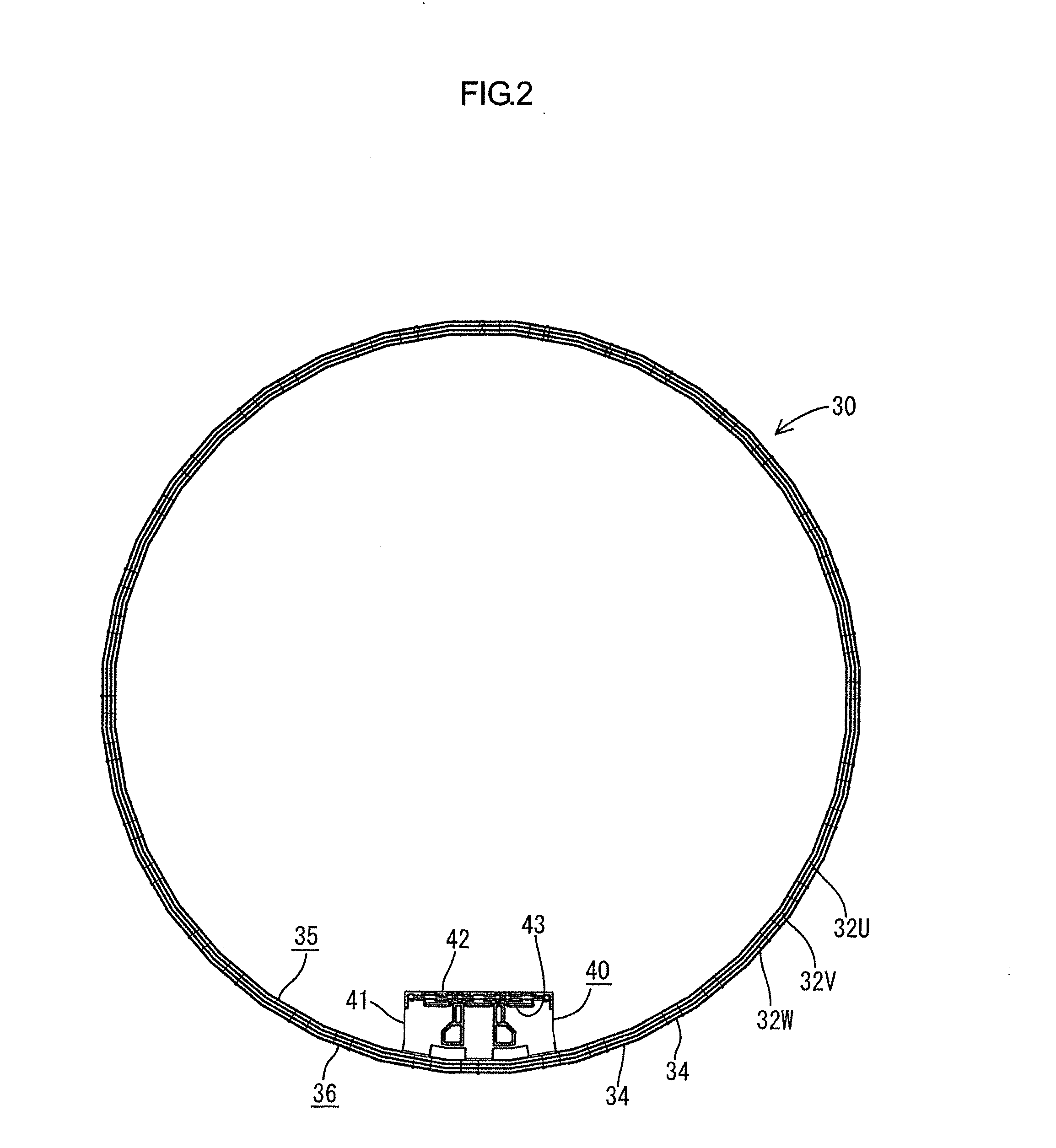

Centralized power distribution member for motor

InactiveUS20150381002A1Save spacePrevent disengagementManufacturing winding connectionsWindings conductor shape/form/constructionBusbarEngineering

A centralized power distribution member A configured to feed power to windings of a stator S of a multi-phase motor includes a plurality of annular busbars 10 each including a power feeding terminal 20 and connection terminals 15 to be connected to one ends of the windings of each phase on one side edge, an annular holder 30 made of synthetic resin and configured to accommodate the busbars 10 laminated in a radial direction in a mutually insulated manner, neutral point busbars 50 configured to connect the other ends of the windings of each phase, and auxiliary holders 60, 60X made of synthetic resin and configured to accommodate the neutral point busbars 50. The auxiliary holders 60, 60X are arranged on one end surface side of the annular holder 30 where the power feeding terminals 20 and the connection terminals 15 are arranged.

Owner:SUMITOMO WIRING SYST LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com