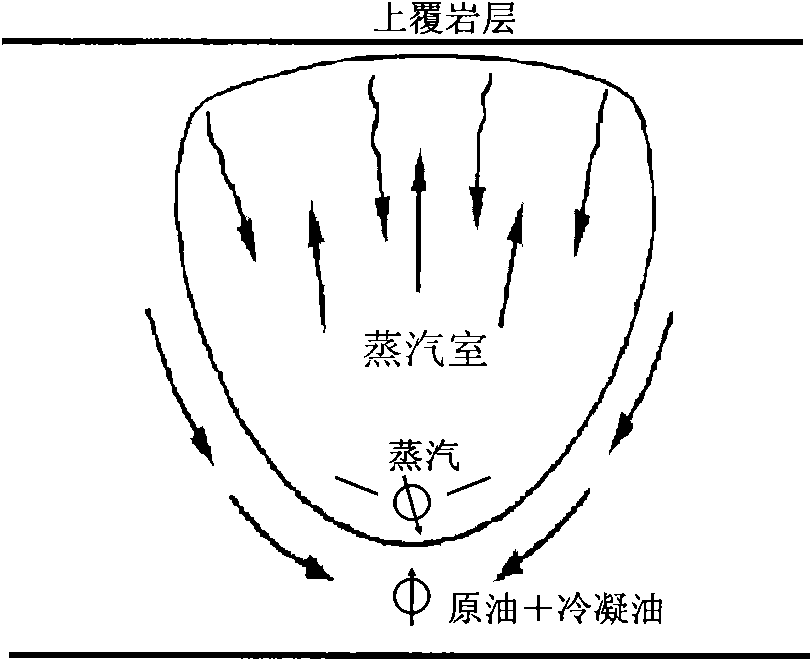

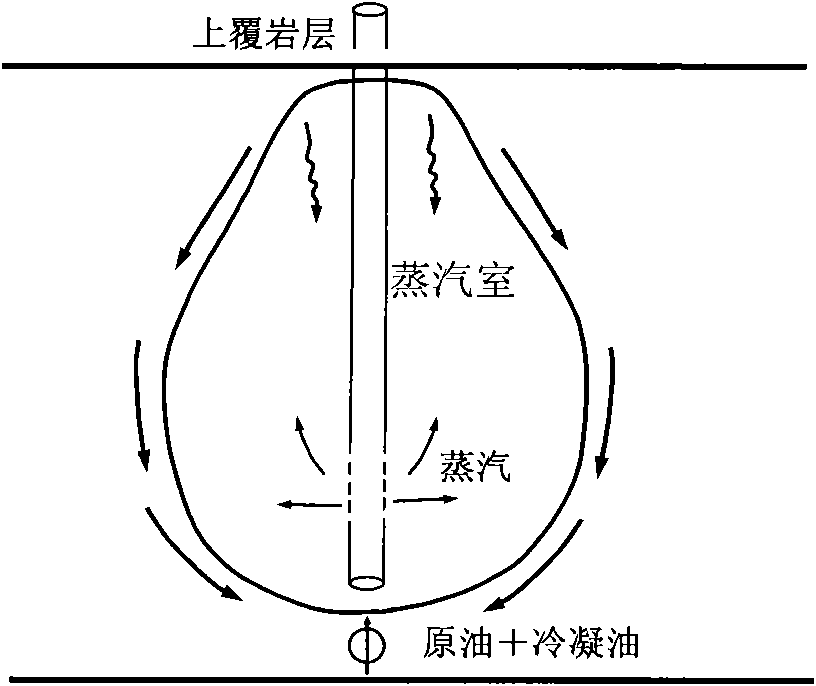

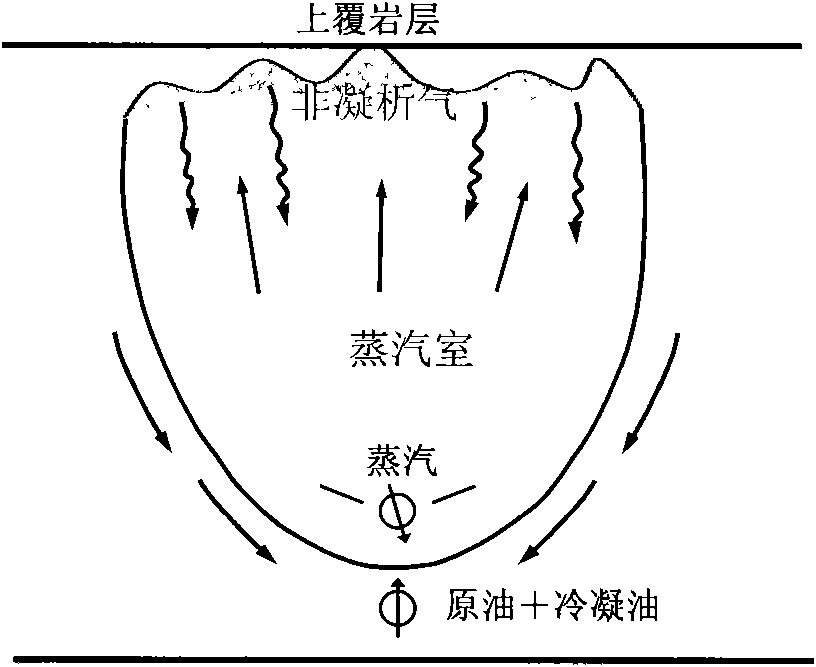

Gas-assisted SAGD method for exploiting super heavy oil

A gas-assisted, super-heavy oil technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of reducing oil production, uneven expansion of steam chamber, waste of heat, etc., to increase the swept volume, Beneficial for uniform spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Oilfield 1 reservoir is buried deep at 530m, the effective thickness of the oil layer is 106.0m, the net total thickness ratio is 0.92, the average porosity is 36.5%, the average horizontal permeability is 5540md, and the ratio of horizontal permeability to vertical permeability is 0.7. There is no pure mudstone interlayer, and the viscosity of crude oil is 23.2×10 4 cp. The oil field has been developed with vertical well steam huff and puff for 5 years, the staged recovery rate is 10.7%, the production decline rate is 23.4%, and the formation pressure is 2-3MPa.

[0022] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: the oil layer is shallower than 530m, the remaining oil saturation is greater than 0.50, the oil layer thickness is greater than 10.0m, the horizontal permeability is greater than 250md, the vertical to horizontal permeability ratio is greater t...

Embodiment 2

[0027] The buried depth of the oil reservoir in Oilfield 2 is 300m, the effective thickness of the oil layer is 32.0m, the net total thickness ratio is 0.82, the average porosity is 26.0%, the average horizontal permeability is 1250md, and the ratio of horizontal permeability to vertical permeability is 0.60. Pure mudstone interlayer, crude oil viscosity under oil reservoir conditions is 12.0×10 4 cp. The oilfield is a newly developed block with an original oil saturation of 70% and an original reservoir pressure of 3.0MPa.

[0028] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: the oil layer is shallower than 300m, the original oil saturation > 0.50, the oil layer thickness > 10.0m, the horizontal permeability > 250md, the ratio of vertical to horizontal permeability > 0.1, the oil layer porosity > 0.20, and no There are continuously distributed impermeable mud an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com