Method and apparatus for wire termination on outwardly spooled multi-pole stators

a multi-pole stators and wire termination technology, which is applied in the direction of winding connections, electrical equipment, manufacturing dynamo-electric machines, etc., can solve the problems of affecting the operation of the winding machine, the end protruding a certain amount beyond the terminal, and the manoeuvre of terminating without blocking the wire is risky,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

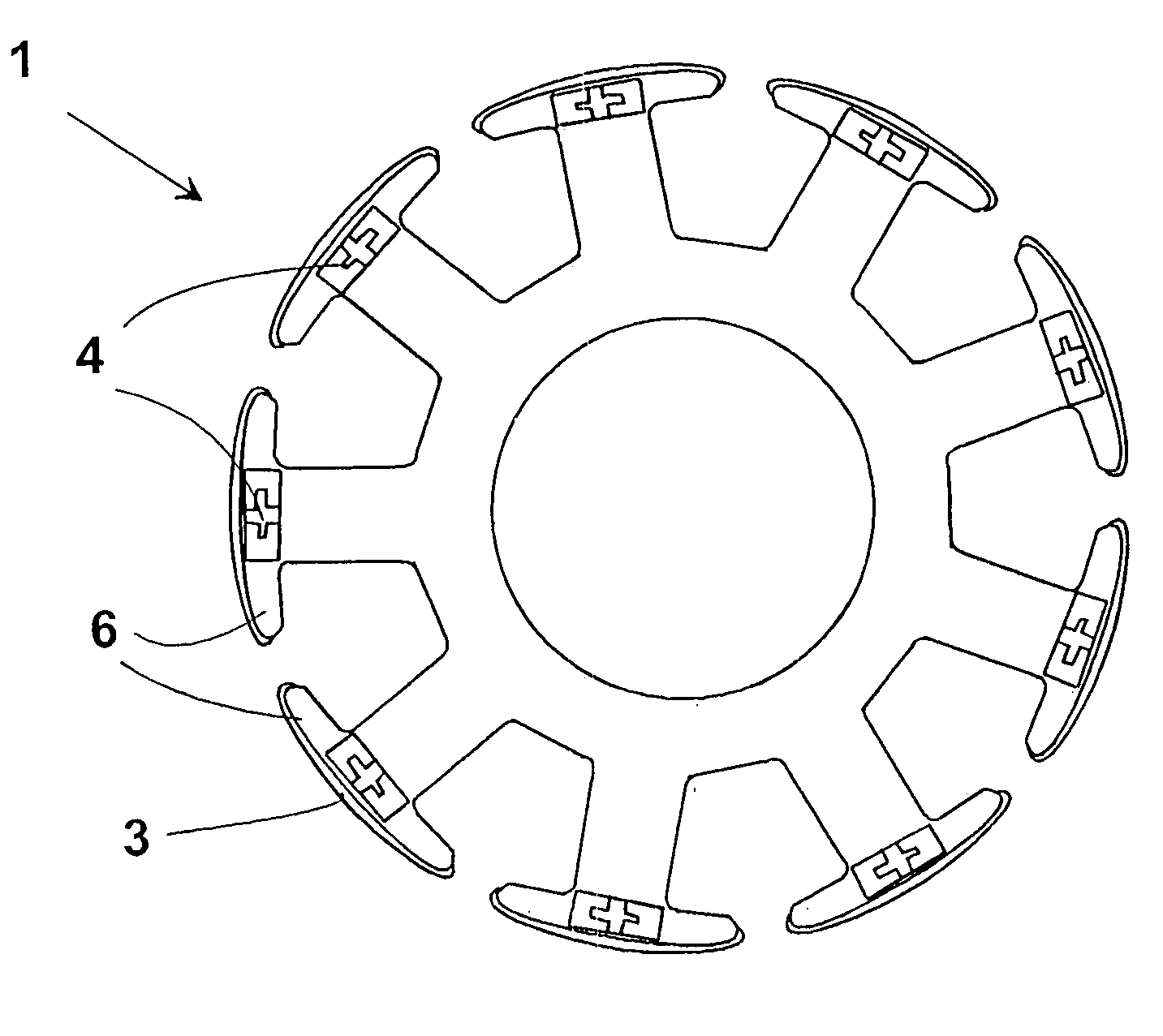

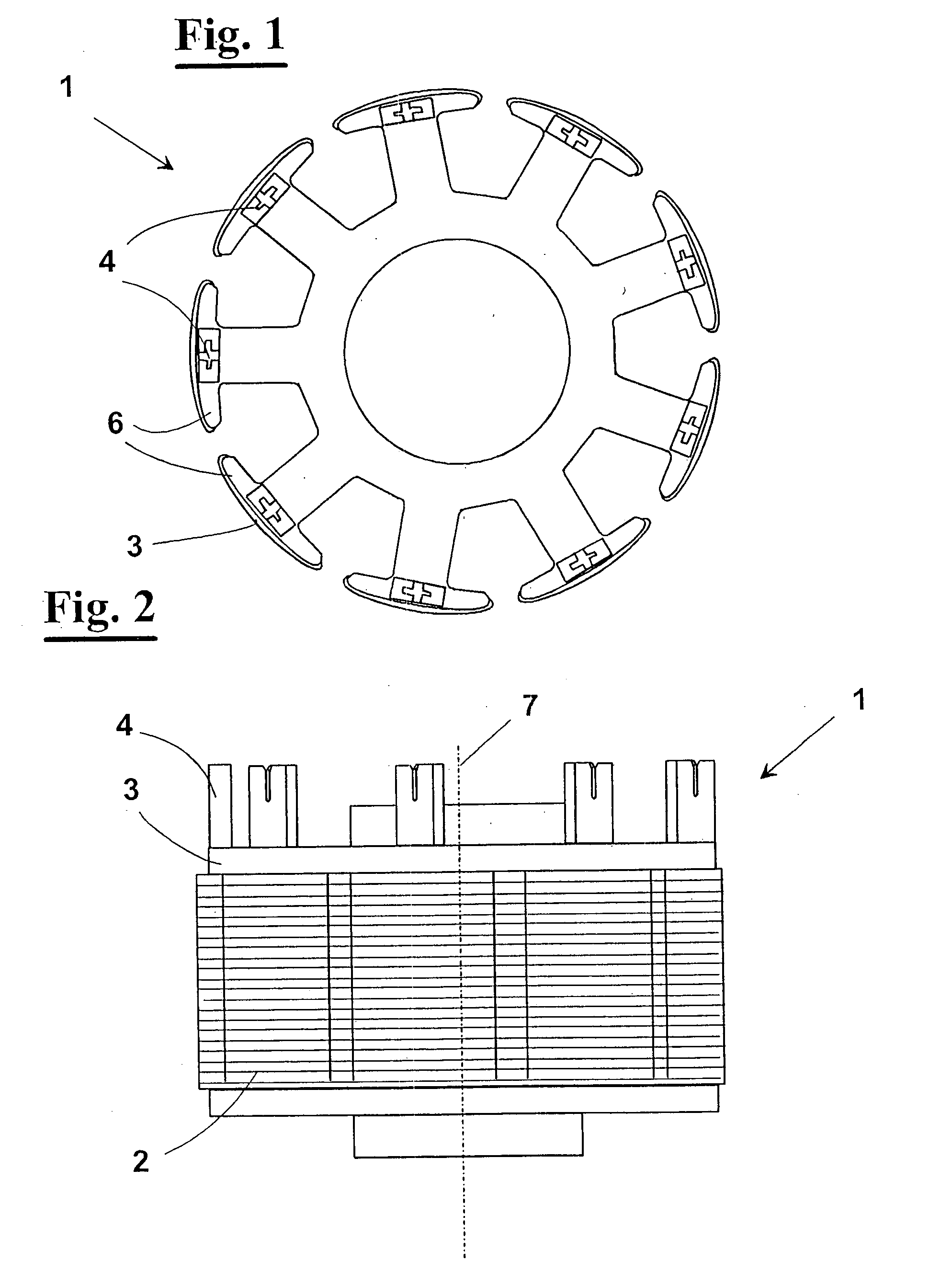

[0052] With reference to FIGS. 1 and 2, an outwardly spooled multi-pole stator 1 has a core formed by a stack of ferromagnetic sheets 2, having an axis of symmetry 7 and a plurality of poles 6 that radially extend defining grooves between them. Stack 2 is in part covered by a terminal board 3 that has a plurality of terminals 4. Terminals have a slit wherein has to be inserted a terminal of wire spooled about poles 6.

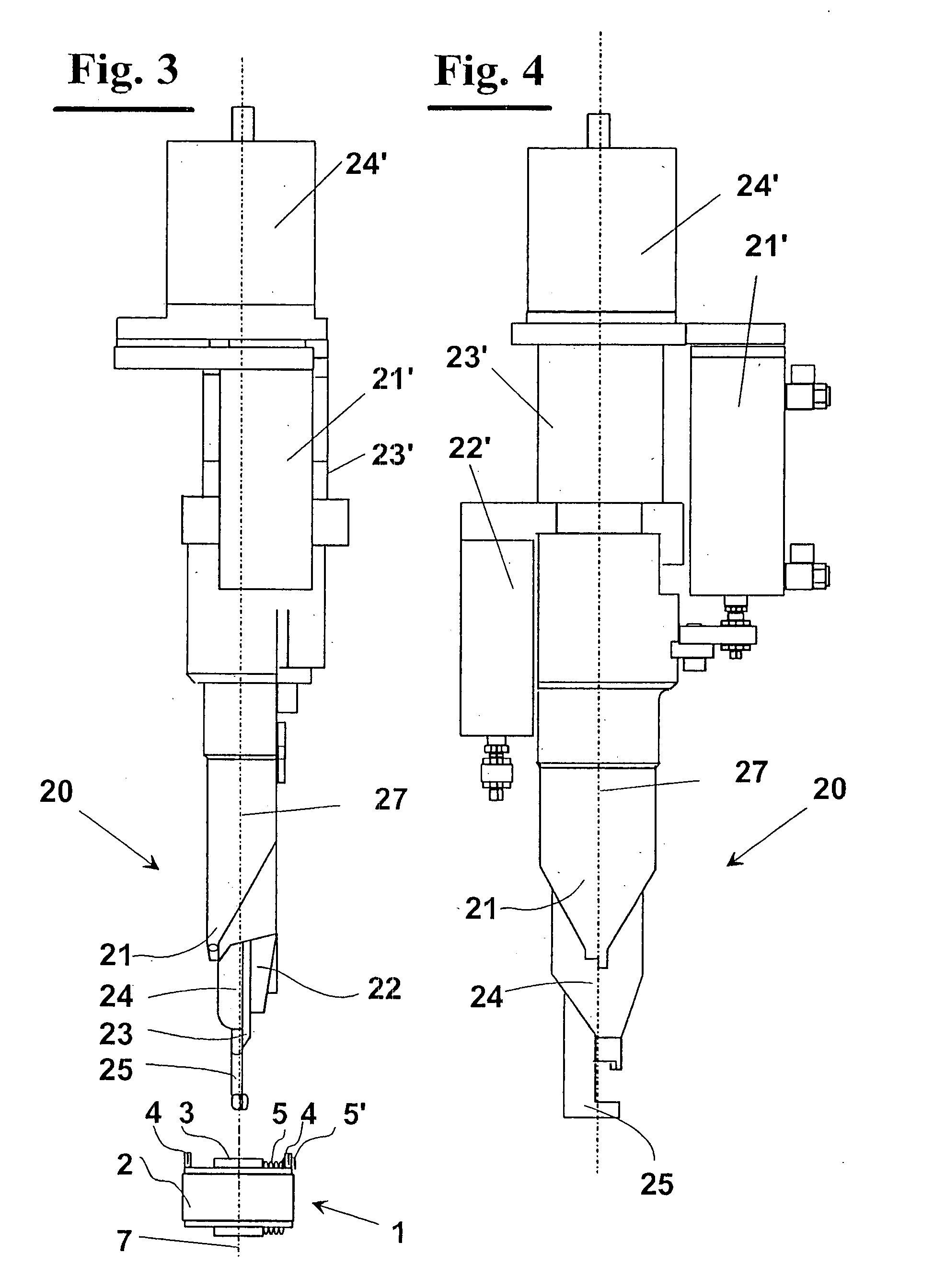

[0053] A winding step, for example, is shown in FIG. 14. Wire 15 is wound about poles 6 distributed by a rotatable arm 10, or flier, having a needle end 11. Wire 15 slides through flier 11, while it is kept stretched and fed by means not shown, and known to a person skilled in the art. At winding, wire is guided by shrouds 16 that move radially with respect to stator 1 thus overlapping the respective pole 6. In FIG. 14, a pole 6 already wound with a coil 5 is shown on the right edge of the stator, with an end 5′ that engages a terminal 4.

[0054] Before and after windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| movement | aaaaa | aaaaa |

| ferromagnetic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com