Material processing system

A processing system and material technology, applied in the directions of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems that the conveyor belt cannot achieve rapid transmission, material position deviation, falling off, etc., to save manpower, simplify the structure, and achieve fast transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

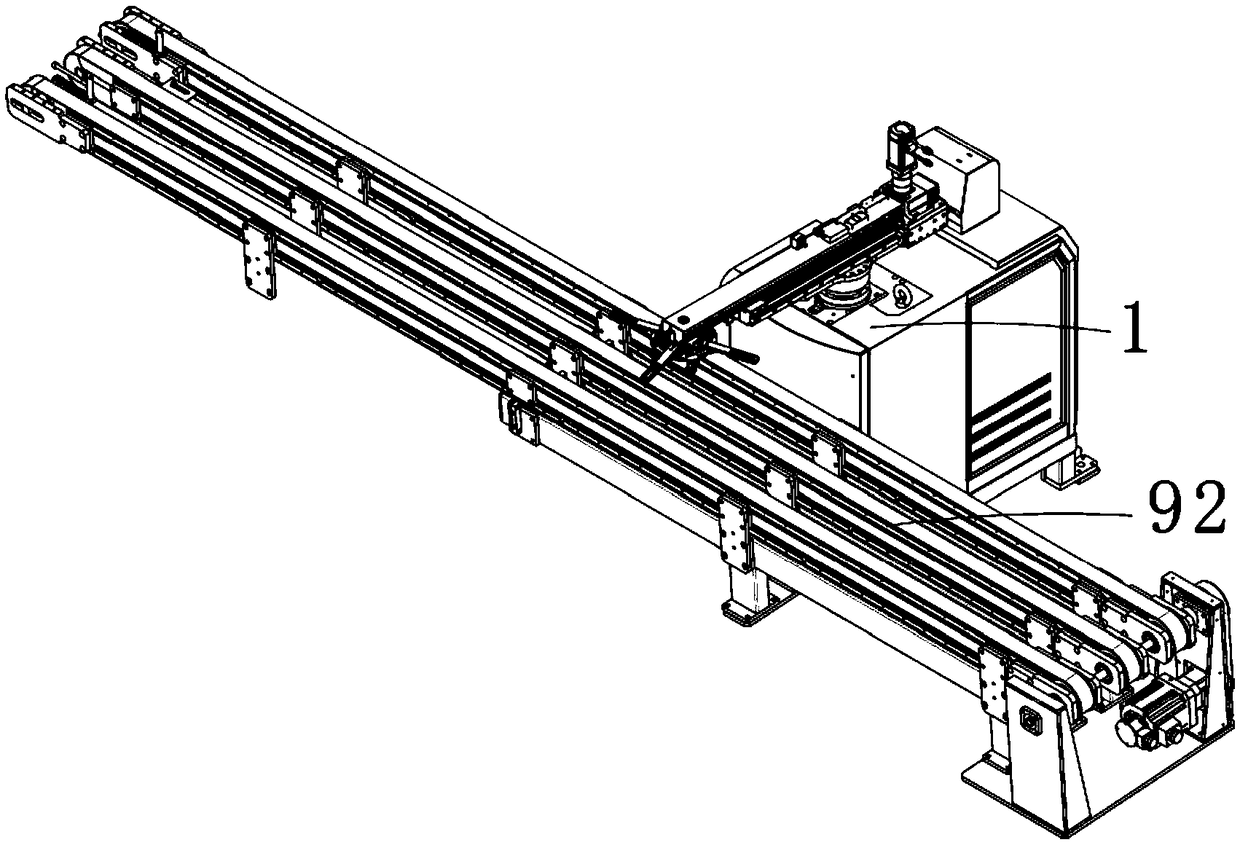

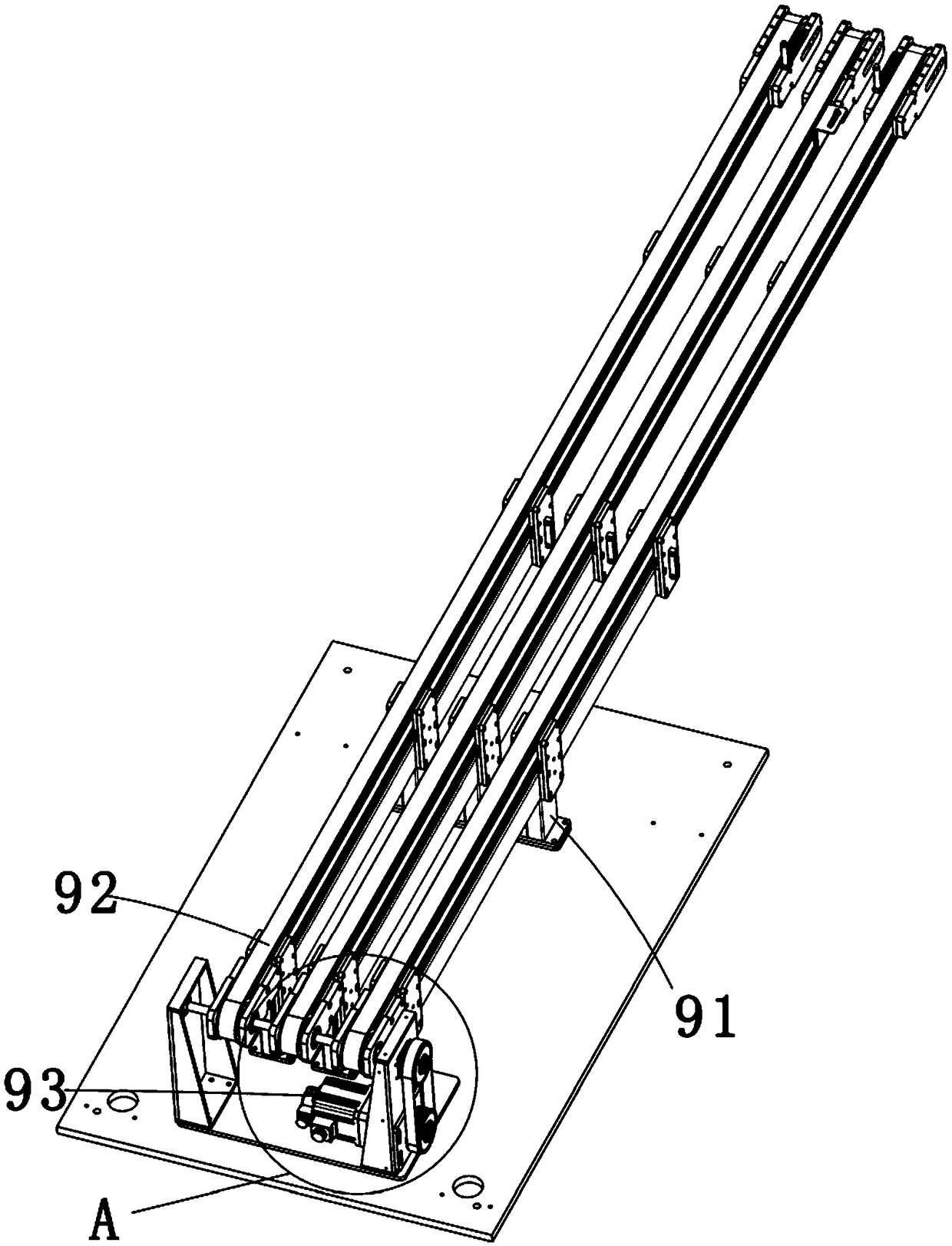

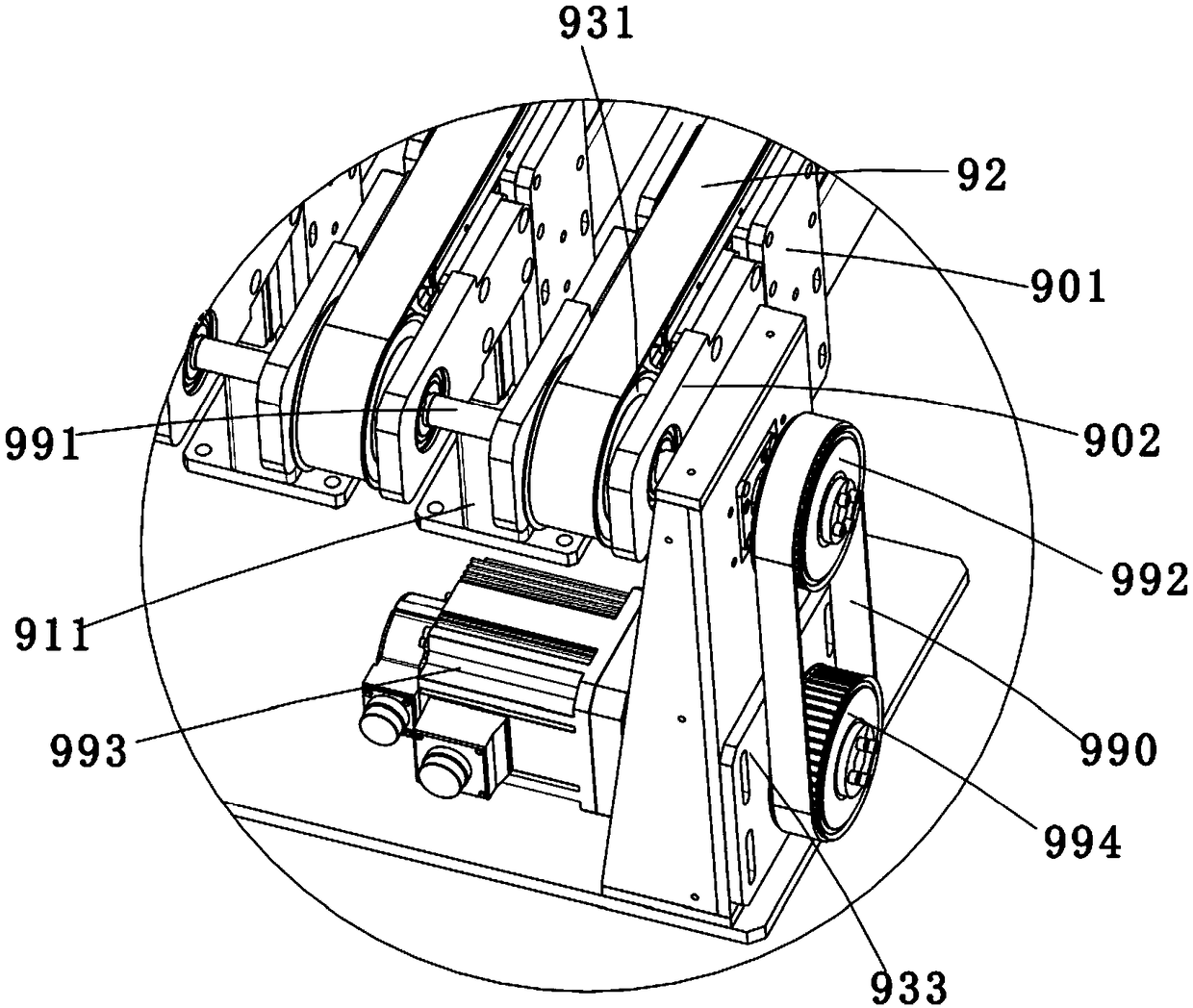

[0047] like Figure 1-9 As shown, a material processing system includes a material conveying device and a material grabbing device, and the material conveying device cooperates with the material grabbing device; specifically, the material conveying device includes a support member 91, a conveyor belt 92 , the power part 93 and the magnetic part 94, wherein the support part 91 includes a bracket 911 and a beam 912, the bracket 911 is a vertical metal frame, and the bracket 911 is directly mounted on the ground or a metal plate, in the A cross bar 910 is connected to the bracket 911, the end of the cross bar 910 is connected to the bracket 911, and a second connecting block 901...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com